1

/

of

6

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

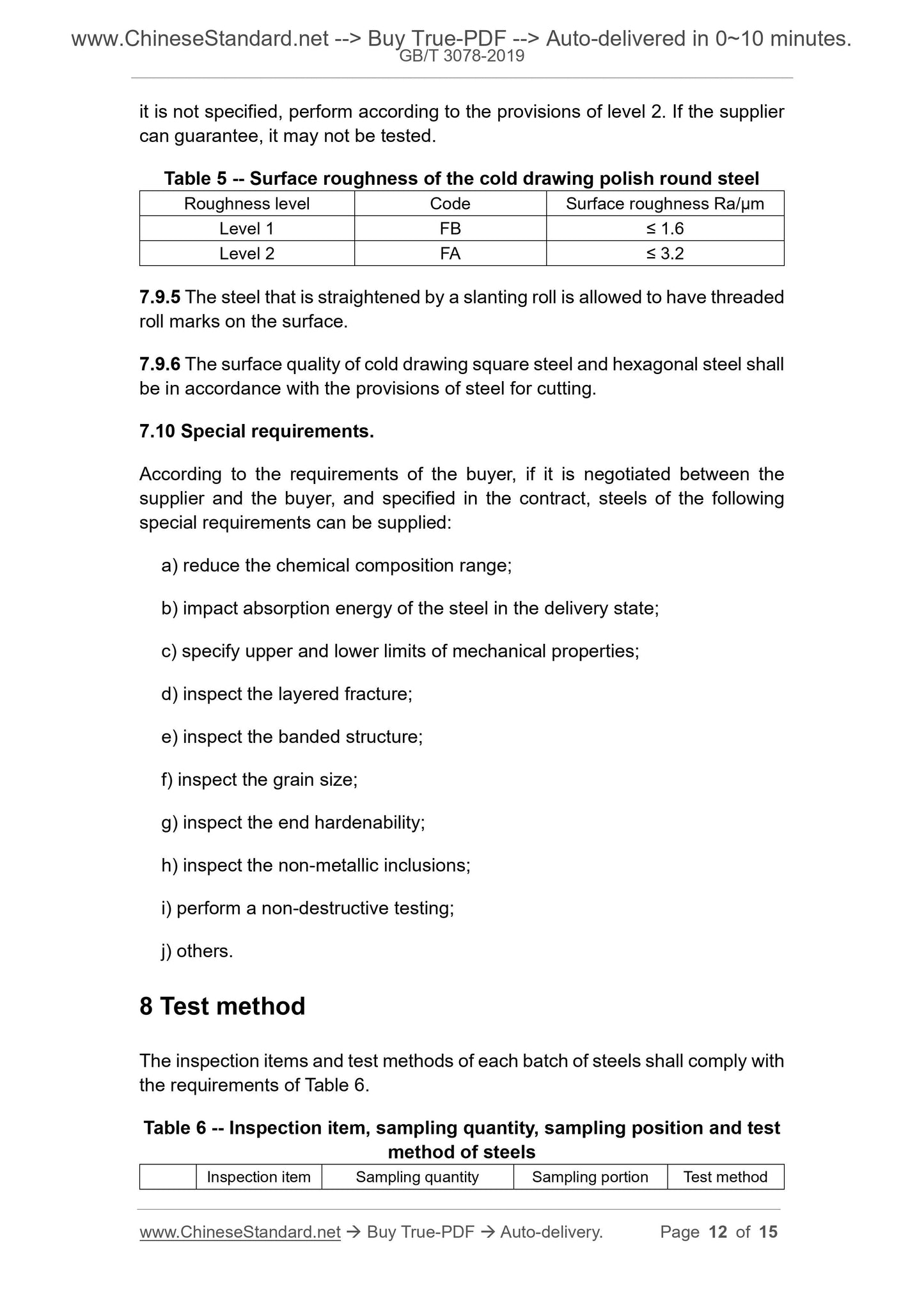

GB/T 3078-2019 English PDF (GBT3078-2019)

GB/T 3078-2019 English PDF (GBT3078-2019)

Regular price

$135.00 USD

Regular price

Sale price

$135.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get Quotation: Click GB/T 3078-2019 (Self-service in 1-minute)

Historical versions (Master-website): GB/T 3078-2019

Preview True-PDF (Reload/Scroll-down if blank)

GB/T 3078-2019: Quality structural steel cold drawn bars

GB/T 3078-2019

(High quality structural steel cold drawn steel)

ICS 77.140.60

H44

National Standards of People's Republic of China

Replace GB/T 3078-2008

High quality structural steel cold drawn steel

Published on.2019-08-30

2020-07-01 implementation

State market supervision and administration

China National Standardization Administration issued

Foreword

This standard was drafted in accordance with the rules given in GB/T 1.1-2009.

This standard replaces GB/T 3078-2008 "High-quality structural steel cold drawn steel". This standard is compared with GB/T 3078-2008, the main technology

The changes are as follows.

--- Added "terms and definitions" (see Chapter 3);

--- Added delivery status code symbol (see 7.3.1);

--- Modified the steel hardness requirements, and canceled the three grades of 20SiMnVB, 20CrV, 45CrVA (see 7.4,.2008 edition 6.4);

--- The unit of tensile strength is modified to "MPa" (see 7.5,.2008 edition 6.5);

--- Low-magnification organization requirements to be modified to meet the requirements of GB/T 699 and GB/T 3077 (see 7.7,.2008 edition 6.7);

--- Defining the test method (see Chapter 7, Chapter 7 of the.2008 edition);

--- Standardized batch rules (see Chapter 8, Chapter 8 of the.2008 edition);

--- Increased the level of surface roughness of cold drawn steel (see 7.9.4).

This standard was proposed by the China Iron and Steel Association.

This standard is under the jurisdiction of the National Steel Standardization Technical Committee (SAC/TC183).

This standard was drafted. Northeast Special Steel Group Co., Ltd., Jiangyin Xingcheng Special Steel Co., Ltd., Fangda Special Steel Technology Co., Ltd.

Co., Ltd., Metallurgical Industry Standard Information Research Institute, Liaoning Xindali Steel Co., Ltd., Xiwang Metal Technology Co., Ltd.

The main drafters of this standard. Jin Weisong, Hao Xixiu, Xu Xiaohong, Zhuang Na, Yan Yuming, Zheng Shuguo, Wen Zhengmao, Zhang Qingsheng, Zhang Kui, Xin Lin,

Wang Xinhe.

The previous versions of the standards replaced by this standard are.

---GB 3078-1982, GB/T 3078-1994, GB/T 3078-2008.

High quality structural steel cold drawn steel

1 Scope

This standard specifies the classification, ordering content, size, shape and allowable deviation of structural steel cold drawn and cold drawn polished steel, technical requirements, test

Test methods, inspection rules, packaging, signs and quality certificates.

This standard applies to high quality carbon structural steel and alloy structural steel cold drawn steel bars (round steel, square steel and hexagonal steel) and cold drawn polished round steel (below

Collectively referred to as "steel").

2 Normative references

The following documents are indispensable for the application of this document. For dated references, only dated versions apply to this article.

Pieces. For undated references, the latest edition (including all amendments) applies to this document.

Permissible deviation of chemical composition of finished products of GB/T 222 steel

Decarburization layer depth measurement method for GB/T 224 steel

End quenching test method for hardenability of GB/T 225 steel (Jominy test)

Low-magnification structure and defect acid etching test method for GB/T 226 steel

GB/T 228.1 tensile testing of metallic materials - Part 1

GB/T 229 metal material Charpy pendulum impact test method

GB/T 231.1 Brinell hardness test for metallic materials - Part 1. Test methods

GB/T 341-2008 Wire classification and terminology

GB/T 699 high quality carbon structural steel

GB/T 905-1994 Cold drawn round steel, square steel, hexagonal steel size, shape, weight and tolerance

GB/T 1814 steel fracture test method

GB/T 1979 structural steel low-fold tissue defect rating map

General provisions for GB/T 2101 steel acceptance, packaging, marking and quality certificates

GB/T 2975-2018 Steel and steel products, mechanical properties test sampling position and sample preparation

GB/T 3077 alloy structural steel

GB/T 3207-2008 Silver Bright Steel

GB/T 4162 forging steel bar ultrasonic testing method

GB/T 6394 method for determination of average grain size of metals

Low-defect ultrasonic inspection method for GB/T 7736 steel

GB/T 8170 Numerical Rounding Rules and Representation and Determination of Limit Values

GB/T 10561 Steels - Determination of non-metallic inclusions - Standards

GB/T 13298 metal microstructure inspection method

General technical requirements for the delivery of GB/T 17505 steel and steel products

GB/T 20066 Sampling and sample preparation method for samples for determination of chemical composition of steel and iron

GB/T 34474.1 Evaluation of ribbons in steel - Part 1

YB/T 5293 metal material upsetting test method

3 Terms and definitions

The terms and definitions defined in GB/T 341-2008 and GB/T 3207-2008 apply to this document. For ease of use, the following

Some terms and definitions in GB/T 341-2008 and GB/T 3207-2008 are listed.

3.1

Cold pull colddrawing

A process formed by a pressure processing method such as die drawing or roll drawing at normal temperature.

[GB/T 341-2008, definition 3.1.6]

3.2

Polishing stone polishsteel

Polished round steel after drawing or peeling.

[GB/T 3207-2008, definition 3.3]

4 classification

Steel is divided into.

a) Pressure processing steel (UP).

1) Steel for hot press processing (UHP);

2) Cold top forging steel (UCF);

3) Steel for hot forging (UHF).

b) Steel for machining (UC).

5 Ordering content

Contracts ordered under this standard shall include the following.

a) the standard number;

b) product name;

c) the grade or uniform digital code of the steel;

d) the weight (or quantity) of the delivery;

e) size, shape and tolerances (see Chapter 6);

f) use of processing (when not specified, steel for cutting);

g) delivery status (see 7.3.1);

h) mechanical properties (see 7.5);

i) cold or hot upset (see 7.6 if required);

j) decarburization layer (see 7.8 if required);

k) Special requirements (see 7.10 if required).

6 size, shape and tolerance

6.1 The dimensions, shape and allowable deviation of cold drawn steel bars shall comply with the provisions of GB/T 905-1994, and the specific requirements shall be indicated in the contract.

When specified, please follow the h11 level.

6.2 The size, shape and allowable deviation of cold-drawn polished round steel shall comply with the provisions of GB/T 3207-2008, and the specific requirements shall be noted in the contract.

Ming, if not specified, according to h11 level.

7 Technical requirements

7.1 Brand and chemical composition

7.1.1 Steel grade and chemical composition, high-quality carbon structural steel shall comply with the provisions of GB/T 699, alloy structural steel shall comply with GB/T 3077

Provisions. According to the requirements of the purchaser, and in the contract, it can be ordered according to other brands.

7.1.2 The allowable deviation of chemical composition of finished steel products shall comply with the provisions of GB/T 222.

7.2 Smelting method

Unless otherwise specified in the contract, the smelting method is chosen by the supplier.

7.3 Delivery status

7.3.1 The delivery status of steel is shown in Table 1. The specific delivery status should be indicated in the contract. If not specified, delivery in cold tension.

Table 1 Delivery status of steel

Delivery status code

Cold pull WCD

Cold-rolled polished WCD SP

Cold drawn heat treatment

Annealing WCD A

Bright Annealed WCD L

Normalizing WCD N

High temperature tempering WCD HT

Tempering after normalizing WCD NT

7.3.2 After consultation between the supplier and the buyer, and indicated in the contract, it can be delivered in other states.

7.4 hardness

7.4.1 The delivery hardness value of steel (except for normalized state) shall comply with the requirements of Table 2. According to the requirements of the purchaser, the cold-drawn heat is not listed in Table 2.

The hardness value of the alloy structural steel delivered (excluding the normalized state) shall comply with the provisions of GB/T 3077; cold drawing, cold drawing and polishing state

The hardness of the steel of the goods should not exceed 285HBW. This hardness value is the reference value and is not used as the basis for determination. The hardness value of the steel delivered on normalizing

The supply and demand sides negotiated the regulations.

7.4.2 Steel for delivery in cold-drawn state for heating pressure processing, Brinell hard for 50Mn2, 35CrMnSi, 42CrMo, 35CrMoV steel

The degree should be in accordance with Table 2. The Brinell hardness value of 38CrSi and 38CrMoAl steel should not exceed 285HBW, and the cloth of other grades of steel.

The hardness value should be no more than 269HBW.

7.4.3 For steels with a nominal cross-section (diameter, thickness or diagonal length) of less than 5 mm, no hardness test shall be carried out. According to the requirements of the purchaser, and

It is stated in the contract that the hardness can be replaced by tensile strength, and the specific requirements are determined by both parties.

Table 2 Delivery state hardness

Serial number

Delivery state hardness/HBW, not greater than

Cold pull,

Cold-rolled polishing

Annealing, bright annealing, high temperature

Tempering or tempering after normalizing

Serial number

Delivery state hardness/HBW, not greater than

Cold pull,

Cold-rolled polishing

Annealing, bright annealing, high temperature

Tempering or tempering after normalizing

1 10 229 179 38 40CrV 269 229

2 15 229 179 39 38CrSi 269 255

3 20 229 179 40 20CrMnSi 255 217

4 25 229 179 41 25CrMnSi 269 229

5 30 229 179 42 30CrMnSi 269 229

6 35 241 187 43 35CrMnSi 285 241

7 40 241 207 44 20CrMnTi 255 207

8 45 255 229 45 15CrMo 229 187

9 50 255 229 46 20CrMo 241 197

10 55 269 241 47 30CrMo 269 229

11 60 269 241 48 35CrMo 269 241

12 65 (285) 255 49 42CrMo 285 255

13 15Mn 207 163 50 20CrMnMo 269 229

14 20Mn 229 187 51 40CrMnMo 269 241

15 25Mn 241 197 52 35CrMoV 285 255

16 30Mn 241 197 53 38CrMoAl 269 229

17 35Mn 255 207 54 15Cr 229 179

18 40Mn 269 217 55 20Cr 229 179

19 45Mn 269 229 56 30Cr 241 187

20 50Mn 269 229 57 35Cr 269 217

21 60Mn (285) 255 58 40Cr 269 217

22 65Mn (285) 269 59 45Cr 269 229

23 20Mn2 241 197 60 20CrNi 255 207

24 35Mn2 255 207 61 40CrNi (285) 255

25 40Mn2 269 217 62 45CrNi (285) 269

26 45Mn2 269 229 63 12CrNi2 269 217

27 50Mn2 285 229 64 12CrNi3 269 229

28 27SiMn 255 217 65 20CrNi3 269 241

29 35SiMn 269 229 66 30CrNi3 (285) 255

30 42SiMn (285) 241 67 37CrNi3 (285) 269

31 20MnV 229 187 68 12Cr2Ni4 (285) 255

32 40B 241 207 69 20Cr2Ni4 (285) 269

33 45B 255 229 70 40CrNiMo (285) 269

34 50B 255 229 71 45CrNiMoV (285) 269

35 40MnB 269 217 72 18Cr2Ni4W (285) 269

36 45MnB 269 229 73 25Cr2Ni4W (285) 269

37 40MnVB 269 217 - - - -

a Reference value in parentheses is not used as a basis for judgment.

7.5 Mechanical properties

According to the requirements of the purchaser and stated in the contract, the steel can test the mechanical properties of the steel delivery state, and its mechanical properties should meet the requirements of Table 3.

Provisions. The mechanical properties of the delivery status of the steels not listed in Table 3 are determined by negotiation between the supplier and the buyer.

Table 3 Mechanical properties of delivery status

Serial number

Cold drawn annealing

tensile strength

Rm/MPa

Elongation after break

A/%

rate of reduction in area

Z/%

tensile strength

Rm/MPa

Elongation after break

A/%

rate of reduction in area

Z/%

Not less than not less than

1 10 440 8 50 295 26 55

2 15 470 8 45 345 28 55

3 20 510 7.5 40 390 21 50

4 25 540 7 40 410 19 50

5 30 560 7 35 440 17 45

6 35 590 6.5 35 470 15 45

7 40 610 6 35 510 14 40

8 45 635 6 30 540 13 40

9 50 655 6 30 560 12 40

10 15Mn 490 7.5 40 390 21 50

11 50Mn 685 5.5 30 590 10 35

12 50Mn2 735 5 25 635 9 30

7.6 top forging

The upset forging steel shall be subjected to a top forging test and the cold or hot upset shall be indicated in the contract. Cold forging test is forged to one-half of the original height of the sample,

The hot upset forging test is forged to one third of the original height of the specimen, and the surface of the specimen after the upset forging shall not have visible cracks. If the supplier can guarantee the top

The forging test is qualified and may not be tested.

7.7 low-fold organization

7.7.1 Low-weight organization of high-quality carbon structural steel shall comply with the provisions of GB/T 699.

7.7.2 Alloy structure The low-fold structure of steel shall comply with the provisions of GB/T 3077.

7.8 Decarburization layer

According to the requirements of the purchaser, steel with a carbon content of not less than 0.30% can be subjected to decarburization inspection, while the total decarburization layer (ferrite transition layer) is deep.

Should comply with the provisions of Table 4.

Table 4 Decarburization depth

Shape nominal diameter/mm group a

Total decarburization depth on one side b/mm

no greater than

Cold-drawn, bright-annealed, annealed, cold-polished

Round steel

≥6.5

< 6.5

1 group 1.0% D 1.5% D

2 groups of 1.5% D negotiated by both parties

- 0.10 negotiation between the two parties

The two sides negotiated no decarbonization

Square steel, hexagonal steel negotiated

D is the nominal diameter of the steel.

a When a group is required, it should be indicated in the contract. If it is not specified, it should be specified in the second group.

b Steel with a silicon content of not less than 0.90% or an aluminum content of not less than 0.70%, the depth of the decarburization layer is negotiated by both parties.

7.9 Surface quality

7.9.1 The surface of the steel should be clean, smooth, free from cracks, folds, crusting, inclusions, cracks and scales; heat-treated cold drawn steel surfaces

Oxidation is allowed.

7.9.2 For steels used for cutting, the surface shall be allowed to have a depth that does not ...

Get Quotation: Click GB/T 3078-2019 (Self-service in 1-minute)

Historical versions (Master-website): GB/T 3078-2019

Preview True-PDF (Reload/Scroll-down if blank)

GB/T 3078-2019: Quality structural steel cold drawn bars

GB/T 3078-2019

(High quality structural steel cold drawn steel)

ICS 77.140.60

H44

National Standards of People's Republic of China

Replace GB/T 3078-2008

High quality structural steel cold drawn steel

Published on.2019-08-30

2020-07-01 implementation

State market supervision and administration

China National Standardization Administration issued

Foreword

This standard was drafted in accordance with the rules given in GB/T 1.1-2009.

This standard replaces GB/T 3078-2008 "High-quality structural steel cold drawn steel". This standard is compared with GB/T 3078-2008, the main technology

The changes are as follows.

--- Added "terms and definitions" (see Chapter 3);

--- Added delivery status code symbol (see 7.3.1);

--- Modified the steel hardness requirements, and canceled the three grades of 20SiMnVB, 20CrV, 45CrVA (see 7.4,.2008 edition 6.4);

--- The unit of tensile strength is modified to "MPa" (see 7.5,.2008 edition 6.5);

--- Low-magnification organization requirements to be modified to meet the requirements of GB/T 699 and GB/T 3077 (see 7.7,.2008 edition 6.7);

--- Defining the test method (see Chapter 7, Chapter 7 of the.2008 edition);

--- Standardized batch rules (see Chapter 8, Chapter 8 of the.2008 edition);

--- Increased the level of surface roughness of cold drawn steel (see 7.9.4).

This standard was proposed by the China Iron and Steel Association.

This standard is under the jurisdiction of the National Steel Standardization Technical Committee (SAC/TC183).

This standard was drafted. Northeast Special Steel Group Co., Ltd., Jiangyin Xingcheng Special Steel Co., Ltd., Fangda Special Steel Technology Co., Ltd.

Co., Ltd., Metallurgical Industry Standard Information Research Institute, Liaoning Xindali Steel Co., Ltd., Xiwang Metal Technology Co., Ltd.

The main drafters of this standard. Jin Weisong, Hao Xixiu, Xu Xiaohong, Zhuang Na, Yan Yuming, Zheng Shuguo, Wen Zhengmao, Zhang Qingsheng, Zhang Kui, Xin Lin,

Wang Xinhe.

The previous versions of the standards replaced by this standard are.

---GB 3078-1982, GB/T 3078-1994, GB/T 3078-2008.

High quality structural steel cold drawn steel

1 Scope

This standard specifies the classification, ordering content, size, shape and allowable deviation of structural steel cold drawn and cold drawn polished steel, technical requirements, test

Test methods, inspection rules, packaging, signs and quality certificates.

This standard applies to high quality carbon structural steel and alloy structural steel cold drawn steel bars (round steel, square steel and hexagonal steel) and cold drawn polished round steel (below

Collectively referred to as "steel").

2 Normative references

The following documents are indispensable for the application of this document. For dated references, only dated versions apply to this article.

Pieces. For undated references, the latest edition (including all amendments) applies to this document.

Permissible deviation of chemical composition of finished products of GB/T 222 steel

Decarburization layer depth measurement method for GB/T 224 steel

End quenching test method for hardenability of GB/T 225 steel (Jominy test)

Low-magnification structure and defect acid etching test method for GB/T 226 steel

GB/T 228.1 tensile testing of metallic materials - Part 1

GB/T 229 metal material Charpy pendulum impact test method

GB/T 231.1 Brinell hardness test for metallic materials - Part 1. Test methods

GB/T 341-2008 Wire classification and terminology

GB/T 699 high quality carbon structural steel

GB/T 905-1994 Cold drawn round steel, square steel, hexagonal steel size, shape, weight and tolerance

GB/T 1814 steel fracture test method

GB/T 1979 structural steel low-fold tissue defect rating map

General provisions for GB/T 2101 steel acceptance, packaging, marking and quality certificates

GB/T 2975-2018 Steel and steel products, mechanical properties test sampling position and sample preparation

GB/T 3077 alloy structural steel

GB/T 3207-2008 Silver Bright Steel

GB/T 4162 forging steel bar ultrasonic testing method

GB/T 6394 method for determination of average grain size of metals

Low-defect ultrasonic inspection method for GB/T 7736 steel

GB/T 8170 Numerical Rounding Rules and Representation and Determination of Limit Values

GB/T 10561 Steels - Determination of non-metallic inclusions - Standards

GB/T 13298 metal microstructure inspection method

General technical requirements for the delivery of GB/T 17505 steel and steel products

GB/T 20066 Sampling and sample preparation method for samples for determination of chemical composition of steel and iron

GB/T 34474.1 Evaluation of ribbons in steel - Part 1

YB/T 5293 metal material upsetting test method

3 Terms and definitions

The terms and definitions defined in GB/T 341-2008 and GB/T 3207-2008 apply to this document. For ease of use, the following

Some terms and definitions in GB/T 341-2008 and GB/T 3207-2008 are listed.

3.1

Cold pull colddrawing

A process formed by a pressure processing method such as die drawing or roll drawing at normal temperature.

[GB/T 341-2008, definition 3.1.6]

3.2

Polishing stone polishsteel

Polished round steel after drawing or peeling.

[GB/T 3207-2008, definition 3.3]

4 classification

Steel is divided into.

a) Pressure processing steel (UP).

1) Steel for hot press processing (UHP);

2) Cold top forging steel (UCF);

3) Steel for hot forging (UHF).

b) Steel for machining (UC).

5 Ordering content

Contracts ordered under this standard shall include the following.

a) the standard number;

b) product name;

c) the grade or uniform digital code of the steel;

d) the weight (or quantity) of the delivery;

e) size, shape and tolerances (see Chapter 6);

f) use of processing (when not specified, steel for cutting);

g) delivery status (see 7.3.1);

h) mechanical properties (see 7.5);

i) cold or hot upset (see 7.6 if required);

j) decarburization layer (see 7.8 if required);

k) Special requirements (see 7.10 if required).

6 size, shape and tolerance

6.1 The dimensions, shape and allowable deviation of cold drawn steel bars shall comply with the provisions of GB/T 905-1994, and the specific requirements shall be indicated in the contract.

When specified, please follow the h11 level.

6.2 The size, shape and allowable deviation of cold-drawn polished round steel shall comply with the provisions of GB/T 3207-2008, and the specific requirements shall be noted in the contract.

Ming, if not specified, according to h11 level.

7 Technical requirements

7.1 Brand and chemical composition

7.1.1 Steel grade and chemical composition, high-quality carbon structural steel shall comply with the provisions of GB/T 699, alloy structural steel shall comply with GB/T 3077

Provisions. According to the requirements of the purchaser, and in the contract, it can be ordered according to other brands.

7.1.2 The allowable deviation of chemical composition of finished steel products shall comply with the provisions of GB/T 222.

7.2 Smelting method

Unless otherwise specified in the contract, the smelting method is chosen by the supplier.

7.3 Delivery status

7.3.1 The delivery status of steel is shown in Table 1. The specific delivery status should be indicated in the contract. If not specified, delivery in cold tension.

Table 1 Delivery status of steel

Delivery status code

Cold pull WCD

Cold-rolled polished WCD SP

Cold drawn heat treatment

Annealing WCD A

Bright Annealed WCD L

Normalizing WCD N

High temperature tempering WCD HT

Tempering after normalizing WCD NT

7.3.2 After consultation between the supplier and the buyer, and indicated in the contract, it can be delivered in other states.

7.4 hardness

7.4.1 The delivery hardness value of steel (except for normalized state) shall comply with the requirements of Table 2. According to the requirements of the purchaser, the cold-drawn heat is not listed in Table 2.

The hardness value of the alloy structural steel delivered (excluding the normalized state) shall comply with the provisions of GB/T 3077; cold drawing, cold drawing and polishing state

The hardness of the steel of the goods should not exceed 285HBW. This hardness value is the reference value and is not used as the basis for determination. The hardness value of the steel delivered on normalizing

The supply and demand sides negotiated the regulations.

7.4.2 Steel for delivery in cold-drawn state for heating pressure processing, Brinell hard for 50Mn2, 35CrMnSi, 42CrMo, 35CrMoV steel

The degree should be in accordance with Table 2. The Brinell hardness value of 38CrSi and 38CrMoAl steel should not exceed 285HBW, and the cloth of other grades of steel.

The hardness value should be no more than 269HBW.

7.4.3 For steels with a nominal cross-section (diameter, thickness or diagonal length) of less than 5 mm, no hardness test shall be carried out. According to the requirements of the purchaser, and

It is stated in the contract that the hardness can be replaced by tensile strength, and the specific requirements are determined by both parties.

Table 2 Delivery state hardness

Serial number

Delivery state hardness/HBW, not greater than

Cold pull,

Cold-rolled polishing

Annealing, bright annealing, high temperature

Tempering or tempering after normalizing

Serial number

Delivery state hardness/HBW, not greater than

Cold pull,

Cold-rolled polishing

Annealing, bright annealing, high temperature

Tempering or tempering after normalizing

1 10 229 179 38 40CrV 269 229

2 15 229 179 39 38CrSi 269 255

3 20 229 179 40 20CrMnSi 255 217

4 25 229 179 41 25CrMnSi 269 229

5 30 229 179 42 30CrMnSi 269 229

6 35 241 187 43 35CrMnSi 285 241

7 40 241 207 44 20CrMnTi 255 207

8 45 255 229 45 15CrMo 229 187

9 50 255 229 46 20CrMo 241 197

10 55 269 241 47 30CrMo 269 229

11 60 269 241 48 35CrMo 269 241

12 65 (285) 255 49 42CrMo 285 255

13 15Mn 207 163 50 20CrMnMo 269 229

14 20Mn 229 187 51 40CrMnMo 269 241

15 25Mn 241 197 52 35CrMoV 285 255

16 30Mn 241 197 53 38CrMoAl 269 229

17 35Mn 255 207 54 15Cr 229 179

18 40Mn 269 217 55 20Cr 229 179

19 45Mn 269 229 56 30Cr 241 187

20 50Mn 269 229 57 35Cr 269 217

21 60Mn (285) 255 58 40Cr 269 217

22 65Mn (285) 269 59 45Cr 269 229

23 20Mn2 241 197 60 20CrNi 255 207

24 35Mn2 255 207 61 40CrNi (285) 255

25 40Mn2 269 217 62 45CrNi (285) 269

26 45Mn2 269 229 63 12CrNi2 269 217

27 50Mn2 285 229 64 12CrNi3 269 229

28 27SiMn 255 217 65 20CrNi3 269 241

29 35SiMn 269 229 66 30CrNi3 (285) 255

30 42SiMn (285) 241 67 37CrNi3 (285) 269

31 20MnV 229 187 68 12Cr2Ni4 (285) 255

32 40B 241 207 69 20Cr2Ni4 (285) 269

33 45B 255 229 70 40CrNiMo (285) 269

34 50B 255 229 71 45CrNiMoV (285) 269

35 40MnB 269 217 72 18Cr2Ni4W (285) 269

36 45MnB 269 229 73 25Cr2Ni4W (285) 269

37 40MnVB 269 217 - - - -

a Reference value in parentheses is not used as a basis for judgment.

7.5 Mechanical properties

According to the requirements of the purchaser and stated in the contract, the steel can test the mechanical properties of the steel delivery state, and its mechanical properties should meet the requirements of Table 3.

Provisions. The mechanical properties of the delivery status of the steels not listed in Table 3 are determined by negotiation between the supplier and the buyer.

Table 3 Mechanical properties of delivery status

Serial number

Cold drawn annealing

tensile strength

Rm/MPa

Elongation after break

A/%

rate of reduction in area

Z/%

tensile strength

Rm/MPa

Elongation after break

A/%

rate of reduction in area

Z/%

Not less than not less than

1 10 440 8 50 295 26 55

2 15 470 8 45 345 28 55

3 20 510 7.5 40 390 21 50

4 25 540 7 40 410 19 50

5 30 560 7 35 440 17 45

6 35 590 6.5 35 470 15 45

7 40 610 6 35 510 14 40

8 45 635 6 30 540 13 40

9 50 655 6 30 560 12 40

10 15Mn 490 7.5 40 390 21 50

11 50Mn 685 5.5 30 590 10 35

12 50Mn2 735 5 25 635 9 30

7.6 top forging

The upset forging steel shall be subjected to a top forging test and the cold or hot upset shall be indicated in the contract. Cold forging test is forged to one-half of the original height of the sample,

The hot upset forging test is forged to one third of the original height of the specimen, and the surface of the specimen after the upset forging shall not have visible cracks. If the supplier can guarantee the top

The forging test is qualified and may not be tested.

7.7 low-fold organization

7.7.1 Low-weight organization of high-quality carbon structural steel shall comply with the provisions of GB/T 699.

7.7.2 Alloy structure The low-fold structure of steel shall comply with the provisions of GB/T 3077.

7.8 Decarburization layer

According to the requirements of the purchaser, steel with a carbon content of not less than 0.30% can be subjected to decarburization inspection, while the total decarburization layer (ferrite transition layer) is deep.

Should comply with the provisions of Table 4.

Table 4 Decarburization depth

Shape nominal diameter/mm group a

Total decarburization depth on one side b/mm

no greater than

Cold-drawn, bright-annealed, annealed, cold-polished

Round steel

≥6.5

< 6.5

1 group 1.0% D 1.5% D

2 groups of 1.5% D negotiated by both parties

- 0.10 negotiation between the two parties

The two sides negotiated no decarbonization

Square steel, hexagonal steel negotiated

D is the nominal diameter of the steel.

a When a group is required, it should be indicated in the contract. If it is not specified, it should be specified in the second group.

b Steel with a silicon content of not less than 0.90% or an aluminum content of not less than 0.70%, the depth of the decarburization layer is negotiated by both parties.

7.9 Surface quality

7.9.1 The surface of the steel should be clean, smooth, free from cracks, folds, crusting, inclusions, cracks and scales; heat-treated cold drawn steel surfaces

Oxidation is allowed.

7.9.2 For steels used for cutting, the surface shall be allowed to have a depth that does not ...

Share