1

/

of

8

PayPal, credit cards. Download editable-PDF & invoice in 1 second!

GB/T 39861-2021 English PDF (GBT39861-2021)

GB/T 39861-2021 English PDF (GBT39861-2021)

Regular price

$170.00 USD

Regular price

Sale price

$170.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click GB/T 39861-2021

Historical versions: GB/T 39861-2021

Preview True-PDF (Reload/Scroll if blank)

GB/T 39861-2021: Electrochemical performance test of lithium manganese oxide -- Test method for discharge plateau capacity ratio and cycle life

GB/T 39861-2021

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.160

CCS H 21

Electrochemical Performance Test of Lithium

Manganese Oxide - Test Method for Discharge Plateau

Capacity Ratio and Cycle Life

ISSUED ON: MARCH 9, 2021

IMPLEMENTED ON: OCTOBER 1, 2021

Issued by: State Administration for Market Regulation;

Standardization Administration of the People’s Republic of

China.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative References ... 4

3 Terms and Definitions ... 4

4 Test Conditions ... 4

5 Reagents or Materials ... 5

6 Instruments and Equipment ... 6

7 Test Procedures ... 7

8 Test Data Processing ... 15

9 Test Report ... 16

Electrochemical Performance Test of Lithium

Manganese Oxide - Test Method for Discharge Plateau

Capacity Ratio and Cycle Life

1 Scope

This Standard specifies the test method for discharge plateau capacity ratio and cycle

life of lithium manganese oxide as the cathode material of lithium ion batteries.

This Standard is applicable to the test of discharge plateau capacity ratio and cycle life

of lithium manganese oxide as the cathode material of lithium ion batteries.

2 Normative References

The content in the following document constitutes indispensable clauses of this

document through normative references in the text. In terms of references with a

specified date, only versions with a specified date are applicable to this document. In

terms of references without a specified date, the latest version (including all the

modifications) is applicable to this document.

GB/T 18287 General Specification of Lithium-ion Cells and Batteries for Mobile Phone

3 Terms and Definitions

The following terms and definitions are applicable to this document.

3.1 Solid Content

Solid content refers to the mass fraction (of the total amount) of the remaining part of

emulsion or paint after drying under the specified conditions.

4 Test Conditions

When there are no special instructions, the various test procedures specified in this

document should be carried out in a drying room (the environmental dew-point

temperature is ≤ -20 °C). For the situation where there is no drying room, the various

test procedures shall be carried out under the following environmental conditions: the

relative humidity is ≤ 20.0% and the temperature is 20 °C ~ 30 °C.

160 μm; the thickness of the aluminum foil coated on the surface of the aluminum-

plastic film is: 30 μm ~ 40 μm.

5.17 Insulating glue: with a length of 53.0 mm ± 1.0 mm.

5.18 Nitrogen: purity (volume fraction) ≥ 99.9%.

5.19 Electrolyte for lithium ion batteries: composed of a solution (with a concentration

of 1 mol/L) of lithium hexafluorophosphate (LiPF6) dissolved in an organic solvent (the

volume ratio of ethylene carbonate EC, dimethyl carbonate DMC, ethyl methyl

carbonate EMC is 1 : 1 : 1); moisture content ≤ 0.0015%; free acid (HF) ≤ 0.003%;

density: 1.23 g/cm3 ± 0.02 g/cm3; chroma ≤ 50 Hazen.

6 Instruments and Equipment

6.1 Electronic balance: with a measuring range of 3,000 g and a division value of 0.01

g.

6.2 Electronic balance: with a measuring range of 100 g and a division value of 0.0001

g.

6.3 Drying oven.

6.4 Desiccator.

6.5 Sanding machine.

6.6 Planetary stirrer.

6.7 Coating machine: the length of drying tunnel is > 2.0 m.

6.8 Vacuum oven.

6.9 Cutting machine.

6.10 Banister brush.

6.11 Adjustable slitting machine.

6.12 Sheet-punching machine: the mold is a square with a side length of 10 cm or a

circle with a diameter of 10 cm.

6.13 Desktop digital thickness gauge: with a resolution of 1 μm.

6.14 Roller machine: exclusive to lithium batteries.

6.15 Ruler: stainless-steel; with a measuring range of 100 cm, accurate to 0.5 mm.

Add the weighed NMP (5.4) into the stirring tank in the sanding machine (6.5);

gradually add the weighed polyvinylidene fluoride (5.3) and perform dispersive stirring,

until it is completely dissolved. Afterwards, add the weighed conductive agent (5.2) and

perform dispersive stirring. After the dispersion is uniform, add the weighed lithium

manganese oxide (5.1) and perform dispersive stirring, until the dispersion is uniform.

7.2.3 Coating

Use the coating machine (6.7) to evenly coat the stirred cathode paste on both sides

of the aluminum foil (5.5). The coating speed parameter of the coating machine (6.7)

is set to 800 mm/min; the blast baking temperature is set to 130 °C. Control the single

surface areal density within the range of 200 g/m2 ~ 230 g/m2, the thickness difference

≤ 3 μm and the areal density deviation of the front and back surfaces < 5.0 g/m2. After

the coating is completed, transfer the preliminarily dried and winded cathode sheet to

the vacuum oven (6.8) for secondary drying. The baking temperature is controlled at

110 °C ~ 120 °C; bake for 12 h; cool down under nitrogen (5.18) atmosphere.

7.2.4 Preparation

Take the cathode sheet in 7.2.3, which is dried and reaches the requirements of being

processed; use the sheet-punching machine (6.12) to punch out a circular or square

cathode sheet with an area of Sc. Use the electronic balance (6.2) and the desktop

digital thickness gauge (6.13) to perform mass measurement mc and thickness

measurement dc on the punched cathode sheet.

Use the sheet-punching machine (6.12) to punch out an aluminum foil substrate with

an area of Sc. Use the electronic balance (6.2) and the desktop digital thickness gauge

(6.13) to perform mass measurement mAl and thickness measurement dAl on the

punched aluminum foil substrate.

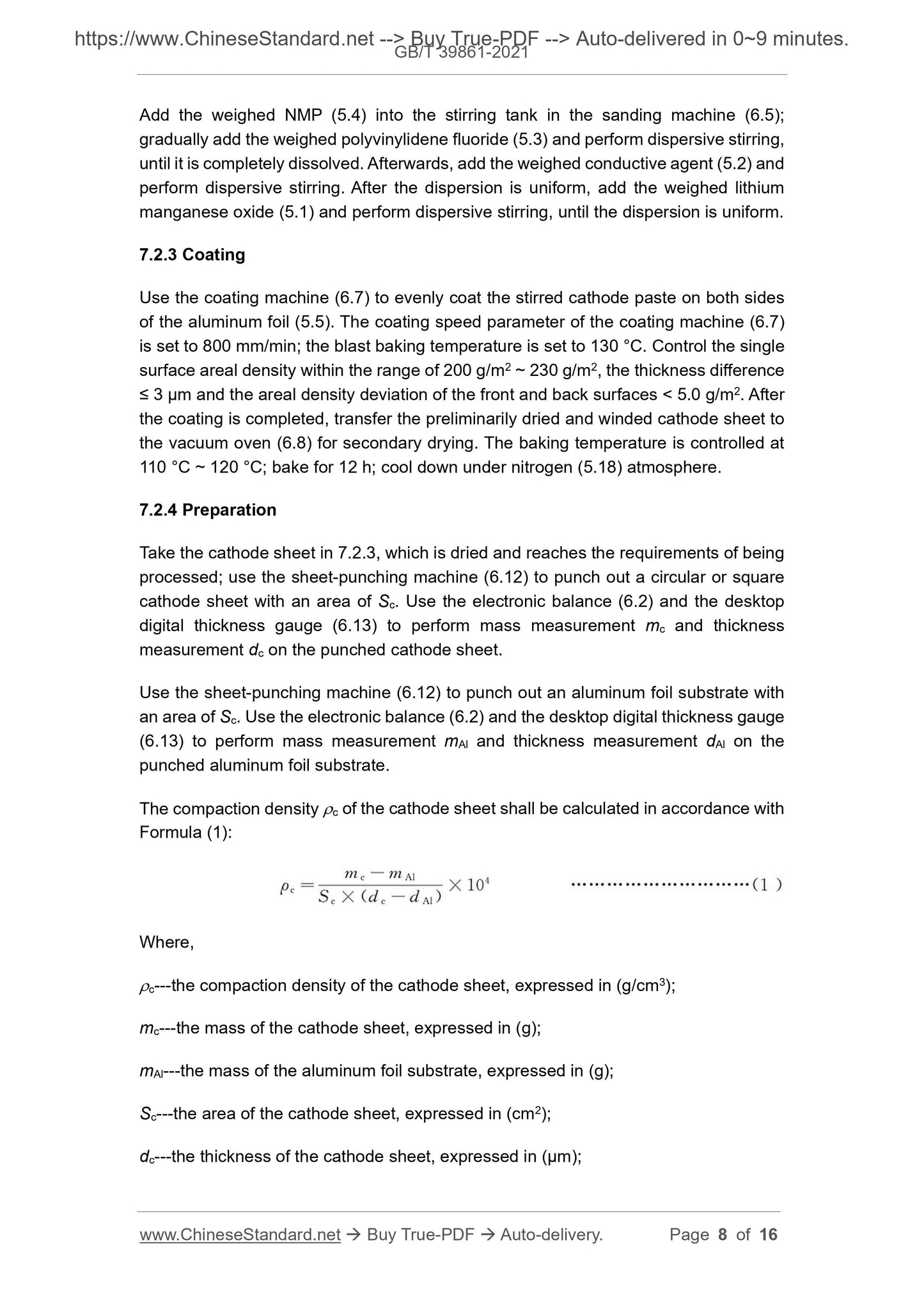

The compaction density c of the cathode sheet shall be calculated in accordance with

Formula (1):

Where,

c---the compaction density of the cathode sheet, expressed in (g/cm3);

mc---the mass of the cathode sheet, expressed in (g);

mAl---the mass of the aluminum foil substrate, expressed in (g);

Sc---the area of the cathode sheet, expressed in (cm2);

dc---the thickness of the cathode sheet, expressed in (μm);

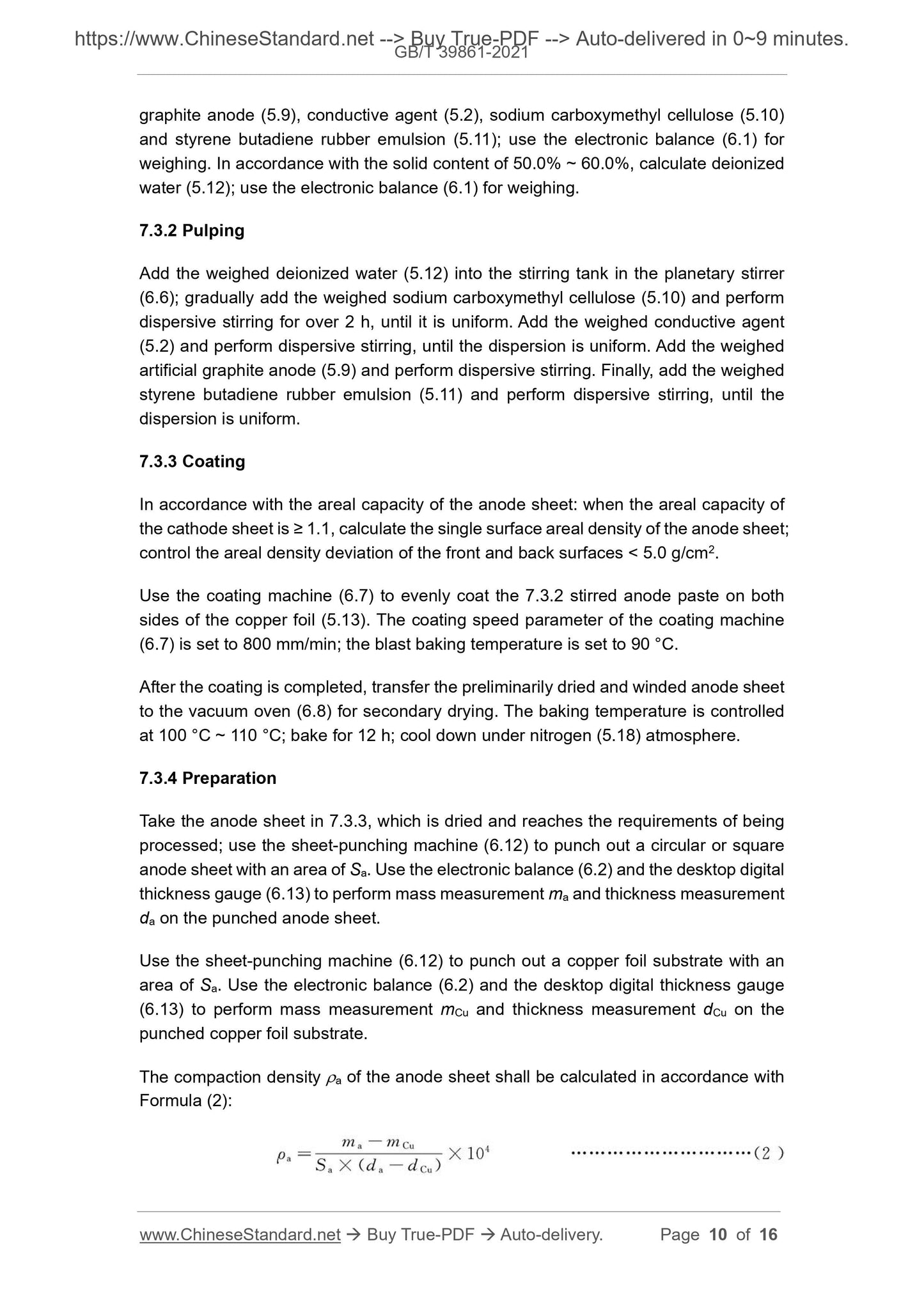

graphite anode (5.9), conductive agent (5.2), sodium carboxymethyl cellulose (5.10)

and styrene butadiene rubber emulsion (5.11); use the electronic balance (6.1) for

weighing. In accordance with the solid content of 50.0% ~ 60.0%, calculate deionized

water (5.12); use the electronic balance (6.1) for weighing.

7.3.2 Pulping

Add the weighed deionized water (5.12) into the stirring tank in the planetary stirrer

(6.6); gradually add the weighed sodium carboxymethyl cellulose (5.10) and perform

dispersive stirring for over 2 h, until it is uniform. Add the weighed conductive agent

(5.2) and perform dispersive stirring, until the dispersion is uniform. Add the weighed

artificial graphite anode (5.9) and perform dispersive stirring. Finally, add the weighed

styrene butadiene rubber emulsion (5.11) and perform dispersive stirring, until the

dispersion is uniform.

7.3.3 Coating

In accordance with the areal capacity of the anode sheet: when the areal capacity of

the cathode sheet is ≥ 1.1, calculate the single surface areal density of the anode sheet;

control the areal density deviation of the front and back surfaces < 5.0 g/cm2.

Use the coating machine (6.7) to evenly coat the 7.3.2 stirred anode paste on both

sides of the copper foil (5.13). The coating speed parameter of the coating machine

(6.7) is set to 800 mm/min; the blast baking temperature is set to 90 °C.

After the coating is completed, transfer the preliminarily dried and winded a...

Get QUOTATION in 1-minute: Click GB/T 39861-2021

Historical versions: GB/T 39861-2021

Preview True-PDF (Reload/Scroll if blank)

GB/T 39861-2021: Electrochemical performance test of lithium manganese oxide -- Test method for discharge plateau capacity ratio and cycle life

GB/T 39861-2021

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.160

CCS H 21

Electrochemical Performance Test of Lithium

Manganese Oxide - Test Method for Discharge Plateau

Capacity Ratio and Cycle Life

ISSUED ON: MARCH 9, 2021

IMPLEMENTED ON: OCTOBER 1, 2021

Issued by: State Administration for Market Regulation;

Standardization Administration of the People’s Republic of

China.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative References ... 4

3 Terms and Definitions ... 4

4 Test Conditions ... 4

5 Reagents or Materials ... 5

6 Instruments and Equipment ... 6

7 Test Procedures ... 7

8 Test Data Processing ... 15

9 Test Report ... 16

Electrochemical Performance Test of Lithium

Manganese Oxide - Test Method for Discharge Plateau

Capacity Ratio and Cycle Life

1 Scope

This Standard specifies the test method for discharge plateau capacity ratio and cycle

life of lithium manganese oxide as the cathode material of lithium ion batteries.

This Standard is applicable to the test of discharge plateau capacity ratio and cycle life

of lithium manganese oxide as the cathode material of lithium ion batteries.

2 Normative References

The content in the following document constitutes indispensable clauses of this

document through normative references in the text. In terms of references with a

specified date, only versions with a specified date are applicable to this document. In

terms of references without a specified date, the latest version (including all the

modifications) is applicable to this document.

GB/T 18287 General Specification of Lithium-ion Cells and Batteries for Mobile Phone

3 Terms and Definitions

The following terms and definitions are applicable to this document.

3.1 Solid Content

Solid content refers to the mass fraction (of the total amount) of the remaining part of

emulsion or paint after drying under the specified conditions.

4 Test Conditions

When there are no special instructions, the various test procedures specified in this

document should be carried out in a drying room (the environmental dew-point

temperature is ≤ -20 °C). For the situation where there is no drying room, the various

test procedures shall be carried out under the following environmental conditions: the

relative humidity is ≤ 20.0% and the temperature is 20 °C ~ 30 °C.

160 μm; the thickness of the aluminum foil coated on the surface of the aluminum-

plastic film is: 30 μm ~ 40 μm.

5.17 Insulating glue: with a length of 53.0 mm ± 1.0 mm.

5.18 Nitrogen: purity (volume fraction) ≥ 99.9%.

5.19 Electrolyte for lithium ion batteries: composed of a solution (with a concentration

of 1 mol/L) of lithium hexafluorophosphate (LiPF6) dissolved in an organic solvent (the

volume ratio of ethylene carbonate EC, dimethyl carbonate DMC, ethyl methyl

carbonate EMC is 1 : 1 : 1); moisture content ≤ 0.0015%; free acid (HF) ≤ 0.003%;

density: 1.23 g/cm3 ± 0.02 g/cm3; chroma ≤ 50 Hazen.

6 Instruments and Equipment

6.1 Electronic balance: with a measuring range of 3,000 g and a division value of 0.01

g.

6.2 Electronic balance: with a measuring range of 100 g and a division value of 0.0001

g.

6.3 Drying oven.

6.4 Desiccator.

6.5 Sanding machine.

6.6 Planetary stirrer.

6.7 Coating machine: the length of drying tunnel is > 2.0 m.

6.8 Vacuum oven.

6.9 Cutting machine.

6.10 Banister brush.

6.11 Adjustable slitting machine.

6.12 Sheet-punching machine: the mold is a square with a side length of 10 cm or a

circle with a diameter of 10 cm.

6.13 Desktop digital thickness gauge: with a resolution of 1 μm.

6.14 Roller machine: exclusive to lithium batteries.

6.15 Ruler: stainless-steel; with a measuring range of 100 cm, accurate to 0.5 mm.

Add the weighed NMP (5.4) into the stirring tank in the sanding machine (6.5);

gradually add the weighed polyvinylidene fluoride (5.3) and perform dispersive stirring,

until it is completely dissolved. Afterwards, add the weighed conductive agent (5.2) and

perform dispersive stirring. After the dispersion is uniform, add the weighed lithium

manganese oxide (5.1) and perform dispersive stirring, until the dispersion is uniform.

7.2.3 Coating

Use the coating machine (6.7) to evenly coat the stirred cathode paste on both sides

of the aluminum foil (5.5). The coating speed parameter of the coating machine (6.7)

is set to 800 mm/min; the blast baking temperature is set to 130 °C. Control the single

surface areal density within the range of 200 g/m2 ~ 230 g/m2, the thickness difference

≤ 3 μm and the areal density deviation of the front and back surfaces < 5.0 g/m2. After

the coating is completed, transfer the preliminarily dried and winded cathode sheet to

the vacuum oven (6.8) for secondary drying. The baking temperature is controlled at

110 °C ~ 120 °C; bake for 12 h; cool down under nitrogen (5.18) atmosphere.

7.2.4 Preparation

Take the cathode sheet in 7.2.3, which is dried and reaches the requirements of being

processed; use the sheet-punching machine (6.12) to punch out a circular or square

cathode sheet with an area of Sc. Use the electronic balance (6.2) and the desktop

digital thickness gauge (6.13) to perform mass measurement mc and thickness

measurement dc on the punched cathode sheet.

Use the sheet-punching machine (6.12) to punch out an aluminum foil substrate with

an area of Sc. Use the electronic balance (6.2) and the desktop digital thickness gauge

(6.13) to perform mass measurement mAl and thickness measurement dAl on the

punched aluminum foil substrate.

The compaction density c of the cathode sheet shall be calculated in accordance with

Formula (1):

Where,

c---the compaction density of the cathode sheet, expressed in (g/cm3);

mc---the mass of the cathode sheet, expressed in (g);

mAl---the mass of the aluminum foil substrate, expressed in (g);

Sc---the area of the cathode sheet, expressed in (cm2);

dc---the thickness of the cathode sheet, expressed in (μm);

graphite anode (5.9), conductive agent (5.2), sodium carboxymethyl cellulose (5.10)

and styrene butadiene rubber emulsion (5.11); use the electronic balance (6.1) for

weighing. In accordance with the solid content of 50.0% ~ 60.0%, calculate deionized

water (5.12); use the electronic balance (6.1) for weighing.

7.3.2 Pulping

Add the weighed deionized water (5.12) into the stirring tank in the planetary stirrer

(6.6); gradually add the weighed sodium carboxymethyl cellulose (5.10) and perform

dispersive stirring for over 2 h, until it is uniform. Add the weighed conductive agent

(5.2) and perform dispersive stirring, until the dispersion is uniform. Add the weighed

artificial graphite anode (5.9) and perform dispersive stirring. Finally, add the weighed

styrene butadiene rubber emulsion (5.11) and perform dispersive stirring, until the

dispersion is uniform.

7.3.3 Coating

In accordance with the areal capacity of the anode sheet: when the areal capacity of

the cathode sheet is ≥ 1.1, calculate the single surface areal density of the anode sheet;

control the areal density deviation of the front and back surfaces < 5.0 g/cm2.

Use the coating machine (6.7) to evenly coat the 7.3.2 stirred anode paste on both

sides of the copper foil (5.13). The coating speed parameter of the coating machine

(6.7) is set to 800 mm/min; the blast baking temperature is set to 90 °C.

After the coating is completed, transfer the preliminarily dried and winded a...

Share