1

/

of

7

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 34560.6-2017 English PDF (GB/T34560.6-2017)

GB/T 34560.6-2017 English PDF (GB/T34560.6-2017)

Regular price

$150.00

Regular price

Sale price

$150.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB/T 34560.6-2017: Structural steels -- Part 6: Technical delivery conditions for seismic-improved structural steels for building

Delivery: 9 seconds. Download (& Email) true-PDF + Invoice.

Get Quotation: Click GB/T 34560.6-2017 (Self-service in 1-minute)

Historical versions (Master-website): GB/T 34560.6-2017

Preview True-PDF (Reload/Scroll-down if blank)

GB/T 34560.6-2017

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.140.01

H 40

Structural steels - Part 6: Technical delivery conditions

for seismic-improved structural steels for building

(ISO 630-6:2014, MOD)

ISSUED ON: OCTOBER 14, 2017

IMPLEMENTED ON: JULY 01, 2018

Issued by: General Administration of Quality Supervision, Inspection and

Quarantine of the PRC;

Standardization Administration of the PRC.

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Terms and definitions ... 7

4 Classification and designation representation ... 8

5 Order content ... 8

6 Dimension, shape, weight and tolerance ... 9

7 Technical requirements ... 9

8 Test methods ... 13

9 Inspection rules ... 14

10 Package, mark, and certification ... 15

Annex A (Informative) Structural changes in this Part compared to ISO 630-

6:2014 ... 16

Annex B (Informative) Technical differences between this Part and ISO 630-

6:2014 and their causes ... 17

Annex C (Normative) Chemical composition, mechanical and processing

properties of Q390, Q420, and Q460 steels ... 19

Annex D (Normative) Carbon equivalent formulas and requirements ... 22

Structural steels - Part 6: Technical delivery conditions

for seismic-improved structural steels for building

1 Scope

This Part of GB/T 34560 specifies the terms and definitions, classification and

designation representation, order content, dimension, shape, weight and

tolerance, technical requirements, test methods, inspection rules, package,

mark, and certification of seismic-improved structural steels for building.

This Part applies to steel plates with a thickness of 6 mm~150 mm, wide flat

steels, and hot-rolled section steels with flange thickness not more than 140

mm (hereinafter referred to as “steels”).

2 Normative references

The following documents are indispensable for the application of this document.

For the dated references, only the editions with the dates indicated are

applicable to this document. For the undated references, the latest edition

(including all the amendments) are applicable to this document.

GB/T 222 Permissible Tolerances for Chemical Composition of Steel

Products

GB/T 223.3 Methods for chemical analysis of iron, steel and alloy - The

diantipyrylmethane phosphomolybdate gravimetric method for the

determination of phosphorus content

GB/T 223.10 Methods for chemical analysis of iron, steel and alloy - The

cupferron separation-chrome azurol S photometric method for the

determination of aluminium content

GB/T 223.11 Iron, steel and alloy - Determination of chromium content -

Visual titration or potentiometric titration method

GB/T 223.14 Methods for Chemical Analysis of Iron, Steel and Alloy - The N-

Benzoy-N-Phenylhydroxylamine Extraction Photometric Method for the

Determination of Vanadium Content

GB/T 223.17 Methods for chemical analysis of iron, steel and alloy - The

diantipyrylmethane photometric method for the determination of titanium

content

GB/T 223.18 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Sodium Thiosulfate Separation Iodimetric Method for the Determination of

Copper Content

GB/T 223.23 Iron, Steel and Alloy - Determination of Nickel Content - The

Dimethylglyoxime Spectrophotometric Method

GB/T 223.26 Iron, steel and alloy - Determination of molybdenum content -

The thiocyanate spectrophotometric method

GB/T 223.27 Methods for chemical analysis of iron, steel and alloy - The

thiocyanate-butyl acetate extraction spectrophotometric method for the

determination of molybdenum content

GB/T 223.40 Iron, Steel and Alloy - Determination of Niobium Content by the

Sulphochlorophenol S Spectrophotometric Method

GB/T 223.60 Methods for chemical analysis of iron, steel and alloy - The

perchloric acid dehydration gravimetric method for the determination of

silicon content

GB/T 223.63 Methods for chemical analysis of iron, steel and alloy - The

sodium (potassium) periodate photometric method for the determination of

manganese content

GB/T 223.68 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Potassium Iodate Titration Method after Combustion in the Pipe Furnace for

the Determination of Sulfur Content

GB/T 223.69 Iron, steel and alloy - Determination of carbon contents - Gas-

volumetric method after combustion in the pipe furnace

GB/T 223.75 Iron steel and alloy - Determination of boron content - Methanol

distillation-curcumin photometric method

GB/T 223.76 Methods for chemical analysis of iron, steel and alloy - The

flame atomic absorption spectrometric method for the determination of

vanadium content

GB/T 228.1 Metallic materials - Tensile testing - Part 1: Method of test at

room temperature (GB/T 228.1-2010, ISO 6892-1:2009 MOD)

GB/T 229 Metallic materials - Charpy pendulum impact test method (GB/T

229-2007, ISO 148-1:2006, MOD)

4 Classification and designation representation

4.1 According to GB/T 13304.1, the steel of this Part is classified into unalloyed

steel and low-alloy steel.

4.2 The steel designation consists of four parts: the first letter Q of Chinese

phonetic alphabet representing “Qu” of yield strength, specified minimum upper

yield strength value, the initials “KZ” of Chinese phonetic alphabet for “seismic-

improved”, quality grade symbol (C, D, E, F).

Example: Q3450KZE

Where:

Q - The first letter of Chinese phonetic alphabet of “Qu” for yield strength of steel;

345 - The specified minimum upper yield strength value, in megapascals (MPa);

KZ - Represent “seismic-improved”;

E - The quality grade is Grade E.

4.3 When the purchaser requires the steel plate to have the through-thickness

(Z-direction) characteristics, after the above specified designation, ADD the

through-thickness characteristics level of the steel plate, such as Q345KZEZ25.

5 Order content

5.1 Contracts or orders for ordering according to this Part shall include the

following:

a) Standard number;

b) Product type;

c) Steel grade + delivery condition + quality grade;

d) Dimension, shape, and tolerance;

e) Selected content of all requirements;

f) Type of inspection document.

5.2 Through negotiation between the supplier and the purchaser, and indicated

in the contract, the following content may be selected as the order content of

this Part. If the purchaser does not specify when providing the inquiry and order,

7.1.8 Through negotiation between the supplier and the purchaser, the

chemical composition inspection of steel products may be carried out.

Permissible tolerances for chemical composition of products shall meet the

requirements of GB/T 222.

7.2 Smelting method

The steel shall be smelted by an oxygen converter or an electric furnace. Unless

otherwise specified, the smelting method shall be selected by the supplier.

7.3 Delivery condition

The steels are generally delivered in the hot-rolled condition. Unless otherwise

agreed, the hot-rolled condition, normalized rolled, normalized or quenched and

tempered condition are allowed at the manufacturer’s discretion. The thermo-

mechanical rolling is not allowed at the manufacturer’s discretion. Through

negotiation between the supplier and the purchaser, thermo-mechanical rolling

may be applied to any steel grade. The delivery condition shall be stated in the

contract.

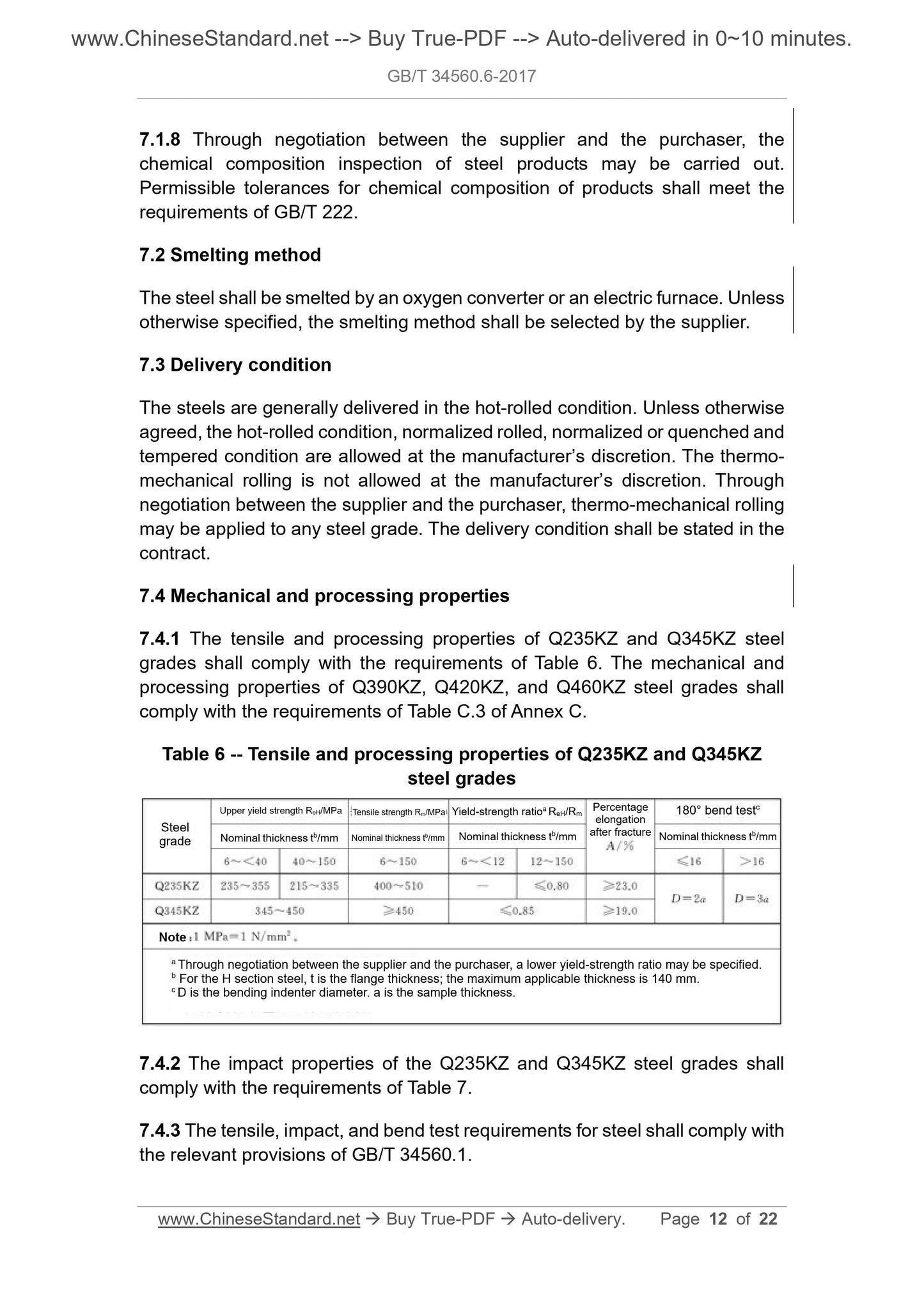

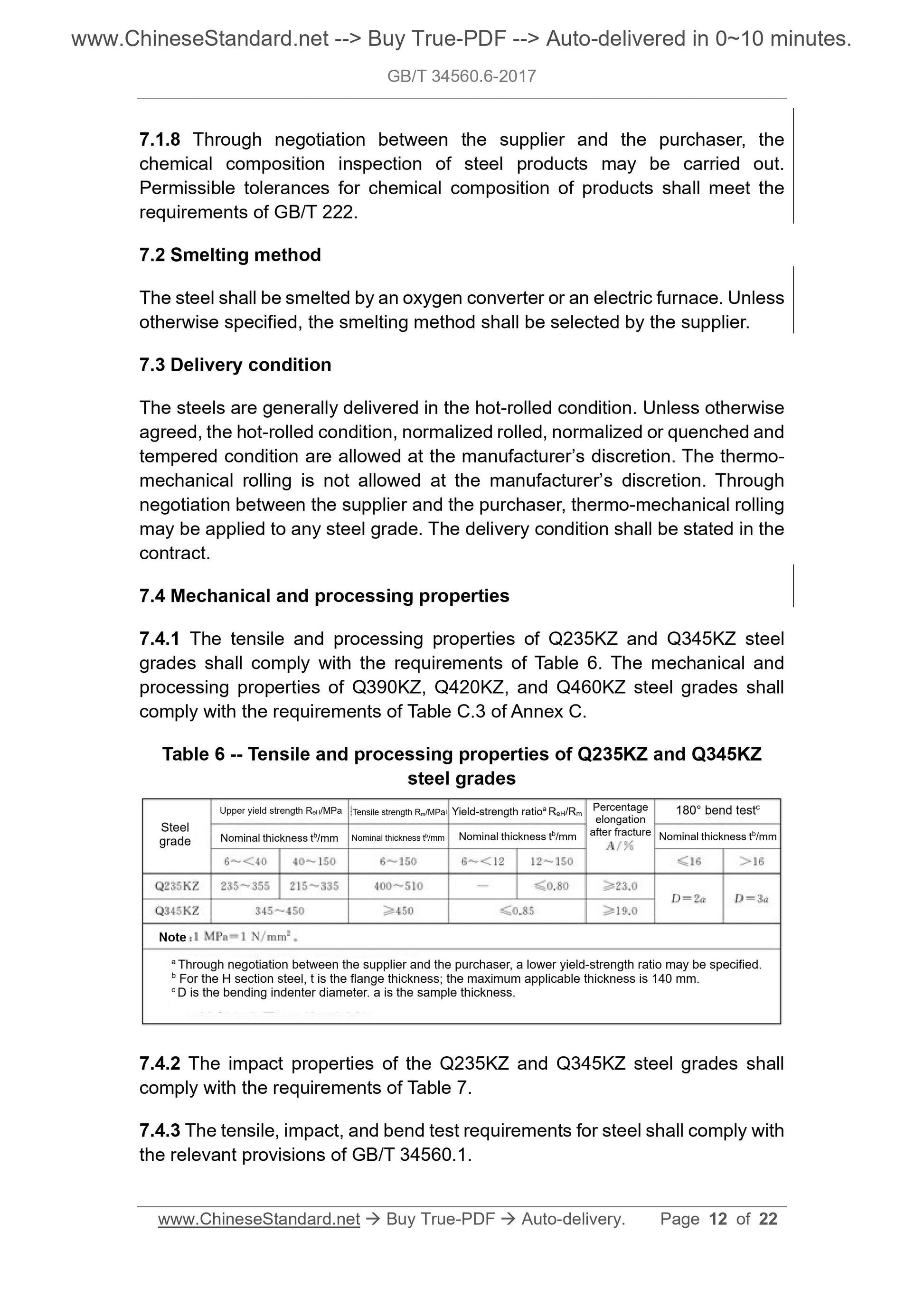

7.4 Mechanical and processing properties

7.4.1 The tensile and processing properties of Q235KZ and Q345KZ steel

grades shall comply with the requirements of Table 6. The mechanical and

processing properties of Q390KZ, Q420KZ, and Q460KZ steel grades shall

comply with the requirements of Table C.3 of Annex C.

Table 6 -- Tensile and processing properties of Q235KZ and Q345KZ

steel grades

7.4.2 The impact properties of the Q235KZ and Q345KZ steel grades shall

comply with the requirements of Table 7.

7.4.3 The tensile, impact, and bend test requirements for steel shall comply with

the relevant provisions of GB/T 34560.1.

Steel

grade

Upper yield strength ReH/MPa

Nominal thickness tb/mm Nominal thickness tb/mm Nominal thickness tb/mm Nominal thickness tb/mm

Tensile strength Rm/MPa Yield-strength ratioa ReH/Rm 180° bend testc Percentage elongation

after fracture

Note

a Through negotiation between the supplier and the purchaser, a lower yield-strength ratio may be specified.

b For the H section steel, t is the flange thickness; the maximum applicable thickness is 140 mm.

c D is the bending indenter diameter. a is the sample thickness.

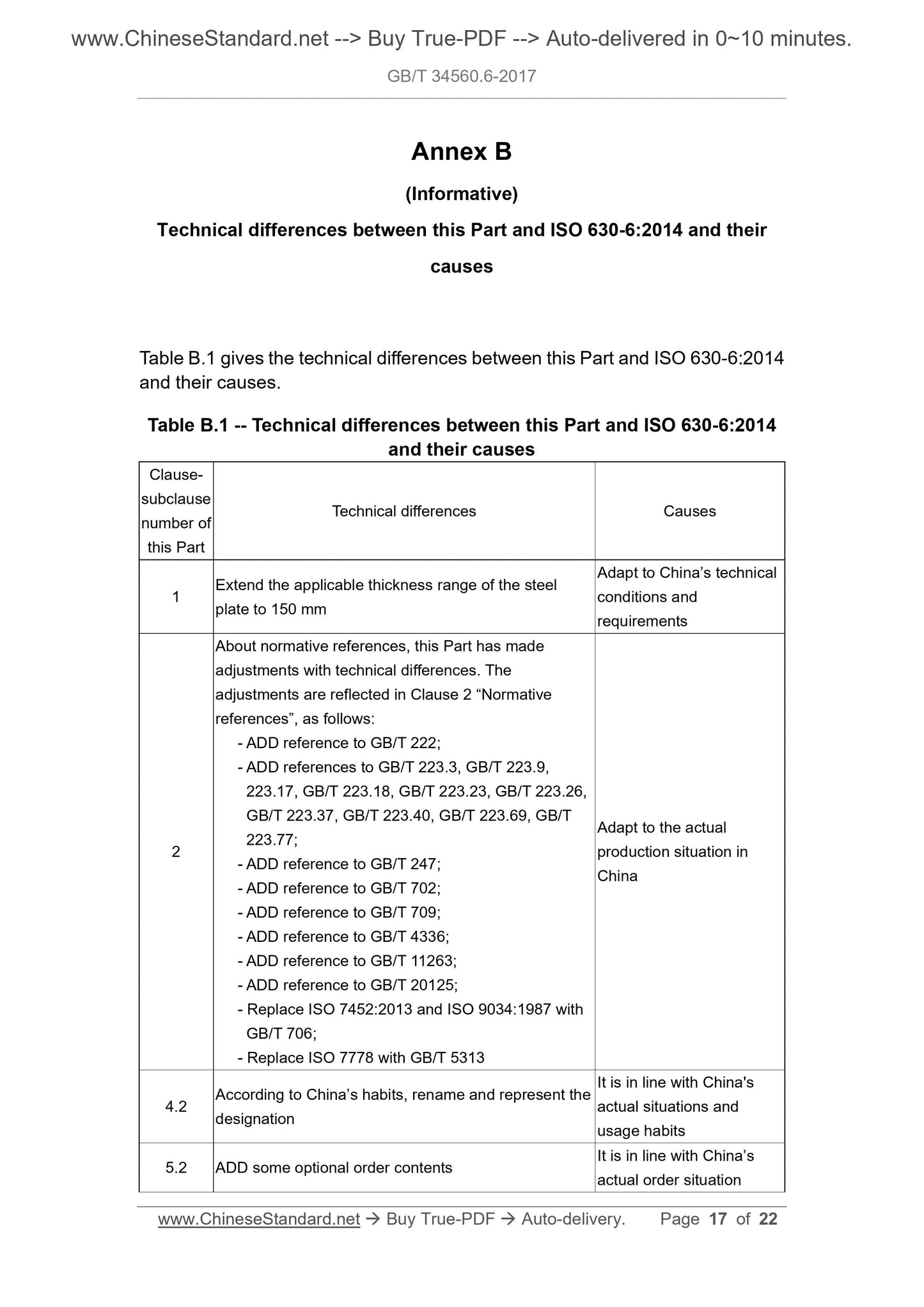

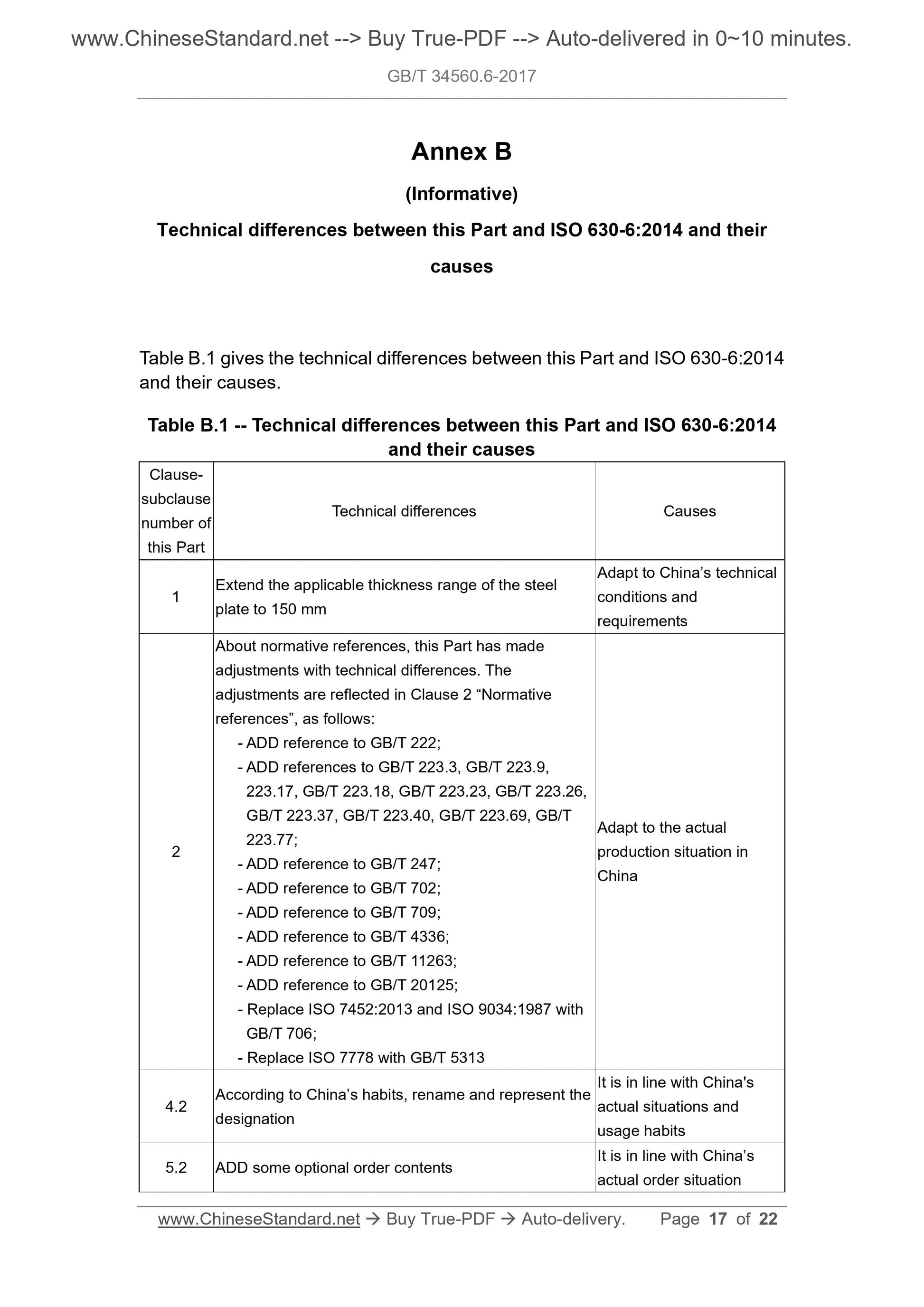

Annex B

(Informative)

Technical differences between this Part and ISO 630-6:2014 and their

causes

Table B.1 gives the technical differences between this Part and ISO 630-6:2014

and their causes.

Table B.1 -- Technical differences between this Part and ISO 630-6:2014

and their causes

Clause-

subclause

number of

this Part

Technical differences Causes

1 Extend the applicable thickness range of the steel plate to 150 mm

Adapt to China’s technical

conditions and

requirements

About normative references, this Part has made

adjustments with technical differences. The

adjustments are reflected in Clause 2 “Normative

references”, as follows:

- ADD reference to GB/T 222;

- ADD references to GB/T 223.3, GB/T 223.9,

223.17, GB/T 223.18, GB/T 223.23, GB/T 223.26,

GB/T 223.37, GB/T 223.40, GB/T 223.69, GB/T

223.77;

- ADD reference to GB/T 247;

- ADD reference to GB/T 702;

- ADD reference to GB/T 709;

- ADD reference to GB/T 4336;

- ADD reference to GB/T 11263;

- ADD reference to GB/T 20125;

- Replace ISO 7452:2013 and ISO 9034:1987 with

GB/T 706;

- Replace ISO 7778 with GB/T 5313

Adapt to the actual

production situation in

China

4.2 According to China’s habits, rename and represent the designation

It is in line with China's

actual situations and

usage habits

5.2 ADD some optional order contents It is in line with China’s actual order situation

GB/T 34560.6-2017

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.140.01

H 40

Structural steels - Part 6: Technical delivery conditions

for seismic-improved structural steels for building

(ISO 630-6:2014, MOD)

ISSUED ON: OCTOBER 14, 2017

IMPLEMENTED ON: JULY 01, 2018

Issued by: General Administration of Quality Supervision, Inspection and

Quarantine of the PRC;

Standardization Administration of the PRC.

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Terms and definitions ... 7

4 Classification and designation representation ... 8

5 Order content ... 8

6 Dimension, shape, weight and tolerance ... 9

7 Technical requirements ... 9

8 Test methods ... 13

9 Inspection rules ... 14

10 Package, mark, and certification ... 15

Annex A (Informative) Structural changes in this Part compared to ISO 630-

6:2014 ... 16

Annex B (Informative) Technical differences between this Part and ISO 630-

6:2014 and their causes ... 17

Annex C (Normative) Chemical composition, mechanical and processing

properties of Q390, Q420, and Q460 steels ... 19

Annex D (Normative) Carbon equivalent formulas and requirements ... 22

Structural steels - Part 6: Technical delivery conditions

for seismic-improved structural steels for building

1 Scope

This Part of GB/T 34560 specifies the terms and definitions, classification and

designation representation, order content, dimension, shape, weight and

tolerance, technical requirements, test methods, inspection rules, package,

mark, and certification of seismic-improved structural steels for building.

This Part applies to steel plates with a thickness of 6 mm~150 mm, wide flat

steels, and hot-rolled section steels with flange thickness not more than 140

mm (hereinafter referred to as “steels”).

2 Normative references

The following documents are indispensable for the application of this document.

For the dated references, only the editions with the dates indicated are

applicable to this document. For the undated references, the latest edition

(including all the amendments) are applicable to this document.

GB/T 222 Permissible Tolerances for Chemical Composition of Steel

Products

GB/T 223.3 Methods for chemical analysis of iron, steel and alloy - The

diantipyrylmethane phosphomolybdate gravimetric method for the

determination of phosphorus content

GB/T 223.10 Methods for chemical analysis of iron, steel and alloy - The

cupferron separation-chrome azurol S photometric method for the

determination of aluminium content

GB/T 223.11 Iron, steel and alloy - Determination of chromium content -

Visual titration or potentiometric titration method

GB/T 223.14 Methods for Chemical Analysis of Iron, Steel and Alloy - The N-

Benzoy-N-Phenylhydroxylamine Extraction Photometric Method for the

Determination of Vanadium Content

GB/T 223.17 Methods for chemical analysis of iron, steel and alloy - The

diantipyrylmethane photometric method for the determination of titanium

content

GB/T 223.18 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Sodium Thiosulfate Separation Iodimetric Method for the Determination of

Copper Content

GB/T 223.23 Iron, Steel and Alloy - Determination of Nickel Content - The

Dimethylglyoxime Spectrophotometric Method

GB/T 223.26 Iron, steel and alloy - Determination of molybdenum content -

The thiocyanate spectrophotometric method

GB/T 223.27 Methods for chemical analysis of iron, steel and alloy - The

thiocyanate-butyl acetate extraction spectrophotometric method for the

determination of molybdenum content

GB/T 223.40 Iron, Steel and Alloy - Determination of Niobium Content by the

Sulphochlorophenol S Spectrophotometric Method

GB/T 223.60 Methods for chemical analysis of iron, steel and alloy - The

perchloric acid dehydration gravimetric method for the determination of

silicon content

GB/T 223.63 Methods for chemical analysi...

Delivery: 9 seconds. Download (& Email) true-PDF + Invoice.

Get Quotation: Click GB/T 34560.6-2017 (Self-service in 1-minute)

Historical versions (Master-website): GB/T 34560.6-2017

Preview True-PDF (Reload/Scroll-down if blank)

GB/T 34560.6-2017

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.140.01

H 40

Structural steels - Part 6: Technical delivery conditions

for seismic-improved structural steels for building

(ISO 630-6:2014, MOD)

ISSUED ON: OCTOBER 14, 2017

IMPLEMENTED ON: JULY 01, 2018

Issued by: General Administration of Quality Supervision, Inspection and

Quarantine of the PRC;

Standardization Administration of the PRC.

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Terms and definitions ... 7

4 Classification and designation representation ... 8

5 Order content ... 8

6 Dimension, shape, weight and tolerance ... 9

7 Technical requirements ... 9

8 Test methods ... 13

9 Inspection rules ... 14

10 Package, mark, and certification ... 15

Annex A (Informative) Structural changes in this Part compared to ISO 630-

6:2014 ... 16

Annex B (Informative) Technical differences between this Part and ISO 630-

6:2014 and their causes ... 17

Annex C (Normative) Chemical composition, mechanical and processing

properties of Q390, Q420, and Q460 steels ... 19

Annex D (Normative) Carbon equivalent formulas and requirements ... 22

Structural steels - Part 6: Technical delivery conditions

for seismic-improved structural steels for building

1 Scope

This Part of GB/T 34560 specifies the terms and definitions, classification and

designation representation, order content, dimension, shape, weight and

tolerance, technical requirements, test methods, inspection rules, package,

mark, and certification of seismic-improved structural steels for building.

This Part applies to steel plates with a thickness of 6 mm~150 mm, wide flat

steels, and hot-rolled section steels with flange thickness not more than 140

mm (hereinafter referred to as “steels”).

2 Normative references

The following documents are indispensable for the application of this document.

For the dated references, only the editions with the dates indicated are

applicable to this document. For the undated references, the latest edition

(including all the amendments) are applicable to this document.

GB/T 222 Permissible Tolerances for Chemical Composition of Steel

Products

GB/T 223.3 Methods for chemical analysis of iron, steel and alloy - The

diantipyrylmethane phosphomolybdate gravimetric method for the

determination of phosphorus content

GB/T 223.10 Methods for chemical analysis of iron, steel and alloy - The

cupferron separation-chrome azurol S photometric method for the

determination of aluminium content

GB/T 223.11 Iron, steel and alloy - Determination of chromium content -

Visual titration or potentiometric titration method

GB/T 223.14 Methods for Chemical Analysis of Iron, Steel and Alloy - The N-

Benzoy-N-Phenylhydroxylamine Extraction Photometric Method for the

Determination of Vanadium Content

GB/T 223.17 Methods for chemical analysis of iron, steel and alloy - The

diantipyrylmethane photometric method for the determination of titanium

content

GB/T 223.18 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Sodium Thiosulfate Separation Iodimetric Method for the Determination of

Copper Content

GB/T 223.23 Iron, Steel and Alloy - Determination of Nickel Content - The

Dimethylglyoxime Spectrophotometric Method

GB/T 223.26 Iron, steel and alloy - Determination of molybdenum content -

The thiocyanate spectrophotometric method

GB/T 223.27 Methods for chemical analysis of iron, steel and alloy - The

thiocyanate-butyl acetate extraction spectrophotometric method for the

determination of molybdenum content

GB/T 223.40 Iron, Steel and Alloy - Determination of Niobium Content by the

Sulphochlorophenol S Spectrophotometric Method

GB/T 223.60 Methods for chemical analysis of iron, steel and alloy - The

perchloric acid dehydration gravimetric method for the determination of

silicon content

GB/T 223.63 Methods for chemical analysis of iron, steel and alloy - The

sodium (potassium) periodate photometric method for the determination of

manganese content

GB/T 223.68 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Potassium Iodate Titration Method after Combustion in the Pipe Furnace for

the Determination of Sulfur Content

GB/T 223.69 Iron, steel and alloy - Determination of carbon contents - Gas-

volumetric method after combustion in the pipe furnace

GB/T 223.75 Iron steel and alloy - Determination of boron content - Methanol

distillation-curcumin photometric method

GB/T 223.76 Methods for chemical analysis of iron, steel and alloy - The

flame atomic absorption spectrometric method for the determination of

vanadium content

GB/T 228.1 Metallic materials - Tensile testing - Part 1: Method of test at

room temperature (GB/T 228.1-2010, ISO 6892-1:2009 MOD)

GB/T 229 Metallic materials - Charpy pendulum impact test method (GB/T

229-2007, ISO 148-1:2006, MOD)

4 Classification and designation representation

4.1 According to GB/T 13304.1, the steel of this Part is classified into unalloyed

steel and low-alloy steel.

4.2 The steel designation consists of four parts: the first letter Q of Chinese

phonetic alphabet representing “Qu” of yield strength, specified minimum upper

yield strength value, the initials “KZ” of Chinese phonetic alphabet for “seismic-

improved”, quality grade symbol (C, D, E, F).

Example: Q3450KZE

Where:

Q - The first letter of Chinese phonetic alphabet of “Qu” for yield strength of steel;

345 - The specified minimum upper yield strength value, in megapascals (MPa);

KZ - Represent “seismic-improved”;

E - The quality grade is Grade E.

4.3 When the purchaser requires the steel plate to have the through-thickness

(Z-direction) characteristics, after the above specified designation, ADD the

through-thickness characteristics level of the steel plate, such as Q345KZEZ25.

5 Order content

5.1 Contracts or orders for ordering according to this Part shall include the

following:

a) Standard number;

b) Product type;

c) Steel grade + delivery condition + quality grade;

d) Dimension, shape, and tolerance;

e) Selected content of all requirements;

f) Type of inspection document.

5.2 Through negotiation between the supplier and the purchaser, and indicated

in the contract, the following content may be selected as the order content of

this Part. If the purchaser does not specify when providing the inquiry and order,

7.1.8 Through negotiation between the supplier and the purchaser, the

chemical composition inspection of steel products may be carried out.

Permissible tolerances for chemical composition of products shall meet the

requirements of GB/T 222.

7.2 Smelting method

The steel shall be smelted by an oxygen converter or an electric furnace. Unless

otherwise specified, the smelting method shall be selected by the supplier.

7.3 Delivery condition

The steels are generally delivered in the hot-rolled condition. Unless otherwise

agreed, the hot-rolled condition, normalized rolled, normalized or quenched and

tempered condition are allowed at the manufacturer’s discretion. The thermo-

mechanical rolling is not allowed at the manufacturer’s discretion. Through

negotiation between the supplier and the purchaser, thermo-mechanical rolling

may be applied to any steel grade. The delivery condition shall be stated in the

contract.

7.4 Mechanical and processing properties

7.4.1 The tensile and processing properties of Q235KZ and Q345KZ steel

grades shall comply with the requirements of Table 6. The mechanical and

processing properties of Q390KZ, Q420KZ, and Q460KZ steel grades shall

comply with the requirements of Table C.3 of Annex C.

Table 6 -- Tensile and processing properties of Q235KZ and Q345KZ

steel grades

7.4.2 The impact properties of the Q235KZ and Q345KZ steel grades shall

comply with the requirements of Table 7.

7.4.3 The tensile, impact, and bend test requirements for steel shall comply with

the relevant provisions of GB/T 34560.1.

Steel

grade

Upper yield strength ReH/MPa

Nominal thickness tb/mm Nominal thickness tb/mm Nominal thickness tb/mm Nominal thickness tb/mm

Tensile strength Rm/MPa Yield-strength ratioa ReH/Rm 180° bend testc Percentage elongation

after fracture

Note

a Through negotiation between the supplier and the purchaser, a lower yield-strength ratio may be specified.

b For the H section steel, t is the flange thickness; the maximum applicable thickness is 140 mm.

c D is the bending indenter diameter. a is the sample thickness.

Annex B

(Informative)

Technical differences between this Part and ISO 630-6:2014 and their

causes

Table B.1 gives the technical differences between this Part and ISO 630-6:2014

and their causes.

Table B.1 -- Technical differences between this Part and ISO 630-6:2014

and their causes

Clause-

subclause

number of

this Part

Technical differences Causes

1 Extend the applicable thickness range of the steel plate to 150 mm

Adapt to China’s technical

conditions and

requirements

About normative references, this Part has made

adjustments with technical differences. The

adjustments are reflected in Clause 2 “Normative

references”, as follows:

- ADD reference to GB/T 222;

- ADD references to GB/T 223.3, GB/T 223.9,

223.17, GB/T 223.18, GB/T 223.23, GB/T 223.26,

GB/T 223.37, GB/T 223.40, GB/T 223.69, GB/T

223.77;

- ADD reference to GB/T 247;

- ADD reference to GB/T 702;

- ADD reference to GB/T 709;

- ADD reference to GB/T 4336;

- ADD reference to GB/T 11263;

- ADD reference to GB/T 20125;

- Replace ISO 7452:2013 and ISO 9034:1987 with

GB/T 706;

- Replace ISO 7778 with GB/T 5313

Adapt to the actual

production situation in

China

4.2 According to China’s habits, rename and represent the designation

It is in line with China's

actual situations and

usage habits

5.2 ADD some optional order contents It is in line with China’s actual order situation

GB/T 34560.6-2017

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.140.01

H 40

Structural steels - Part 6: Technical delivery conditions

for seismic-improved structural steels for building

(ISO 630-6:2014, MOD)

ISSUED ON: OCTOBER 14, 2017

IMPLEMENTED ON: JULY 01, 2018

Issued by: General Administration of Quality Supervision, Inspection and

Quarantine of the PRC;

Standardization Administration of the PRC.

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Terms and definitions ... 7

4 Classification and designation representation ... 8

5 Order content ... 8

6 Dimension, shape, weight and tolerance ... 9

7 Technical requirements ... 9

8 Test methods ... 13

9 Inspection rules ... 14

10 Package, mark, and certification ... 15

Annex A (Informative) Structural changes in this Part compared to ISO 630-

6:2014 ... 16

Annex B (Informative) Technical differences between this Part and ISO 630-

6:2014 and their causes ... 17

Annex C (Normative) Chemical composition, mechanical and processing

properties of Q390, Q420, and Q460 steels ... 19

Annex D (Normative) Carbon equivalent formulas and requirements ... 22

Structural steels - Part 6: Technical delivery conditions

for seismic-improved structural steels for building

1 Scope

This Part of GB/T 34560 specifies the terms and definitions, classification and

designation representation, order content, dimension, shape, weight and

tolerance, technical requirements, test methods, inspection rules, package,

mark, and certification of seismic-improved structural steels for building.

This Part applies to steel plates with a thickness of 6 mm~150 mm, wide flat

steels, and hot-rolled section steels with flange thickness not more than 140

mm (hereinafter referred to as “steels”).

2 Normative references

The following documents are indispensable for the application of this document.

For the dated references, only the editions with the dates indicated are

applicable to this document. For the undated references, the latest edition

(including all the amendments) are applicable to this document.

GB/T 222 Permissible Tolerances for Chemical Composition of Steel

Products

GB/T 223.3 Methods for chemical analysis of iron, steel and alloy - The

diantipyrylmethane phosphomolybdate gravimetric method for the

determination of phosphorus content

GB/T 223.10 Methods for chemical analysis of iron, steel and alloy - The

cupferron separation-chrome azurol S photometric method for the

determination of aluminium content

GB/T 223.11 Iron, steel and alloy - Determination of chromium content -

Visual titration or potentiometric titration method

GB/T 223.14 Methods for Chemical Analysis of Iron, Steel and Alloy - The N-

Benzoy-N-Phenylhydroxylamine Extraction Photometric Method for the

Determination of Vanadium Content

GB/T 223.17 Methods for chemical analysis of iron, steel and alloy - The

diantipyrylmethane photometric method for the determination of titanium

content

GB/T 223.18 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Sodium Thiosulfate Separation Iodimetric Method for the Determination of

Copper Content

GB/T 223.23 Iron, Steel and Alloy - Determination of Nickel Content - The

Dimethylglyoxime Spectrophotometric Method

GB/T 223.26 Iron, steel and alloy - Determination of molybdenum content -

The thiocyanate spectrophotometric method

GB/T 223.27 Methods for chemical analysis of iron, steel and alloy - The

thiocyanate-butyl acetate extraction spectrophotometric method for the

determination of molybdenum content

GB/T 223.40 Iron, Steel and Alloy - Determination of Niobium Content by the

Sulphochlorophenol S Spectrophotometric Method

GB/T 223.60 Methods for chemical analysis of iron, steel and alloy - The

perchloric acid dehydration gravimetric method for the determination of

silicon content

GB/T 223.63 Methods for chemical analysi...

Share