1

/

of

9

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

GB/T 29510-2013 English PDF (GBT29510-2013)

GB/T 29510-2013 English PDF (GBT29510-2013)

Regular price

$220.00 USD

Regular price

Sale price

$220.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click GB/T 29510-2013

Historical versions: GB/T 29510-2013

Preview True-PDF (Reload/Scroll if blank)

GB/T 29510-2013: General requirements for the distribution of personal protection equipment

GB/T 29510-2013

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 13.340.01

C 73

General requirements for the distribution of personal

protection equipment

ISSUED ON: MAY 09, 2013

IMPLEMENTED ON: FEBRUARY 01, 2014

Issued by: General Administration of Quality Supervision, Inspection and

Quarantine;

Standardization Administration of the People's Republic of

China.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Terms and definitions ... 5

4 Basic requirements ... 5

5 Principles and methods for identifying hazard and harmful factors ... 6

6 Distribution procedures ... 7

7 Classification, rating and scope of application ... 8

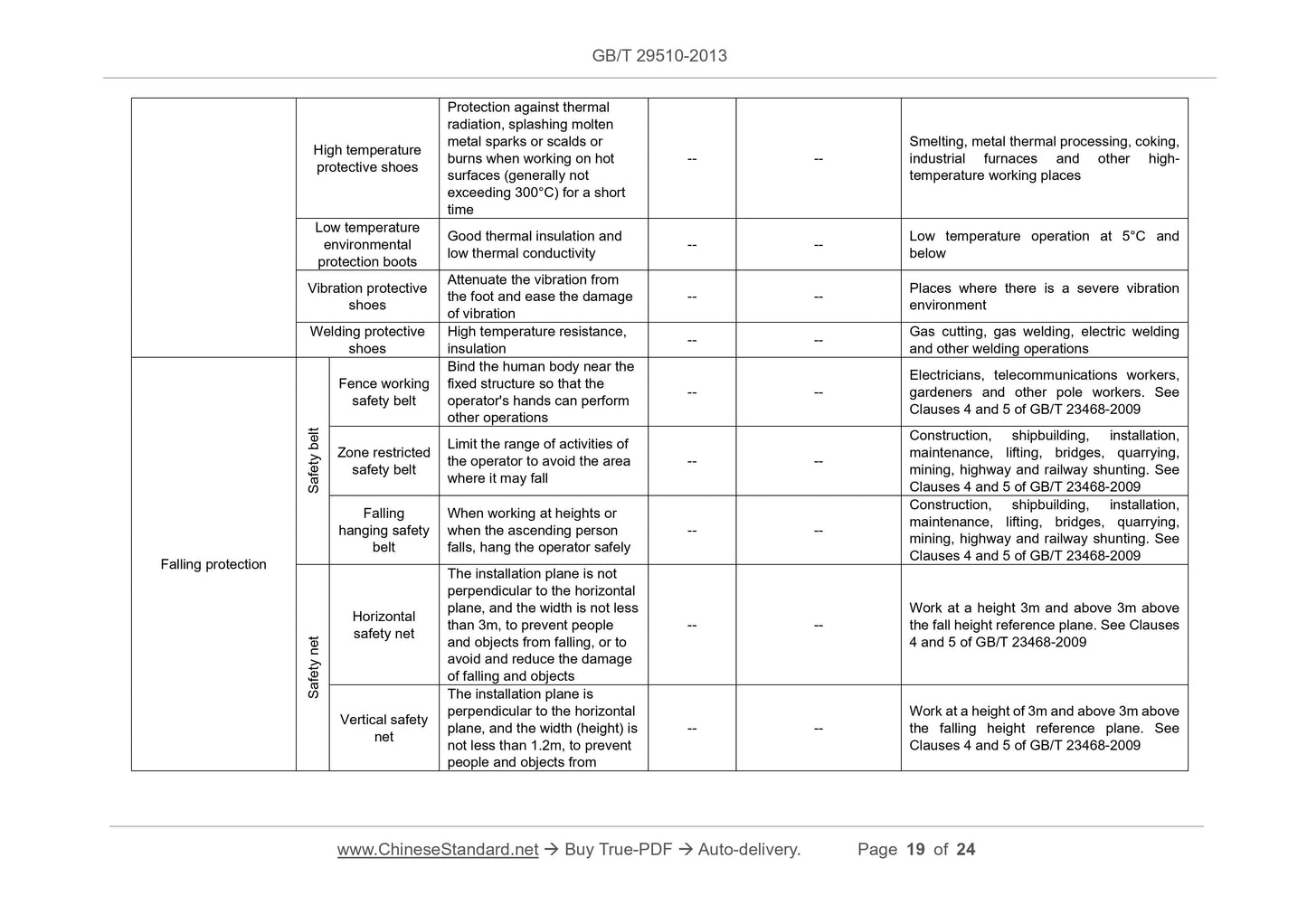

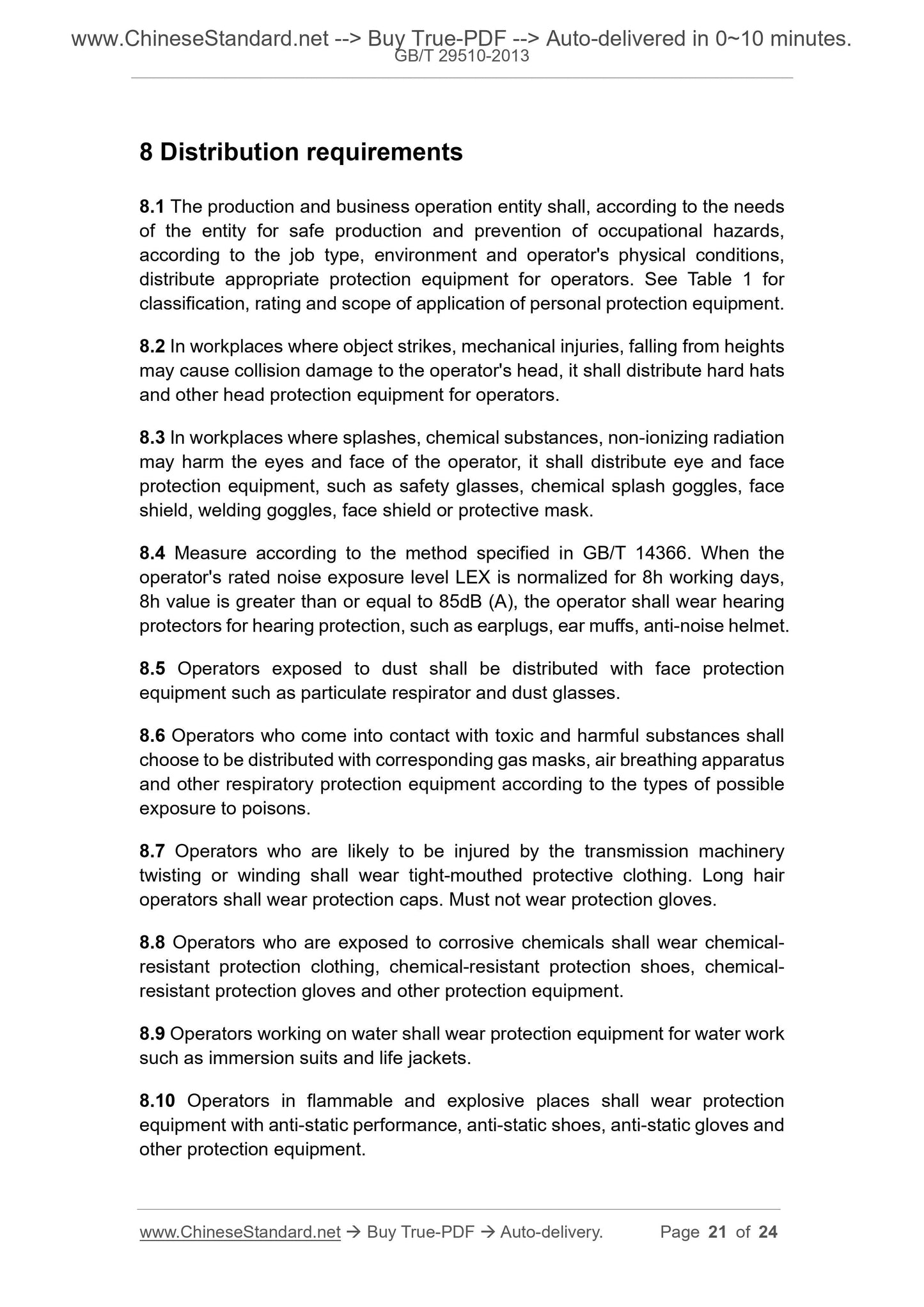

8 Distribution requirements ... 21

9 Management and training ... 22

Bibliography ... 24

General requirements for the distribution of personal

protection equipment

1 Scope

This Standard specifies basic requirements, identification principles and

methods of dangerous and harmful factors, equipment procedures,

classification, rating and scope of application, equipment requirements,

management and training for distribution of personal protection equipment.

This Standard is applicable to selection, distribution, use, maintenance and

scrap management for personal protection equipment of production and

business operation entity.

2 Normative references

The following referenced documents are indispensable for the application of

this document. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any

amendments) applies.

GB 2890-2009, Respiratory protection - Non-powered air-purifying

respirators

GB/T 6441, The classification for casualty accidents of enterprise staff and

workers

GB/T 11651-2009, Code of practice for selection of personal protective

equipment

GB/T 12903, Personal protective equipment terminology

GB/T 14366, Acoustics - Estimation of noise-induced hearing loss

GB/T 18664-2002, Selection, use and maintenance of respiratory protective

equipment

GB/T 23466-2009, Guideline for selection of hearing protectors

GB/T 23468-2009, Code of practice for safety use of fall protection

equipment

4.5 When multiple protection equipment is required at the same time, the use

compatibility and functional substitution shall be considered to avoid protection

failure.

5 Principles and methods for identifying hazard and

harmful factors

5.1 Identification principle

5.1.1 Identify hazard and harmful factors based on scientific, systematic and

comprehensive basic principles.

5.1.2 According to safety science theory, national laws, regulations, standards

and professional knowledge, according to the characteristics of different

workplaces, production processes and operating environments, identify

possible hazard and harmful factors.

5.1.3 Systematically analyze hazard and harmful factors in all links of

production and operation activities. Determine the location of the hazard and

harmful factors, the hazards, the ways and consequences of the accident.

5.1.4 Identify in terms of personnel, equipment and facilities, environmental

conditions, management systems. It shall not only analyze hazard and harmful

factors existing in normal production operations, but also possible hazard and

harmful factors in the case of changes in technology, materials, processes,

equipment damage or failure, and personnel operation errors.

5.2 Identification method

5.2.1 The production and business operation entity shall, according to the

accident categories specified in GB 6441, the hazard factors in the "Category

of Occupational Disease Hazard Factors" published by the Ministry of Health

and other occupational health regulations, identify hazard and harmful factors.

5.2.2 Professionals shall analyze the hazard and harmful factors in the working

environment by means of on-site investigation, measurement, inspection of

relevant records, safety checklists, inquiry and communication. Determine

hazard and harmful factors, types of injuries, likelihood, extent and

consequences of harm to humans.

5.2.3 When identifying hazard and harmful factors, it shall analyze mainly from

the following aspects:

- Normal working condition;

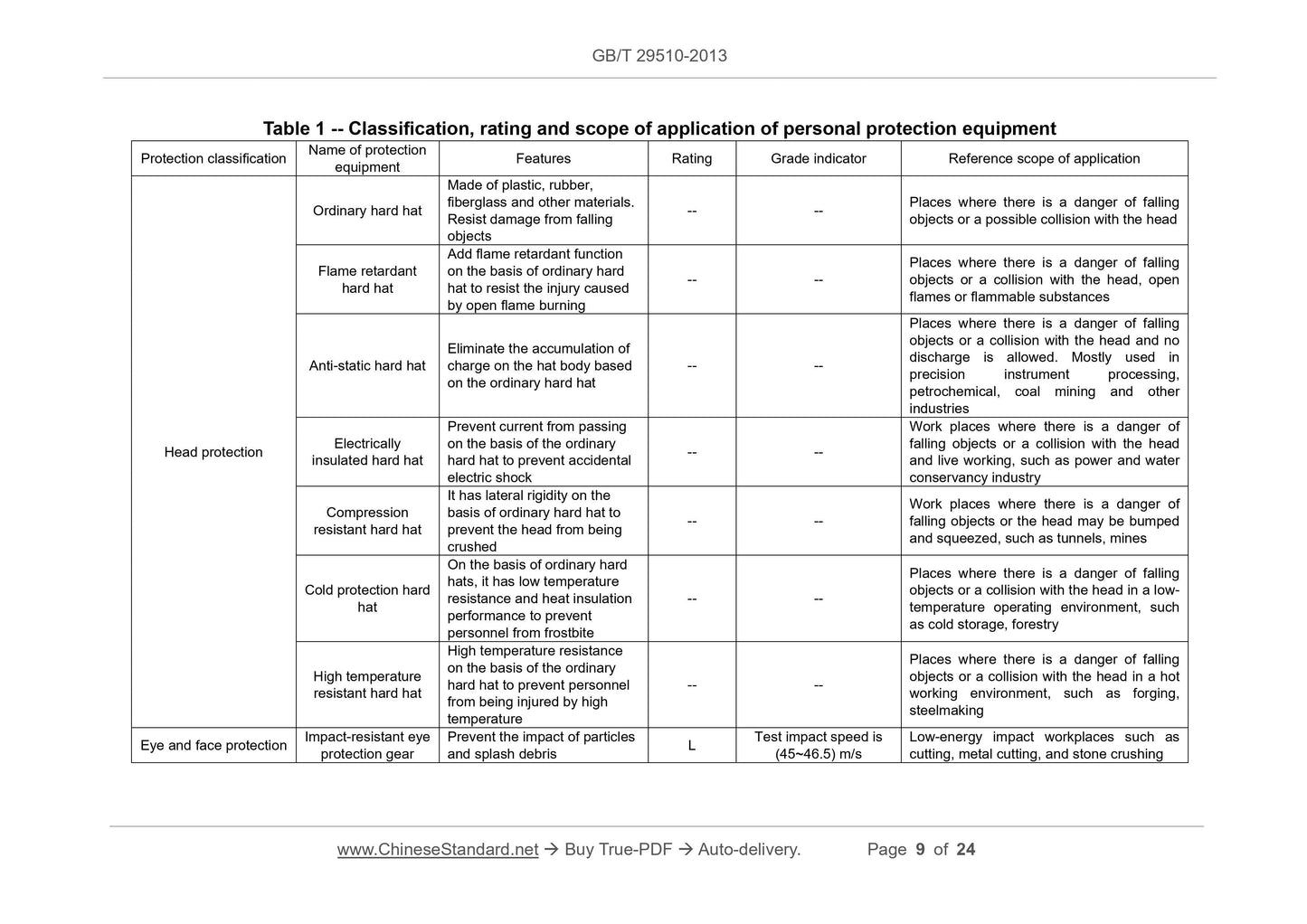

Table 1 -- Classification, rating and scope of application of personal protection equipment

Protection classification Name of protection equipment Features Rating Grade indicator Reference scope of application

Head protection

Ordinary hard hat

Made of plastic, rubber,

fiberglass and other materials.

Resist damage from falling

objects

-- -- Places where there is a danger of falling objects or a possible collision with the head

Flame retardant

hard hat

Add flame retardant function

on the basis of ordinary hard

hat to resist the injury caused

by open flame burning

-- --

Places where there is a danger of falling

objects or a collision with the head, open

flames or flammable substances

Anti-static hard hat

Eliminate the accumulation of

charge on the hat body based

on the ordinary hard hat

-- --

Places where there is a danger of falling

objects or a collision with the head and no

discharge is allowed. Mostly used in

precision instrument processing,

petrochemical, coal mining and other

industries

Electrically

insulated hard hat

Prevent current from passing

on the basis of the ordinary

hard hat to prevent accidental

electric shock

-- --

Work places where there is a danger of

falling objects or a collision with the head

and live working, such as power and water

conservancy industry

Compression

resistant hard hat

It has lateral rigidity on the

basis of ordinary hard hat to

prevent the head from being

crushed

-- --

Work places where there is a danger of

falling objects or the head may be bumped

and squeezed, such as tunnels, mines

Cold protection hard

hat

On the basis of ordinary hard

hats, it has low temperature

resistance and heat insulation

performance to prevent

personnel from frostbite

-- --

Places where there is a danger of falling

objects or a collision with the head in a low-

temperature operating environment, such

as cold storage, forestry

High temperature

resistant hard hat

High temperature resistance

on the basis of the ordinary

hard hat to prevent personnel

from being injured by high

temperature

-- --

Places where there is a danger of falling

objects or a collision with the head in a hot

working environment, such as forging,

steelmaking

Eye and face protection Impact-resistant eye protection gear

Prevent the impact of particles

and splash debris L

Test impact speed is

(45~46.5) m/s

Low-energy impact workplaces such as

cutting, metal cutting, and stone crushing

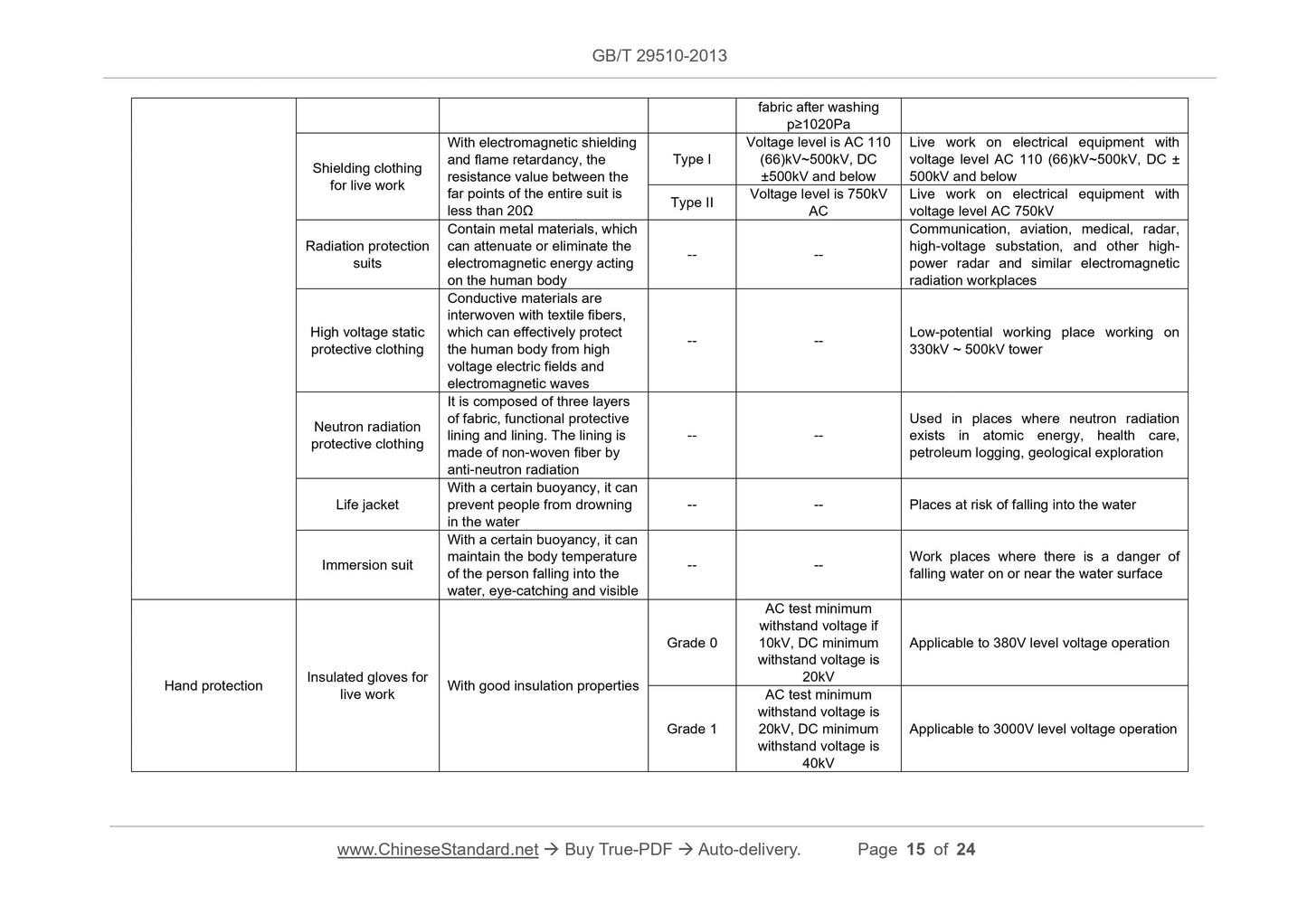

fabric after washing

p≥1020Pa

Shielding clothing

for live work

With electromagnetic shielding

and flame retardancy, the

resistance value between the

far points of the entire suit is

less than 20Ω

Type I

Voltage level is AC 110

(66)kV~500kV, DC

±500kV and below

Live work on electrical equipment with

voltage level AC 110 (66)kV~500kV, DC ±

500kV and below

Type II Voltage level is 750kV AC

Live work on electrical equipment with

voltage level AC 750kV

Radiation prote...

Get QUOTATION in 1-minute: Click GB/T 29510-2013

Historical versions: GB/T 29510-2013

Preview True-PDF (Reload/Scroll if blank)

GB/T 29510-2013: General requirements for the distribution of personal protection equipment

GB/T 29510-2013

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 13.340.01

C 73

General requirements for the distribution of personal

protection equipment

ISSUED ON: MAY 09, 2013

IMPLEMENTED ON: FEBRUARY 01, 2014

Issued by: General Administration of Quality Supervision, Inspection and

Quarantine;

Standardization Administration of the People's Republic of

China.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Terms and definitions ... 5

4 Basic requirements ... 5

5 Principles and methods for identifying hazard and harmful factors ... 6

6 Distribution procedures ... 7

7 Classification, rating and scope of application ... 8

8 Distribution requirements ... 21

9 Management and training ... 22

Bibliography ... 24

General requirements for the distribution of personal

protection equipment

1 Scope

This Standard specifies basic requirements, identification principles and

methods of dangerous and harmful factors, equipment procedures,

classification, rating and scope of application, equipment requirements,

management and training for distribution of personal protection equipment.

This Standard is applicable to selection, distribution, use, maintenance and

scrap management for personal protection equipment of production and

business operation entity.

2 Normative references

The following referenced documents are indispensable for the application of

this document. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any

amendments) applies.

GB 2890-2009, Respiratory protection - Non-powered air-purifying

respirators

GB/T 6441, The classification for casualty accidents of enterprise staff and

workers

GB/T 11651-2009, Code of practice for selection of personal protective

equipment

GB/T 12903, Personal protective equipment terminology

GB/T 14366, Acoustics - Estimation of noise-induced hearing loss

GB/T 18664-2002, Selection, use and maintenance of respiratory protective

equipment

GB/T 23466-2009, Guideline for selection of hearing protectors

GB/T 23468-2009, Code of practice for safety use of fall protection

equipment

4.5 When multiple protection equipment is required at the same time, the use

compatibility and functional substitution shall be considered to avoid protection

failure.

5 Principles and methods for identifying hazard and

harmful factors

5.1 Identification principle

5.1.1 Identify hazard and harmful factors based on scientific, systematic and

comprehensive basic principles.

5.1.2 According to safety science theory, national laws, regulations, standards

and professional knowledge, according to the characteristics of different

workplaces, production processes and operating environments, identify

possible hazard and harmful factors.

5.1.3 Systematically analyze hazard and harmful factors in all links of

production and operation activities. Determine the location of the hazard and

harmful factors, the hazards, the ways and consequences of the accident.

5.1.4 Identify in terms of personnel, equipment and facilities, environmental

conditions, management systems. It shall not only analyze hazard and harmful

factors existing in normal production operations, but also possible hazard and

harmful factors in the case of changes in technology, materials, processes,

equipment damage or failure, and personnel operation errors.

5.2 Identification method

5.2.1 The production and business operation entity shall, according to the

accident categories specified in GB 6441, the hazard factors in the "Category

of Occupational Disease Hazard Factors" published by the Ministry of Health

and other occupational health regulations, identify hazard and harmful factors.

5.2.2 Professionals shall analyze the hazard and harmful factors in the working

environment by means of on-site investigation, measurement, inspection of

relevant records, safety checklists, inquiry and communication. Determine

hazard and harmful factors, types of injuries, likelihood, extent and

consequences of harm to humans.

5.2.3 When identifying hazard and harmful factors, it shall analyze mainly from

the following aspects:

- Normal working condition;

Table 1 -- Classification, rating and scope of application of personal protection equipment

Protection classification Name of protection equipment Features Rating Grade indicator Reference scope of application

Head protection

Ordinary hard hat

Made of plastic, rubber,

fiberglass and other materials.

Resist damage from falling

objects

-- -- Places where there is a danger of falling objects or a possible collision with the head

Flame retardant

hard hat

Add flame retardant function

on the basis of ordinary hard

hat to resist the injury caused

by open flame burning

-- --

Places where there is a danger of falling

objects or a collision with the head, open

flames or flammable substances

Anti-static hard hat

Eliminate the accumulation of

charge on the hat body based

on the ordinary hard hat

-- --

Places where there is a danger of falling

objects or a collision with the head and no

discharge is allowed. Mostly used in

precision instrument processing,

petrochemical, coal mining and other

industries

Electrically

insulated hard hat

Prevent current from passing

on the basis of the ordinary

hard hat to prevent accidental

electric shock

-- --

Work places where there is a danger of

falling objects or a collision with the head

and live working, such as power and water

conservancy industry

Compression

resistant hard hat

It has lateral rigidity on the

basis of ordinary hard hat to

prevent the head from being

crushed

-- --

Work places where there is a danger of

falling objects or the head may be bumped

and squeezed, such as tunnels, mines

Cold protection hard

hat

On the basis of ordinary hard

hats, it has low temperature

resistance and heat insulation

performance to prevent

personnel from frostbite

-- --

Places where there is a danger of falling

objects or a collision with the head in a low-

temperature operating environment, such

as cold storage, forestry

High temperature

resistant hard hat

High temperature resistance

on the basis of the ordinary

hard hat to prevent personnel

from being injured by high

temperature

-- --

Places where there is a danger of falling

objects or a collision with the head in a hot

working environment, such as forging,

steelmaking

Eye and face protection Impact-resistant eye protection gear

Prevent the impact of particles

and splash debris L

Test impact speed is

(45~46.5) m/s

Low-energy impact workplaces such as

cutting, metal cutting, and stone crushing

fabric after washing

p≥1020Pa

Shielding clothing

for live work

With electromagnetic shielding

and flame retardancy, the

resistance value between the

far points of the entire suit is

less than 20Ω

Type I

Voltage level is AC 110

(66)kV~500kV, DC

±500kV and below

Live work on electrical equipment with

voltage level AC 110 (66)kV~500kV, DC ±

500kV and below

Type II Voltage level is 750kV AC

Live work on electrical equipment with

voltage level AC 750kV

Radiation prote...

Share