1

/

of

6

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

GB/T 40084-2021 English PDF (GB/T40084-2021)

GB/T 40084-2021 English PDF (GB/T40084-2021)

Regular price

$225.00 USD

Regular price

Sale price

$225.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click GB/T 40084-2021

Historical versions: GB/T 40084-2021

Preview True-PDF (Reload/Scroll if blank)

GB/T 40084-2021: Guidance for energy management performance assessment in iron and steel industry

GB/T 40084-2021

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 27.010

F 01

Guidance for energy management performance

assessment in iron and steel industry

ISSUED ON: APRIL 30, 2021

IMPLEMENTED ON: NOVEMBER 01, 2021

Issued by: State Administration for Market Regulation;

Standardization Administration of the People’s Republic of

China.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Terms and definitions ... 5

4 Basic requirements ... 5

4.1 Assessment principle ... 5

4.2 Assessment basis... 5

4.3 Assessment conditions ... 5

4.4 Assessment boundary ... 6

5 Assessment contents ... 6

5.1 Assessment preparation ... 6

5.2 Data and information collection and statistics ... 7

5.3 Energy management maturity assessment ... 8

5.4 Energy performance assessment ... 8

6 Assessment report ... 15

Appendix A (Informative) Energy management performance assessment report

outline of ×× iron and steel enterprise ... 16

References ... 18

Guidance for energy management performance

assessment in iron and steel industry

1 Scope

This Standard provides guidance for the basic requirements, assessment

contents and assessment reports of energy management performance

assessment in iron and steel industry.

This Standard applies to the energy management performance assessment of

iron and steel enterprises that target iron and steel smelting and rolling

processing.

2 Normative references

The following documents are indispensable for the application of this document.

For dated references, only the dated version applies to this document. For

undated references, the latest edition (including all amendments) applies to this

document.

GB/T 2589, General principles for calculation of the comprehensive energy

consumption

GB 17167, General principle for equipping and managing of the measuring

instrument of energy in organization of energy using

GB 21256, The norm of energy consumption per unit product of major

individual - Process of crude steel manufacturing process

GB 21342, The norm of energy consumption per unit product of coke

GB/T 21368, Specification for equipping and managing of measuring

instrument of energy in the iron and steel industry

GB/T 23331, Energy management systems - Requirements with guidance

for use

GB/T 39775-2021, General principle for energy management performance

assessment

GB 50506, Code for design of water saving for iron and steel enterprises

e) In accordance with the requirements of GB/T 23331, an energy

management system has been established and operated;

f) Have continuous and accurate statistics on energy performance.

4.4 Assessment boundary

Determine the boundaries of energy management performance assessment

according to the management responsibilities, product scope and geographic

area of iron and steel enterprises.

The boundary of energy management performance assessment of iron and

steel enterprises can include the main production system, auxiliary production

system and subsidiary production system of the enterprise, excluding the

mining and washing system.

a) Main production system: It mainly includes coking, sintering, pelletizing,

iron-making, steel-making, hot rolling, cold rolling, color coating,

galvanizing and other main production systems.

b) Auxiliary production system: It mainly includes auxiliary production

systems such as power, power supply, water supply, oxygen production,

heating power, gas, air supply, machine repair, and transportation.

c) Subsidiary production system: It mainly includes the production command

system (factory headquarters) and the departments and units (such as

staff canteens, workshop bathrooms) that serve production in the factory

area.

5 Assessment contents

5.1 Assessment preparation

Before conducting energy management performance assessment, make the

following preparations:

a) Identify laws, regulations, standards and requirements from countries,

industries, localities and other related parties.

b) Determine the assessment scope. Due to the differences in the processes

and products of iron and steel enterprises, the energy management

performance assessment scope can include all or part of the systems

within the scope of assessment boundary of 4.4; it is an independent

accounting unit.

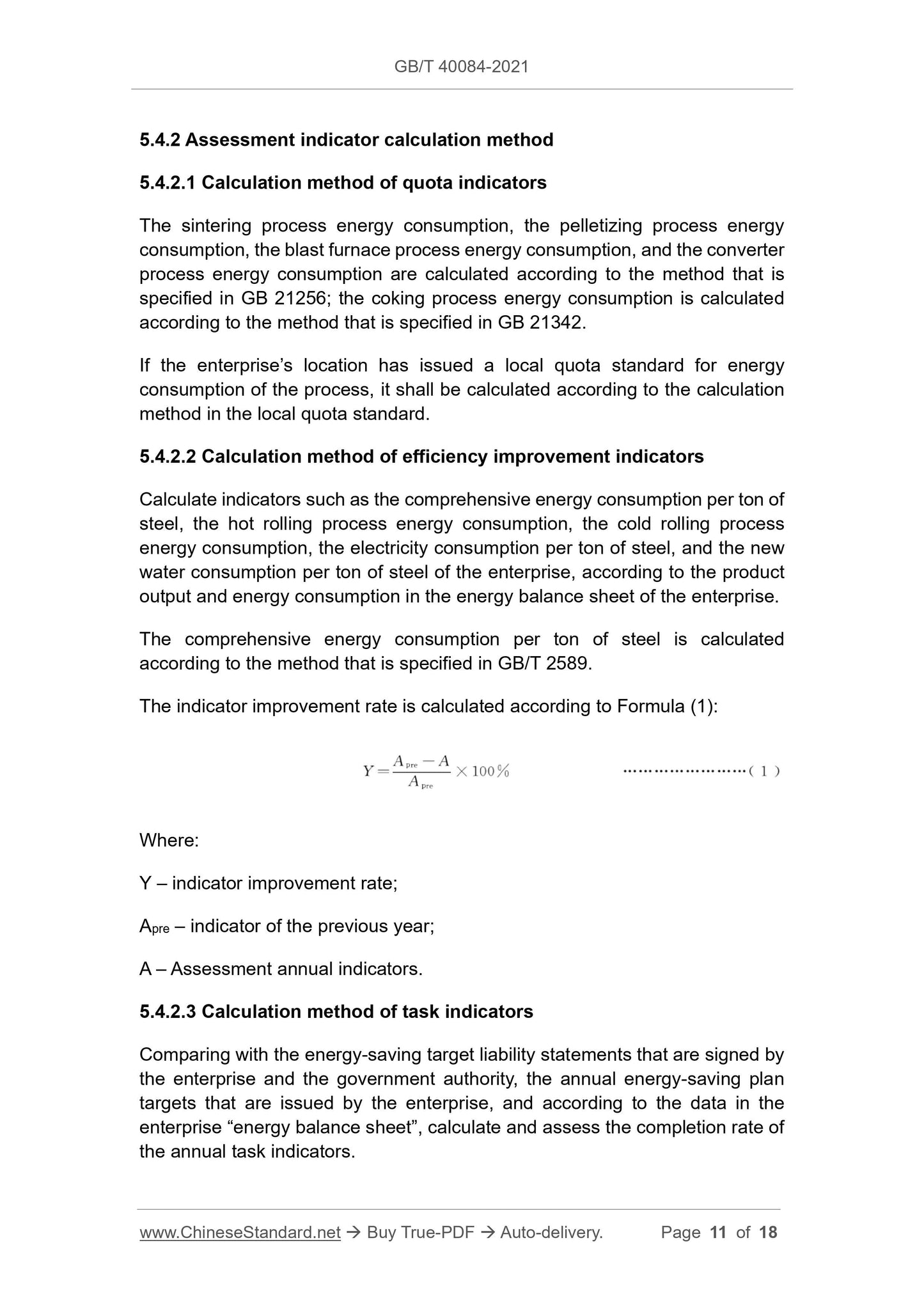

5.4.2 Assessment indicator calculation method

5.4.2.1 Calculation method of quota indicators

The sintering process energy consumption, the pelletizing process energy

consumption, the blast furnace process energy consumption, and the converter

process energy consumption are calculated according to the method that is

specified in GB 21256; the coking process energy consumption is calculated

according to the method that is specified in GB 21342.

If the enterprise’s location has issued a local quota standard for energy

consumption of the process, it shall be calculated according to the calculation

method in the local quota standard.

5.4.2.2 Calculation method of efficiency improvement indicators

Calculate indicators such as the comprehensive energy consumption per ton of

steel, the hot rolling process energy consumption, the cold rolling process

energy consumption, the electricity consumption per ton of steel, and the new

water consumption per ton of steel of the enterprise, according to the product

output and energy consumption in the energy balance sheet of the enterprise.

The comprehensive energy consumption per ton of steel is calculated

according to the method that is specified in GB/T 2589.

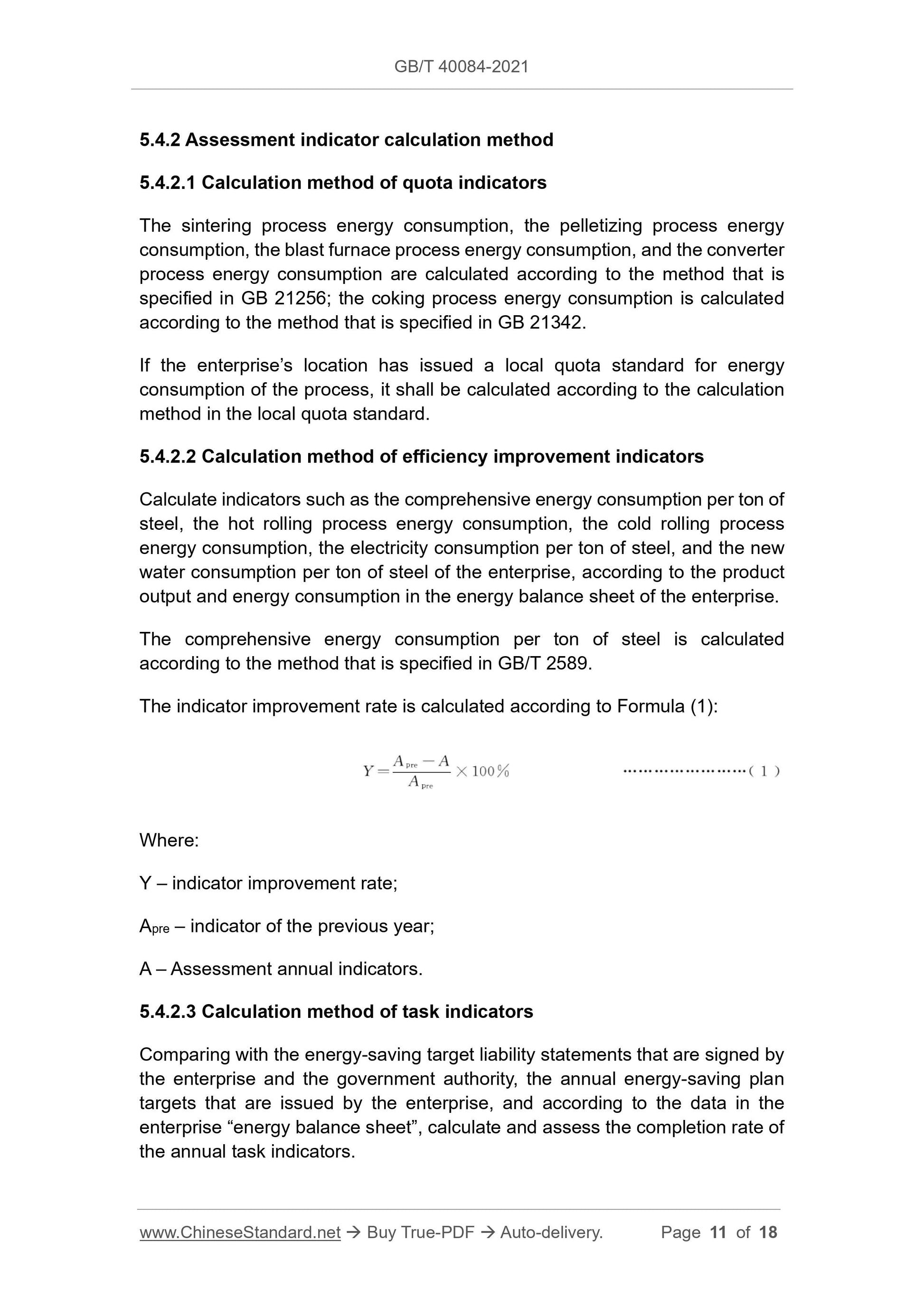

The indicator improvement rate is calculated according to Formula (1):

Where:

Y – indicator improvement rate;

Apre – indicator of the previous year;

A – Assessment annual indicators.

5.4.2.3 Calculation method of task indicators

Comparing with the energy-saving target liability statements that are signed by

the enterprise and the government authority, the annual energy-saving plan

targets that are issued by the enterprise, and according to the data in the

enterprise “energy balance sheet”, calculate and assess the completion rate of

the annual task indicators.

a) Whether it is suitable for the scale of the enterprise, manufacturing

techniques, and energy use;

b) Whether it fully covers the main production system, auxiliary production

system and subsidiary production system of the enterprise;

c) Whether it fully covers the main processes and activities of energy design,

procurement, storage, processing and conversion, transportation and

distribution, use, and surplus energy recovery and utilization.

5.4.4.3 Validity assessment of energy performance indicators

The validity of energy performance indicators depends on the validity and

reliability of basic data and related documents.

In the assessment process, identify the factors that affect the validity of energy

performance indicators. Possible influencing factors include:

-- The validity and reliability of basic data and related documents cannot be

fully verified;

-- Major changes have taken place in the manufacturing techniques and

product structure;

-- Major changes have taken place in the main equipment;

-- Major changes have taken place in the production organization and

production scale;

-- Major changes have taken place in the energy structure;

-- Force majeure, etc.

When the identified influencing factors have a significant impact on the...

Get QUOTATION in 1-minute: Click GB/T 40084-2021

Historical versions: GB/T 40084-2021

Preview True-PDF (Reload/Scroll if blank)

GB/T 40084-2021: Guidance for energy management performance assessment in iron and steel industry

GB/T 40084-2021

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 27.010

F 01

Guidance for energy management performance

assessment in iron and steel industry

ISSUED ON: APRIL 30, 2021

IMPLEMENTED ON: NOVEMBER 01, 2021

Issued by: State Administration for Market Regulation;

Standardization Administration of the People’s Republic of

China.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Terms and definitions ... 5

4 Basic requirements ... 5

4.1 Assessment principle ... 5

4.2 Assessment basis... 5

4.3 Assessment conditions ... 5

4.4 Assessment boundary ... 6

5 Assessment contents ... 6

5.1 Assessment preparation ... 6

5.2 Data and information collection and statistics ... 7

5.3 Energy management maturity assessment ... 8

5.4 Energy performance assessment ... 8

6 Assessment report ... 15

Appendix A (Informative) Energy management performance assessment report

outline of ×× iron and steel enterprise ... 16

References ... 18

Guidance for energy management performance

assessment in iron and steel industry

1 Scope

This Standard provides guidance for the basic requirements, assessment

contents and assessment reports of energy management performance

assessment in iron and steel industry.

This Standard applies to the energy management performance assessment of

iron and steel enterprises that target iron and steel smelting and rolling

processing.

2 Normative references

The following documents are indispensable for the application of this document.

For dated references, only the dated version applies to this document. For

undated references, the latest edition (including all amendments) applies to this

document.

GB/T 2589, General principles for calculation of the comprehensive energy

consumption

GB 17167, General principle for equipping and managing of the measuring

instrument of energy in organization of energy using

GB 21256, The norm of energy consumption per unit product of major

individual - Process of crude steel manufacturing process

GB 21342, The norm of energy consumption per unit product of coke

GB/T 21368, Specification for equipping and managing of measuring

instrument of energy in the iron and steel industry

GB/T 23331, Energy management systems - Requirements with guidance

for use

GB/T 39775-2021, General principle for energy management performance

assessment

GB 50506, Code for design of water saving for iron and steel enterprises

e) In accordance with the requirements of GB/T 23331, an energy

management system has been established and operated;

f) Have continuous and accurate statistics on energy performance.

4.4 Assessment boundary

Determine the boundaries of energy management performance assessment

according to the management responsibilities, product scope and geographic

area of iron and steel enterprises.

The boundary of energy management performance assessment of iron and

steel enterprises can include the main production system, auxiliary production

system and subsidiary production system of the enterprise, excluding the

mining and washing system.

a) Main production system: It mainly includes coking, sintering, pelletizing,

iron-making, steel-making, hot rolling, cold rolling, color coating,

galvanizing and other main production systems.

b) Auxiliary production system: It mainly includes auxiliary production

systems such as power, power supply, water supply, oxygen production,

heating power, gas, air supply, machine repair, and transportation.

c) Subsidiary production system: It mainly includes the production command

system (factory headquarters) and the departments and units (such as

staff canteens, workshop bathrooms) that serve production in the factory

area.

5 Assessment contents

5.1 Assessment preparation

Before conducting energy management performance assessment, make the

following preparations:

a) Identify laws, regulations, standards and requirements from countries,

industries, localities and other related parties.

b) Determine the assessment scope. Due to the differences in the processes

and products of iron and steel enterprises, the energy management

performance assessment scope can include all or part of the systems

within the scope of assessment boundary of 4.4; it is an independent

accounting unit.

5.4.2 Assessment indicator calculation method

5.4.2.1 Calculation method of quota indicators

The sintering process energy consumption, the pelletizing process energy

consumption, the blast furnace process energy consumption, and the converter

process energy consumption are calculated according to the method that is

specified in GB 21256; the coking process energy consumption is calculated

according to the method that is specified in GB 21342.

If the enterprise’s location has issued a local quota standard for energy

consumption of the process, it shall be calculated according to the calculation

method in the local quota standard.

5.4.2.2 Calculation method of efficiency improvement indicators

Calculate indicators such as the comprehensive energy consumption per ton of

steel, the hot rolling process energy consumption, the cold rolling process

energy consumption, the electricity consumption per ton of steel, and the new

water consumption per ton of steel of the enterprise, according to the product

output and energy consumption in the energy balance sheet of the enterprise.

The comprehensive energy consumption per ton of steel is calculated

according to the method that is specified in GB/T 2589.

The indicator improvement rate is calculated according to Formula (1):

Where:

Y – indicator improvement rate;

Apre – indicator of the previous year;

A – Assessment annual indicators.

5.4.2.3 Calculation method of task indicators

Comparing with the energy-saving target liability statements that are signed by

the enterprise and the government authority, the annual energy-saving plan

targets that are issued by the enterprise, and according to the data in the

enterprise “energy balance sheet”, calculate and assess the completion rate of

the annual task indicators.

a) Whether it is suitable for the scale of the enterprise, manufacturing

techniques, and energy use;

b) Whether it fully covers the main production system, auxiliary production

system and subsidiary production system of the enterprise;

c) Whether it fully covers the main processes and activities of energy design,

procurement, storage, processing and conversion, transportation and

distribution, use, and surplus energy recovery and utilization.

5.4.4.3 Validity assessment of energy performance indicators

The validity of energy performance indicators depends on the validity and

reliability of basic data and related documents.

In the assessment process, identify the factors that affect the validity of energy

performance indicators. Possible influencing factors include:

-- The validity and reliability of basic data and related documents cannot be

fully verified;

-- Major changes have taken place in the manufacturing techniques and

product structure;

-- Major changes have taken place in the main equipment;

-- Major changes have taken place in the production organization and

production scale;

-- Major changes have taken place in the energy structure;

-- Force majeure, etc.

When the identified influencing factors have a significant impact on the...

Share