1

/

of

5

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

GB/T 38473-2020 English PDF (GB/T38473-2020)

GB/T 38473-2020 English PDF (GB/T38473-2020)

Regular price

$145.00 USD

Regular price

Sale price

$145.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click GB/T 38473-2020

Historical versions: GB/T 38473-2020

Preview True-PDF (Reload/Scroll if blank)

GB/T 38473-2020: Textiles -- Determination of drying rate in dynamic state (sweating guarded-hotplate test)

GB/T 38473-2020

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 59.080.30

W 04

Textiles - Determination of drying rate in dynamic

state (sweating guarded-hotplate test)

(ISO 13029:2012, Textiles - Determination of drying rate in dynamic state by

the modified sweating-guarded hotplate, MOD)

ISSUED ON: MARCH 06, 2020

IMPLEMENTED ON: OCTOBER 01, 2020

Issued by: State Administration for Market Regulation;

Standardization Administration of the People’s Republic of

China.

Table of Contents

Foreword ... 3

Introduction ... 5

1 Scope ... 6

2 Normative references ... 6

3 Terms and definitions ... 6

4 Symbols and units ... 7

5 Principle ... 7

6 Instruments ... 8

7 Test procedure ... 9

8 Test report ... 11

Appendix A (Informative) Examples of test results ... 12

References ... 13

Textiles - Determination of drying rate in dynamic

state (sweating guarded-hotplate test)

1 Scope

This Standard specifies the method of using sweating guarded-hotplate to

measure the drying rate of fabrics in dynamic state.

This Standard applies to all kinds of fabrics and products for sports and leisure

or underwear that are in direct contact with the skin.

This Standard does not apply to fabrics impervious to water vapour or having a

thickness greater than 5 mm.

2 Normative references

The following documents are indispensable for the application of this document.

For dated references, only the dated version applies to this document. For

undated references, the latest edition (including all amendments) applies to this

document.

GB/T 6682, Water for analytical laboratory use - Specification and test

methods (GB/T 6682-2008, ISO 3696:1987, MOD)

GB/T 11048, Textiles - Physiological effects - Measurement of thermal and

water-vapour resistance under steady-state conditions (sweating guarded-

hotplate test) (GB/T 11048-2018, ISO 11092:2014, MOD)

3 Terms and definitions

Terms and definitions determined by GB/T 11048 and the following ones are

applicable to this document.

3.1 Moisture management

The characteristics of textile fabrics that can control or increase the rate of

sweat absorption and evaporation.

Note 1: Moisture management may include the characteristics that the contact

surfaces of the fabric with the skin and air have different diffusion rates.

Note 2: It is different from the dynamic moisture transfer test of static dry; see

the test method of GB/T 21655.2.

3.2 Drying rate

Under constant temperature, the time that is required for the sample to reach

its initial water vapour stable state after being wetted by 5 mL of water.

3.3 Dynamic state

Through continuous adjustment, reach the drying state under the specified heat

and humidity gradient.

3.4 Water vapour resistance

Ret

The ratio OF the water vapour pressure difference on both sides of the sample

TO the evaporation heat flux per unit area that passes vertically through the

sample.

Note 1: evaporative heat flux can be composed of diffusion and convection.

Note 2: water vapour resistance Ret is measured in square meters Pascals per

watt (m2·Pa/W), which means the latent heat flux of evaporation

through the specified area when the textile is under a stable water

vapour pressure gradient condition.

Note 3: water vapour resistance Ret is measured according to GB/T 11048.

4 Symbols and units

Ta: the temperature of the air in the climate chamber, in Celsius degrees (°C).

Tm: the temperature of the test board, in Celsius degrees (°C).

Ts: the temperature of the thermal guard ring, in Celsius degrees (°C).

RH: the relative humidity in the climate chamber, in %.

H: the heating power that is provided to the test board, in watts (W).

5 Principle

Perform the test in the test environment for water vapour resistance test of GB/T

11048; simulate the dynamic environment of constant temperature of the skin

surface and continuous permeation of sweat when the fabric is in contact with

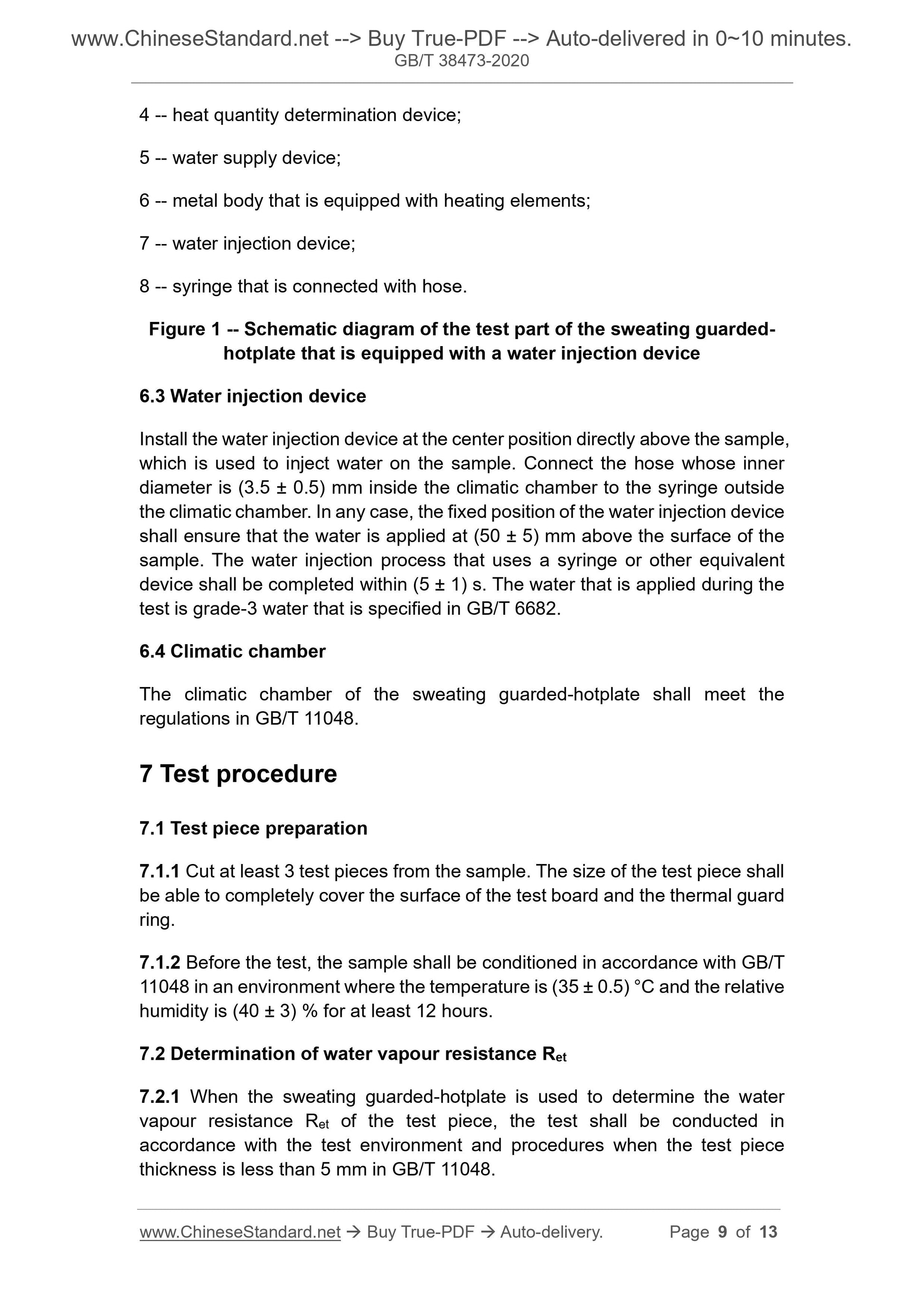

4 -- heat quantity determination device;

5 -- water supply device;

6 -- metal body that is equipped with heating elements;

7 -- water injection device;

8 -- syringe that is connected with hose.

Figure 1 -- Schematic diagram of the test part of the sweating guarded-

hotplate that is equipped with a water injection device

6.3 Water injection device

Install the water injection device at the center position directly above the sample,

which is used to inject water on the sample. Connect the hose whose inner

diameter is (3.5 ± 0.5) mm inside the climatic chamber to the syringe outside

the climatic chamber. In any case, the fixed position of the water injection device

shall ensure that the water is applied at (50 ± 5) mm above the surface of the

sample. The water injection process that uses a syringe or other equivalent

device shall be completed within (5 ± 1) s. The water that is applied during the

test is grade-3 water that is specified in GB/T 6682.

6.4 Climatic chamber

The climatic chamber of the sweating guarded-hotplate shall meet the

regulations in GB/T 11048.

7 Test procedure

7.1 Test piece preparation

7.1.1 Cut at least 3 test pieces from the sample. The size of the test piece shall

be able to completely cover the surface of the test board and the thermal guard

ring.

7.1.2 Before the test, the sample shall be conditioned in accordance with GB/T

11048 in an environment where the temperature is (35 ± 0.5) °C and the relative

humidity is (40 ± 3) % for at least 12 hours.

7.2 Determination of water vapour resistance Ret

7.2.1 When the sweating guarded-hotplate is used to determine the water

vapour resistance Ret of the test piece, the test shall be conducted in

accordance with the test environment and procedures when the test piece

thickness is less than 5 mm in GB/T 11048.

Get QUOTATION in 1-minute: Click GB/T 38473-2020

Historical versions: GB/T 38473-2020

Preview True-PDF (Reload/Scroll if blank)

GB/T 38473-2020: Textiles -- Determination of drying rate in dynamic state (sweating guarded-hotplate test)

GB/T 38473-2020

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 59.080.30

W 04

Textiles - Determination of drying rate in dynamic

state (sweating guarded-hotplate test)

(ISO 13029:2012, Textiles - Determination of drying rate in dynamic state by

the modified sweating-guarded hotplate, MOD)

ISSUED ON: MARCH 06, 2020

IMPLEMENTED ON: OCTOBER 01, 2020

Issued by: State Administration for Market Regulation;

Standardization Administration of the People’s Republic of

China.

Table of Contents

Foreword ... 3

Introduction ... 5

1 Scope ... 6

2 Normative references ... 6

3 Terms and definitions ... 6

4 Symbols and units ... 7

5 Principle ... 7

6 Instruments ... 8

7 Test procedure ... 9

8 Test report ... 11

Appendix A (Informative) Examples of test results ... 12

References ... 13

Textiles - Determination of drying rate in dynamic

state (sweating guarded-hotplate test)

1 Scope

This Standard specifies the method of using sweating guarded-hotplate to

measure the drying rate of fabrics in dynamic state.

This Standard applies to all kinds of fabrics and products for sports and leisure

or underwear that are in direct contact with the skin.

This Standard does not apply to fabrics impervious to water vapour or having a

thickness greater than 5 mm.

2 Normative references

The following documents are indispensable for the application of this document.

For dated references, only the dated version applies to this document. For

undated references, the latest edition (including all amendments) applies to this

document.

GB/T 6682, Water for analytical laboratory use - Specification and test

methods (GB/T 6682-2008, ISO 3696:1987, MOD)

GB/T 11048, Textiles - Physiological effects - Measurement of thermal and

water-vapour resistance under steady-state conditions (sweating guarded-

hotplate test) (GB/T 11048-2018, ISO 11092:2014, MOD)

3 Terms and definitions

Terms and definitions determined by GB/T 11048 and the following ones are

applicable to this document.

3.1 Moisture management

The characteristics of textile fabrics that can control or increase the rate of

sweat absorption and evaporation.

Note 1: Moisture management may include the characteristics that the contact

surfaces of the fabric with the skin and air have different diffusion rates.

Note 2: It is different from the dynamic moisture transfer test of static dry; see

the test method of GB/T 21655.2.

3.2 Drying rate

Under constant temperature, the time that is required for the sample to reach

its initial water vapour stable state after being wetted by 5 mL of water.

3.3 Dynamic state

Through continuous adjustment, reach the drying state under the specified heat

and humidity gradient.

3.4 Water vapour resistance

Ret

The ratio OF the water vapour pressure difference on both sides of the sample

TO the evaporation heat flux per unit area that passes vertically through the

sample.

Note 1: evaporative heat flux can be composed of diffusion and convection.

Note 2: water vapour resistance Ret is measured in square meters Pascals per

watt (m2·Pa/W), which means the latent heat flux of evaporation

through the specified area when the textile is under a stable water

vapour pressure gradient condition.

Note 3: water vapour resistance Ret is measured according to GB/T 11048.

4 Symbols and units

Ta: the temperature of the air in the climate chamber, in Celsius degrees (°C).

Tm: the temperature of the test board, in Celsius degrees (°C).

Ts: the temperature of the thermal guard ring, in Celsius degrees (°C).

RH: the relative humidity in the climate chamber, in %.

H: the heating power that is provided to the test board, in watts (W).

5 Principle

Perform the test in the test environment for water vapour resistance test of GB/T

11048; simulate the dynamic environment of constant temperature of the skin

surface and continuous permeation of sweat when the fabric is in contact with

4 -- heat quantity determination device;

5 -- water supply device;

6 -- metal body that is equipped with heating elements;

7 -- water injection device;

8 -- syringe that is connected with hose.

Figure 1 -- Schematic diagram of the test part of the sweating guarded-

hotplate that is equipped with a water injection device

6.3 Water injection device

Install the water injection device at the center position directly above the sample,

which is used to inject water on the sample. Connect the hose whose inner

diameter is (3.5 ± 0.5) mm inside the climatic chamber to the syringe outside

the climatic chamber. In any case, the fixed position of the water injection device

shall ensure that the water is applied at (50 ± 5) mm above the surface of the

sample. The water injection process that uses a syringe or other equivalent

device shall be completed within (5 ± 1) s. The water that is applied during the

test is grade-3 water that is specified in GB/T 6682.

6.4 Climatic chamber

The climatic chamber of the sweating guarded-hotplate shall meet the

regulations in GB/T 11048.

7 Test procedure

7.1 Test piece preparation

7.1.1 Cut at least 3 test pieces from the sample. The size of the test piece shall

be able to completely cover the surface of the test board and the thermal guard

ring.

7.1.2 Before the test, the sample shall be conditioned in accordance with GB/T

11048 in an environment where the temperature is (35 ± 0.5) °C and the relative

humidity is (40 ± 3) % for at least 12 hours.

7.2 Determination of water vapour resistance Ret

7.2.1 When the sweating guarded-hotplate is used to determine the water

vapour resistance Ret of the test piece, the test shall be conducted in

accordance with the test environment and procedures when the test piece

thickness is less than 5 mm in GB/T 11048.

Share