1

/

of

7

PayPal, credit cards. Download editable-PDF & invoice in 1 second!

GB/T 32957-2016 English PDF (GBT32957-2016)

GB/T 32957-2016 English PDF (GBT32957-2016)

Regular price

$125.00 USD

Regular price

Sale price

$125.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get Quotation: Click GB/T 32957-2016 (Self-service in 1-minute)

Historical versions (Master-website): GB/T 32957-2016

Preview True-PDF (Reload/Scroll-down if blank)

GB/T 32957-2016: Cold-drawn or Cold-rolled Precision Inside Diameter Seamless Steel Tube for Hydraulic and Pneumatic System Service

GB/T 32957-2016

Cold-drawn or cold-rolled precision inside diameter seamless steel tubes for hydraulic and pneumatic system service

ICS 77.140.75

H48

National Standards of People's Republic of China

Hydraulic and pneumatic systems equipment drawn or cold-rolled

Precision diameter seamless steel pipe

Issued on. 2016-08-29

2017-07-01 implementation

Administration of Quality Supervision, Inspection and Quarantine of People's Republic of China

Standardization Administration of China released

Foreword

This standard was drafted in accordance with GB/T 1.1-2009 given rules.

The standard proposed by China Iron and Steel Association.

This standard by the National Steel Standardization Technical Committee (SAC/TC183) centralized.

This standard was drafted. Xuzhou Xugong Hydraulic Co., Pangang Group Chengdu Steel and Vanadium Co., Ltd., Hengyang Valin Steel Tube Co.,

Yichang CENTRAL Precision Steel Tube Co., Ltd. Wuxi Jiangnan cold drawn precision tubes, Jiangsu Cheng Industrial Pipe Co., Ltd., Jiangyin

City, Hung Teng Machinery Co., Ltd. Daikin high-precision cold drawn steel tube Wuxi Co., Zhangjiagang City Huicheng Pipe Co., Ltd. Zhejiang Po-lun metal

Industry Co., Ltd.

The main drafters of this Standard. Wangjia Cong, Liu taught, Li Qi, Zhao Bin, Lu Fengyun, support to the military, Han Bo, Xi Jin law, Renwei Jiang, Zhang and the

Zheng Zhong Choi.

Hydraulic and pneumatic systems equipment drawn or cold-rolled

Precision diameter seamless steel pipe

1 Scope

This standard specifies the equipment hydraulic and pneumatic systems drawn or cold rolled precision diameter seamless steel tubes and classification code, content ordering, feet

Inch, shape, weight and tolerance, technical requirements, test methods, inspection rules, packaging, marking and quality certification.

This standard applies to the inner diameter 25mm ~ 500mm equipment hydraulic and pneumatic systems using cold drawn or cold rolled precision diameter seamless steel pipe

(Hereinafter referred to as steel).

2 Normative references

The following documents for the application of this document is essential. For dated references, only the dated version suitable for use herein

Member. For undated references, the latest edition (including any amendments) applies to this document.

GB/T 222 chemical composition of finished steel tolerance

GB/T 223.5 steel measuring soluble silicon and total silicon content reduced silicon molybdate salt spectrophotometric method

GB/T 223.12 Methods for chemical analysis of iron, steel and alloys of sodium carbonate separation - diphenyl hydrazine spectrophotometric determination of chromium content

GB/T 223.23 steel and alloy - Determination of nickel content dimethylglyoxime spectrophotometry

GB/T 223.26 steel and alloy - Determination of molybdenum content - Thiocyanate spectrophotometric

GB/T 223.53 Methods for chemical analysis of iron, steel and alloys by flame atomic absorption spectrophotometric method for determination of copper content

GB/T 223.59 Steel and Alloy Determination of phosphorus content by bismuth phosphomolybdate blue spectrophotometric method and antimony phosphomolybdate blue spectrophotometry

GB/T 223.63 Methods for chemical analysis of iron, steel and alloy The sodium (potassium) for Determination of amount

Determination of sulfur content of potassium iodate titration method after GB/T 223.68 Methods for chemical analysis of iron, steel and alloy tube furnace combustion

GB/T 223.69 after carbon and alloy steel - Determination of the pipe furnace combustion gas volumetric method

RT Test Method. Test Part 1 GB/T 228.1 metallic materials tensile

GB/T 229 metal Charpy pendulum impact test method

Opening Test methods GB/T 242 metal tube expansion

GB/T 246 metal pipe Flattening test methods

GB/T 699-2015 quality carbon structural steel

GB/T 1031 Geometrical product specifications (GPS) Surface texture Profile method Surface roughness parameters and their values

GB/T 1591-2008 High strength low alloy structural steel

GB/T 2102 Acceptance, packing, marking and quality certification

GB/T 2975 Steel and steel products for mechanical testing and sample preparation position

GB/T 3077-2015 alloy steel

GB/T 4336 carbon steel and low alloy steel spark source atomic emission spectrometry method (conventional method)

GB/T 6394 Determination of average grain size of metal

GB/T 7735-2004 steel pipe eddy current testing method

Whole circumference GB/T 12606-2016 seamless and welded (except submerged arc welded) ferromagnetic steel tubes for longitudinal and/or transverse imperfections automatic MFL

Detect

GB/T 17395 seamless steel pipe size, shape, weight and tolerance

GB/T 20066 Steel and iron - Sampling and determination of the chemical composition of the manufacturing method of the sample

GB/T 20123 Steel - Determination of total carbon and sulfur content of the high-frequency induction furnace combustion infrared absorption method (conventional method)

Inductively coupled plasma atomic GB/T 20125 low-alloy steel multi-element content Emission Spectrometry

3 Classification and designation

Pipe delivery status classification according to its code as follows.

a) cold-drawn or cold-rolled/Hard. C;

b) cold-drawn or cold-rolled/soft. LC;

c) After the cold-drawn or cold stress relief annealing. SR;

d) annealing. A;

e) normalizing. N.

4 ordering content

Pipe ordered under this standard contract or order shall include but are not limited to, the following.

a) the standard number;

b) the product name;

c) steel grades (quality grade);

d) Dimensions;

e) the number of orders (total weight or length);

f) Delivery status;

g) the manufacturing method;

h) special requirements.

5 size, shape, weight and tolerance

5.1 Dimensions

5.1.1 pipe inner diameter and wall thickness is usually delivered. When the demand side to the outer and inner or outer diameter and wall thickness at delivery should be in the contract

Noted.

5.1.2 The inner diameter and wall thickness of the pipe should be preferred dimensions listed in Table 1. Negotiated by both sides, it may be supplied in Table 1 except for the size of the pipe.

5.1.3 cold (C, LC) state steel pipe inner diameter and the outer diameter deviation should be allowed in accordance with Table 1, Table 2 provisions. Heat treatment (SR,

A, N) state steel, inner and outer diameter tolerances shall comply with the provisions in Table 3.

5.1.4 According to the requirements, negotiated by both sides, and in the contract, can supply in Table 1, Table 2, Table 3 other than the predetermined tolerance

Steel Pipe.

Table 2 cold (C, LC) status pipe diameter in millimeters of tolerance

The inner diameter (d) wall thickness (S)/outer diameter (D) a tolerance outside diameter

25≤d≤180

S/D≥0.05 ± 0.40

0.025≤S/D < 0.05 ± 0.50

S/D < 0.025 ± 0.60

180 \u003cd≤320

S/D≥0.05 ± 0.70

0.025≤S/D < 0.05 ± 0.80

S/D < 0.025 ± 0.90

320 \u003cd≤500

S/D≥0.05 ± 1.00

0.025≤S/D < 0.05 ± 1.10

S/D < 0.025 ± 1.20

When a steel pipe with an inner diameter and wall thickness when delivery, D to calculate an outer diameter; when the steel pipe OD and ID delivery, S for the calculation of the wall thickness.

Table 3 heat treatment (SR, A, N) state and inner pipe diameter in millimeters of tolerance

Wall thickness (S)/outer diameter (D) a tolerance

S/D≥0.05 according to Table 1, Table 2, a predetermined value

0.025≤S/D < 0.05 according to Table 1, Table 2, the predetermined value of 1.2 times

S/D < 0.025 Table 1, Table 2, the predetermined value of 1.5 times

When a steel pipe with an inner diameter and wall thickness when delivery, D to calculate an outer diameter; when the steel pipe OD and ID delivery, S for the calculation of the wall thickness.

5.1.5 steel pipe inner diameter and wall thickness or diameter and wall thickness delivery, the wall thickness tolerances shall comply with the requirements of Table 4. Association by both sides

Manufacturers, other than those specified in Table 4 can supply the thickness tolerances of the pipe.

Table 4 pipe wall thickness tolerances in millimeters

Pipe wall thickness S 1.5 \u003cS≤7 7\u003cS≤13.5 13.5\u003cS≤20 S\u003e 20

Tolerance ± 8% S ± 7% S ± 6.5% S ± 6% S

5.1.6 pipe with outer and inner diameter of delivery, not the wall thickness shall not exceed 16% of the wall thickness calculation.

5.2 length

5.2.1 usual length

Pipe length should generally 3000mm ~ 12000mm.

5.2.2 length and multiple length

5.2.2.1 According to the requirements, negotiated by both sides, and specified in the contract, the pipe can be cut to length or double length delivery.

5.2.2.2 pipe length and the total length of the double length should be within the usual length range. Cut length tolerances shall comply with the following provisions.

A) The length of not more than 5000mm, 5 0mm;

B) When a length greater than 5000mm, 10 0 mm.

5.2.2.3 Each double length should be cut leaving a margin as specified below.

a) D≤159mm when, 5mm ~ 10mm;

b) D> When 159mm, 10mm ~ 15mm.

5.3 curvature

Curvature 5.3.1 tubes shall meet every meter of the full-length bending curvature requirements. When the contract does not specify precision grade, curvature

Performed in A level.

5.3.2 Pipe bending per meter divided into three accuracy classes.

a) A level no greater than 1.0mm/m;

b) B-grade, no greater than 0.5mm/m;

c) C-class, no greater than 0.3mm/m.

5.3.3 The total length of pipe curvature are divided into three accuracy classes.

a) A level, the entire length of not more than 0.1%;

b) Level B, not more than 0.05% of the full-length;

c) C-class, the entire length of not more than 0.03%.

5.3.4 According to the requirements, negotiated by both sides, and in the contract, bending and bending the entire length per meter pipe use other

Provisions.

5.4 tip shape

Both ends of the end surface of the steel pipe and steel pipe should be perpendicular to the axis, cut burr should be removed.

5.5 roundness

When the pipe inner diameter and wall thickness delivery, roundness pipe diameter should be less than 80% of the steel pipe inner diameter tolerances. Specific measurement diameter

Location should meet the provisions of Table 5.

Table 5 pipe inner diameter roundness measuring position in millimeters

Wall thickness (S)/outer diameter (D) measured from the end position (L)

S/D < 0.025 L≥40% D, and L≥50mm

0.025≤S/D < 0.05 L≥30% D, and L≥35mm

S/D≥0.05 L≥20% D, and L≥25mm

5.6 wt.

Pipe according to the actual weight of the delivery, the delivery also by theoretical weight. Steel pipe theoretical weight per meter according to the provisions of GB/T 17395 density (steel

Is 7.85kg/dm3).

6 Technical Requirements

Grades and chemical composition of the steel 6.1

6.1.1 Steel grades and chemical composition (melting component) shall conform to GB/T 699-2015 in 20,45,25Mn, GB/T 1591-

2008 Q345B (C, D, E) and GB/T 3077-2015 in 27SiMn provisions.

6.1.2 When the demand side to do chemical analysis of the finished product, should be specified in the contract, the chemical composition of finished steel of tolerance should be consistent

GB/T 222 requirements.

6.1.3 According to the requirements, negotiated by both sides, and specified in the contract, for other grades of steel.

6.2 Manufacturing Methods

6.2.1 The steel should be used outside the outer arc furnace plus refining or oxygen converter plus smelting furnace refining method, and vacuum degassing. By both sides

Consultations and noted in the contract, use other methods of smelting high requirements. When the demand side to specify a particular method of smelting, should be in the contract

Noted.

6.2.2 The pipe should be cold-drawn or cold-rolled methods. When you need to specify a particular manufacturing method should be specified in the contract.

6.3 Delivery Status

Pipe should be in a state shown in Table 6 lead.

Table 6 Delivery Status

Delivery Status Code Description

Cold drawn/cold-hard or hard/C is not the final heat treatment after cold working

Drawing/cold or cold-rolled soft/soft LC after the final heat treatment appropriate cold

After cold-drawn or cold rolled after stress relief annealing SR final cold, steel stress relief annealing

A final annealing after cold working, fully annealed steel pipe

After normalizing N final cold, steel normalizing

6.4 Mechanical Properties

6.4.1 various longitudinal mechanical properties of the delivery status of the tubes shall be in accordance with Table 7. Other mechanical properties of steel grades, by both parties

OK consultations.

Table 7 Mechanical properties of the steel pipe

Trademark

A delivery status

Cb LCb SR Ac N

an outer diameter of not more than 30mm and a wall thickness of no more than 3mm of steel pipe, the minimum yield strength can be reduced 10MPa.

b by cold deformation extent, very close to the yield strength tensile strength, therefore, we recommend the following relationship formula.

--- C Status. ReH≥0.8Rm;

--- LC Status. ReH≥0.7Rm.

c recommended the following relation formula.

ReH≥0.5Rm.

6.4.2 grades 25Mn, Q345B (C, D, E) and pipe wall thickness of not less than 10mm, should impact test. When inadequate pipe size

In the processing of 10mm × 5mm specimens, the impact test is not required. Table 8 shock absorbing energy of a standard sample size Charpy V-missing

Notch impact energy absorption value, when a small-size impact test specimens, small-size Charpy V-notch impact specimens absorb energy should be a standard ruler

Inch specimens impact absorption energy value by decreasing the coefficient in Table 8.

Table 8 impact absorption energy coefficient decreasing

Sample size Sample size (height × width)/(mm × mm) decreasing coefficient

Standard sample 10 × 10 1.00

Small specimens 10 × 7.5 0.75

Small specimens 10 × 5 0.50

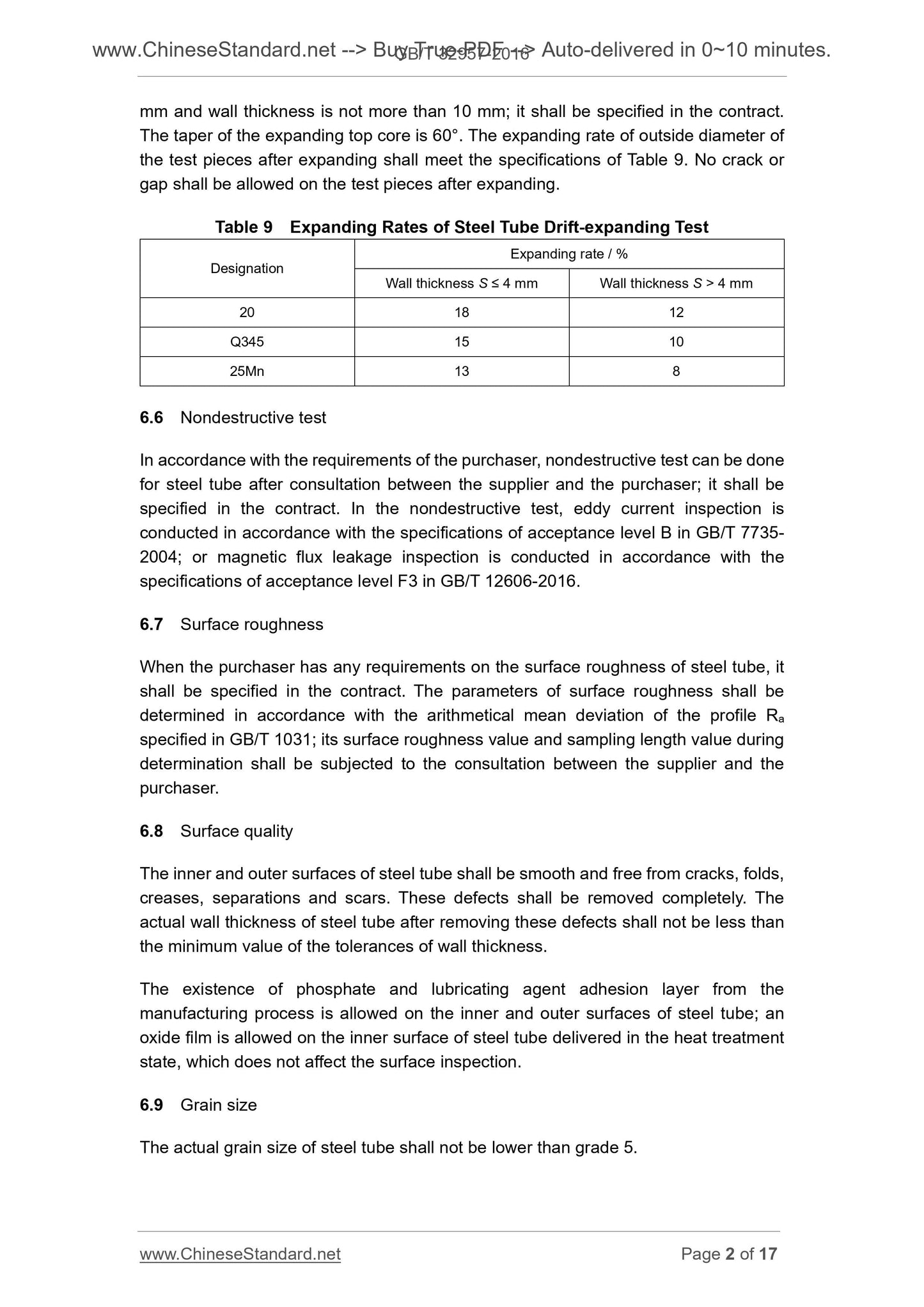

6.5 Process Performance

6.5.1 Flattening test

According to the requirements, negotiated by both sides, and in the contract, and the thickness ratio of the outer diameter of less than 15% of A and N status

20, Q345,25Mn steel pipe can be used for flattening test, after flattening test, cracks or gaps are not allowed on the specimen. After flattening the sample between the plate ...

Get Quotation: Click GB/T 32957-2016 (Self-service in 1-minute)

Historical versions (Master-website): GB/T 32957-2016

Preview True-PDF (Reload/Scroll-down if blank)

GB/T 32957-2016: Cold-drawn or Cold-rolled Precision Inside Diameter Seamless Steel Tube for Hydraulic and Pneumatic System Service

GB/T 32957-2016

Cold-drawn or cold-rolled precision inside diameter seamless steel tubes for hydraulic and pneumatic system service

ICS 77.140.75

H48

National Standards of People's Republic of China

Hydraulic and pneumatic systems equipment drawn or cold-rolled

Precision diameter seamless steel pipe

Issued on. 2016-08-29

2017-07-01 implementation

Administration of Quality Supervision, Inspection and Quarantine of People's Republic of China

Standardization Administration of China released

Foreword

This standard was drafted in accordance with GB/T 1.1-2009 given rules.

The standard proposed by China Iron and Steel Association.

This standard by the National Steel Standardization Technical Committee (SAC/TC183) centralized.

This standard was drafted. Xuzhou Xugong Hydraulic Co., Pangang Group Chengdu Steel and Vanadium Co., Ltd., Hengyang Valin Steel Tube Co.,

Yichang CENTRAL Precision Steel Tube Co., Ltd. Wuxi Jiangnan cold drawn precision tubes, Jiangsu Cheng Industrial Pipe Co., Ltd., Jiangyin

City, Hung Teng Machinery Co., Ltd. Daikin high-precision cold drawn steel tube Wuxi Co., Zhangjiagang City Huicheng Pipe Co., Ltd. Zhejiang Po-lun metal

Industry Co., Ltd.

The main drafters of this Standard. Wangjia Cong, Liu taught, Li Qi, Zhao Bin, Lu Fengyun, support to the military, Han Bo, Xi Jin law, Renwei Jiang, Zhang and the

Zheng Zhong Choi.

Hydraulic and pneumatic systems equipment drawn or cold-rolled

Precision diameter seamless steel pipe

1 Scope

This standard specifies the equipment hydraulic and pneumatic systems drawn or cold rolled precision diameter seamless steel tubes and classification code, content ordering, feet

Inch, shape, weight and tolerance, technical requirements, test methods, inspection rules, packaging, marking and quality certification.

This standard applies to the inner diameter 25mm ~ 500mm equipment hydraulic and pneumatic systems using cold drawn or cold rolled precision diameter seamless steel pipe

(Hereinafter referred to as steel).

2 Normative references

The following documents for the application of this document is essential. For dated references, only the dated version suitable for use herein

Member. For undated references, the latest edition (including any amendments) applies to this document.

GB/T 222 chemical composition of finished steel tolerance

GB/T 223.5 steel measuring soluble silicon and total silicon content reduced silicon molybdate salt spectrophotometric method

GB/T 223.12 Methods for chemical analysis of iron, steel and alloys of sodium carbonate separation - diphenyl hydrazine spectrophotometric determination of chromium content

GB/T 223.23 steel and alloy - Determination of nickel content dimethylglyoxime spectrophotometry

GB/T 223.26 steel and alloy - Determination of molybdenum content - Thiocyanate spectrophotometric

GB/T 223.53 Methods for chemical analysis of iron, steel and alloys by flame atomic absorption spectrophotometric method for determination of copper content

GB/T 223.59 Steel and Alloy Determination of phosphorus content by bismuth phosphomolybdate blue spectrophotometric method and antimony phosphomolybdate blue spectrophotometry

GB/T 223.63 Methods for chemical analysis of iron, steel and alloy The sodium (potassium) for Determination of amount

Determination of sulfur content of potassium iodate titration method after GB/T 223.68 Methods for chemical analysis of iron, steel and alloy tube furnace combustion

GB/T 223.69 after carbon and alloy steel - Determination of the pipe furnace combustion gas volumetric method

RT Test Method. Test Part 1 GB/T 228.1 metallic materials tensile

GB/T 229 metal Charpy pendulum impact test method

Opening Test methods GB/T 242 metal tube expansion

GB/T 246 metal pipe Flattening test methods

GB/T 699-2015 quality carbon structural steel

GB/T 1031 Geometrical product specifications (GPS) Surface texture Profile method Surface roughness parameters and their values

GB/T 1591-2008 High strength low alloy structural steel

GB/T 2102 Acceptance, packing, marking and quality certification

GB/T 2975 Steel and steel products for mechanical testing and sample preparation position

GB/T 3077-2015 alloy steel

GB/T 4336 carbon steel and low alloy steel spark source atomic emission spectrometry method (conventional method)

GB/T 6394 Determination of average grain size of metal

GB/T 7735-2004 steel pipe eddy current testing method

Whole circumference GB/T 12606-2016 seamless and welded (except submerged arc welded) ferromagnetic steel tubes for longitudinal and/or transverse imperfections automatic MFL

Detect

GB/T 17395 seamless steel pipe size, shape, weight and tolerance

GB/T 20066 Steel and iron - Sampling and determination of the chemical composition of the manufacturing method of the sample

GB/T 20123 Steel - Determination of total carbon and sulfur content of the high-frequency induction furnace combustion infrared absorption method (conventional method)

Inductively coupled plasma atomic GB/T 20125 low-alloy steel multi-element content Emission Spectrometry

3 Classification and designation

Pipe delivery status classification according to its code as follows.

a) cold-drawn or cold-rolled/Hard. C;

b) cold-drawn or cold-rolled/soft. LC;

c) After the cold-drawn or cold stress relief annealing. SR;

d) annealing. A;

e) normalizing. N.

4 ordering content

Pipe ordered under this standard contract or order shall include but are not limited to, the following.

a) the standard number;

b) the product name;

c) steel grades (quality grade);

d) Dimensions;

e) the number of orders (total weight or length);

f) Delivery status;

g) the manufacturing method;

h) special requirements.

5 size, shape, weight and tolerance

5.1 Dimensions

5.1.1 pipe inner diameter and wall thickness is usually delivered. When the demand side to the outer and inner or outer diameter and wall thickness at delivery should be in the contract

Noted.

5.1.2 The inner diameter and wall thickness of the pipe should be preferred dimensions listed in Table 1. Negotiated by both sides, it may be supplied in Table 1 except for the size of the pipe.

5.1.3 cold (C, LC) state steel pipe inner diameter and the outer diameter deviation should be allowed in accordance with Table 1, Table 2 provisions. Heat treatment (SR,

A, N) state steel, inner and outer diameter tolerances shall comply with the provisions in Table 3.

5.1.4 According to the requirements, negotiated by both sides, and in the contract, can supply in Table 1, Table 2, Table 3 other than the predetermined tolerance

Steel Pipe.

Table 2 cold (C, LC) status pipe diameter in millimeters of tolerance

The inner diameter (d) wall thickness (S)/outer diameter (D) a tolerance outside diameter

25≤d≤180

S/D≥0.05 ± 0.40

0.025≤S/D < 0.05 ± 0.50

S/D < 0.025 ± 0.60

180 \u003cd≤320

S/D≥0.05 ± 0.70

0.025≤S/D < 0.05 ± 0.80

S/D < 0.025 ± 0.90

320 \u003cd≤500

S/D≥0.05 ± 1.00

0.025≤S/D < 0.05 ± 1.10

S/D < 0.025 ± 1.20

When a steel pipe with an inner diameter and wall thickness when delivery, D to calculate an outer diameter; when the steel pipe OD and ID delivery, S for the calculation of the wall thickness.

Table 3 heat treatment (SR, A, N) state and inner pipe diameter in millimeters of tolerance

Wall thickness (S)/outer diameter (D) a tolerance

S/D≥0.05 according to Table 1, Table 2, a predetermined value

0.025≤S/D < 0.05 according to Table 1, Table 2, the predetermined value of 1.2 times

S/D < 0.025 Table 1, Table 2, the predetermined value of 1.5 times

When a steel pipe with an inner diameter and wall thickness when delivery, D to calculate an outer diameter; when the steel pipe OD and ID delivery, S for the calculation of the wall thickness.

5.1.5 steel pipe inner diameter and wall thickness or diameter and wall thickness delivery, the wall thickness tolerances shall comply with the requirements of Table 4. Association by both sides

Manufacturers, other than those specified in Table 4 can supply the thickness tolerances of the pipe.

Table 4 pipe wall thickness tolerances in millimeters

Pipe wall thickness S 1.5 \u003cS≤7 7\u003cS≤13.5 13.5\u003cS≤20 S\u003e 20

Tolerance ± 8% S ± 7% S ± 6.5% S ± 6% S

5.1.6 pipe with outer and inner diameter of delivery, not the wall thickness shall not exceed 16% of the wall thickness calculation.

5.2 length

5.2.1 usual length

Pipe length should generally 3000mm ~ 12000mm.

5.2.2 length and multiple length

5.2.2.1 According to the requirements, negotiated by both sides, and specified in the contract, the pipe can be cut to length or double length delivery.

5.2.2.2 pipe length and the total length of the double length should be within the usual length range. Cut length tolerances shall comply with the following provisions.

A) The length of not more than 5000mm, 5 0mm;

B) When a length greater than 5000mm, 10 0 mm.

5.2.2.3 Each double length should be cut leaving a margin as specified below.

a) D≤159mm when, 5mm ~ 10mm;

b) D> When 159mm, 10mm ~ 15mm.

5.3 curvature

Curvature 5.3.1 tubes shall meet every meter of the full-length bending curvature requirements. When the contract does not specify precision grade, curvature

Performed in A level.

5.3.2 Pipe bending per meter divided into three accuracy classes.

a) A level no greater than 1.0mm/m;

b) B-grade, no greater than 0.5mm/m;

c) C-class, no greater than 0.3mm/m.

5.3.3 The total length of pipe curvature are divided into three accuracy classes.

a) A level, the entire length of not more than 0.1%;

b) Level B, not more than 0.05% of the full-length;

c) C-class, the entire length of not more than 0.03%.

5.3.4 According to the requirements, negotiated by both sides, and in the contract, bending and bending the entire length per meter pipe use other

Provisions.

5.4 tip shape

Both ends of the end surface of the steel pipe and steel pipe should be perpendicular to the axis, cut burr should be removed.

5.5 roundness

When the pipe inner diameter and wall thickness delivery, roundness pipe diameter should be less than 80% of the steel pipe inner diameter tolerances. Specific measurement diameter

Location should meet the provisions of Table 5.

Table 5 pipe inner diameter roundness measuring position in millimeters

Wall thickness (S)/outer diameter (D) measured from the end position (L)

S/D < 0.025 L≥40% D, and L≥50mm

0.025≤S/D < 0.05 L≥30% D, and L≥35mm

S/D≥0.05 L≥20% D, and L≥25mm

5.6 wt.

Pipe according to the actual weight of the delivery, the delivery also by theoretical weight. Steel pipe theoretical weight per meter according to the provisions of GB/T 17395 density (steel

Is 7.85kg/dm3).

6 Technical Requirements

Grades and chemical composition of the steel 6.1

6.1.1 Steel grades and chemical composition (melting component) shall conform to GB/T 699-2015 in 20,45,25Mn, GB/T 1591-

2008 Q345B (C, D, E) and GB/T 3077-2015 in 27SiMn provisions.

6.1.2 When the demand side to do chemical analysis of the finished product, should be specified in the contract, the chemical composition of finished steel of tolerance should be consistent

GB/T 222 requirements.

6.1.3 According to the requirements, negotiated by both sides, and specified in the contract, for other grades of steel.

6.2 Manufacturing Methods

6.2.1 The steel should be used outside the outer arc furnace plus refining or oxygen converter plus smelting furnace refining method, and vacuum degassing. By both sides

Consultations and noted in the contract, use other methods of smelting high requirements. When the demand side to specify a particular method of smelting, should be in the contract

Noted.

6.2.2 The pipe should be cold-drawn or cold-rolled methods. When you need to specify a particular manufacturing method should be specified in the contract.

6.3 Delivery Status

Pipe should be in a state shown in Table 6 lead.

Table 6 Delivery Status

Delivery Status Code Description

Cold drawn/cold-hard or hard/C is not the final heat treatment after cold working

Drawing/cold or cold-rolled soft/soft LC after the final heat treatment appropriate cold

After cold-drawn or cold rolled after stress relief annealing SR final cold, steel stress relief annealing

A final annealing after cold working, fully annealed steel pipe

After normalizing N final cold, steel normalizing

6.4 Mechanical Properties

6.4.1 various longitudinal mechanical properties of the delivery status of the tubes shall be in accordance with Table 7. Other mechanical properties of steel grades, by both parties

OK consultations.

Table 7 Mechanical properties of the steel pipe

Trademark

A delivery status

Cb LCb SR Ac N

an outer diameter of not more than 30mm and a wall thickness of no more than 3mm of steel pipe, the minimum yield strength can be reduced 10MPa.

b by cold deformation extent, very close to the yield strength tensile strength, therefore, we recommend the following relationship formula.

--- C Status. ReH≥0.8Rm;

--- LC Status. ReH≥0.7Rm.

c recommended the following relation formula.

ReH≥0.5Rm.

6.4.2 grades 25Mn, Q345B (C, D, E) and pipe wall thickness of not less than 10mm, should impact test. When inadequate pipe size

In the processing of 10mm × 5mm specimens, the impact test is not required. Table 8 shock absorbing energy of a standard sample size Charpy V-missing

Notch impact energy absorption value, when a small-size impact test specimens, small-size Charpy V-notch impact specimens absorb energy should be a standard ruler

Inch specimens impact absorption energy value by decreasing the coefficient in Table 8.

Table 8 impact absorption energy coefficient decreasing

Sample size Sample size (height × width)/(mm × mm) decreasing coefficient

Standard sample 10 × 10 1.00

Small specimens 10 × 7.5 0.75

Small specimens 10 × 5 0.50

6.5 Process Performance

6.5.1 Flattening test

According to the requirements, negotiated by both sides, and in the contract, and the thickness ratio of the outer diameter of less than 15% of A and N status

20, Q345,25Mn steel pipe can be used for flattening test, after flattening test, cracks or gaps are not allowed on the specimen. After flattening the sample between the plate ...

Share