1

/

of

8

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

GB/T 37829-2019 English PDF (GBT37829-2019)

GB/T 37829-2019 English PDF (GBT37829-2019)

Regular price

$230.00 USD

Regular price

Sale price

$230.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click GB/T 37829-2019

Historical versions: GB/T 37829-2019

Preview True-PDF (Reload/Scroll if blank)

GB/T 37829-2019: Iron ore fines in bulk -- Determination of transportable moisture limits -- Flow-table method

GB/T 37829-2019

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 73.060.10

D 31

Iron Ore Fines in Bulk – Determination of

Transportable Moisture Limits – Flow-Table Method

ISSUED ON: AUGUST 30, 2019

IMPLEMENTED ON: JULY 01, 2020

Issued by: State Administration for Market Regulation;

Standardization Administration of PRC.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative References ... 4

3 Terms and Definitions ... 5

4 Principle ... 5

5 Instrument ... 5

6 Preparation of the Specimen ... 6

7 Pre-Test of Flow Moisture Point ... 7

8 Main Test of Flow Moisture Point ... 8

9 Calculation of Flow Moisture Point ... 9

10 Calculation of Transportable Moisture Limits (TML) ... 9

11 Precision ... 10

12 Test Report ... 10

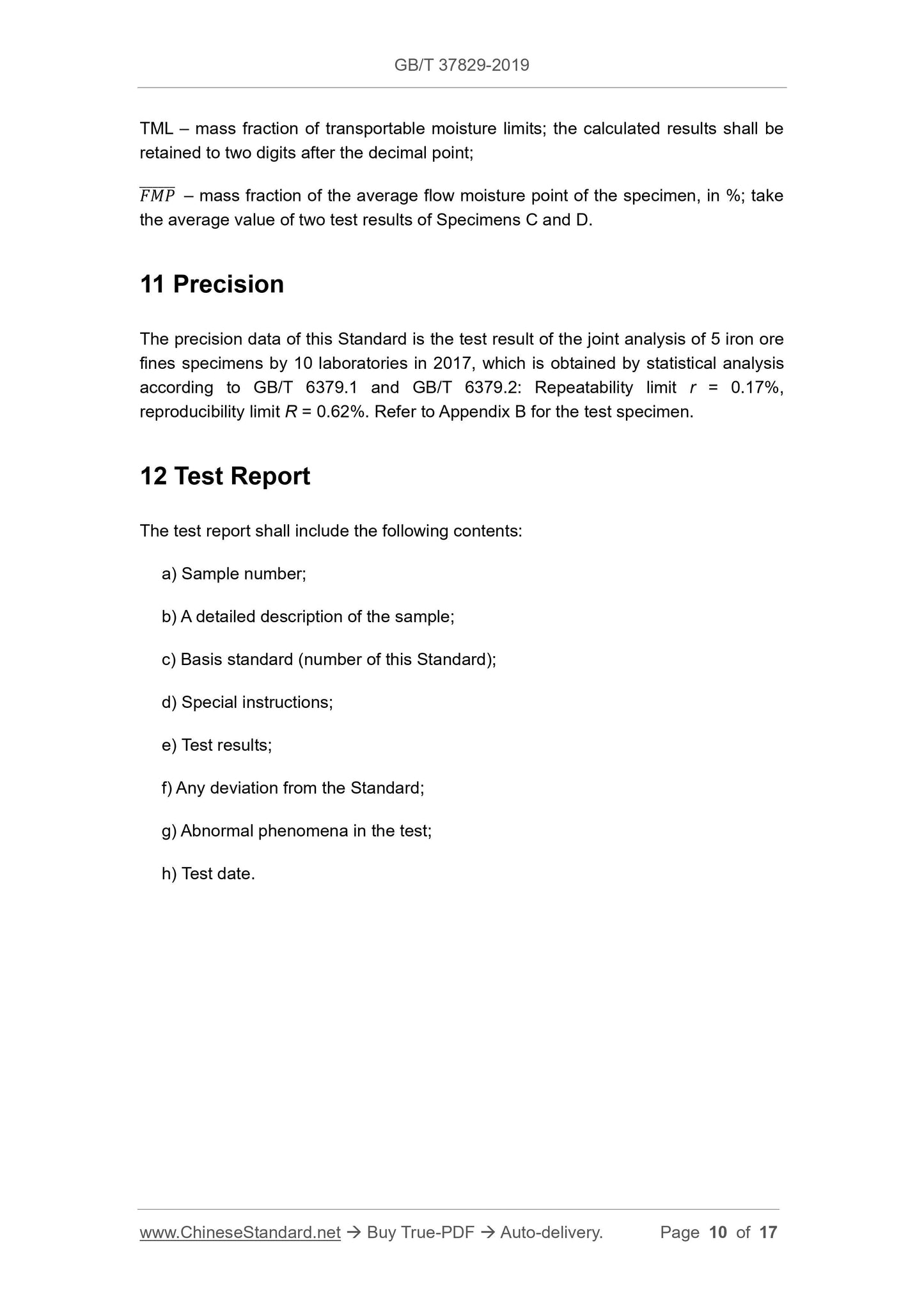

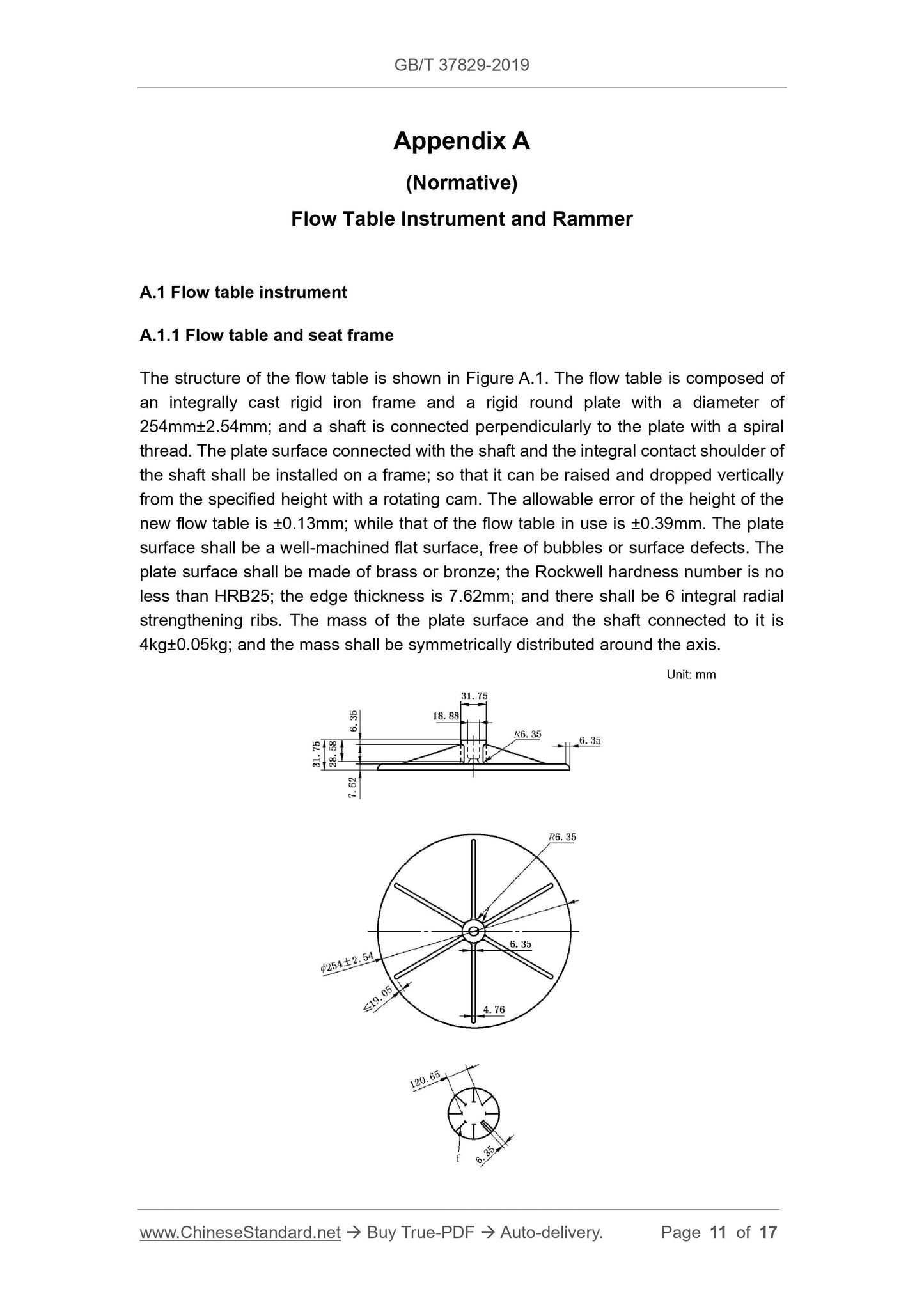

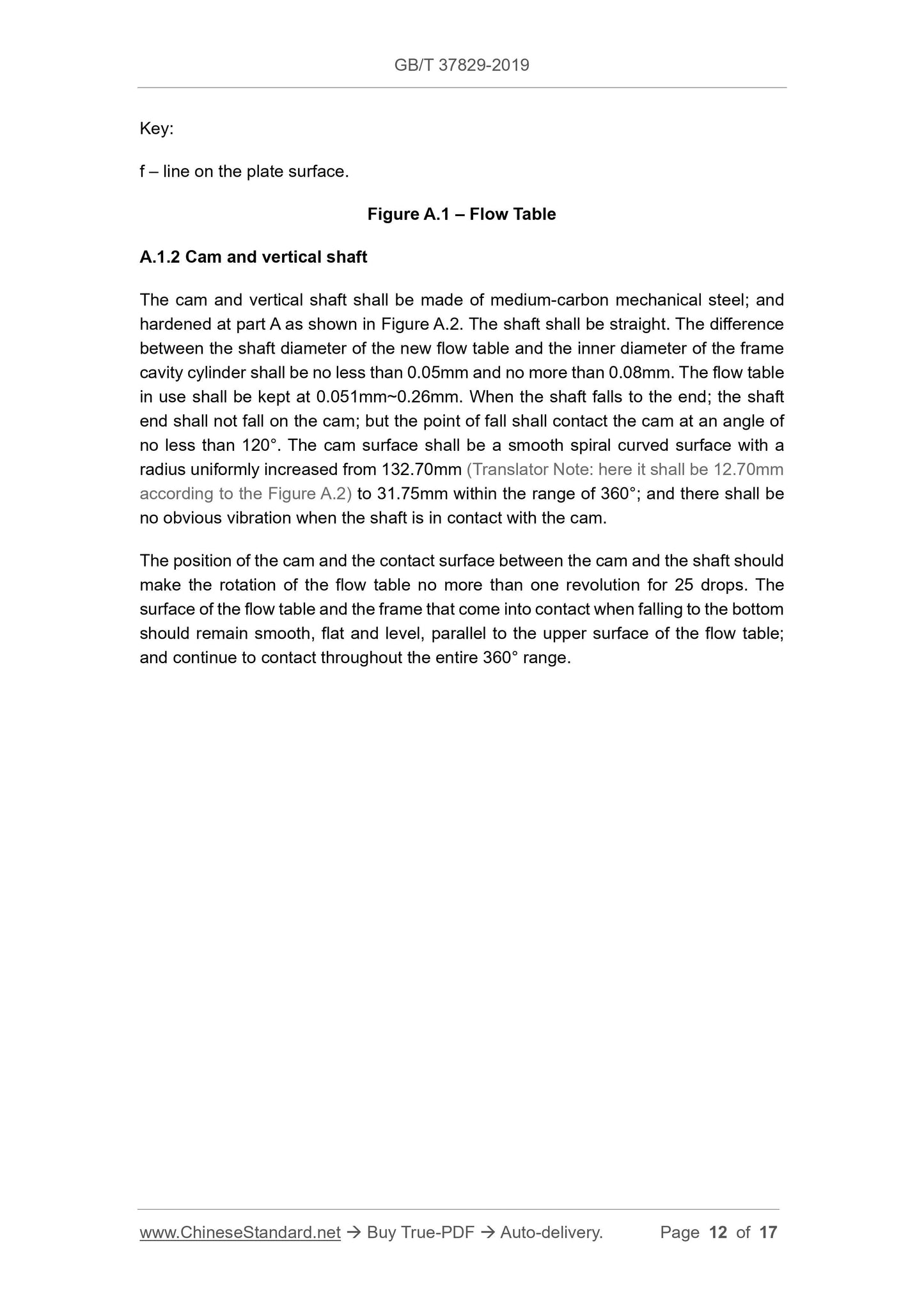

Appendix A (Normative) Flow Table Instrument and Rammer ... 11

Appendix B (Informative) Specimen for Precision Test ... 17

Iron Ore Fines in Bulk – Determination of

Transportable Moisture Limits – Flow-Table Method

WARNING: Personnel using this Standard shall have practical experience in

working in formal laboratory. This Standard does not address all possible safety

issues. The user is responsible for taking appropriate safety and health

measures and ensuring compliance with the conditions stipulated by relevant

national laws and regulations.

1 Scope

This Standard specifies the flow-table test method for the transportable moisture limit

(TML) of iron ore fines in bulk.

This Standard is applicable to the determination of the transportable moisture limit of

iron ore fines with a nominal maximum particle size of 1 mm; and iron ore fines with a

nominal maximum particle size of 1 mm ~ 7 mm can be used as a reference.

2 Normative References

The following documents are essential to the application of this document. For the

dated documents, only the versions with the dates indicated are applicable to this

document; for the undated documents, only the latest version (including all the

amendments) is applicable to this document.

GB/T 6379.1 Accuracy (Trueness and Precision) of Measurement Methods and

Results - Part 1: General Principles and Definitions

GB/T 6379.2 Accuracy (Trueness and Precision) of Measurement Methods and

Results - Part 2: Basic Method for the Determination of Repeatability and

Reproducibility of a Standard Measurement Method

GB/T 10322.1 Iron Ores - Sampling and Sample Preparation Procedures

GB/T 10322.5 Iron Ores - Determination of the Moisture Content of a Lot

GB/T 20565 Iron Ores and Direct Reduced Iron - Vocabulary

specified number of test samples with a thickness not exceeding 31.5mm.

5.4 Measuring cylinder: A glass measuring cylinder with a scale of 100mL and 10mL

respectively.

5.5 Mixing container: A mixing container capable of satisfying about 5kg of iron ore

fines or an automatic mixer of a considerable size.

5.6 Balance: The maximum weighable is no less than 2kg, accurate to 0.1g.

5.7 Oven: With automatic temperature control and blast device, the temperature can

be controlled at 105°C±5°C.

5.8 Vernier calliper, accurate to 0.1mm.

6 Preparation of the Specimen

6.1 General requirements

The sample shall be carried out in a room free from changes in temperature, airflow

and humidity; and the sample preparation phase and the test process shall be

completed in the same day. In addition, the container for the specimen shall be a closed

container or covered with plastic film and other suitable materials. In order to prevent

possible changes in the fluidization characteristics of bulk iron ore fines, samples must

not be broken during sample preparation.

6.2 Preparation of the specimen

Take samples according to GB/T 10322.1. Put a representative specimen of iron ore

fines into a mixing container and stir thoroughly; and then divide the specimen into a

specimen for original moisture measurement (Specimen A), a pre-test specimen

(Specimen B) and specimens for two parallel main tests (Specimens C and D). The

amount of the specimen for the original moisture measurement is about 1kg; weigh it

immediately; and determine the moisture content of the specimen "on receipt"

according to GB/T 10322.5. The pre-test and the single main test respectively require

the specimen volume to be no less than 3 times the mould capacity. The sample

volume varies with the mass ratio of iron ore fines, which is about 3kg respectively.

6.3 Filling the round mould

Place the round mould in the centre of the flow table; and fill the round mould with the

specimen thoroughly stirred in the mixing container in three layers. The first layer after

tamping shall account for about one-third of the depth of the round mould. The second

layer after tamping shall reach about two-thirds of the depth of the round mould. And

the last layer after tamping of specimen should be filled to about 5mm down from the

top of the round mould.

into the mixer container; and spray 5mL~10mL or more of water on the surface of the

specimen; and then stir the specimen evenly. Repeat procedures 6.3 ~ 6.5 until it

reaches a fluid state.

7.2.2 The vibration of the flow table causes the particles to be re-embedded to form a

compact state, which increases the percentage of water content in the specimen in a

certain state. When the moisture is saturated in the compact specimen and the

specimen is plastically deformed, that is, the flow state is generated; it is considered

that the moisture content of the specimen has reached the flow moisture point. At this

time, the truncated cone shall deform to form a convex or concave surface. In most

cases, measuring deformation helps to determine whether plastic flow has occurred.

The following states are used as one of the characteristics for judging whether the

specimen has reached the plastic flow state:

a) Use a vernier calliper to measure the feature that the diameter of any part of the

truncated cone increases by more than 3mm;

b) Add water equivalent to 0.4%~0.5% moisture content; repeat the procedures

6.3~6.5; vibrate the flow table for 25 times. Measure the bottom or middle

diameter of the truncated cone; for the first time, the diameter shall increase by

1mm~5mm; add water again; then the bottom diameter shall increase by

5mm~10mm;

c) When the water content (increasing gradually) is close to the flow water point,

the truncated cone shall have a tendency to stick in the round mould;

d) When the truncated cone is pushed out of the flow table, wet marks (streaks)

shall be left on the flow table, which indicates that the water content may exceed

the flow moisture point; but the invisible wet marks (streaks) do not indicate that

the water content is lower than the flow moisture point.

8 Main Test of Flow Moisture Point

After reaching the fluid state in the pre-test, adjust the water content of Specimen C

and Specimen D to be 1% to 2% lower than the last water content that did not cause

fluidization in the pre-test. The final test is carried out by Specimen C and Specimen

D with adjusted water content. The method is the same as the pre-test, but the amount

of water added each time does not exceed 0.5%. The lower the flow moisture point in

the pre-test, the smaller the amount of the added water.

When the specimen taken from Specimen C and Specimen D are adjusted to start

plastic flow or that of after a little water is added; the specimen in the round mould can

be placed in a clean container of known mass and weighed immediately; and test the...

Get QUOTATION in 1-minute: Click GB/T 37829-2019

Historical versions: GB/T 37829-2019

Preview True-PDF (Reload/Scroll if blank)

GB/T 37829-2019: Iron ore fines in bulk -- Determination of transportable moisture limits -- Flow-table method

GB/T 37829-2019

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 73.060.10

D 31

Iron Ore Fines in Bulk – Determination of

Transportable Moisture Limits – Flow-Table Method

ISSUED ON: AUGUST 30, 2019

IMPLEMENTED ON: JULY 01, 2020

Issued by: State Administration for Market Regulation;

Standardization Administration of PRC.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative References ... 4

3 Terms and Definitions ... 5

4 Principle ... 5

5 Instrument ... 5

6 Preparation of the Specimen ... 6

7 Pre-Test of Flow Moisture Point ... 7

8 Main Test of Flow Moisture Point ... 8

9 Calculation of Flow Moisture Point ... 9

10 Calculation of Transportable Moisture Limits (TML) ... 9

11 Precision ... 10

12 Test Report ... 10

Appendix A (Normative) Flow Table Instrument and Rammer ... 11

Appendix B (Informative) Specimen for Precision Test ... 17

Iron Ore Fines in Bulk – Determination of

Transportable Moisture Limits – Flow-Table Method

WARNING: Personnel using this Standard shall have practical experience in

working in formal laboratory. This Standard does not address all possible safety

issues. The user is responsible for taking appropriate safety and health

measures and ensuring compliance with the conditions stipulated by relevant

national laws and regulations.

1 Scope

This Standard specifies the flow-table test method for the transportable moisture limit

(TML) of iron ore fines in bulk.

This Standard is applicable to the determination of the transportable moisture limit of

iron ore fines with a nominal maximum particle size of 1 mm; and iron ore fines with a

nominal maximum particle size of 1 mm ~ 7 mm can be used as a reference.

2 Normative References

The following documents are essential to the application of this document. For the

dated documents, only the versions with the dates indicated are applicable to this

document; for the undated documents, only the latest version (including all the

amendments) is applicable to this document.

GB/T 6379.1 Accuracy (Trueness and Precision) of Measurement Methods and

Results - Part 1: General Principles and Definitions

GB/T 6379.2 Accuracy (Trueness and Precision) of Measurement Methods and

Results - Part 2: Basic Method for the Determination of Repeatability and

Reproducibility of a Standard Measurement Method

GB/T 10322.1 Iron Ores - Sampling and Sample Preparation Procedures

GB/T 10322.5 Iron Ores - Determination of the Moisture Content of a Lot

GB/T 20565 Iron Ores and Direct Reduced Iron - Vocabulary

specified number of test samples with a thickness not exceeding 31.5mm.

5.4 Measuring cylinder: A glass measuring cylinder with a scale of 100mL and 10mL

respectively.

5.5 Mixing container: A mixing container capable of satisfying about 5kg of iron ore

fines or an automatic mixer of a considerable size.

5.6 Balance: The maximum weighable is no less than 2kg, accurate to 0.1g.

5.7 Oven: With automatic temperature control and blast device, the temperature can

be controlled at 105°C±5°C.

5.8 Vernier calliper, accurate to 0.1mm.

6 Preparation of the Specimen

6.1 General requirements

The sample shall be carried out in a room free from changes in temperature, airflow

and humidity; and the sample preparation phase and the test process shall be

completed in the same day. In addition, the container for the specimen shall be a closed

container or covered with plastic film and other suitable materials. In order to prevent

possible changes in the fluidization characteristics of bulk iron ore fines, samples must

not be broken during sample preparation.

6.2 Preparation of the specimen

Take samples according to GB/T 10322.1. Put a representative specimen of iron ore

fines into a mixing container and stir thoroughly; and then divide the specimen into a

specimen for original moisture measurement (Specimen A), a pre-test specimen

(Specimen B) and specimens for two parallel main tests (Specimens C and D). The

amount of the specimen for the original moisture measurement is about 1kg; weigh it

immediately; and determine the moisture content of the specimen "on receipt"

according to GB/T 10322.5. The pre-test and the single main test respectively require

the specimen volume to be no less than 3 times the mould capacity. The sample

volume varies with the mass ratio of iron ore fines, which is about 3kg respectively.

6.3 Filling the round mould

Place the round mould in the centre of the flow table; and fill the round mould with the

specimen thoroughly stirred in the mixing container in three layers. The first layer after

tamping shall account for about one-third of the depth of the round mould. The second

layer after tamping shall reach about two-thirds of the depth of the round mould. And

the last layer after tamping of specimen should be filled to about 5mm down from the

top of the round mould.

into the mixer container; and spray 5mL~10mL or more of water on the surface of the

specimen; and then stir the specimen evenly. Repeat procedures 6.3 ~ 6.5 until it

reaches a fluid state.

7.2.2 The vibration of the flow table causes the particles to be re-embedded to form a

compact state, which increases the percentage of water content in the specimen in a

certain state. When the moisture is saturated in the compact specimen and the

specimen is plastically deformed, that is, the flow state is generated; it is considered

that the moisture content of the specimen has reached the flow moisture point. At this

time, the truncated cone shall deform to form a convex or concave surface. In most

cases, measuring deformation helps to determine whether plastic flow has occurred.

The following states are used as one of the characteristics for judging whether the

specimen has reached the plastic flow state:

a) Use a vernier calliper to measure the feature that the diameter of any part of the

truncated cone increases by more than 3mm;

b) Add water equivalent to 0.4%~0.5% moisture content; repeat the procedures

6.3~6.5; vibrate the flow table for 25 times. Measure the bottom or middle

diameter of the truncated cone; for the first time, the diameter shall increase by

1mm~5mm; add water again; then the bottom diameter shall increase by

5mm~10mm;

c) When the water content (increasing gradually) is close to the flow water point,

the truncated cone shall have a tendency to stick in the round mould;

d) When the truncated cone is pushed out of the flow table, wet marks (streaks)

shall be left on the flow table, which indicates that the water content may exceed

the flow moisture point; but the invisible wet marks (streaks) do not indicate that

the water content is lower than the flow moisture point.

8 Main Test of Flow Moisture Point

After reaching the fluid state in the pre-test, adjust the water content of Specimen C

and Specimen D to be 1% to 2% lower than the last water content that did not cause

fluidization in the pre-test. The final test is carried out by Specimen C and Specimen

D with adjusted water content. The method is the same as the pre-test, but the amount

of water added each time does not exceed 0.5%. The lower the flow moisture point in

the pre-test, the smaller the amount of the added water.

When the specimen taken from Specimen C and Specimen D are adjusted to start

plastic flow or that of after a little water is added; the specimen in the round mould can

be placed in a clean container of known mass and weighed immediately; and test the...

Share