1

/

of

6

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 37207-2018 English PDF (GB/T37207-2018)

GB/T 37207-2018 English PDF (GB/T37207-2018)

Regular price

$175.00

Regular price

Sale price

$175.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB/T 37207-2018: Electrochemical performance test of lithium nickel cobalt manganese oxide - Test method for discharge plateau capacity ratio and cycle life

Delivery: 9 seconds. Download (& Email) true-PDF + Invoice.

Get Quotation: Click GB/T 37207-2018 (Self-service in 1-minute)

Historical versions (Master-website): GB/T 37207-2018

Preview True-PDF (Reload/Scroll-down if blank)

GB/T 37207-2018

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.160

H 21

Electrochemical performance test of lithium nickel

cobalt manganese oxide - Test method for discharge

plateau capacity ratio and cycle life

ISSUED ON: DECEMBER 28, 2018

IMPLEMENTED ON: NOVEMBER 01, 2019

Issued by: State Administration for Market Regulation;

Standardization Administration of the PRC.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Reagents and materials ... 4

4 Instruments and equipment ... 6

5 Test procedures ... 7

6 Test report ... 13

Electrochemical performance test of lithium nickel

cobalt manganese oxide - Test method for discharge

plateau capacity ratio and cycle life

1 Scope

This Standard specifies the test method for discharge plateau capacity ratio and

cycle life for lithium nickel cobalt manganese oxide of lithium-ion battery

cathode material.

This Standard applies to the testing of discharge plateau capacity ratio and

cycle life for lithium nickel cobalt manganese oxide of lithium-ion battery

cathode material.

2 Normative references

The following documents are indispensable for the application of this document.

For the dated references, only the editions with the dates indicated are

applicable to this document. For the undated references, the latest edition

(including all the amendments) are applicable to this document.

GB/T 18287-2013 General specification of lithium-ion cells and batteries for

mobile phone

3 Reagents and materials

3.1 Lithium nickel cobalt manganese oxide: D50 is 7 μm ~ 15 μm. The specific

surface area is 0.2 m2/g ~ 1.0 m2/g. The sampling amount is 2.0 kg ~ 5.0 kg.

3.2 Graphite anode: D50 is 12.0 μm ~ 20.0 μm. The discharge specific capacity

of the first cycle is ≥ 320.0 mA • h/g. The charge-discharge coulombic

efficiency of the first cycle is ≥ 88.0%.

3.3 Lithium-ion battery diaphragm: Polyolefin porous diaphragm. Porosity 35.0%

~ 60.0%; air permeability 300 s/100 mL ~ 700 s/100 mL; average pore size ≤

1.0 μm; thickness 9.0 μm ~ 32.0 μm; length 720 mm±1.0 mm; width 47 mm±0.5

mm.

3.4 Lithium-ion battery electrolyte: Lithium-ion battery electrolyte consisting of

4 Instruments and equipment

4.1 Electronic balance: The range is 5000 g, accurate to 0.1 g.

4.2 Spiral micrometer.

4.3 Ruler: Made of stainless steel. The range is 100 cm, accurate to 0.5 mm.

4.4 Vacuum mixer.

4.5 Lithium battery pole piece coating machine.

4.6 Pole piece punching machine: Punching die size is φ50 mm ~ φ100 mm.

4.7 Slitting machine.

4.8 Roller machine.

4.9 Adjustable slitting machine.

4.10 Ultrasonic welder.

4.11 Spot-welder.

4.12 Winding machine.

4.13 Battery flat press.

4.14 Aluminum-plastic film heat sealing machine.

4.15 Argon glove box: Water vapor and oxygen content are not more than

0.0005%.

4.16 Injector: 20 mL.

4.17 Vacuum oven.

4.18 Electric blast drying oven.

4.19 Lithium-ion battery electrochemical performance tester.

4.20 Banister brush.

4.21 Rubber pipette bulb.

4.22 Oil-free vacuum pump.

the vacuum mixer in stages for mixing and stirring, so that various materials

are uniformly mixed.

5.2.2.2 During the whole process of mixing and stirring, the temperature of the

positive electrode slurry is controlled below 40 °C; and the viscosity is controlled

at 6000 mPa • s ~ 10000 mPa • s. Finally, after slow stirring, vacuum is applied;

and the slurry is discharged to enter the next process.

5.2.3 Coating

5.2.3.1 Coating shall be carried out under environmental conditions of relative

humidity ≤ 30.0% and temperature ≤ 35 °C. The instruments and equipment

used shall be clean.

5.2.3.2 USE a lithium battery pole piece coating machine (4.5) to uniformly coat

the mixed positive electrode slurry on both sides of an aluminum foil (3.12).

USE a spiral micrometer (4.2) to measure the thickness of the coated positive

plate.

5.2.3.3 The preparation process of the positive plate coating is strictly controlled.

The baking temperature at the time of coating shall not be higher than 130 °C.

The thickness shall be consistent. The test data is recorded.

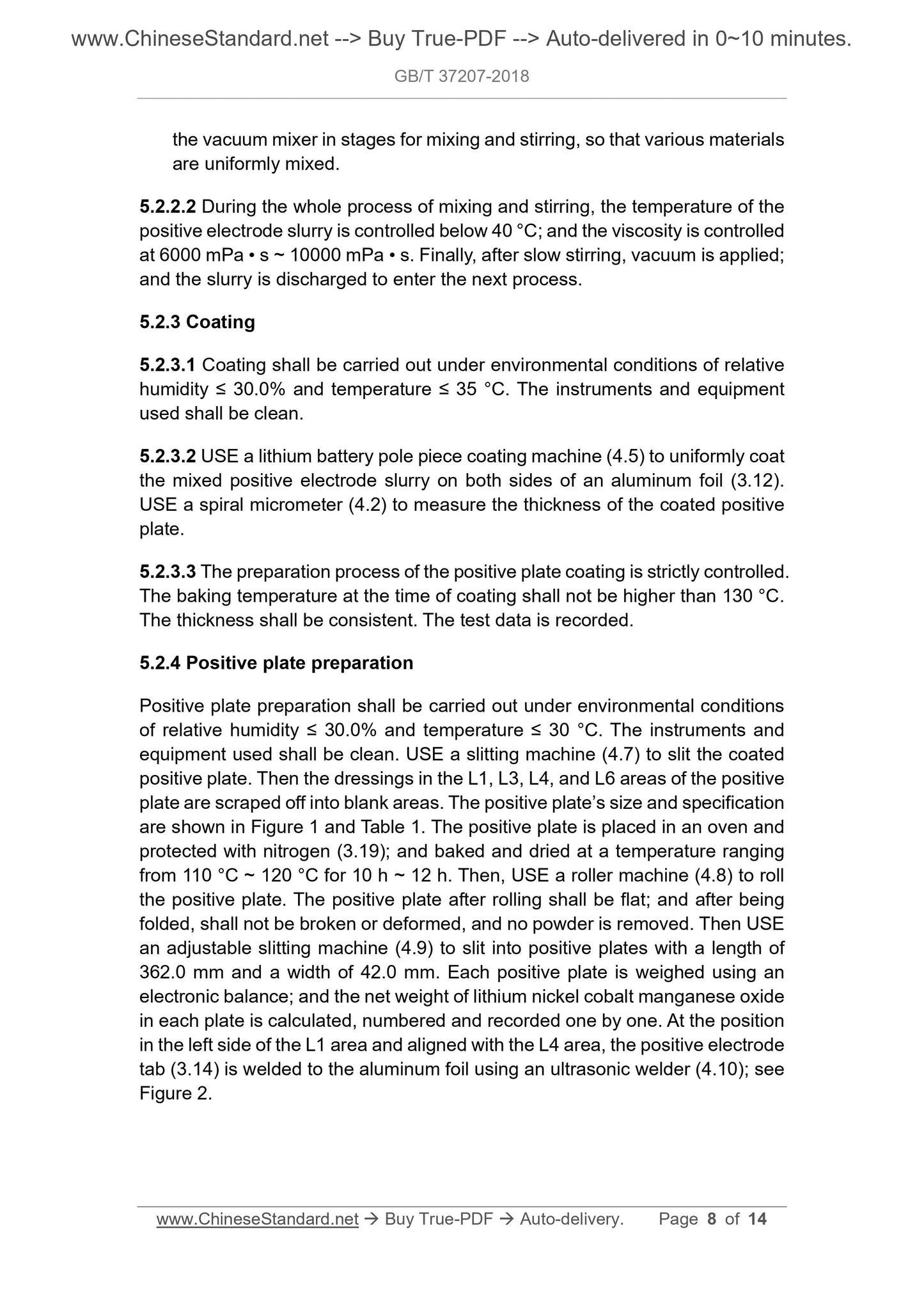

5.2.4 Positive plate preparation

Positive plate preparation shall be carried out under environmental conditions

of relative humidity ≤ 30.0% and temperature ≤ 30 °C. The instruments and

equipment used shall be clean. USE a slitting machine (4.7) to slit the coated

positive plate. Then the dressings in the L1, L3, L4, and L6 areas of the positive

plate are scraped off into blank areas. The positive plate’s size and specification

are shown in Figure 1 and Table 1. The positive plate is placed in an oven and

protected with nitrogen (3.19); and baked and dried at a temperature ranging

from 110 °C ~ 120 °C for 10 h ~ 12 h. Then, USE a roller machine (4.8) to roll

the positive plate. The positive plate after rolling shall be flat; and after being

folded, shall not be broken or deformed, and no powder is removed. Then USE

an adjustable slitting machine (4.9) to slit into positive plates with a length of

362.0 mm and a width of 42.0 mm. Each positive plate is weighed using an

electronic balance; and the net weight of lithium nickel cobalt manganese oxide

in each plate is calculated, numbered and recorded one by one. At the position

in the left side of the L1 area and aligned with the L4 area, the positive electrode

tab (3.14) is welded to the aluminum foil using an ultrasonic welder (4.10); see

Figure 2.

portions). Then DISPERSE and stir until the CMC is completely dissolved

into the deionized water;

- The weighed carbon black conductive agent is added to the vacuum mixer

for mixing and stirring, so that various materials are uniformly mixed;

- The weighed graphite is gradually added to the vacuum mixer in stages for

mixing and stirring, so that various materials are uniformly mixed;

- ADD SBR for slow stirring until completely dispersed.

5.3.2.2 During the whole process of mixing and stirring, the temperature of the

negative electrode slurry is controlled below 40 °C; and the viscosity is

controlled at 1500 mPa • s ~ 3000 mPa • s. Finally, after slow stirring, vacuum

is applied; and the slurry is discharged.

5.3.3 Coating

5.3.3.1 Coating shall be carried out under environmental conditions of relative

humidity ≤ 50.0% and temperature ≤ 35 °C. The instruments and equipment

used shall be clean.

5.3.3.2 USE a lithium battery pole piece coating machine to uniformly coat the

mixed negative electrode slurry on both sides of a copper foil (3.13). USE a

spiral micrometer to measure the thickness of the coated negative plate.

5.3.3.3 The preparation process of the negative plate coating is strictly

controlled. The baking temperature at the time of coating shall not be higher

than 110 °C. The thickness shall be consistent. The test data is recorded.

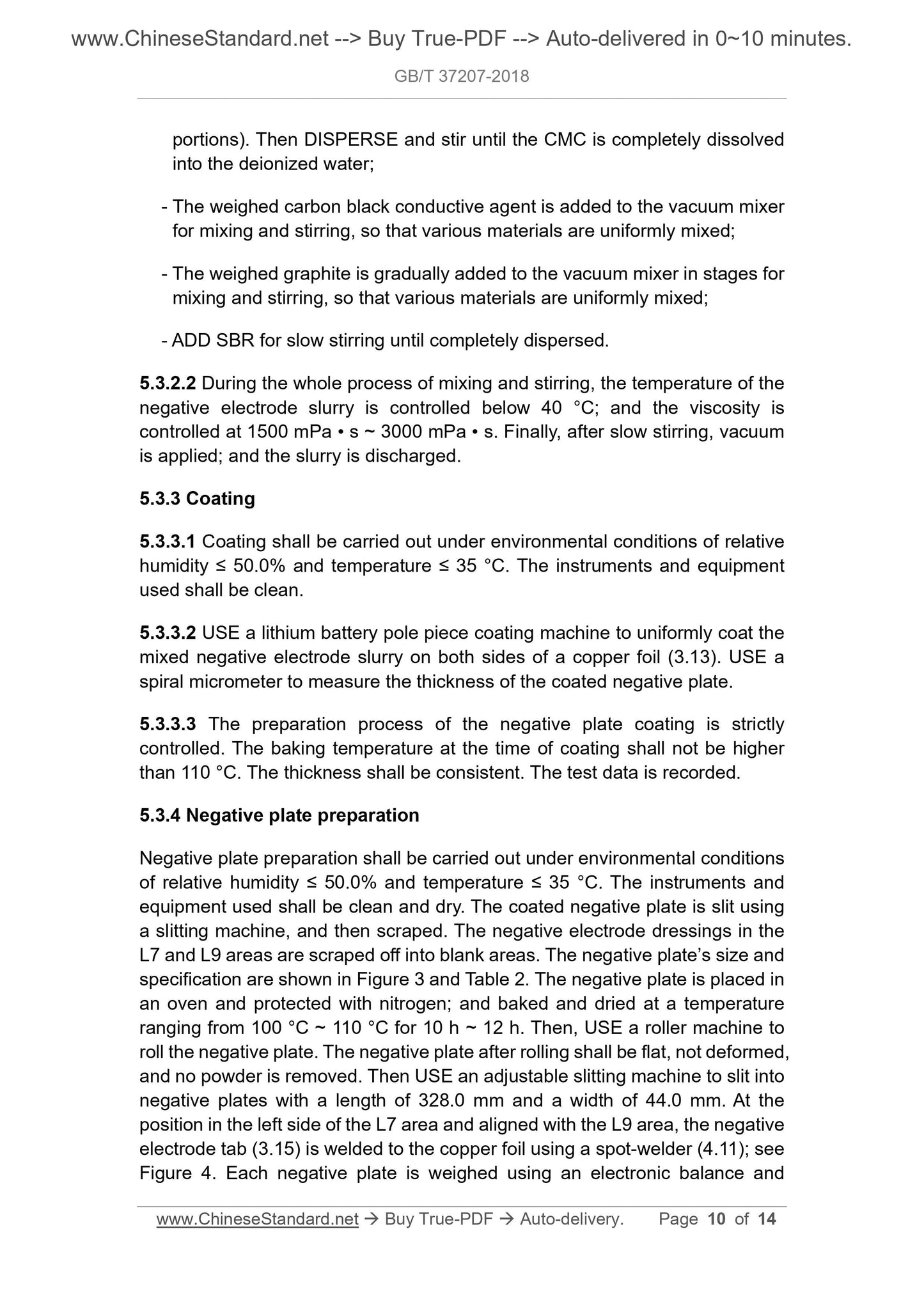

5.3.4 Negative plate preparation

Negative plate preparation shall be carried out under environmental conditions

of relative humidity ≤ 50.0% and temperature ≤ 35 °C. The instruments and

equipment used shall be clean and dry. The coated negative plate is slit using

a slitting machine, and then scraped. The negative electrode dressings in the

L7 and L9 areas are scraped off into blank areas. The negative plate’s size and

specification are shown in Figure 3 and Table 2. The negative plate is placed in

an oven and protected with nitrogen; and baked and dried at a temperature

ranging from 100 °C ~ 110 °C for 10 h ~ 12 h. Then, USE a roller machine to

roll the negative plate. The negative plate after rolling shall be flat, not deformed,

and no powder is removed. Then USE an adjustable slitting machine to slit into

negative plates with a length of 328.0 mm and a width of 44.0 mm. At the

position in the left side of the L7 area and aligned with the L9 area, the negative

electrode tab (3.15) is welded to the copper foil using a spot-welder (4.11); see

Figure 4. Each negative plate is weighed using an electronic balance and

GB/T 37207-2018

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.160

H 21

Electrochemical performance test of lithium nickel

cobalt manganese oxide - Test method for discharge

plateau capacity ratio and cycle life

ISSUED ON: DECEMBER 28, 2018

IMPLEMENTED ON: NOVEMBER 01, 2019

Issued by: State Administration for Market Regulation;

Standardization Administration of the PRC.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Reagents and materials ... 4

4 Instruments and equipment ... 6

5 Test procedures ... 7

6 Test report ... 13

Electrochemical performance test of lithium nickel

cobalt manganese oxide - Test method for discharge

plateau capacity ratio and cycle life

1 Scope

This Standard specifies the test method for discharge plateau capacity ratio and

cycle life for lithium nickel cobalt manganese oxide of lithium-ion battery

cathode material.

This Standard applies to the testing of discharge plateau capacity ratio and

cycle life for lithium nickel cobalt manganese oxide of lithium-ion battery

cathode material.

2 Normative references

The following documents are indispensable for the application of this document.

For the dated references, only the editions with the dates indicated are

applicable to this document. For the undated references, the latest edition

(including all the amendments) are applicable to this document.

GB/T 18287-2013 General specification of lithium-ion cells and batteries for

mobile phone

3 Reagents and materials

3.1 Lithium nickel cobalt manganese oxide: D50 is 7 μm ~ 15 μm. The specific

surface area is 0.2 m2/g ~ 1.0 m2/g. The sampling amount is 2.0 kg ~ 5.0 kg.

3.2 Graphite anode: D50 is 12.0 μm ~ 20.0 μm. The discharge specific capacity

of the first cycle is ≥ 320.0 mA • h/g. The charge-discharge coulombic

efficiency of the first cycle is ≥ 88.0%.

3.3 Lithium-ion battery diaphragm: Polyolefin porous diaphragm. Porosity 35.0%

~ 60.0%; air permeability 300 s/100 mL ~ 700 s/100 mL; average pore size ≤

1.0 μm; thickness 9.0 μm ~ 32.0 μm; length 720 mm±1.0 mm; width 47 mm±0.5

mm.

3.4 Lithium-ion battery electrolyte: Lithium-ion battery electrolyte consisting of

4 Instruments and equipment

4.1 Electronic balance: The range is 5000 g, accurate to 0.1 g.

4.2 Spiral micrometer.

4.3 Ruler: Made of stainless steel. The range is 100 cm, accurate to 0.5 mm.

4.4 Vacuum mixer.

4.5 Lithium battery pole piece coating machine.

4.6 Pole piece punching machine: Punching die size is φ50 mm ~ φ100 mm.

4.7 Slitting machine.

4.8 Roller machine.

4.9 Adjustable slitting machine.

4.10 Ultrasonic welder.

4.11 Spot-welder.

4.12 Winding machine.

4.13 Battery flat press.

4.14 Aluminum-plastic film heat sealing machine.

4.15 Argon glove box: Water vapor and oxygen content are not more than

0.0005%.

4.16 Injector: 20 mL.

4.17 Vacuum oven.

4.18 Electric blast drying oven.

4.19 Lithium-ion battery electrochemical performance tester.

4.20 Banister brush.

4.21 Rubber pipette bulb.

4.22 Oil-free vacuum pump.

the vacuum mixer in stages for mixing and stirring, so that various materials

are uniformly mixed.

5.2.2.2 During the whole process of mixing and stirring, the temperature of the

positive electrode slurry is controlled below 40 °C; and the viscosity is controlled

at 6000 mPa • s ~ 10000 mPa • s. Finally, after slow stirring, vacuum is applied;

and the slurry is discharged to enter the next process.

5.2.3 Coating

5.2.3.1 Coating shall be carried out under environmental conditions of relative

humidity ≤ 30.0% and temperature ≤ 35 °C. The instruments and equipment

used shall be clean.

5.2.3.2 USE a lithium battery pole piece coating machine (4.5) to uniformly coat

the mixed positive electrode slurry on both sides of an aluminum foil (3.12).

USE a spiral micrometer (4.2) to measure the thickness of the coated positive

plate.

5.2.3.3 The preparation process of the positive plate coating is strictly controlled.

The baking temperature at the time of coating shall not be higher than 130 °C.

The thickness shall be consistent. The test data is recorded.

5.2.4 Positive plate preparation

Positive plate preparation shall be carried out under environmental conditions

of relative humidity ≤ 30.0% and temperature ≤ 30 °C. The instruments and

equipment used shall be clean. USE a slitting machine (4.7) to slit the coated

positive plate. Then the dressings in the L1, L3, L4, and L6 areas of the positive

plate are scraped off into blank areas. The positive plate’s size and specification

are shown in Figure 1 and Table 1. The positive plate is placed in an oven and

protected with nitrogen (3.19); and baked and dried at a temperature ranging

from 110 °C ~ 120 °C for 10 h ~ 12 h. Then, USE a roller machine (4.8) to roll

the positive plate. The positive plate after rolling shall be flat; and after being

folded, shall not be broken or deformed, and no powder is removed. Then USE

an adjustable slitting machine (4.9) to slit into positive plates with a length of

362.0 mm and a width of 42.0 mm. Each positive plate is weighed using an

electronic balance; and the net weight of lithium nickel cobalt manganese oxide

in each plate is calculated, numbered and recorded one by one. At the position

in the left side of the L1 area and aligned with the L4 area, the positive electrode

tab (3.14) is welded to the aluminum foil using an ultrasonic welder (4.10); see

Figure 2.

portions). Then DISPERSE and stir until the CMC is completely dissolved

into the deionized water;

- The weighed carbon black conductive agent is added to the vacuum mixer

for mixing and stirring, so that various materials are uniformly mixed;

- The weighed graphite is gradually added to the vacuum mixer in stages for

mixing and stirring, so that various materials are uniformly mixed;

- ADD SBR for slow stirring until completely dispersed.

5.3.2.2 During the whole process o...

Delivery: 9 seconds. Download (& Email) true-PDF + Invoice.

Get Quotation: Click GB/T 37207-2018 (Self-service in 1-minute)

Historical versions (Master-website): GB/T 37207-2018

Preview True-PDF (Reload/Scroll-down if blank)

GB/T 37207-2018

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.160

H 21

Electrochemical performance test of lithium nickel

cobalt manganese oxide - Test method for discharge

plateau capacity ratio and cycle life

ISSUED ON: DECEMBER 28, 2018

IMPLEMENTED ON: NOVEMBER 01, 2019

Issued by: State Administration for Market Regulation;

Standardization Administration of the PRC.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Reagents and materials ... 4

4 Instruments and equipment ... 6

5 Test procedures ... 7

6 Test report ... 13

Electrochemical performance test of lithium nickel

cobalt manganese oxide - Test method for discharge

plateau capacity ratio and cycle life

1 Scope

This Standard specifies the test method for discharge plateau capacity ratio and

cycle life for lithium nickel cobalt manganese oxide of lithium-ion battery

cathode material.

This Standard applies to the testing of discharge plateau capacity ratio and

cycle life for lithium nickel cobalt manganese oxide of lithium-ion battery

cathode material.

2 Normative references

The following documents are indispensable for the application of this document.

For the dated references, only the editions with the dates indicated are

applicable to this document. For the undated references, the latest edition

(including all the amendments) are applicable to this document.

GB/T 18287-2013 General specification of lithium-ion cells and batteries for

mobile phone

3 Reagents and materials

3.1 Lithium nickel cobalt manganese oxide: D50 is 7 μm ~ 15 μm. The specific

surface area is 0.2 m2/g ~ 1.0 m2/g. The sampling amount is 2.0 kg ~ 5.0 kg.

3.2 Graphite anode: D50 is 12.0 μm ~ 20.0 μm. The discharge specific capacity

of the first cycle is ≥ 320.0 mA • h/g. The charge-discharge coulombic

efficiency of the first cycle is ≥ 88.0%.

3.3 Lithium-ion battery diaphragm: Polyolefin porous diaphragm. Porosity 35.0%

~ 60.0%; air permeability 300 s/100 mL ~ 700 s/100 mL; average pore size ≤

1.0 μm; thickness 9.0 μm ~ 32.0 μm; length 720 mm±1.0 mm; width 47 mm±0.5

mm.

3.4 Lithium-ion battery electrolyte: Lithium-ion battery electrolyte consisting of

4 Instruments and equipment

4.1 Electronic balance: The range is 5000 g, accurate to 0.1 g.

4.2 Spiral micrometer.

4.3 Ruler: Made of stainless steel. The range is 100 cm, accurate to 0.5 mm.

4.4 Vacuum mixer.

4.5 Lithium battery pole piece coating machine.

4.6 Pole piece punching machine: Punching die size is φ50 mm ~ φ100 mm.

4.7 Slitting machine.

4.8 Roller machine.

4.9 Adjustable slitting machine.

4.10 Ultrasonic welder.

4.11 Spot-welder.

4.12 Winding machine.

4.13 Battery flat press.

4.14 Aluminum-plastic film heat sealing machine.

4.15 Argon glove box: Water vapor and oxygen content are not more than

0.0005%.

4.16 Injector: 20 mL.

4.17 Vacuum oven.

4.18 Electric blast drying oven.

4.19 Lithium-ion battery electrochemical performance tester.

4.20 Banister brush.

4.21 Rubber pipette bulb.

4.22 Oil-free vacuum pump.

the vacuum mixer in stages for mixing and stirring, so that various materials

are uniformly mixed.

5.2.2.2 During the whole process of mixing and stirring, the temperature of the

positive electrode slurry is controlled below 40 °C; and the viscosity is controlled

at 6000 mPa • s ~ 10000 mPa • s. Finally, after slow stirring, vacuum is applied;

and the slurry is discharged to enter the next process.

5.2.3 Coating

5.2.3.1 Coating shall be carried out under environmental conditions of relative

humidity ≤ 30.0% and temperature ≤ 35 °C. The instruments and equipment

used shall be clean.

5.2.3.2 USE a lithium battery pole piece coating machine (4.5) to uniformly coat

the mixed positive electrode slurry on both sides of an aluminum foil (3.12).

USE a spiral micrometer (4.2) to measure the thickness of the coated positive

plate.

5.2.3.3 The preparation process of the positive plate coating is strictly controlled.

The baking temperature at the time of coating shall not be higher than 130 °C.

The thickness shall be consistent. The test data is recorded.

5.2.4 Positive plate preparation

Positive plate preparation shall be carried out under environmental conditions

of relative humidity ≤ 30.0% and temperature ≤ 30 °C. The instruments and

equipment used shall be clean. USE a slitting machine (4.7) to slit the coated

positive plate. Then the dressings in the L1, L3, L4, and L6 areas of the positive

plate are scraped off into blank areas. The positive plate’s size and specification

are shown in Figure 1 and Table 1. The positive plate is placed in an oven and

protected with nitrogen (3.19); and baked and dried at a temperature ranging

from 110 °C ~ 120 °C for 10 h ~ 12 h. Then, USE a roller machine (4.8) to roll

the positive plate. The positive plate after rolling shall be flat; and after being

folded, shall not be broken or deformed, and no powder is removed. Then USE

an adjustable slitting machine (4.9) to slit into positive plates with a length of

362.0 mm and a width of 42.0 mm. Each positive plate is weighed using an

electronic balance; and the net weight of lithium nickel cobalt manganese oxide

in each plate is calculated, numbered and recorded one by one. At the position

in the left side of the L1 area and aligned with the L4 area, the positive electrode

tab (3.14) is welded to the aluminum foil using an ultrasonic welder (4.10); see

Figure 2.

portions). Then DISPERSE and stir until the CMC is completely dissolved

into the deionized water;

- The weighed carbon black conductive agent is added to the vacuum mixer

for mixing and stirring, so that various materials are uniformly mixed;

- The weighed graphite is gradually added to the vacuum mixer in stages for

mixing and stirring, so that various materials are uniformly mixed;

- ADD SBR for slow stirring until completely dispersed.

5.3.2.2 During the whole process of mixing and stirring, the temperature of the

negative electrode slurry is controlled below 40 °C; and the viscosity is

controlled at 1500 mPa • s ~ 3000 mPa • s. Finally, after slow stirring, vacuum

is applied; and the slurry is discharged.

5.3.3 Coating

5.3.3.1 Coating shall be carried out under environmental conditions of relative

humidity ≤ 50.0% and temperature ≤ 35 °C. The instruments and equipment

used shall be clean.

5.3.3.2 USE a lithium battery pole piece coating machine to uniformly coat the

mixed negative electrode slurry on both sides of a copper foil (3.13). USE a

spiral micrometer to measure the thickness of the coated negative plate.

5.3.3.3 The preparation process of the negative plate coating is strictly

controlled. The baking temperature at the time of coating shall not be higher

than 110 °C. The thickness shall be consistent. The test data is recorded.

5.3.4 Negative plate preparation

Negative plate preparation shall be carried out under environmental conditions

of relative humidity ≤ 50.0% and temperature ≤ 35 °C. The instruments and

equipment used shall be clean and dry. The coated negative plate is slit using

a slitting machine, and then scraped. The negative electrode dressings in the

L7 and L9 areas are scraped off into blank areas. The negative plate’s size and

specification are shown in Figure 3 and Table 2. The negative plate is placed in

an oven and protected with nitrogen; and baked and dried at a temperature

ranging from 100 °C ~ 110 °C for 10 h ~ 12 h. Then, USE a roller machine to

roll the negative plate. The negative plate after rolling shall be flat, not deformed,

and no powder is removed. Then USE an adjustable slitting machine to slit into

negative plates with a length of 328.0 mm and a width of 44.0 mm. At the

position in the left side of the L7 area and aligned with the L9 area, the negative

electrode tab (3.15) is welded to the copper foil using a spot-welder (4.11); see

Figure 4. Each negative plate is weighed using an electronic balance and

GB/T 37207-2018

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.160

H 21

Electrochemical performance test of lithium nickel

cobalt manganese oxide - Test method for discharge

plateau capacity ratio and cycle life

ISSUED ON: DECEMBER 28, 2018

IMPLEMENTED ON: NOVEMBER 01, 2019

Issued by: State Administration for Market Regulation;

Standardization Administration of the PRC.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Reagents and materials ... 4

4 Instruments and equipment ... 6

5 Test procedures ... 7

6 Test report ... 13

Electrochemical performance test of lithium nickel

cobalt manganese oxide - Test method for discharge

plateau capacity ratio and cycle life

1 Scope

This Standard specifies the test method for discharge plateau capacity ratio and

cycle life for lithium nickel cobalt manganese oxide of lithium-ion battery

cathode material.

This Standard applies to the testing of discharge plateau capacity ratio and

cycle life for lithium nickel cobalt manganese oxide of lithium-ion battery

cathode material.

2 Normative references

The following documents are indispensable for the application of this document.

For the dated references, only the editions with the dates indicated are

applicable to this document. For the undated references, the latest edition

(including all the amendments) are applicable to this document.

GB/T 18287-2013 General specification of lithium-ion cells and batteries for

mobile phone

3 Reagents and materials

3.1 Lithium nickel cobalt manganese oxide: D50 is 7 μm ~ 15 μm. The specific

surface area is 0.2 m2/g ~ 1.0 m2/g. The sampling amount is 2.0 kg ~ 5.0 kg.

3.2 Graphite anode: D50 is 12.0 μm ~ 20.0 μm. The discharge specific capacity

of the first cycle is ≥ 320.0 mA • h/g. The charge-discharge coulombic

efficiency of the first cycle is ≥ 88.0%.

3.3 Lithium-ion battery diaphragm: Polyolefin porous diaphragm. Porosity 35.0%

~ 60.0%; air permeability 300 s/100 mL ~ 700 s/100 mL; average pore size ≤

1.0 μm; thickness 9.0 μm ~ 32.0 μm; length 720 mm±1.0 mm; width 47 mm±0.5

mm.

3.4 Lithium-ion battery electrolyte: Lithium-ion battery electrolyte consisting of

4 Instruments and equipment

4.1 Electronic balance: The range is 5000 g, accurate to 0.1 g.

4.2 Spiral micrometer.

4.3 Ruler: Made of stainless steel. The range is 100 cm, accurate to 0.5 mm.

4.4 Vacuum mixer.

4.5 Lithium battery pole piece coating machine.

4.6 Pole piece punching machine: Punching die size is φ50 mm ~ φ100 mm.

4.7 Slitting machine.

4.8 Roller machine.

4.9 Adjustable slitting machine.

4.10 Ultrasonic welder.

4.11 Spot-welder.

4.12 Winding machine.

4.13 Battery flat press.

4.14 Aluminum-plastic film heat sealing machine.

4.15 Argon glove box: Water vapor and oxygen content are not more than

0.0005%.

4.16 Injector: 20 mL.

4.17 Vacuum oven.

4.18 Electric blast drying oven.

4.19 Lithium-ion battery electrochemical performance tester.

4.20 Banister brush.

4.21 Rubber pipette bulb.

4.22 Oil-free vacuum pump.

the vacuum mixer in stages for mixing and stirring, so that various materials

are uniformly mixed.

5.2.2.2 During the whole process of mixing and stirring, the temperature of the

positive electrode slurry is controlled below 40 °C; and the viscosity is controlled

at 6000 mPa • s ~ 10000 mPa • s. Finally, after slow stirring, vacuum is applied;

and the slurry is discharged to enter the next process.

5.2.3 Coating

5.2.3.1 Coating shall be carried out under environmental conditions of relative

humidity ≤ 30.0% and temperature ≤ 35 °C. The instruments and equipment

used shall be clean.

5.2.3.2 USE a lithium battery pole piece coating machine (4.5) to uniformly coat

the mixed positive electrode slurry on both sides of an aluminum foil (3.12).

USE a spiral micrometer (4.2) to measure the thickness of the coated positive

plate.

5.2.3.3 The preparation process of the positive plate coating is strictly controlled.

The baking temperature at the time of coating shall not be higher than 130 °C.

The thickness shall be consistent. The test data is recorded.

5.2.4 Positive plate preparation

Positive plate preparation shall be carried out under environmental conditions

of relative humidity ≤ 30.0% and temperature ≤ 30 °C. The instruments and

equipment used shall be clean. USE a slitting machine (4.7) to slit the coated

positive plate. Then the dressings in the L1, L3, L4, and L6 areas of the positive

plate are scraped off into blank areas. The positive plate’s size and specification

are shown in Figure 1 and Table 1. The positive plate is placed in an oven and

protected with nitrogen (3.19); and baked and dried at a temperature ranging

from 110 °C ~ 120 °C for 10 h ~ 12 h. Then, USE a roller machine (4.8) to roll

the positive plate. The positive plate after rolling shall be flat; and after being

folded, shall not be broken or deformed, and no powder is removed. Then USE

an adjustable slitting machine (4.9) to slit into positive plates with a length of

362.0 mm and a width of 42.0 mm. Each positive plate is weighed using an

electronic balance; and the net weight of lithium nickel cobalt manganese oxide

in each plate is calculated, numbered and recorded one by one. At the position

in the left side of the L1 area and aligned with the L4 area, the positive electrode

tab (3.14) is welded to the aluminum foil using an ultrasonic welder (4.10); see

Figure 2.

portions). Then DISPERSE and stir until the CMC is completely dissolved

into the deionized water;

- The weighed carbon black conductive agent is added to the vacuum mixer

for mixing and stirring, so that various materials are uniformly mixed;

- The weighed graphite is gradually added to the vacuum mixer in stages for

mixing and stirring, so that various materials are uniformly mixed;

- ADD SBR for slow stirring until completely dispersed.

5.3.2.2 During the whole process o...

Share