1

/

of

5

PayPal, credit cards. Download editable-PDF & invoice in 1 second!

GB/T 33513-2017 English PDF (GB/T33513-2017)

GB/T 33513-2017 English PDF (GB/T33513-2017)

Regular price

$150.00 USD

Regular price

Sale price

$150.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click GB/T 33513-2017

Historical versions: GB/T 33513-2017

Preview True-PDF (Reload/Scroll if blank)

GB/T 33513-2017: Belt drives -- Pulleys and V-ribbed belts for the automotive industry -- PK profile: Dimensions

GB/T 33513-2017

GB

NATIONAL STANDARD OF

THE PEOPLE’S REPUBLIC OF CHINA

ICS 21.220.10

G 42

Belt drives - Pulleys and V-ribbed belts for the

automotive industry - PK profile. Dimensions

(ISO 9981.1998, MOD)

ISSUED ON. FEBRUARY 28, 2017

IMPLEMENTED ON. SEPTEMBER 1, 2017

Issued by. General Administration of Quality Supervision, Inspection

and Quarantine;

Standardization Administration Committee.

3. No action is required - Full-copy of this standard will be automatically and

immediately delivered to your EMAIL address in 0~60 minutes.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Pulley ... 4

4 V-ribbed belt ... 8

Annex A (Informative) Comparison on structure modification between this

Standard and ISO 9981.1998 ... 12

Annex B (Informative) Technical differences and reasons between this

Standard and ISO 9981.1998 ... 13

Foreword

This Standard was drafted in accordance with the rules given in GB/T

1.1-2009.

This Standard uses redrafting method to modify and adopt ISO 9981.1998

Belt drives - Pulleys and V-ribbed belts for the automotive industry - PK profile.

Dimensions.

Compared with ISO 9981.1998, there are many modifications in this Standard

in structure. Annex A lists the contracts on sub-clause number between this

Standard and ISO 9981.1998.

There are technical differences between this Standard and ISO 9981.1998.

The sub-clauses covered by these differences have been identified by the

vertical single line (︱) at the margin of the outer margin. Annex B gives a list

of the corresponding technical differences and reasons.

This Standard also made the following editorial modification.

- deleted the descriptions of pulleys and V-ribbed belts used for industry

in the scope.

This Standard was proposed by China Petroleum and Chemical Industry

Federation.

This Standard shall be under the jurisdiction of Subcommittee on Friction

Type Belt Drive of National Technical Committee on Pulleys and Belts of

Standardization Administration of China (SAC/TC 428 / SC 3).

The drafting organizations of this Standard. Qingdao Institute of product

quality inspection technology, Ningbo Kai Chi Tape Co., Ltd., Hubei Maoxin

Special Tape Co., Ltd., Laiwu Yong Chi Rubber Co., Ltd., Zhejiang Zijin Port

Tape Co., Ltd., Henan Golden Jiulong Industrial Co., Ltd.

Main drafters of this Standard. Wu Guiqing, Hao Yongliang, Ying Jianli, Xiong

Lijun, Chen Yuezeng, Pang Changzhi, Zhang Liujie.

Belt drives - Pulleys and V-ribbed belts for the

automotive industry - PK profile. Dimensions

1 Scope

This Standard specifies the main dimensions of PK profile ring V-ribbed belts

and pulley grooves for automobile auxiliary transmission.

This Standard is applicable to ring V-ribbed belts and pulleys for PK profile

automobile auxiliary transmission.

2 Normative references

The following referenced documents are indispensable for the application of

this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including

any amendments) applies.

GB/T 1184-1996, Geometrical tolerancing - Geometrical tolerance for

features without individual tolerance indications (egv ISO2768-2.1989)

GB/T 3505, Geometrical product specifications (GPS) - Surface texture.

Profile method - Terms definitions and surface texture parameters (GB/T

3505-2009, ISO4287.1997, IDT)

GB/T 11357, Quality roughness and balance of transmission pulleys (GB/T

11357-2008, ISO 254.1998, MOD)

GB/T 17516.2, V-and ribbed belts drive - Dynamic test to determine pitch

zone location - Part 2. V-ribbed belts (GB/T 17516.2-1998, idt ISO

8370-2.1993)

3 Pulley

3.1 Groove size and tolerance

The groove size shall comply with Table 1 (see Figure 1, Figure 2).

4.2.1.1 Two measuring pulleys of equal diameter, one of which is stationary,

and the other is movable along the track. Its recommended effective diameter

is determined by the value in Table 4. See Figure 1 and Table 1 for pulley

groove sizes.

4.2.1.2 Measuring force application device. used for applying a measuring

force on a movable pulley.

4.2.1.3 Center distance measuring device. used to measure the distance

between the two pulley centers.

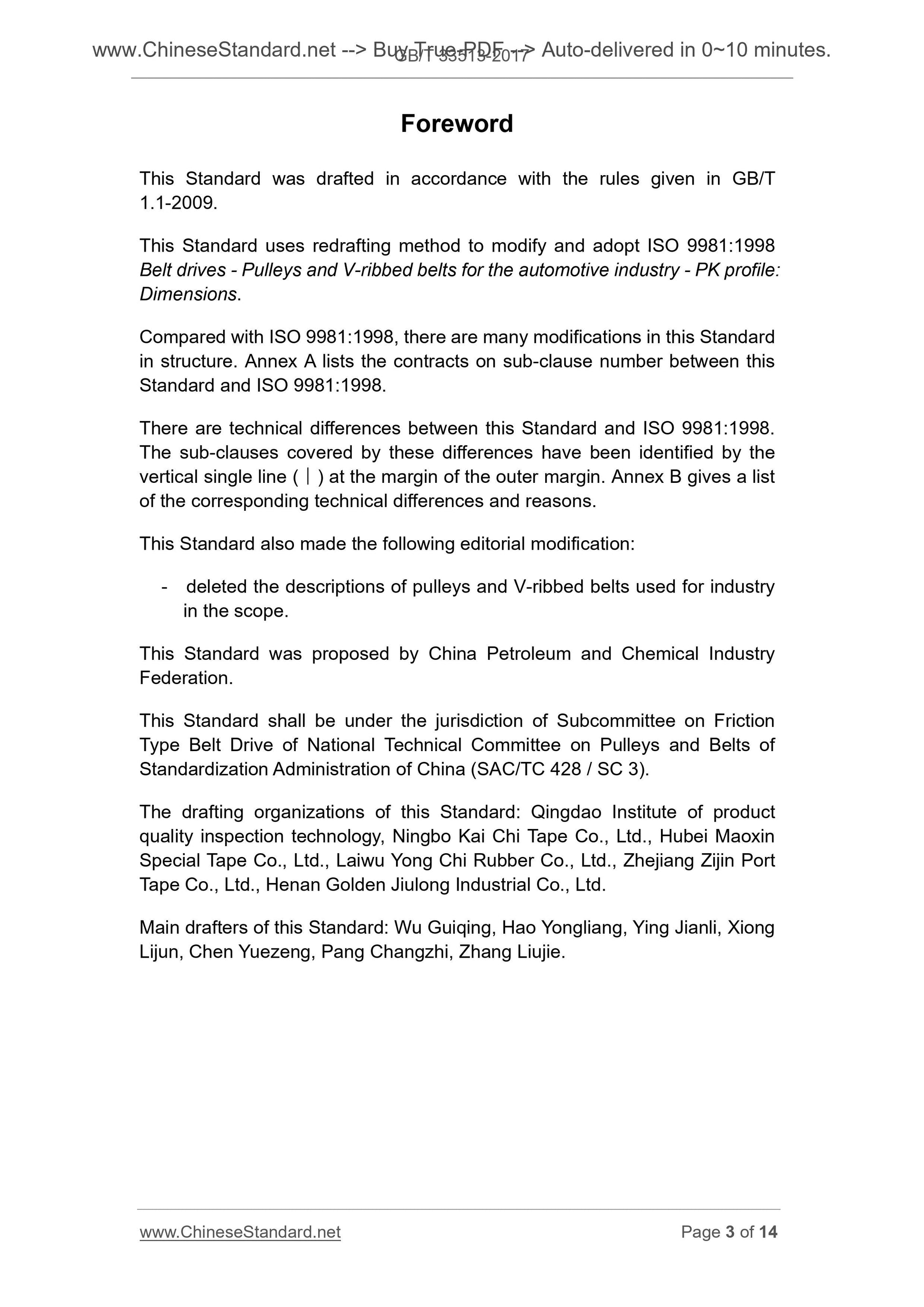

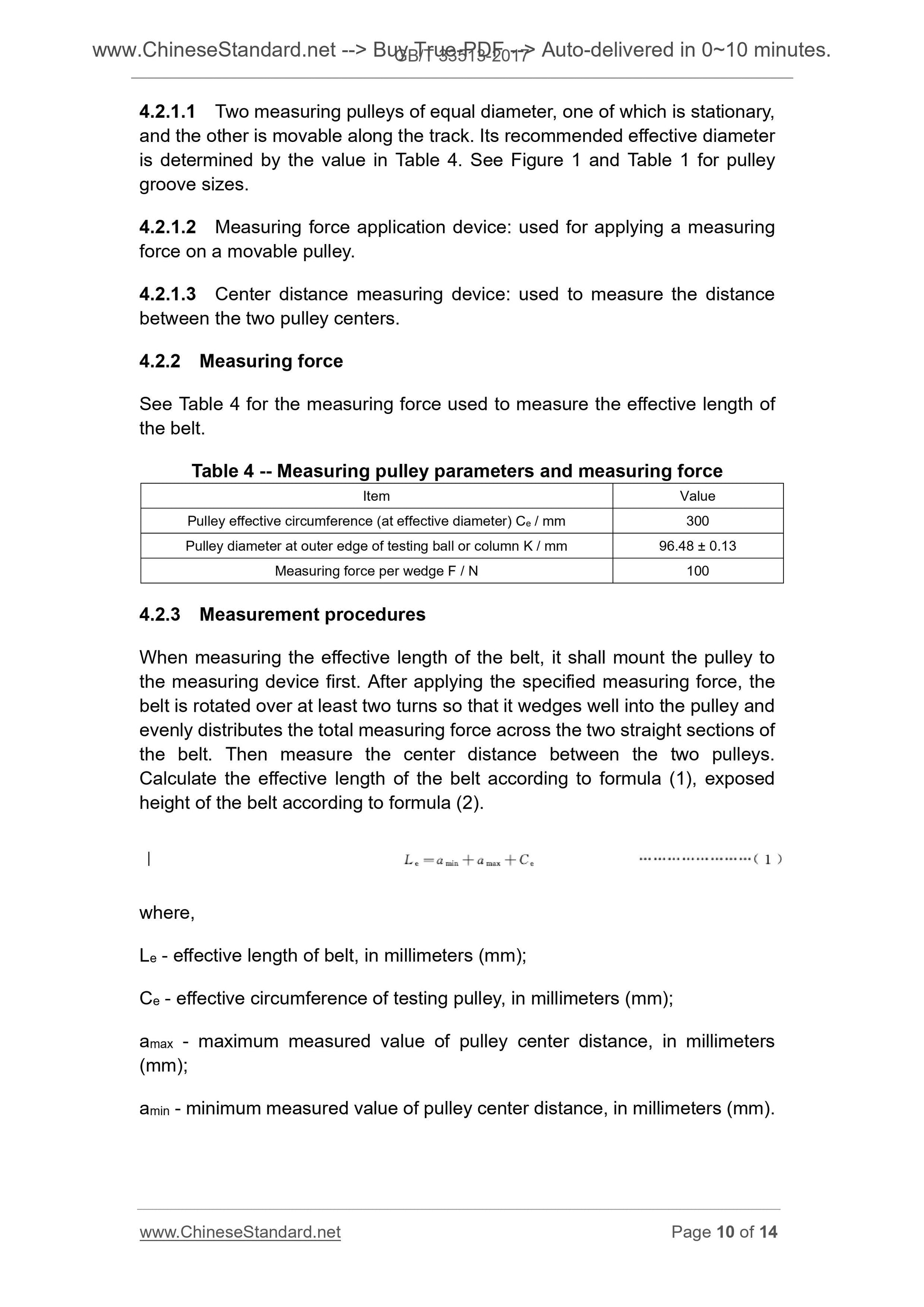

4.2.2 Measuring force

See Table 4 for the measuring force used to measure the effective length of

the belt.

Table 4 -- Measuring pulley parameters and measuring force

Item Value

Pulley effective circumference (at effective diameter) Ce / mm 300

Pulley diameter at outer edge of testing ball or column K / mm 96.48 ± 0.13

Measuring force per wedge F / N 100

4.2.3 Measurement procedures

When measuring the effective length of the belt, it shall mount the pulley to

the measuring device first. After applying the specified measuring force, the

belt is rotated over at least two turns so that it wedges well into the pulley and

evenly distributes the total measuring force across the two straight sections of

the belt. Then measure the center distance between the two pulleys.

Calculate the effective length of the belt according to formula (1), exposed

height of the belt according to formula (2).

where,

Le - effective length of belt, in millimeters (mm);

Ce - effective circumference of testing pulley, in millimeters (mm);

amax - maximum measured value of pulley center distance, in millimeters

(mm);

amin - minimum measured value of pulley center distance, in millimeters (mm).

Get QUOTATION in 1-minute: Click GB/T 33513-2017

Historical versions: GB/T 33513-2017

Preview True-PDF (Reload/Scroll if blank)

GB/T 33513-2017: Belt drives -- Pulleys and V-ribbed belts for the automotive industry -- PK profile: Dimensions

GB/T 33513-2017

GB

NATIONAL STANDARD OF

THE PEOPLE’S REPUBLIC OF CHINA

ICS 21.220.10

G 42

Belt drives - Pulleys and V-ribbed belts for the

automotive industry - PK profile. Dimensions

(ISO 9981.1998, MOD)

ISSUED ON. FEBRUARY 28, 2017

IMPLEMENTED ON. SEPTEMBER 1, 2017

Issued by. General Administration of Quality Supervision, Inspection

and Quarantine;

Standardization Administration Committee.

3. No action is required - Full-copy of this standard will be automatically and

immediately delivered to your EMAIL address in 0~60 minutes.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Pulley ... 4

4 V-ribbed belt ... 8

Annex A (Informative) Comparison on structure modification between this

Standard and ISO 9981.1998 ... 12

Annex B (Informative) Technical differences and reasons between this

Standard and ISO 9981.1998 ... 13

Foreword

This Standard was drafted in accordance with the rules given in GB/T

1.1-2009.

This Standard uses redrafting method to modify and adopt ISO 9981.1998

Belt drives - Pulleys and V-ribbed belts for the automotive industry - PK profile.

Dimensions.

Compared with ISO 9981.1998, there are many modifications in this Standard

in structure. Annex A lists the contracts on sub-clause number between this

Standard and ISO 9981.1998.

There are technical differences between this Standard and ISO 9981.1998.

The sub-clauses covered by these differences have been identified by the

vertical single line (︱) at the margin of the outer margin. Annex B gives a list

of the corresponding technical differences and reasons.

This Standard also made the following editorial modification.

- deleted the descriptions of pulleys and V-ribbed belts used for industry

in the scope.

This Standard was proposed by China Petroleum and Chemical Industry

Federation.

This Standard shall be under the jurisdiction of Subcommittee on Friction

Type Belt Drive of National Technical Committee on Pulleys and Belts of

Standardization Administration of China (SAC/TC 428 / SC 3).

The drafting organizations of this Standard. Qingdao Institute of product

quality inspection technology, Ningbo Kai Chi Tape Co., Ltd., Hubei Maoxin

Special Tape Co., Ltd., Laiwu Yong Chi Rubber Co., Ltd., Zhejiang Zijin Port

Tape Co., Ltd., Henan Golden Jiulong Industrial Co., Ltd.

Main drafters of this Standard. Wu Guiqing, Hao Yongliang, Ying Jianli, Xiong

Lijun, Chen Yuezeng, Pang Changzhi, Zhang Liujie.

Belt drives - Pulleys and V-ribbed belts for the

automotive industry - PK profile. Dimensions

1 Scope

This Standard specifies the main dimensions of PK profile ring V-ribbed belts

and pulley grooves for automobile auxiliary transmission.

This Standard is applicable to ring V-ribbed belts and pulleys for PK profile

automobile auxiliary transmission.

2 Normative references

The following referenced documents are indispensable for the application of

this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including

any amendments) applies.

GB/T 1184-1996, Geometrical tolerancing - Geometrical tolerance for

features without individual tolerance indications (egv ISO2768-2.1989)

GB/T 3505, Geometrical product specifications (GPS) - Surface texture.

Profile method - Terms definitions and surface texture parameters (GB/T

3505-2009, ISO4287.1997, IDT)

GB/T 11357, Quality roughness and balance of transmission pulleys (GB/T

11357-2008, ISO 254.1998, MOD)

GB/T 17516.2, V-and ribbed belts drive - Dynamic test to determine pitch

zone location - Part 2. V-ribbed belts (GB/T 17516.2-1998, idt ISO

8370-2.1993)

3 Pulley

3.1 Groove size and tolerance

The groove size shall comply with Table 1 (see Figure 1, Figure 2).

4.2.1.1 Two measuring pulleys of equal diameter, one of which is stationary,

and the other is movable along the track. Its recommended effective diameter

is determined by the value in Table 4. See Figure 1 and Table 1 for pulley

groove sizes.

4.2.1.2 Measuring force application device. used for applying a measuring

force on a movable pulley.

4.2.1.3 Center distance measuring device. used to measure the distance

between the two pulley centers.

4.2.2 Measuring force

See Table 4 for the measuring force used to measure the effective length of

the belt.

Table 4 -- Measuring pulley parameters and measuring force

Item Value

Pulley effective circumference (at effective diameter) Ce / mm 300

Pulley diameter at outer edge of testing ball or column K / mm 96.48 ± 0.13

Measuring force per wedge F / N 100

4.2.3 Measurement procedures

When measuring the effective length of the belt, it shall mount the pulley to

the measuring device first. After applying the specified measuring force, the

belt is rotated over at least two turns so that it wedges well into the pulley and

evenly distributes the total measuring force across the two straight sections of

the belt. Then measure the center distance between the two pulleys.

Calculate the effective length of the belt according to formula (1), exposed

height of the belt according to formula (2).

where,

Le - effective length of belt, in millimeters (mm);

Ce - effective circumference of testing pulley, in millimeters (mm);

amax - maximum measured value of pulley center distance, in millimeters

(mm);

amin - minimum measured value of pulley center distance, in millimeters (mm).

Share