1

/

of

10

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 33830-2017 English PDF (GB/T33830-2017)

GB/T 33830-2017 English PDF (GB/T33830-2017)

Regular price

$255.00

Regular price

Sale price

$255.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB/T 33830-2017: Test method for snow grip performance of truck and bus tyres

Delivery: 9 seconds. Download (& Email) true-PDF + Invoice.

Get Quotation: Click GB/T 33830-2017 (Self-service in 1-minute)

Historical versions (Master-website): GB/T 33830-2017

Preview True-PDF (Reload/Scroll-down if blank)

GB/T 33830-2017

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 83.160.10

G 41

Test method for snow grip

performance of truck and bus tyres

ISSUED ON: MAY 31, 2017

IMPLEMENTED ON: APRIL 01, 2018

Issued by: General Administration of Quality Supervision, Inspection and

Quarantine of the People's Republic of China;

Standardization Administration of the People's Republic of

China.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Terms and definitions ... 4

4 Test methods ... 6

5 Test report ... 22

Annex A (normative) Snow hardness tester ... 24

Test method for snow grip

performance of truck and bus tyres

1 Scope

This Standard specifies the method for measuring the grip performance of truck

and bus tyres on snowy roads. To reduce measurement deviation, this Standard

uses a test method of comparing with standard reference test tyres.

This Standard applies to truck and bus tyres.

2 Normative references

The following documents are indispensable for the application of this document.

For dated references, only the dated version applies to this document. For

undated references, the latest edition (including all amendments) applies to this

document.

GB/T 6326 Tyre terms and definitions

3 Terms and definitions

For the purpose of this document, terms and definitions defined in GB/T 6326

and the following apply.

3.1

candidate tyre

Tyres that are evaluated through tests.

3.2

standard reference test tyre; SRTT

A set of special candidate tyres that are used as reference in the evaluation

system. To minimize their variation, these tyres have tightly controlled design

characteristics, and are produced, controlled and stored according to relevant

standards.

3.3

average acceleration; AA

Average acceleration calculated from the measured distance recorded when

the vehicle accelerates between two specified speeds.

4 Test methods

4.1 Miniature and light truck and bus tyres with single tyre load index ≤ 121

and speed class of N or higher

4.1.1 Principle

Braking method is used for snow grip performance tests for miniature and light

truck and bus tyres with single tyre load index ≤ 121 and speed class of N or

higher.

In this test method, it uses an instrument to test the deceleration performance

of the tyre during braking on a test vehicle equipped with ABS system (anti-lock

braking system). During the test, the test vehicle travels straight at the specified

initial speed, and then brakes urgently to make the ABS of the four wheels of

the vehicle acts and decelerate stably, and calculate the average deceleration

of the vehicle speed from 25 km/h to 10 km/h.

4.1.2 Test conditions

4.1.2.1 Pavement conditions

4.1.2.1.1 The test snow surface is smooth and even. The length should be more

than 500 m, the width should be more than 5 m, and the slope shall not be more

than 2 %.

4.1.2.1.2 The snow-covered pavement shall have a layer of hard compacted

snow of at least 3 cm thick for the bottom layer, and a compact layer of snow of

approximately 2 cm thick for the surface layer.

4.1.2.1.3 For the snow compaction index, it shall select at least 10 points evenly

on the entire test surface for measurement, and take the average value. The

maximum value and the minimum value shall not differ by more than 8. The

average snow compaction index measured using a snow hardness tester (CTI,

see Annex A) is between 75 and 85.

4.1.2.2 Climate conditions

4.1.2.2.1 The ambient temperature range measured at approximately 1 m

above the ground is -21 °C to -7 °C.

4.1.4.2 Candidate tyres shall be produced in the same batch and kept in the

same environment. Burrs, flashings and any foreign matters on the tread shall

be removed. Before the test, the surface of tyres in contact with snow shall be

clean.

4.1.4.3 Before the test, candidate tyres are pre-run for 100 km on dry paved

roads.

4.1.4.4 Candidate tyres shall be assembled near the test site. Candidate tyres

shall be installed on the rims used in the test vehicle by conventional installation

methods, allowing the use of an appropriate amount of lubricant for ease of

installation. All assembled tyres to be tested shall be placed in the same outdoor

environment for at least 2 hours, and then the tyre inflation pressure shall be

adjusted to the value specified in the test.

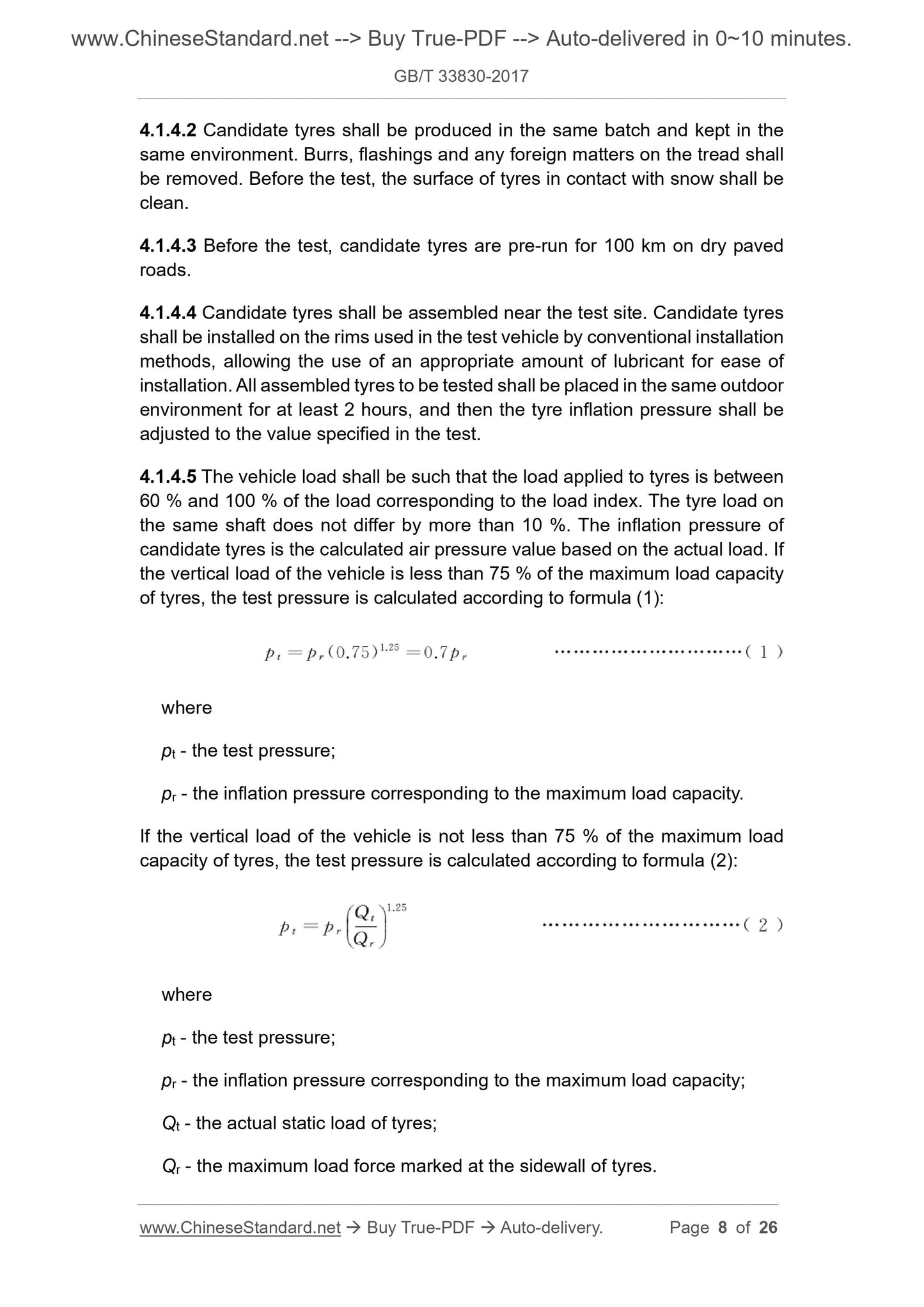

4.1.4.5 The vehicle load shall be such that the load applied to tyres is between

60 % and 100 % of the load corresponding to the load index. The tyre load on

the same shaft does not differ by more than 10 %. The inflation pressure of

candidate tyres is the calculated air pressure value based on the actual load. If

the vertical load of the vehicle is less than 75 % of the maximum load capacity

of tyres, the test pressure is calculated according to formula (1):

where

pt - the test pressure;

pr - the inflation pressure corresponding to the maximum load capacity.

If the vertical load of the vehicle is not less than 75 % of the maximum load

capacity of tyres, the test pressure is calculated according to formula (2):

where

pt - the test pressure;

pr - the inflation pressure corresponding to the maximum load capacity;

Qt - the actual static load of tyres;

Qr - the maximum load force marked at the sidewall of tyres.

4.1.7 Testing snow performance with control tyres

4.1.7.1 General

If the specifications of candidate tyres and standard reference test tyres differ

greatly and cannot be directly compared on the same vehicle, control tyres may

be used for contrast tests.

4.1.7.2 Principle

Control tyre and two different test vehicles are used for contrast tests with

candidate tyres. One of the test vehicles is suitable for assembling with

standard reference test tyres and control tyres, and the other is suitable for

assembling with candidate tyres and control tyres. The former is used to

evaluate the standard reference test tyres and the control tyres, the latter is

used to evaluate the candidate tyres and the control tyres. The two vehicles

shall be tested on the same pavement, and the pavement surface temperature

difference between the two tests is within 5 °C. The two test vehicles use the

same set of four control tyres, which shall be installed in the same position.

Environmental conditions shall be comparable. All tests shall be completed in

the same day.

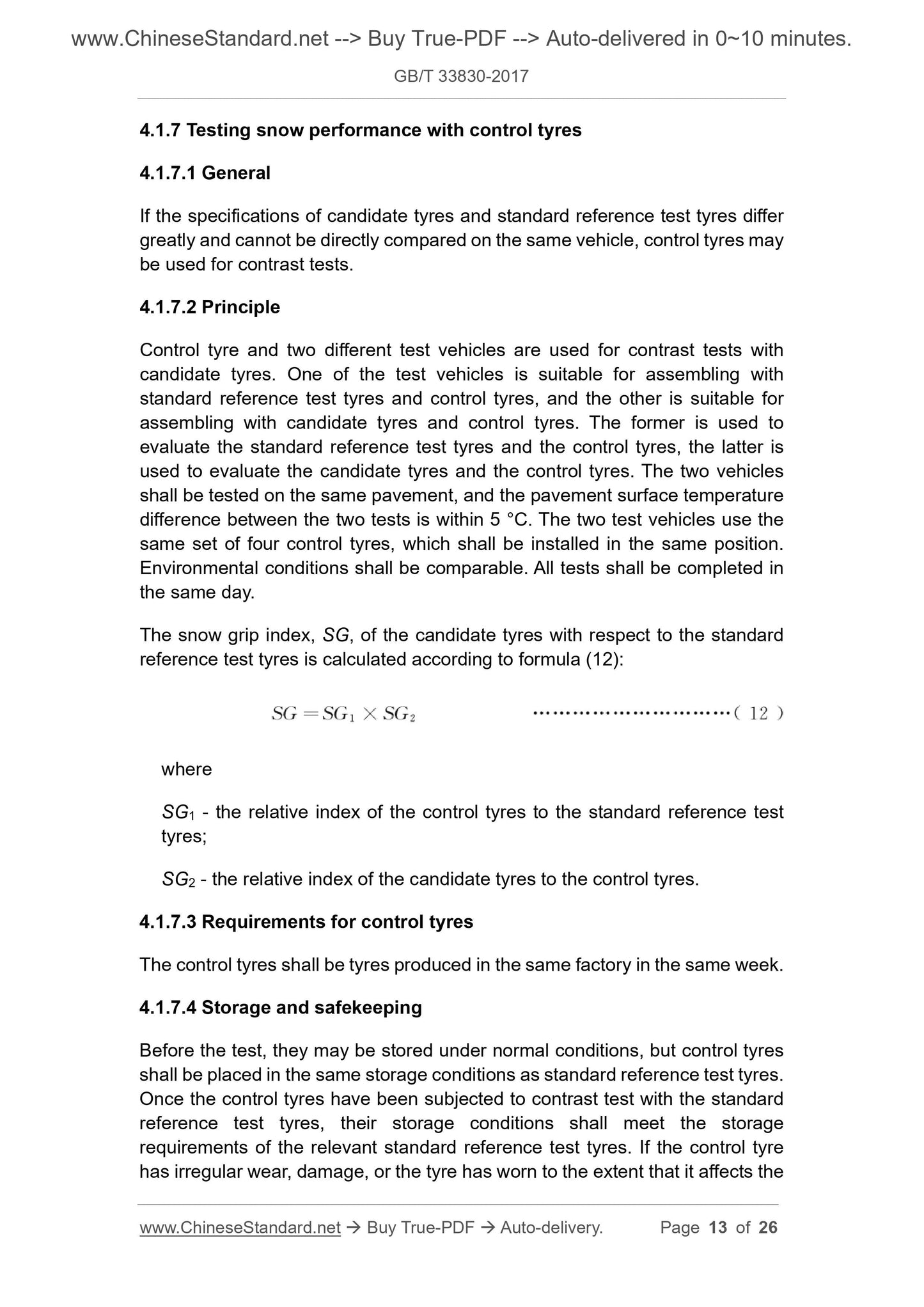

The snow grip index, SG, of the candidate tyres with respect to the standard

reference test tyres is calculated according to formula (12):

where

SG1 - the relative index of the control tyres to the standard reference test

tyres;

SG2 - the relative index of the candidate tyres to the control tyres.

4.1.7.3 Requirements for control tyres

The control tyres shall be tyres produced in the same factory in the same week.

4.1.7.4 Storage and safekeeping

Before the test, they may be stored under normal conditions, but control tyres

shall be placed in the same storage conditions as standard reference test tyres.

Once the control tyres have been subjected to contrast test with the standard

reference test tyres, their storage conditions shall meet the storage

requirements of the relevant standard reference test tyres. If the control tyre

has irregular wear, damage, or the tyre has worn to the extent that it affects the

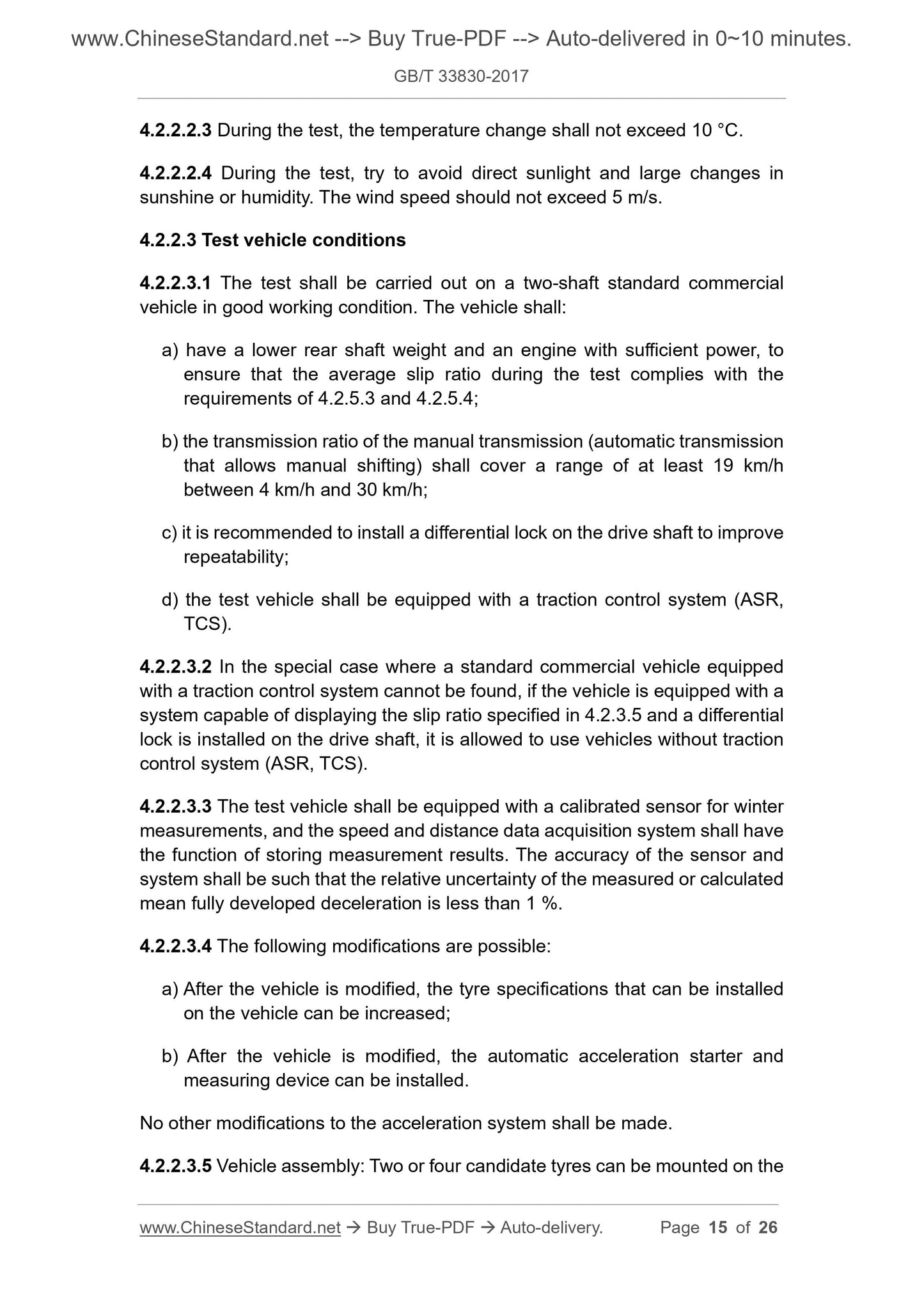

4.2.2.2.3 During the test, the temperature change shall not exceed 10 °C.

4.2.2.2.4 During the test, try to avoid direct sunlight and large changes in

sunshine or humidity. The wind speed should not exceed 5 m/s.

4.2.2.3 Test vehicle conditions

4.2.2.3.1 The test shall be carried out on a two-shaft standard commercial

vehicle in good working condition. The vehicle shall:

a) have a lower rear shaft weight and an engine with sufficient power, to

ensure that the average slip ratio during the test complies with the

requirements of 4.2.5.3 and 4.2.5.4;

b) the transmission ratio of the manual transmission (automatic transmission

that allows manual shifting) shall cover a range of at least 19 km/h

between 4 km/h and 30 km/h;

c) it is recommended to install a differential lock on the drive shaft to improve

repeatability;

d) the test vehicle shall be equipped with a traction control system (ASR,

TCS).

4.2.2.3.2 In the special case where a standard commercial vehicle equipped

with a traction control system cannot be found, if the vehicle is equipped with a

system capable of displaying the slip ratio specified in 4.2.3.5 and a differential

lock is installed on the drive shaft, it is allowed to use vehicles without traction

control system (ASR, TCS).

4.2.2.3.3 The test vehicle shall be equipped with a calibrated sensor for winter

measurements, and the speed and distance data acquisition system shall have

the function of storing measurement results. The accuracy of the sensor and

system shall be such that the relative uncertainty of the measured or calculated

mean fully developed deceleration is less than 1 %.

4.2.2.3.4 The following modifications are possible:

a) After the vehicle is modified, the tyre specifications that can be installed

on the vehicle can be increased;

b) After the vehicle is modified, the automatic acceleration starter and

measuring device can be installed.

No other modifications to the acceleration system shall be made.

4.2.2.3.5 Vehicle assembly: Two or four candidate tyres can be mounted on the

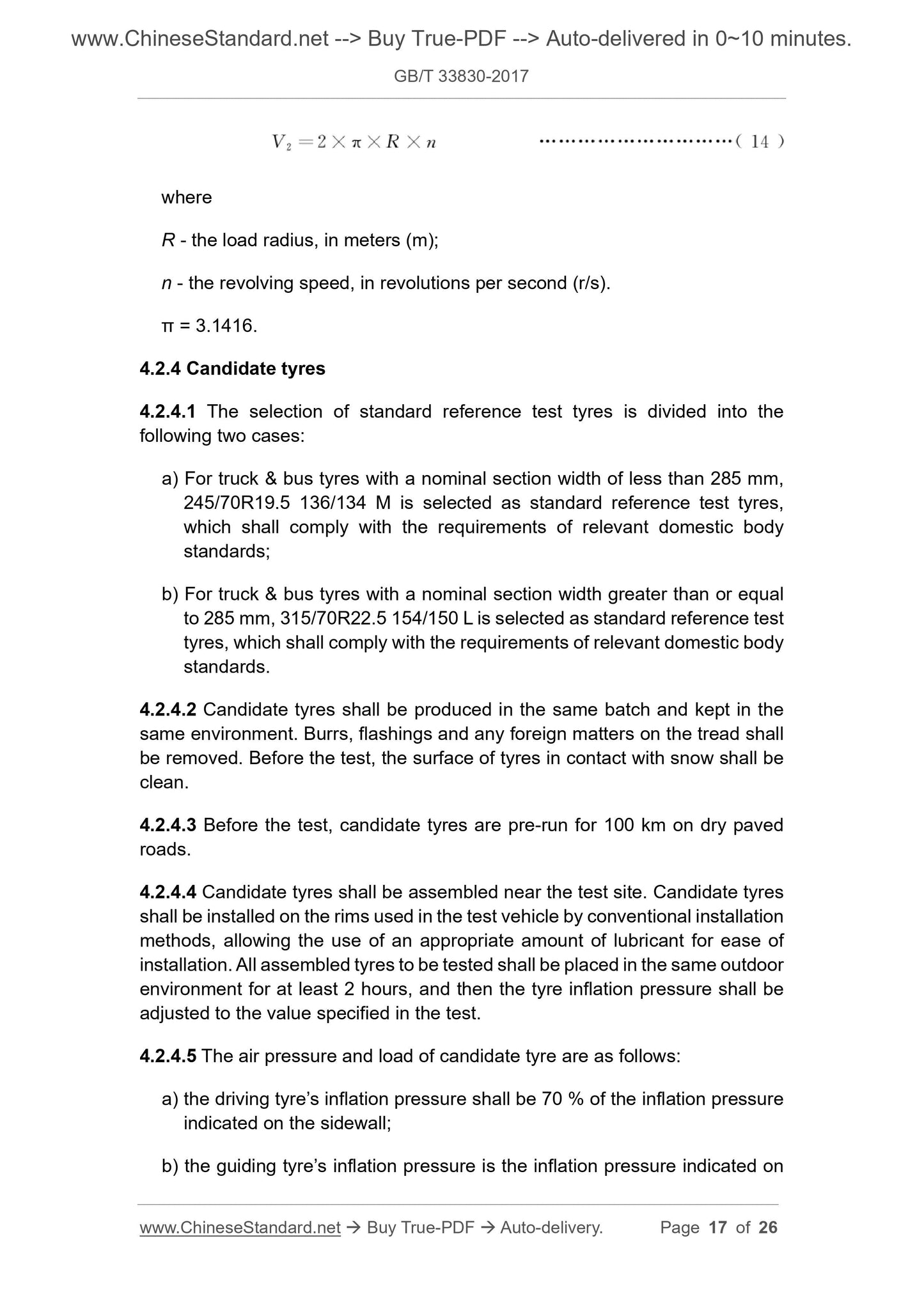

where

R - the load radius, in meters (m);

n - the revolving speed, in revolutions per second (r/s).

π = 3.1416.

4.2.4 Candidate tyres

4.2.4.1 The selection of standard reference test tyres is divided into the

following two cases:

a) For truck and bus tyres with a nominal section width of less than 285 mm,

245/70R19.5 136/134 M is selected as standard reference test tyres,

which shall comply with the requirements of relevant domestic body

standards;

b) For truck and bus tyres with a nominal section width greater than or equal

to 285 mm, 315/70R22.5 154/150 L is selected as standard reference test

tyres, which shall comply with the requirements of relevant domestic body

standards.

4.2.4.2 Candidate tyres shall be produced in the same batch and kept in the

same environment. Burrs, flashings and any foreign matters on the tread shall

be removed. Before the test, the surface of tyres in contact with snow shall be

clean.

4.2.4.3 Before the test, candidate tyres are pre-run for 100 km on dry paved

roads.

4.2.4.4 Candidate tyres shall be assembled near the test site. Candidate tyres

shall be installed on the rims used in the test vehicle by conventional installation

methods, allowing the use of an appropriate amount of lubricant for ease of

installation. All assembled tyres to be tested shall be placed in the same outdoor

environment for at least 2 hours, and then the tyre inflation pressure shall be

adjusted to the value specified in the test.

4.2.4.5 The air pressure and load of candidate tyre are as follows:

a) the driving tyre’s inflation pressure shall be 70 % of the inflation pressure

indicated on the sidewall;

b) the guiding tyre’s inflation pressure is the inflation pressure indicated on

If the specifications of candidate tyres and standard reference test tyres differ

greatly and cannot be directly compared on the same vehicle, control tyres may

be used for contrast tests.

4.2.7.2 Principle

Control tyre and two different test vehicles are used for contrast tests with

candidate tyres. One of the test vehicles is suitable for assembling with

standard reference test tyres and control tyres, and the other is suitable for

assembling with candidate tyres and control tyres. All conditions shall be in

accordance with 4.2.2. The former is used to evaluate the standard reference

test tyres and the control tyres, the latter is used to evaluate the candidate tyres

and the control tyres. The two vehicles shall be tested on the same pavement,

and the pavement surface temperature difference between the two tests is

within 5 °C. The two test vehicles use the same set of four control tyres, which

shall be installed in the same position. Environmental conditions shall be

comparable. All tests shall be completed in the same day.

The snow grip index, SG, of the candidate tyres with respect to the standard

reference test tyres is calculated according to formula (19):

where

SG1 - the relative index of the control tyre to the standard reference test tyres;

SG2 - the relative index of the candidate tyre to the control tyres.

4.2.7.3 Requirements for control tyres

The control tyres shall be tyres produced in the same factory in the same week.

4.2.7.4 Storage and safekeeping of control tyres

Before the test, they may be stored under normal conditions, but control tyres

shall be placed in the same storage conditions as standard reference test tyres.

Once the control tyres have been subjected to contrast test with the standard

reference test tyres, their storage conditions shall meet the storage

requirements of the relevant standard reference test tyres. If the control tyre

has irregular wear, damage, or the tyre has worn to the extent that it affects the

test results, it cannot be used.

5 Test report

The test report should include the following:

Annex A

(normative)

Snow hardness tester

A.1 Conditions of use

A.1.1 The compression degree and shear strength of snow have a great

influence on the snow traction performance of tyres. These parameters cannot

be ignored, but the changes of them can be quantified by vertical and horizontal

compaction tests. The CTI snow hardness tester can measure and characterize

the compression degree of snow surface.

A.1.2 The top of the CTI snow hardness tester is a 1.6 mm radius ball that looks

like a plumb (see Figure A.1), and the other end is a measuring rod. Including

the knurled nut at the top of the measurement, the entire instrument is adjusted

to a weight of 220 g ± 1 g in the laboratory. The height of the measuring rod is

adjusted to 218.9 mm ± 0.25 mm.

...

Delivery: 9 seconds. Download (& Email) true-PDF + Invoice.

Get Quotation: Click GB/T 33830-2017 (Self-service in 1-minute)

Historical versions (Master-website): GB/T 33830-2017

Preview True-PDF (Reload/Scroll-down if blank)

GB/T 33830-2017

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 83.160.10

G 41

Test method for snow grip

performance of truck and bus tyres

ISSUED ON: MAY 31, 2017

IMPLEMENTED ON: APRIL 01, 2018

Issued by: General Administration of Quality Supervision, Inspection and

Quarantine of the People's Republic of China;

Standardization Administration of the People's Republic of

China.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Terms and definitions ... 4

4 Test methods ... 6

5 Test report ... 22

Annex A (normative) Snow hardness tester ... 24

Test method for snow grip

performance of truck and bus tyres

1 Scope

This Standard specifies the method for measuring the grip performance of truck

and bus tyres on snowy roads. To reduce measurement deviation, this Standard

uses a test method of comparing with standard reference test tyres.

This Standard applies to truck and bus tyres.

2 Normative references

The following documents are indispensable for the application of this document.

For dated references, only the dated version applies to this document. For

undated references, the latest edition (including all amendments) applies to this

document.

GB/T 6326 Tyre terms and definitions

3 Terms and definitions

For the purpose of this document, terms and definitions defined in GB/T 6326

and the following apply.

3.1

candidate tyre

Tyres that are evaluated through tests.

3.2

standard reference test tyre; SRTT

A set of special candidate tyres that are used as reference in the evaluation

system. To minimize their variation, these tyres have tightly controlled design

characteristics, and are produced, controlled and stored according to relevant

standards.

3.3

average acceleration; AA

Average acceleration calculated from the measured distance recorded when

the vehicle accelerates between two specified speeds.

4 Test methods

4.1 Miniature and light truck and bus tyres with single tyre load index ≤ 121

and speed class of N or higher

4.1.1 Principle

Braking method is used for snow grip performance tests for miniature and light

truck and bus tyres with single tyre load index ≤ 121 and speed class of N or

higher.

In this test method, it uses an instrument to test the deceleration performance

of the tyre during braking on a test vehicle equipped with ABS system (anti-lock

braking system). During the test, the test vehicle travels straight at the specified

initial speed, and then brakes urgently to make the ABS of the four wheels of

the vehicle acts and decelerate stably, and calculate the average deceleration

of the vehicle speed from 25 km/h to 10 km/h.

4.1.2 Test conditions

4.1.2.1 Pavement conditions

4.1.2.1.1 The test snow surface is smooth and even. The length should be more

than 500 m, the width should be more than 5 m, and the slope shall not be more

than 2 %.

4.1.2.1.2 The snow-covered pavement shall have a layer of hard compacted

snow of at least 3 cm thick for the bottom layer, and a compact layer of snow of

approximately 2 cm thick for the surface layer.

4.1.2.1.3 For the snow compaction index, it shall select at least 10 points evenly

on the entire test surface for measurement, and take the average value. The

maximum value and the minimum value shall not differ by more than 8. The

average snow compaction index measured using a snow hardness tester (CTI,

see Annex A) is between 75 and 85.

4.1.2.2 Climate conditions

4.1.2.2.1 The ambient temperature range measured at approximately 1 m

above the ground is -21 °C to -7 °C.

4.1.4.2 Candidate tyres shall be produced in the same batch and kept in the

same environment. Burrs, flashings and any foreign matters on the tread shall

be removed. Before the test, the surface of tyres in contact with snow shall be

clean.

4.1.4.3 Before the test, candidate tyres are pre-run for 100 km on dry paved

roads.

4.1.4.4 Candidate tyres shall be assembled near the test site. Candidate tyres

shall be installed on the rims used in the test vehicle by conventional installation

methods, allowing the use of an appropriate amount of lubricant for ease of

installation. All assembled tyres to be tested shall be placed in the same outdoor

environment for at least 2 hours, and then the tyre inflation pressure shall be

adjusted to the value specified in the test.

4.1.4.5 The vehicle load shall be such that the load applied to tyres is between

60 % and 100 % of the load corresponding to the load index. The tyre load on

the same shaft does not differ by more than 10 %. The inflation pressure of

candidate tyres is the calculated air pressure value based on the actual load. If

the vertical load of the vehicle is less than 75 % of the maximum load capacity

of tyres, the test pressure is calculated according to formula (1):

where

pt - the test pressure;

pr - the inflation pressure corresponding to the maximum load capacity.

If the vertical load of the vehicle is not less than 75 % of the maximum load

capacity of tyres, the test pressure is calculated according to formula (2):

where

pt - the test pressure;

pr - the inflation pressure corresponding to the maximum load capacity;

Qt - the actual static load of tyres;

Qr - the maximum load force marked at the sidewall of tyres.

4.1.7 Testing snow performance with control tyres

4.1.7.1 General

If the specifications of candidate tyres and standard reference test tyres differ

greatly and cannot be directly compared on the same vehicle, control tyres may

be used for contrast tests.

4.1.7.2 Principle

Control tyre and two different test vehicles are used for contrast tests with

candidate tyres. One of the test vehicles is suitable for assembling with

standard reference test tyres and control tyres, and the other is suitable for

assembling with candidate tyres and control tyres. The former is used to

evaluate the standard reference test tyres and the control tyres, the latter is

used to evaluate the candidate tyres and the control tyres. The two vehicles

shall be tested on the same pavement, and the pavement surface temperature

difference between the two tests is within 5 °C. The two test vehicles use the

same set of four control tyres, which shall be installed in the same position.

Environmental conditions shall be comparable. All tests shall be completed in

the same day.

The snow grip index, SG, of the candidate tyres with respect to the standard

reference test tyres is calculated according to formula (12):

where

SG1 - the relative index of the control tyres to the standard reference test

tyres;

SG2 - the relative index of the candidate tyres to the control tyres.

4.1.7.3 Requirements for control tyres

The control tyres shall be tyres produced in the same factory in the same week.

4.1.7.4 Storage and safekeeping

Before the test, they may be stored under normal conditions, but control tyres

shall be placed in the same storage conditions as standard reference test tyres.

Once the control tyres have been subjected to contrast test with the standard

reference test tyres, their storage conditions shall meet the storage

requirements of the relevant standard reference test tyres. If the control tyre

has irregular wear, damage, or the tyre has worn to the extent that it affects the

4.2.2.2.3 During the test, the temperature change shall not exceed 10 °C.

4.2.2.2.4 During the test, try to avoid direct sunlight and large changes in

sunshine or humidity. The wind speed should not exceed 5 m/s.

4.2.2.3 Test vehicle conditions

4.2.2.3.1 The test shall be carried out on a two-shaft standard commercial

vehicle in good working condition. The vehicle shall:

a) have a lower rear shaft weight and an engine with sufficient power, to

ensure that the average slip ratio during the test complies with the

requirements of 4.2.5.3 and 4.2.5.4;

b) the transmission ratio of the manual transmission (automatic transmission

that allows manual shifting) shall cover a range of at least 19 km/h

between 4 km/h and 30 km/h;

c) it is recommended to install a differential lock on the drive shaft to improve

repeatability;

d) the test vehicle shall be equipped with a traction control system (ASR,

TCS).

4.2.2.3.2 In the special case where a standard commercial vehicle equipped

with a traction control system cannot be found, if the vehicle is equipped with a

system capable of displaying the slip ratio specified in 4.2.3.5 and a differential

lock is installed on the drive shaft, it is allowed to use vehicles without traction

control system (ASR, TCS).

4.2.2.3.3 The test vehicle shall be equipped with a calibrated sensor for winter

measurements, and the speed and distance data acquisition system shall have

the function of storing measurement results. The accuracy of the sensor and

system shall be such that the relative uncertainty of the measured or calculated

mean fully developed deceleration is less than 1 %.

4.2.2.3.4 The following modifications are possible:

a) After the vehicle is modified, the tyre specifications that can be installed

on the vehicle can be increased;

b) After the vehicle is modified, the automatic acceleration starter and

measuring device can be installed.

No other modifications to the acceleration system shall be made.

4.2.2.3.5 Vehicle assembly: Two or four candidate tyres can be mounted on the

where

R - the load radius, in meters (m);

n - the revolving speed, in revolutions per second (r/s).

π = 3.1416.

4.2.4 Candidate tyres

4.2.4.1 The selection of standard reference test tyres is divided into the

following two cases:

a) For truck and bus tyres with a nominal section width of less than 285 mm,

245/70R19.5 136/134 M is selected as standard reference test tyres,

which shall comply with the requirements of relevant domestic body

standards;

b) For truck and bus tyres with a nominal section width greater than or equal

to 285 mm, 315/70R22.5 154/150 L is selected as standard reference test

tyres, which shall comply with the requirements of relevant domestic body

standards.

4.2.4.2 Candidate tyres shall be produced in the same batch and kept in the

same environment. Burrs, flashings and any foreign matters on the tread shall

be removed. Before the test, the surface of tyres in contact with snow shall be

clean.

4.2.4.3 Before the test, candidate tyres are pre-run for 100 km on dry paved

roads.

4.2.4.4 Candidate tyres shall be assembled near the test site. Candidate tyres

shall be installed on the rims used in the test vehicle by conventional installation

methods, allowing the use of an appropriate amount of lubricant for ease of

installation. All assembled tyres to be tested shall be placed in the same outdoor

environment for at least 2 hours, and then the tyre inflation pressure shall be

adjusted to the value specified in the test.

4.2.4.5 The air pressure and load of candidate tyre are as follows:

a) the driving tyre’s inflation pressure shall be 70 % of the inflation pressure

indicated on the sidewall;

b) the guiding tyre’s inflation pressure is the inflation pressure indicated on

If the specifications of candidate tyres and standard reference test tyres differ

greatly and cannot be directly compared on the same vehicle, control tyres may

be used for contrast tests.

4.2.7.2 Principle

Control tyre and two different test vehicles are used for contrast tests with

candidate tyres. One of the test vehicles is suitable for assembling with

standard reference test tyres and control tyres, and the other is suitable for

assembling with candidate tyres and control tyres. All conditions shall be in

accordance with 4.2.2. The former is used to evaluate the standard reference

test tyres and the control tyres, the latter is used to evaluate the candidate tyres

and the control tyres. The two vehicles shall be tested on the same pavement,

and the pavement surface temperature difference between the two tests is

within 5 °C. The two test vehicles use the same set of four control tyres, which

shall be installed in the same position. Environmental conditions shall be

comparable. All tests shall be completed in the same day.

The snow grip index, SG, of the candidate tyres with respect to the standard

reference test tyres is calculated according to formula (19):

where

SG1 - the relative index of the control tyre to the standard reference test tyres;

SG2 - the relative index of the candidate tyre to the control tyres.

4.2.7.3 Requirements for control tyres

The control tyres shall be tyres produced in the same factory in the same week.

4.2.7.4 Storage and safekeeping of control tyres

Before the test, they may be stored under normal conditions, but control tyres

shall be placed in the same storage conditions as standard reference test tyres.

Once the control tyres have been subjected to contrast test with the standard

reference test tyres, their storage conditions shall meet the storage

requirements of the relevant standard reference test tyres. If the control tyre

has irregular wear, damage, or the tyre has worn to the extent that it affects the

test results, it cannot be used.

5 Test report

The test report should include the following:

Annex A

(normative)

Snow hardness tester

A.1 Conditions of use

A.1.1 The compression degree and shear strength of snow have a great

influence on the snow traction performance of tyres. These parameters cannot

be ignored, but the changes of them can be quantified by vertical and horizontal

compaction tests. The CTI snow hardness tester can measure and characterize

the compression degree of snow surface.

A.1.2 The top of the CTI snow hardness tester is a 1.6 mm radius ball that looks

like a plumb (see Figure A.1), and the other end is a measuring rod. Including

the knurled nut at the top of the measurement, the entire instrument is adjusted

to a weight of 220 g ± 1 g in the laboratory. The height of the measuring rod is

adjusted to 218.9 mm ± 0.25 mm.

...

Share