1

/

of

12

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

GB/T 3190-2008 English PDF (GBT3190-2008)

GB/T 3190-2008 English PDF (GBT3190-2008)

Regular price

$85.00 USD

Regular price

Sale price

$85.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.Newer version: (Replacing this standard) GB/T 3190-2020

Get QUOTATION in 1-minute: Click GB/T 3190-2008

Historical versions: GB/T 3190-2008

Preview True-PDF (Reload/Scroll if blank)

GB/T 3190-2008: Wrought aluminium and aluminium alloy -- Chemical composition

GB/T 3190-2008

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.150.10

H 60

Replacing GB/T 3190-1996

Wrought Aluminium and Aluminium Alloy –

Chemical Composition

(ISO 209.2007 Aluminium and Aluminium Alloy - Chemical Composition, MOD)

ISSUED ON JUNE. 17, 2008

IMPLEMENTED ON. DECEMBER 1, 2008

Issued by. General Administration for Quality Supervision and

Inspection and Quarantine (GAQSIQ);

Standardization Administration of China (SAC).

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative References ... 5

3 Requirements ... 5

4 Others ... 7

Annex A ... 32

Annex B ... 34

Foreword

This Standard modifies and adopts ISO209.2007 "Wrought Aluminium and Aluminium

Alloy - Chemical Composition" (English edition), and it is redrafted in accordance with

ISO209.2007. For ease of comparison, the list of corresponding chapters and sections

between the International Standard and this Standard is detailed in Annex B (Informative).

Modifications are done while adopting the International Standard. the technical differences

are marked with vertical single-line on the page margin of the involved articles; they are as

follows.

— Delete the designation and composition of aluminium and aluminium alloy that have

not been produced in China ever;

— Delete the table of comparison between new and old designations in the ISO

standard;

— Add four-letter designation and composition that are special in China;

— Add the requirements for special control of toxic and harmful elements;

— Add the requirements on composition analysis and sampling.

This Standard replaces GB/T3190-1996 "Wrought Aluminium and Aluminium

Alloy-Chemical Composition". Compared with GB/T3190-1996, the main revisions in this

Standard are as follows.

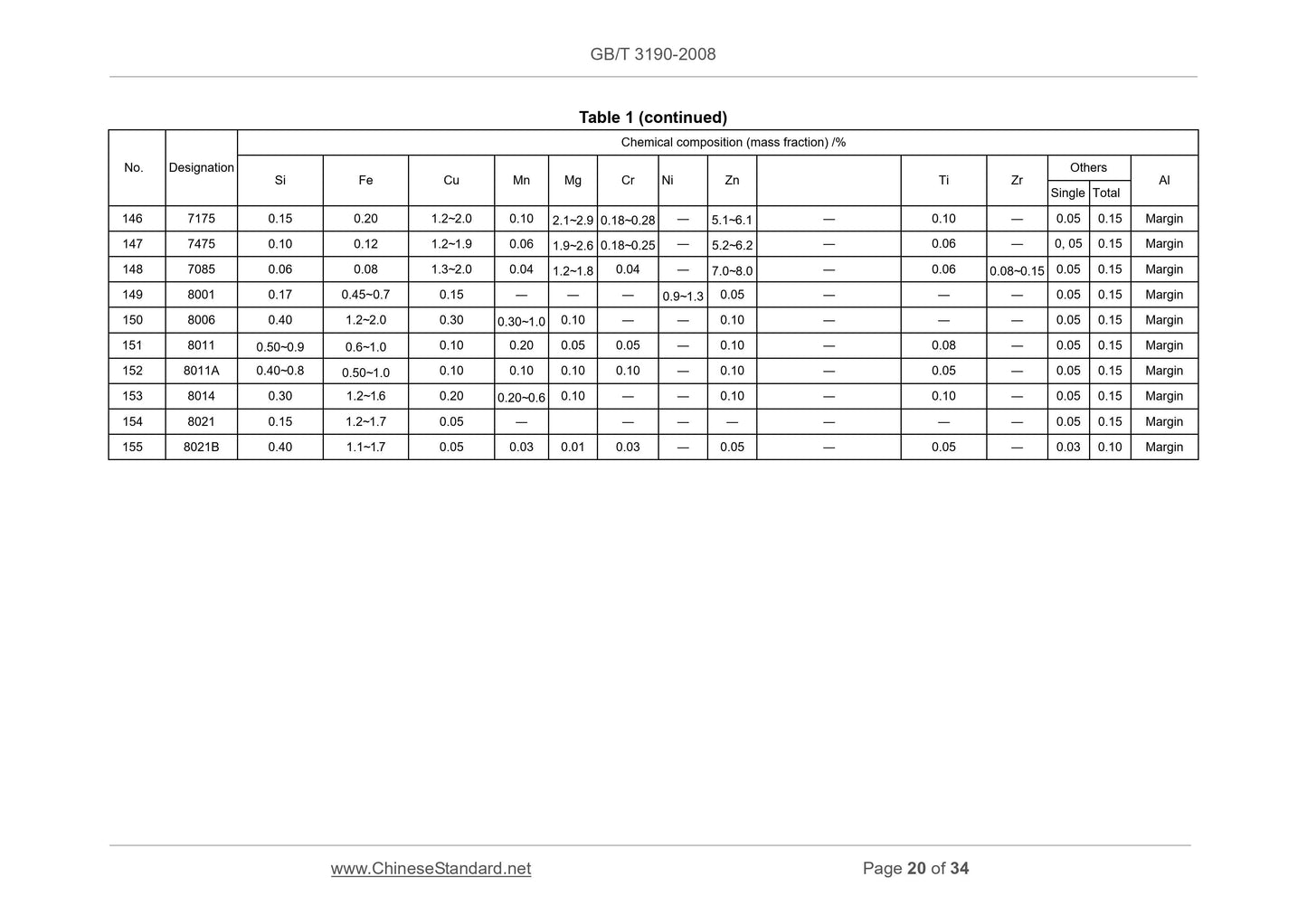

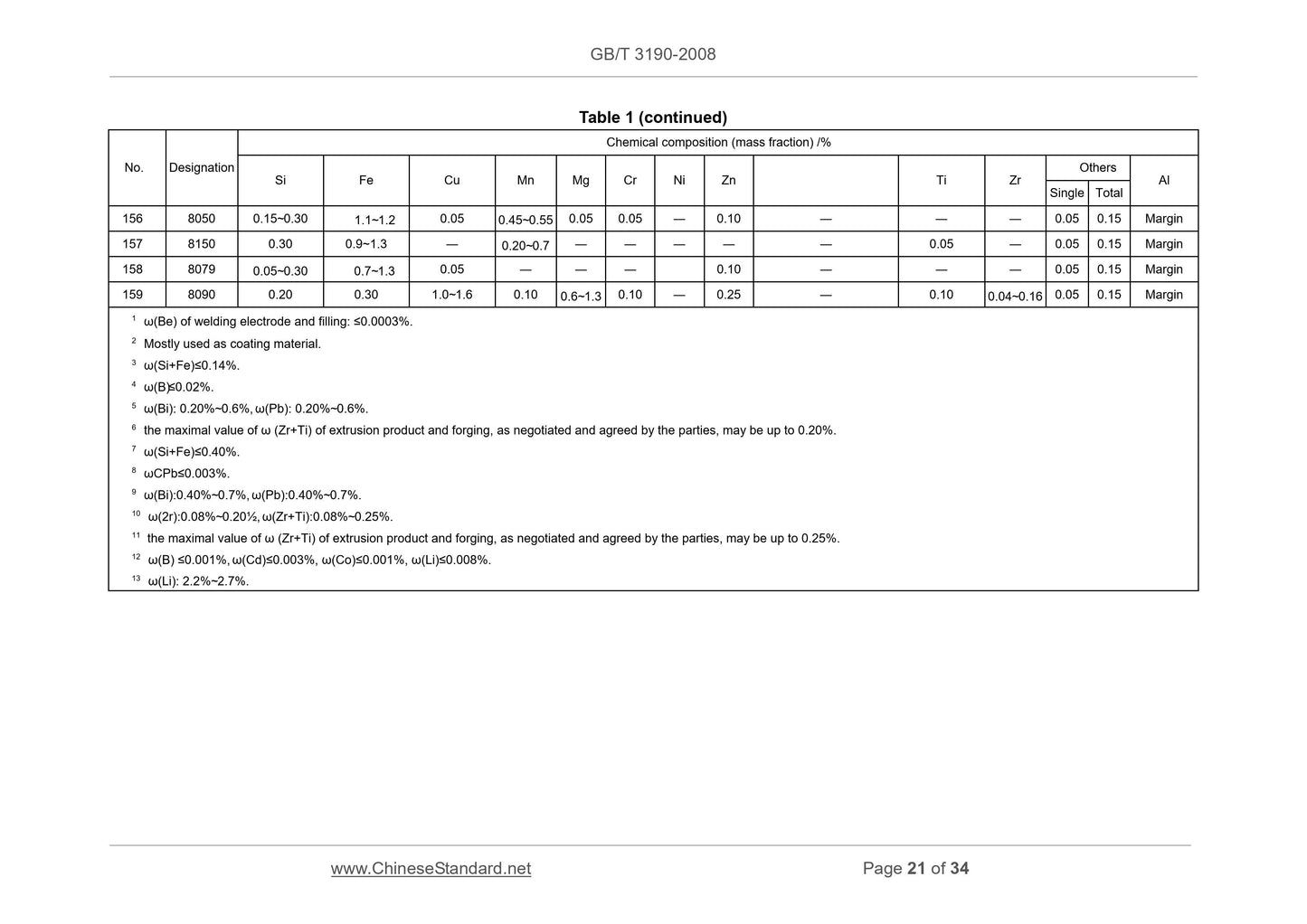

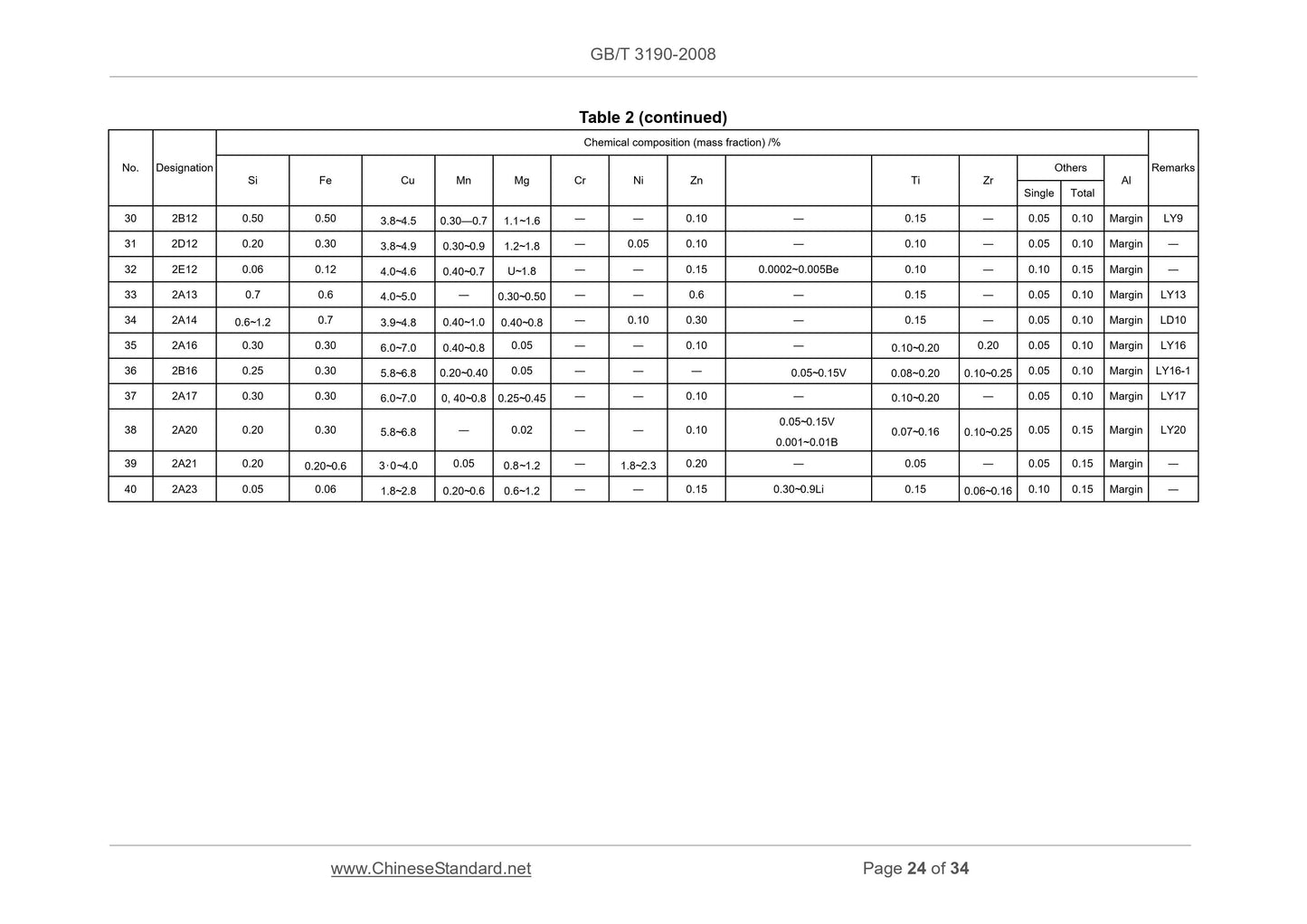

— Add designations and compositions of 130 aluminiums and aluminium alloys; divide

the Table of chemical composition into two parts (two tables). Table 1 is applicable

to international designations, covering 159 designations; Table 2 is applicable to

four-letter designations, covering 114 designations;

— Add the requirements for special control of toxic and harmful elements;

— Add the denotation (method) of limit value;

— Revise "Table of Comparison between New and Old Designations".

Annex A and Annex B of this Standard are informative.

This Standard was proposed by China Non-ferrous Metals Industry Federation.

This Standard shall be under the jurisdiction of the National Standardization Technical

Committee of Non-ferrous Metal.

Main drafting organizations of this Standard. Northeast Light Alloy Co., Ltd., China

Non-ferrous Metals Industry Standard Measurement Quality Institute

Wrought Aluminium and Aluminium Alloy –

Chemical Composition

1 Scope

This Standard specifies the chemical composition of wrought aluminium and aluminium

alloy.

This Standard is applicable to aluminium and aluminium alloy products (plate, strip, foil,

pipe, stick, section, line and forging) produced with press working, and cast ingot and

blanks used for them.

2 Normative References

The following standards contain the provisions which, through reference in this text,

constitute the provisions of this Standard. For the dated reference, the subsequent

amendments (excluding correction) or revisions of these publications do not apply.

However, the parties who enter into agreement according to these specifications are

encouraged to study whether the latest editions of these labels are applicable. For

undated references, the latest edition of the normative document is applicable to this

Standard.

GB/T 7999 Optical emission spectrometric analysis method of aluminum and

aluminum alloys

GB/T 8170 Rules for rounding off of numerical values

GB/T 16474 Wrought aluminium and aluminium alloy - Designation system

GB/T 20975 Chemical analysis methods of aluminium and aluminium alloys (all parts)

3 Requirements

3.1 Chemical composition

3.1.1 The chemical compositions of wrought aluminiums and aluminium alloys shall meet

the requirements of Table 1 and Table 2. The column "others" indicates the metallic

element not listed in the table. For the contents in the table that are in

single-numerical-value, it is the minimal limit for aluminium; and it is the maximal limit for

other elements. The denotation of limit value is as.

Table 2 are suspected exceeding the limits of "single" or "total" values specified in this

Standard, then the manufacturer may do analysis for these elements.

3.3.4 When the content (mass fraction) of aluminium is larger than or equal to 99.00% and

less than 99.90%, it shall be determined by the calculation (method) that 100.00% is

deducted by the sum of the contents of all the elements of which the content is less than

0.010%. The content value of the elements shall be rounded to 0.0x% before summing.

3.3.5 When the content (mass fraction) of aluminium is larger than or equal to 99.00% and

less than or equal to 99.99%, it shall be determined by the calculation (method) that

100.00% is deducted by the sum of the contents of all the elements of which the content is

less than 0.0010%. The content value of the elements shall be rounded to 0.0XX% before

summing. The sum shall be rounded to 0.0X%.

3.3.6 The chemical components shall be analyzed by the method specified in GB/T 7999

or GB/T 20975, or other reliable and accurate method. in the case of dispute, the method

specified in GB/T 20975 or other method agreed by both parties must be adopted for

arbitration analysis.

3.3.7 If the first analytical results does not meet the requirements, second analysis may be

allowed; the second analytical result is deemed as the judgment basis for exit-factory of

the manufacturer and acceptance.

4 Others

4.1 The digit-number of element contents in chemical composition analytical report shall

be of correspondence to the one of the corresponding designation specified in Table 1 or

Table 2.

4.2 The rounding of numerical values shall meet the requirements of GB/T 8170.

4.3 The relation table of comparison for new and old designations is detailed in Annex A.

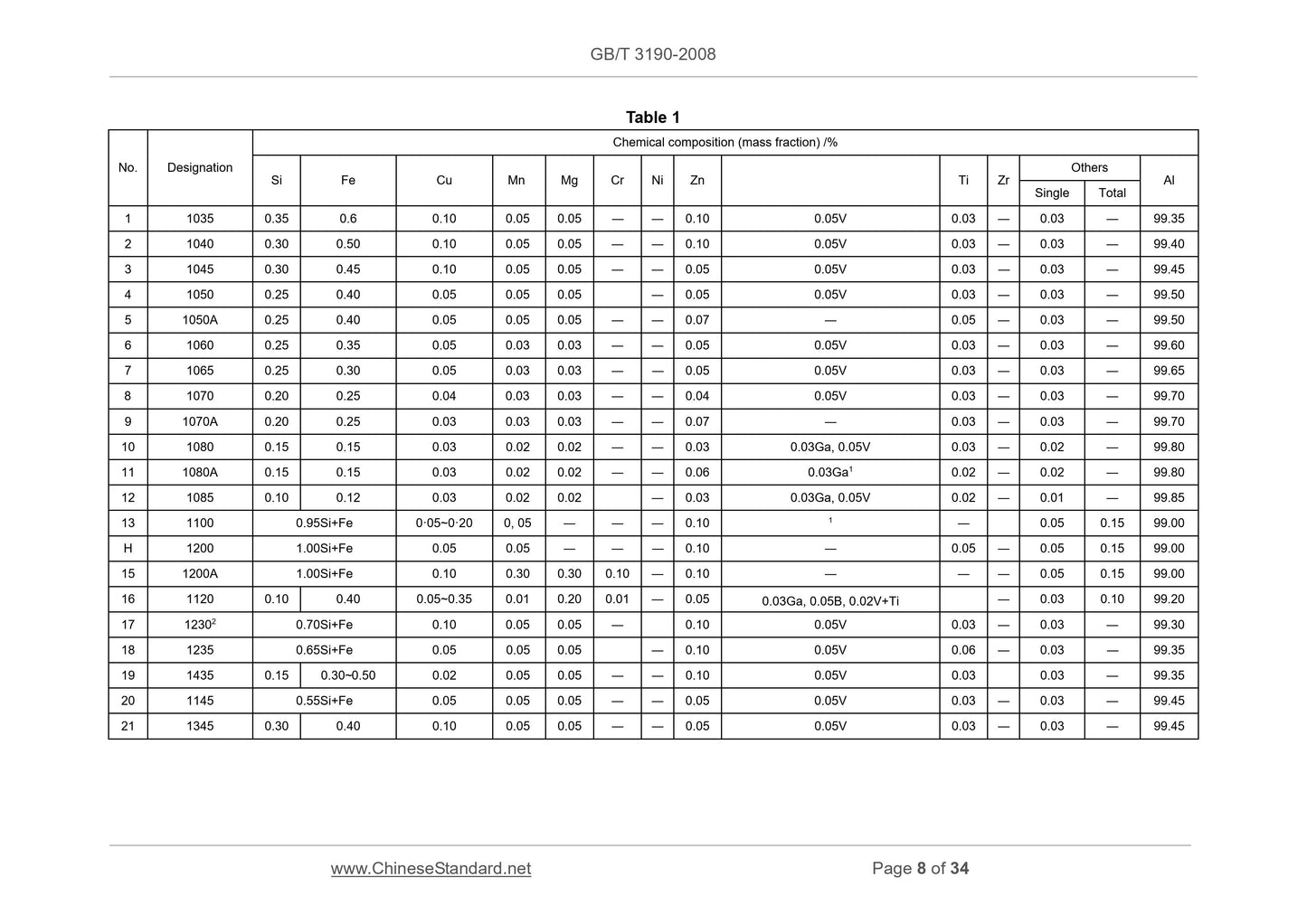

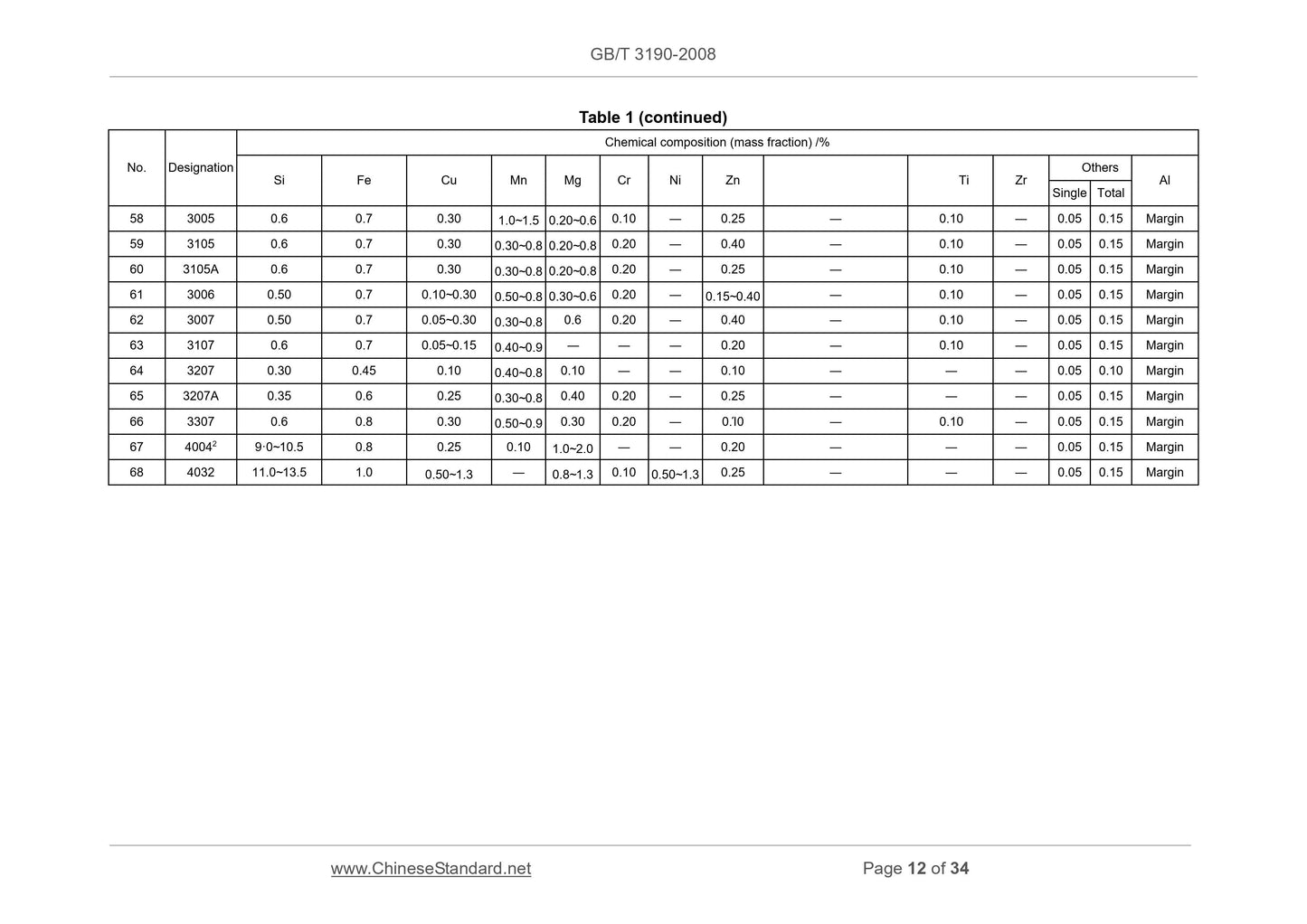

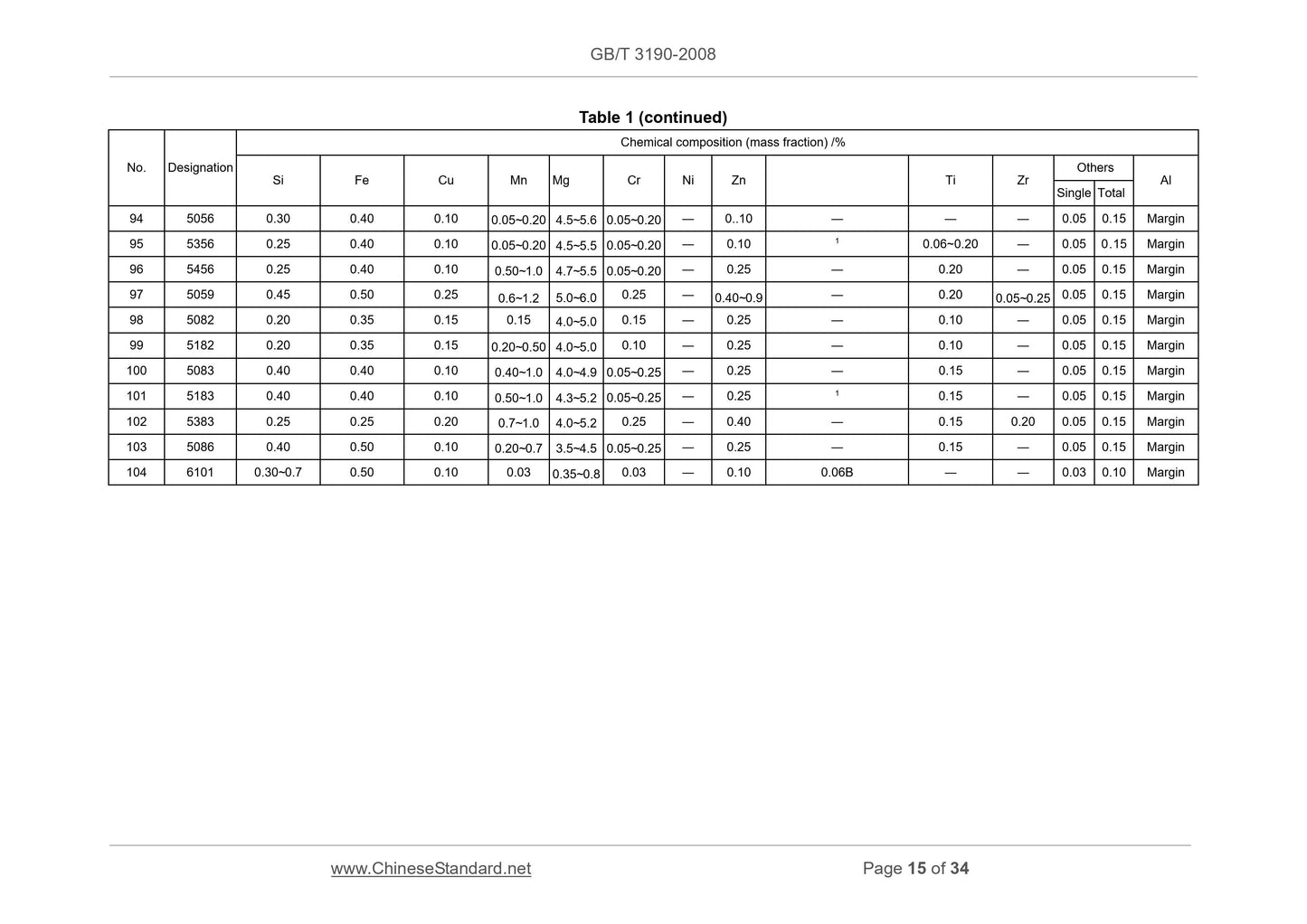

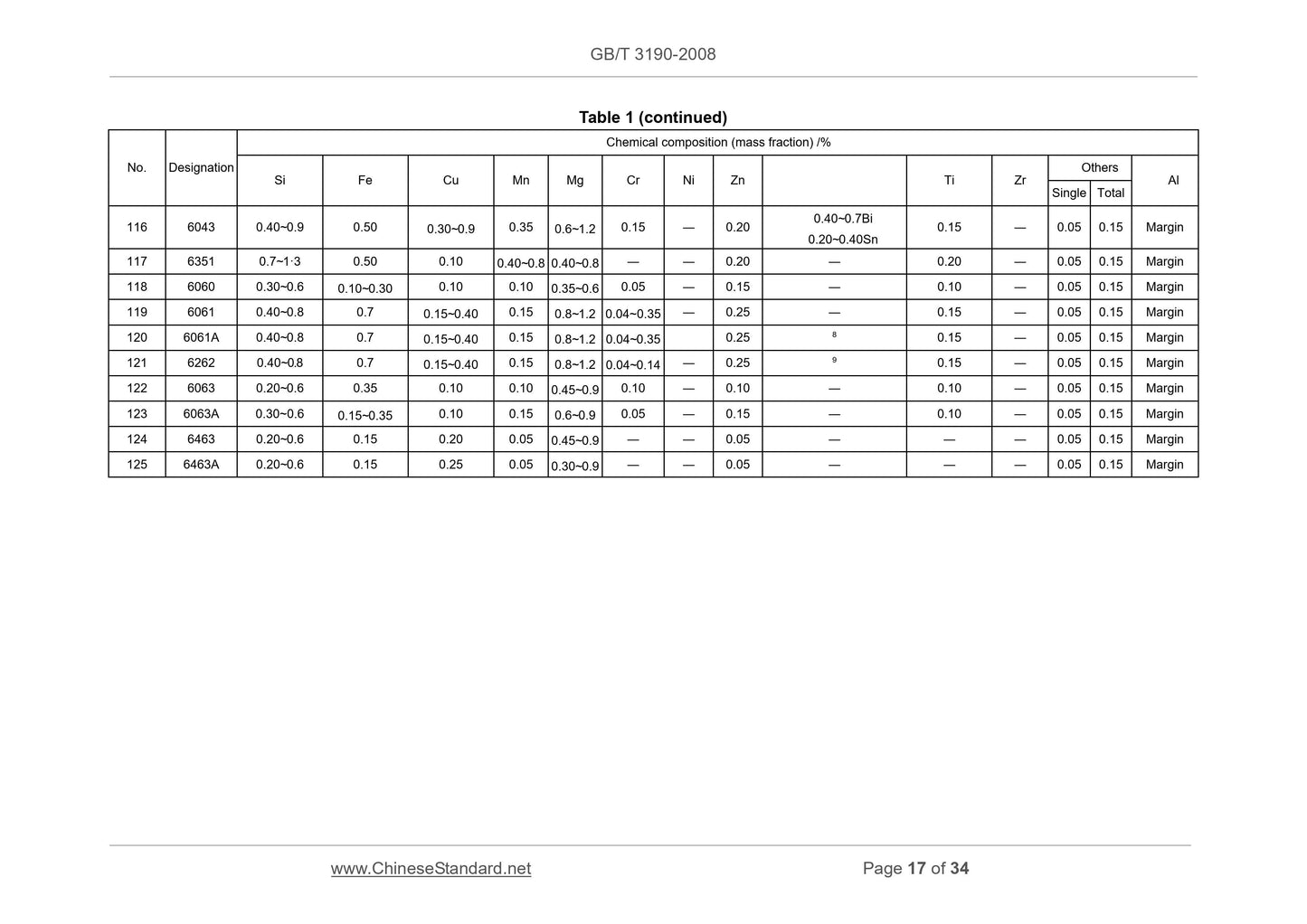

Table 1

No. Designation

Chemical composition (mass fraction) /%

Si Fe Cu Mn Mg Cr Ni Zn

Ti Zr

Others

Al

Single Total

1 1035 0.35 0.6 0.10 0.05 0.05 ― ― 0.10 0.05V 0.03 ― 0.03 ― 99.35

2 1040 0.30 0.50 0.10 0.05 0.05 ― ― 0.10 0.05V 0.03 ― 0.03 ― 99.40

3 1045 0.30 0.45 0.10 0.05 0.05 ― ― 0.05 0.05V 0.03 ― 0.03 ― 99.45

4 1050 0.25 0.40 0.05 0.05 0.05 ― 0.05 0.05V 0.03 ― 0.03 ― 99.50

5 1050A 0.25 0.40 0.05 0.05 0.05 ― ― 0.07 ― 0.05 ― 0.03 ― 99.50

6 1060 0.25 0.35 0.05 0.03 0.03 ― ― 0.05 0.05V 0.03 ― 0.03 ― 99.60

7 1065 0.25 0.30 0.05 0.03 0.03 ― ― 0.05 0.05V 0.03 ― 0.03 ― 99.65

8 1070 0.20 0.25 0.04 0.03 0.03 ― ― 0.04 0.05V 0.03 ― 0.03 ― 99.70

9 1070A 0.20 0.25 0.03 0.03 0.03 ― ― 0.07 ― 0.03 ― 0.03 ― 99.70

10 1080 0.15 0.15 0.03 0.02 0.02 ― ― 0.03 0.03Ga, 0.05V 0.03 ― 0.02 ― 99.80

11 1080A 0.15 0.15 0.03 0.02 0.02 ― ― 0.06 0.03Ga1 0.02 ― 0.02 ― 99.80

12 1085 0.10 0.12 0.03 0.02 0.02 ― 0.03 0.03Ga, 0.05V 0.02 ― 0.01 ― 99.85

13 1100 0.95Si+Fe 0·05~0·20 0, 05 ― ― ― 0.10 1 ― 0.05 0.15 99.00

H 1200 1.00Si+Fe 0.05 0.05 ― ― ― 0.10 ― 0.05 ― 0.05 0.15 99.00

15 1200A 1.00Si+Fe 0.10 0.30 0.30 0.10 ― 0.10 ― ― ― 0.05 0.15 99.00

16 1120 0.10 0.40 0.05~0.35 0.01 0.20 0.01 ― 0.05 0.03Ga, 0.05B, 0.02V+Ti ― 0.03 0.10 99.20

17 12302 0.70Si+Fe 0.10 0.05 0.05 ― 0.10 0.05V 0.03 ― 0.03 ― 99.30

18 1235 0.65Si+Fe 0.05 0.05 0.05...

Get QUOTATION in 1-minute: Click GB/T 3190-2008

Historical versions: GB/T 3190-2008

Preview True-PDF (Reload/Scroll if blank)

GB/T 3190-2008: Wrought aluminium and aluminium alloy -- Chemical composition

GB/T 3190-2008

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.150.10

H 60

Replacing GB/T 3190-1996

Wrought Aluminium and Aluminium Alloy –

Chemical Composition

(ISO 209.2007 Aluminium and Aluminium Alloy - Chemical Composition, MOD)

ISSUED ON JUNE. 17, 2008

IMPLEMENTED ON. DECEMBER 1, 2008

Issued by. General Administration for Quality Supervision and

Inspection and Quarantine (GAQSIQ);

Standardization Administration of China (SAC).

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative References ... 5

3 Requirements ... 5

4 Others ... 7

Annex A ... 32

Annex B ... 34

Foreword

This Standard modifies and adopts ISO209.2007 "Wrought Aluminium and Aluminium

Alloy - Chemical Composition" (English edition), and it is redrafted in accordance with

ISO209.2007. For ease of comparison, the list of corresponding chapters and sections

between the International Standard and this Standard is detailed in Annex B (Informative).

Modifications are done while adopting the International Standard. the technical differences

are marked with vertical single-line on the page margin of the involved articles; they are as

follows.

— Delete the designation and composition of aluminium and aluminium alloy that have

not been produced in China ever;

— Delete the table of comparison between new and old designations in the ISO

standard;

— Add four-letter designation and composition that are special in China;

— Add the requirements for special control of toxic and harmful elements;

— Add the requirements on composition analysis and sampling.

This Standard replaces GB/T3190-1996 "Wrought Aluminium and Aluminium

Alloy-Chemical Composition". Compared with GB/T3190-1996, the main revisions in this

Standard are as follows.

— Add designations and compositions of 130 aluminiums and aluminium alloys; divide

the Table of chemical composition into two parts (two tables). Table 1 is applicable

to international designations, covering 159 designations; Table 2 is applicable to

four-letter designations, covering 114 designations;

— Add the requirements for special control of toxic and harmful elements;

— Add the denotation (method) of limit value;

— Revise "Table of Comparison between New and Old Designations".

Annex A and Annex B of this Standard are informative.

This Standard was proposed by China Non-ferrous Metals Industry Federation.

This Standard shall be under the jurisdiction of the National Standardization Technical

Committee of Non-ferrous Metal.

Main drafting organizations of this Standard. Northeast Light Alloy Co., Ltd., China

Non-ferrous Metals Industry Standard Measurement Quality Institute

Wrought Aluminium and Aluminium Alloy –

Chemical Composition

1 Scope

This Standard specifies the chemical composition of wrought aluminium and aluminium

alloy.

This Standard is applicable to aluminium and aluminium alloy products (plate, strip, foil,

pipe, stick, section, line and forging) produced with press working, and cast ingot and

blanks used for them.

2 Normative References

The following standards contain the provisions which, through reference in this text,

constitute the provisions of this Standard. For the dated reference, the subsequent

amendments (excluding correction) or revisions of these publications do not apply.

However, the parties who enter into agreement according to these specifications are

encouraged to study whether the latest editions of these labels are applicable. For

undated references, the latest edition of the normative document is applicable to this

Standard.

GB/T 7999 Optical emission spectrometric analysis method of aluminum and

aluminum alloys

GB/T 8170 Rules for rounding off of numerical values

GB/T 16474 Wrought aluminium and aluminium alloy - Designation system

GB/T 20975 Chemical analysis methods of aluminium and aluminium alloys (all parts)

3 Requirements

3.1 Chemical composition

3.1.1 The chemical compositions of wrought aluminiums and aluminium alloys shall meet

the requirements of Table 1 and Table 2. The column "others" indicates the metallic

element not listed in the table. For the contents in the table that are in

single-numerical-value, it is the minimal limit for aluminium; and it is the maximal limit for

other elements. The denotation of limit value is as.

Table 2 are suspected exceeding the limits of "single" or "total" values specified in this

Standard, then the manufacturer may do analysis for these elements.

3.3.4 When the content (mass fraction) of aluminium is larger than or equal to 99.00% and

less than 99.90%, it shall be determined by the calculation (method) that 100.00% is

deducted by the sum of the contents of all the elements of which the content is less than

0.010%. The content value of the elements shall be rounded to 0.0x% before summing.

3.3.5 When the content (mass fraction) of aluminium is larger than or equal to 99.00% and

less than or equal to 99.99%, it shall be determined by the calculation (method) that

100.00% is deducted by the sum of the contents of all the elements of which the content is

less than 0.0010%. The content value of the elements shall be rounded to 0.0XX% before

summing. The sum shall be rounded to 0.0X%.

3.3.6 The chemical components shall be analyzed by the method specified in GB/T 7999

or GB/T 20975, or other reliable and accurate method. in the case of dispute, the method

specified in GB/T 20975 or other method agreed by both parties must be adopted for

arbitration analysis.

3.3.7 If the first analytical results does not meet the requirements, second analysis may be

allowed; the second analytical result is deemed as the judgment basis for exit-factory of

the manufacturer and acceptance.

4 Others

4.1 The digit-number of element contents in chemical composition analytical report shall

be of correspondence to the one of the corresponding designation specified in Table 1 or

Table 2.

4.2 The rounding of numerical values shall meet the requirements of GB/T 8170.

4.3 The relation table of comparison for new and old designations is detailed in Annex A.

Table 1

No. Designation

Chemical composition (mass fraction) /%

Si Fe Cu Mn Mg Cr Ni Zn

Ti Zr

Others

Al

Single Total

1 1035 0.35 0.6 0.10 0.05 0.05 ― ― 0.10 0.05V 0.03 ― 0.03 ― 99.35

2 1040 0.30 0.50 0.10 0.05 0.05 ― ― 0.10 0.05V 0.03 ― 0.03 ― 99.40

3 1045 0.30 0.45 0.10 0.05 0.05 ― ― 0.05 0.05V 0.03 ― 0.03 ― 99.45

4 1050 0.25 0.40 0.05 0.05 0.05 ― 0.05 0.05V 0.03 ― 0.03 ― 99.50

5 1050A 0.25 0.40 0.05 0.05 0.05 ― ― 0.07 ― 0.05 ― 0.03 ― 99.50

6 1060 0.25 0.35 0.05 0.03 0.03 ― ― 0.05 0.05V 0.03 ― 0.03 ― 99.60

7 1065 0.25 0.30 0.05 0.03 0.03 ― ― 0.05 0.05V 0.03 ― 0.03 ― 99.65

8 1070 0.20 0.25 0.04 0.03 0.03 ― ― 0.04 0.05V 0.03 ― 0.03 ― 99.70

9 1070A 0.20 0.25 0.03 0.03 0.03 ― ― 0.07 ― 0.03 ― 0.03 ― 99.70

10 1080 0.15 0.15 0.03 0.02 0.02 ― ― 0.03 0.03Ga, 0.05V 0.03 ― 0.02 ― 99.80

11 1080A 0.15 0.15 0.03 0.02 0.02 ― ― 0.06 0.03Ga1 0.02 ― 0.02 ― 99.80

12 1085 0.10 0.12 0.03 0.02 0.02 ― 0.03 0.03Ga, 0.05V 0.02 ― 0.01 ― 99.85

13 1100 0.95Si+Fe 0·05~0·20 0, 05 ― ― ― 0.10 1 ― 0.05 0.15 99.00

H 1200 1.00Si+Fe 0.05 0.05 ― ― ― 0.10 ― 0.05 ― 0.05 0.15 99.00

15 1200A 1.00Si+Fe 0.10 0.30 0.30 0.10 ― 0.10 ― ― ― 0.05 0.15 99.00

16 1120 0.10 0.40 0.05~0.35 0.01 0.20 0.01 ― 0.05 0.03Ga, 0.05B, 0.02V+Ti ― 0.03 0.10 99.20

17 12302 0.70Si+Fe 0.10 0.05 0.05 ― 0.10 0.05V 0.03 ― 0.03 ― 99.30

18 1235 0.65Si+Fe 0.05 0.05 0.05...

Share