1

/

of

10

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

GB/T 40317-2021 English PDF (GB/T40317-2021)

GB/T 40317-2021 English PDF (GB/T40317-2021)

Regular price

$230.00 USD

Regular price

Sale price

$230.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click GB/T 40317-2021

Historical versions: GB/T 40317-2021

Preview True-PDF (Reload/Scroll if blank)

GB/T 40317-2021: Seamless stainless steel pipes for oxygen pipeline

GB/T 40317-2021

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.140.75

CCS H 48

Seamless stainless steel pipes for oxygen pipeline

ISSUED ON: AUGUST 20, 2021

IMPLEMENTED ON: MARCH 1, 2022

Issued by: State Administration for Market Regulation;

Standardization Administration of PRC.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Terms and Definitions ... 6

4 Classification and code ... 6

5 Order contents ... 6

6 Dimensions, shape and weight ... 7

7 Technical requirements ... 10

8 Test methods ... 14

9 Inspection rules ... 16

10 Packaging, marking and quality certificate ... 16

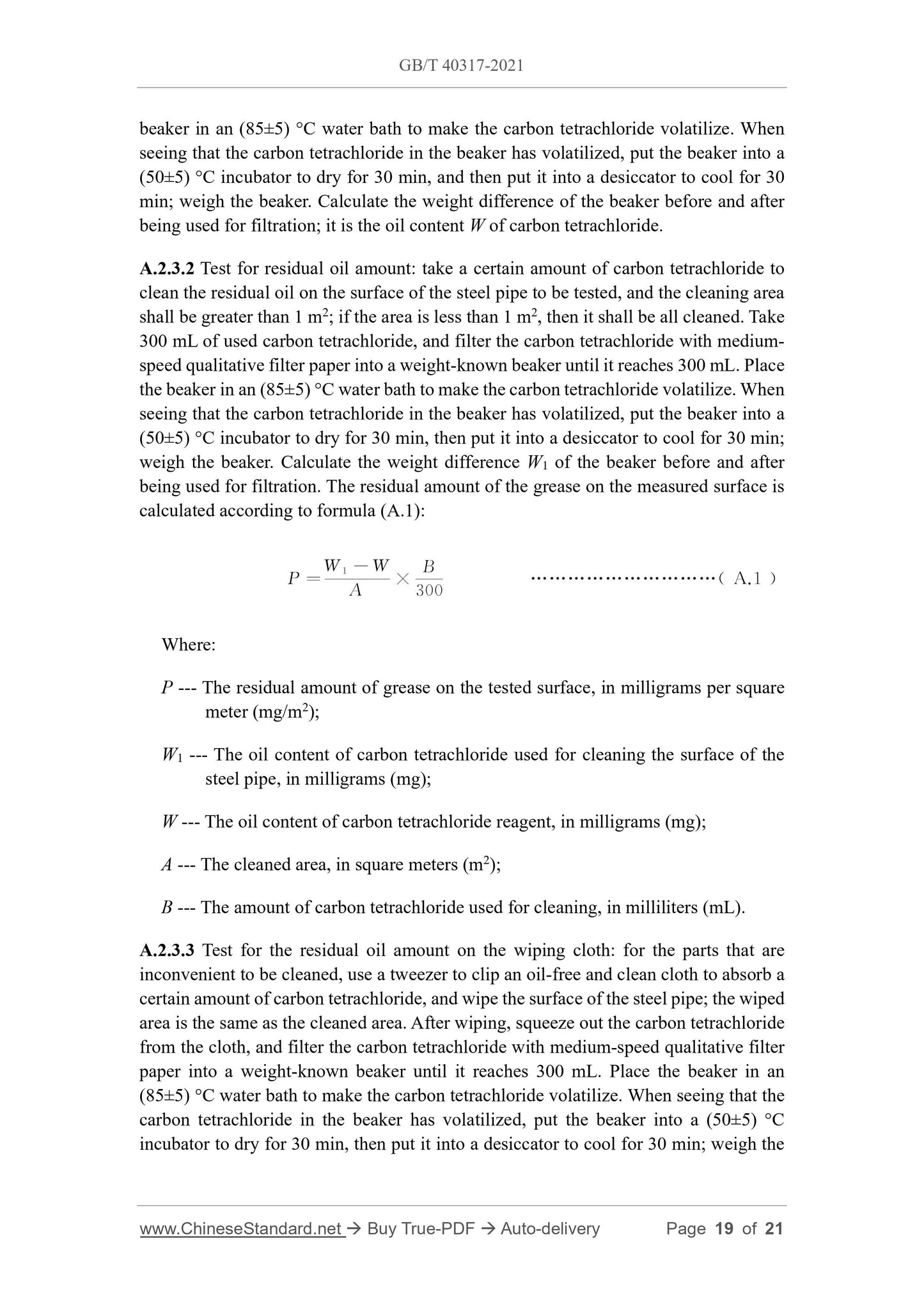

Appendix A (Normative) Determination method of grease residue on the surface of the

steel pipe ... 18

Seamless stainless steel pipes for oxygen pipeline

1 Scope

This document specifies the classification and code, order content, size, shape, weight,

technical requirements, test methods, inspection rules, packaging, marking and quality

certificates of the stainless-steel seamless steel pipe for oxygen pipeline.

This document applies to stainless steel seamless steel pipes (hereinafter referred to as

“steel pipes”) for conveying oxygen and liquid oxygen.

2 Normative references

The following documents are essential to the application of this document. For the dated

documents, only the versions with the dates indicated are applicable to this document;

for the undated documents, only the latest version (including all the amendments) is

applicable to this standard.

GB/T 222 Permissible tolerances for chemical composition of steel products

GB/T 223.11 Iron, steel and alloy -- Determination of chromium content -- Visual

titration or potentiometric titration method

GB/T 223.25 Methods for chemical analysis of iron, steel and alloy. The

dimethylglyoxime gravimetric method for the determination of nickel content

GB/T 223.28 Methods for chemical analysis of iron, steel and alloy. The α-benzoin

oxime gravimetric method for the determination of molybdenum content

GB/T 223.40 Iron, steel and alloy -- Determination of niobium content by the

sulphochlorophenol S spectrophotometric method

GB/T 223.59 Iron, steel and alloy -- Determination of phosphorus content --

Bismuth phosphomolybdate blue spectrophotometric method and antimony

phosphomolybdate blue spectrophotometric method

GB/T 223.60 Methods for chemical analysis of iron, steel and alloy - The perchloric

acid dehydration gravimetric method for the determination of silicon content

GB/T 223.63 Methods for chemical analysis of iron, steel and alloy - The sodium

(potassium) periodate photometric method for the determination of manganese

content

GB/T 223.84 Steel and iron -- Determination of titanium content --

Diantipyrylmethane spectrophotometric method

GB/T 223.85 Steel and iron -- Determination of sulfur content -- Infrared absorption

method after combustion in an induction furnace

GB/T 223.86 Steel and iron -- Determination of total carbon content -- Infrared

absorption method after combustion in an induction furnace

GB/T 228.1 Metallic materials -- Tensile testing -- Part 1: Method of test at room

temperature

GB/T 229 Metallic materials -- Charpy pendulum impact test method

GB/T 241 Metal materials -- Tube -- Hydrostatic pressure test

GB/T 242 Metal materials -- Tube -- Drift-expending test

GB/T 246 Metallic materials -- Tube -- Flattening test

GB/T 1031 Geometrical Product Specifications (GPS) -- Surface texture: Profile

method -- Surface roughness parameters and their values

GB/T 2102 Acceptance, packing, marking and quality certification of steel pipe

GB/T 2975 Steel and steel products -- Location and preparation of samples and test

pieces for mechanical testing

GB/T 5777-2019 Automated full peripheral ultrasonic testing of seamless and

welded (except submerged arc-welded) steel tubes for the detection of longitudinal

and/or transverse imperfections

GB/T 7735-2016 Automated eddy current testing of seamless and welded (except

submerged arc-welded) steel tubes for detection of imperfections

GB/T 11170 Stainless steel -- Determination of multi-element contents -- Spark

discharge atomic emission spectrometric method (Routine method)

GB/T 17395 Dimensions, shapes, masses and tolerances of seamless steel tubes

GB/T 20066 Steel and iron -- Sampling and preparation of samples for the

determination of chemical composition

GB/T 20123 Steel and iron -- Determination of total carbon and sulfur content

Infrared absorption method after combustion in an induction furnace (routine

method)

a) When the wall thickness is not greater than 15 mm, it is 1.5 mm/m;

b) When the wall thickness is greater than 15 mm, it is 2.0 mm/m.

6.4 Terminal outline

6.4.1 The end faces of both ends of the steel pipe shall be perpendicular to the axis of

the steel pipe, and the burrs shall be removed from the incision.

6.4.2 According to the requirements of the buyer, after negotiation between the supplier

and the buyer, and indicated in the contract, the two ends of the steel pipe can be

processed with grooves, and the groove type can be determined by negotiation between

the supplier and the buyer.

6.5 Out of roundness and uneven wall thickness

The out-of-roundness and uneven-wall-thickness of the steel pipe shall not exceed 80%

of the outer diameter tolerance and wall thickness tolerance, respectively.

6.6 Weight

6.6.1 Steel pipes shall be delivered by actual weight. According to the requirements of

the buyer, after negotiation between the supplier and the buyer, and indicated in the

contract, the steel pipe can be delivered according to the theoretical weight.

6.6.2 The theoretical weight per meter of the steel pipe is calculated according to

formula (1):

Where:

W --- Theoretical weight per meter of steel pipe, in kilograms per meter (kg/m);

π --- Pi, to be taken as 3.1416;

ρ --- Density of steel, in kilograms per cubic decimeter (kg/dm3), see Table 4 for the

density of steel;

S --- Wall thickness of steel pipe, in millimeters (mm);

D --- The nominal outer diameter of the steel pipe, in millimeters (mm).

6.6.3 For steel pipes delivered according to the nominal outer diameter and the

minimum wall thickness, the theoretical weight shall be calculated by the average wall

thickness; the average wall thickness shall be the average value of the maximum and

minimum wall thickness calculated according to the wall thickness and the allowable

deviation.

and the buyer, and indicated in the contract, other test pressure can be used for the

hydraulic pressure test.

7.5.4 With the consent of the purchaser, the supplier can replace the hydraulic pressure

test with eddy current inspection; the acceptance level of eddy current inspection shall

comply with E4H or E4 regulations of GB/T 7735-2016.

7.6 Processing property

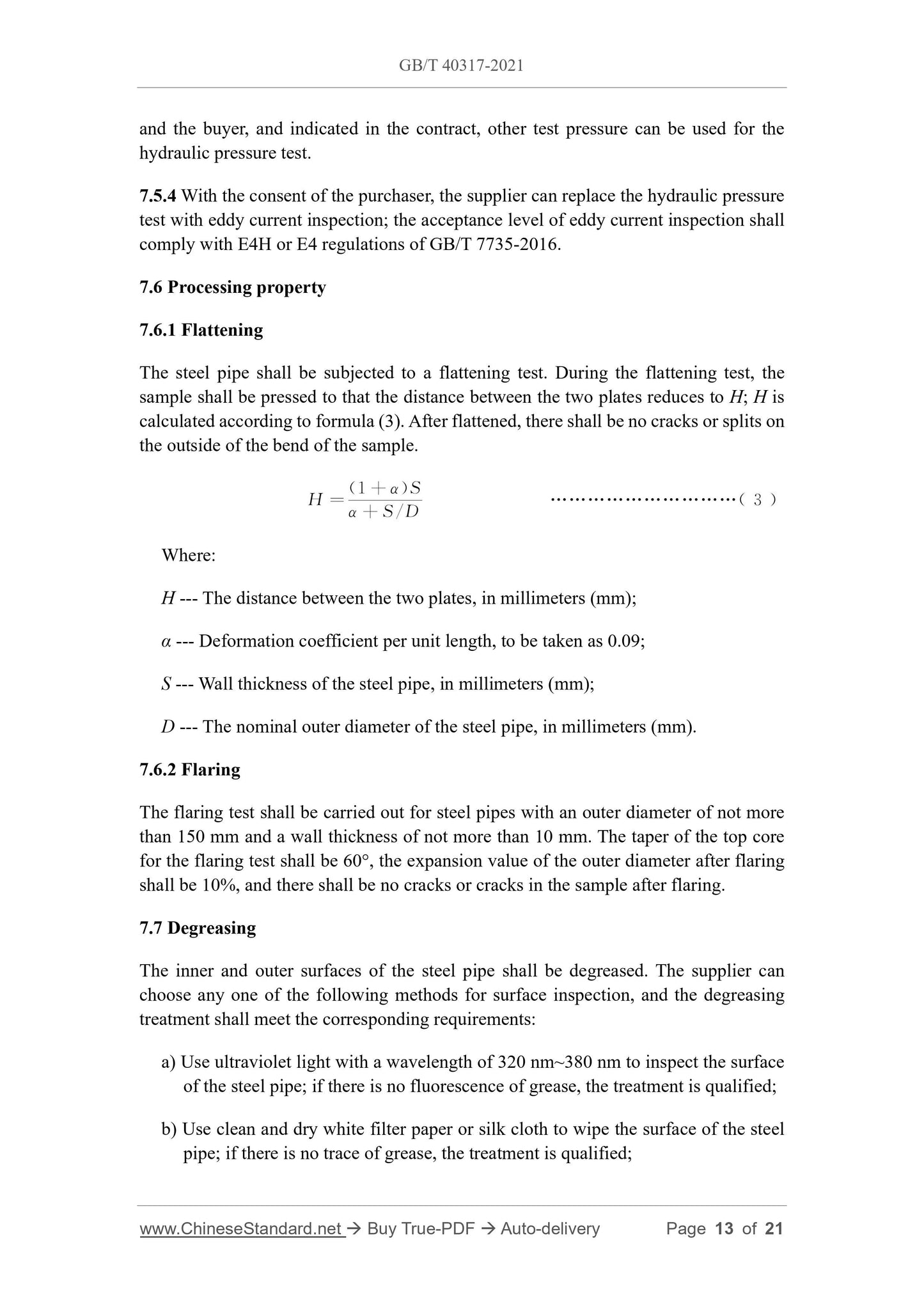

7.6.1 Flattening

The steel pipe shall be subjected to a flattening test. During the flattening test, the

sample shall be pressed to that the distance between the two plates reduces to H; H is

calculated according to formula (3). After flattened, there shall be no cracks or splits on

the outside of the bend of the sample.

Where:

H --- The distance between the two plates, in millimeters (mm);

α --- Deformation coefficient per unit length, to be taken as 0.09;

S --- Wall thickness of the steel pipe, in millimeters (mm);

D --- The nominal outer diameter of the steel pipe, in millimeters (mm).

7.6.2 Flarin...

Get QUOTATION in 1-minute: Click GB/T 40317-2021

Historical versions: GB/T 40317-2021

Preview True-PDF (Reload/Scroll if blank)

GB/T 40317-2021: Seamless stainless steel pipes for oxygen pipeline

GB/T 40317-2021

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.140.75

CCS H 48

Seamless stainless steel pipes for oxygen pipeline

ISSUED ON: AUGUST 20, 2021

IMPLEMENTED ON: MARCH 1, 2022

Issued by: State Administration for Market Regulation;

Standardization Administration of PRC.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Terms and Definitions ... 6

4 Classification and code ... 6

5 Order contents ... 6

6 Dimensions, shape and weight ... 7

7 Technical requirements ... 10

8 Test methods ... 14

9 Inspection rules ... 16

10 Packaging, marking and quality certificate ... 16

Appendix A (Normative) Determination method of grease residue on the surface of the

steel pipe ... 18

Seamless stainless steel pipes for oxygen pipeline

1 Scope

This document specifies the classification and code, order content, size, shape, weight,

technical requirements, test methods, inspection rules, packaging, marking and quality

certificates of the stainless-steel seamless steel pipe for oxygen pipeline.

This document applies to stainless steel seamless steel pipes (hereinafter referred to as

“steel pipes”) for conveying oxygen and liquid oxygen.

2 Normative references

The following documents are essential to the application of this document. For the dated

documents, only the versions with the dates indicated are applicable to this document;

for the undated documents, only the latest version (including all the amendments) is

applicable to this standard.

GB/T 222 Permissible tolerances for chemical composition of steel products

GB/T 223.11 Iron, steel and alloy -- Determination of chromium content -- Visual

titration or potentiometric titration method

GB/T 223.25 Methods for chemical analysis of iron, steel and alloy. The

dimethylglyoxime gravimetric method for the determination of nickel content

GB/T 223.28 Methods for chemical analysis of iron, steel and alloy. The α-benzoin

oxime gravimetric method for the determination of molybdenum content

GB/T 223.40 Iron, steel and alloy -- Determination of niobium content by the

sulphochlorophenol S spectrophotometric method

GB/T 223.59 Iron, steel and alloy -- Determination of phosphorus content --

Bismuth phosphomolybdate blue spectrophotometric method and antimony

phosphomolybdate blue spectrophotometric method

GB/T 223.60 Methods for chemical analysis of iron, steel and alloy - The perchloric

acid dehydration gravimetric method for the determination of silicon content

GB/T 223.63 Methods for chemical analysis of iron, steel and alloy - The sodium

(potassium) periodate photometric method for the determination of manganese

content

GB/T 223.84 Steel and iron -- Determination of titanium content --

Diantipyrylmethane spectrophotometric method

GB/T 223.85 Steel and iron -- Determination of sulfur content -- Infrared absorption

method after combustion in an induction furnace

GB/T 223.86 Steel and iron -- Determination of total carbon content -- Infrared

absorption method after combustion in an induction furnace

GB/T 228.1 Metallic materials -- Tensile testing -- Part 1: Method of test at room

temperature

GB/T 229 Metallic materials -- Charpy pendulum impact test method

GB/T 241 Metal materials -- Tube -- Hydrostatic pressure test

GB/T 242 Metal materials -- Tube -- Drift-expending test

GB/T 246 Metallic materials -- Tube -- Flattening test

GB/T 1031 Geometrical Product Specifications (GPS) -- Surface texture: Profile

method -- Surface roughness parameters and their values

GB/T 2102 Acceptance, packing, marking and quality certification of steel pipe

GB/T 2975 Steel and steel products -- Location and preparation of samples and test

pieces for mechanical testing

GB/T 5777-2019 Automated full peripheral ultrasonic testing of seamless and

welded (except submerged arc-welded) steel tubes for the detection of longitudinal

and/or transverse imperfections

GB/T 7735-2016 Automated eddy current testing of seamless and welded (except

submerged arc-welded) steel tubes for detection of imperfections

GB/T 11170 Stainless steel -- Determination of multi-element contents -- Spark

discharge atomic emission spectrometric method (Routine method)

GB/T 17395 Dimensions, shapes, masses and tolerances of seamless steel tubes

GB/T 20066 Steel and iron -- Sampling and preparation of samples for the

determination of chemical composition

GB/T 20123 Steel and iron -- Determination of total carbon and sulfur content

Infrared absorption method after combustion in an induction furnace (routine

method)

a) When the wall thickness is not greater than 15 mm, it is 1.5 mm/m;

b) When the wall thickness is greater than 15 mm, it is 2.0 mm/m.

6.4 Terminal outline

6.4.1 The end faces of both ends of the steel pipe shall be perpendicular to the axis of

the steel pipe, and the burrs shall be removed from the incision.

6.4.2 According to the requirements of the buyer, after negotiation between the supplier

and the buyer, and indicated in the contract, the two ends of the steel pipe can be

processed with grooves, and the groove type can be determined by negotiation between

the supplier and the buyer.

6.5 Out of roundness and uneven wall thickness

The out-of-roundness and uneven-wall-thickness of the steel pipe shall not exceed 80%

of the outer diameter tolerance and wall thickness tolerance, respectively.

6.6 Weight

6.6.1 Steel pipes shall be delivered by actual weight. According to the requirements of

the buyer, after negotiation between the supplier and the buyer, and indicated in the

contract, the steel pipe can be delivered according to the theoretical weight.

6.6.2 The theoretical weight per meter of the steel pipe is calculated according to

formula (1):

Where:

W --- Theoretical weight per meter of steel pipe, in kilograms per meter (kg/m);

π --- Pi, to be taken as 3.1416;

ρ --- Density of steel, in kilograms per cubic decimeter (kg/dm3), see Table 4 for the

density of steel;

S --- Wall thickness of steel pipe, in millimeters (mm);

D --- The nominal outer diameter of the steel pipe, in millimeters (mm).

6.6.3 For steel pipes delivered according to the nominal outer diameter and the

minimum wall thickness, the theoretical weight shall be calculated by the average wall

thickness; the average wall thickness shall be the average value of the maximum and

minimum wall thickness calculated according to the wall thickness and the allowable

deviation.

and the buyer, and indicated in the contract, other test pressure can be used for the

hydraulic pressure test.

7.5.4 With the consent of the purchaser, the supplier can replace the hydraulic pressure

test with eddy current inspection; the acceptance level of eddy current inspection shall

comply with E4H or E4 regulations of GB/T 7735-2016.

7.6 Processing property

7.6.1 Flattening

The steel pipe shall be subjected to a flattening test. During the flattening test, the

sample shall be pressed to that the distance between the two plates reduces to H; H is

calculated according to formula (3). After flattened, there shall be no cracks or splits on

the outside of the bend of the sample.

Where:

H --- The distance between the two plates, in millimeters (mm);

α --- Deformation coefficient per unit length, to be taken as 0.09;

S --- Wall thickness of the steel pipe, in millimeters (mm);

D --- The nominal outer diameter of the steel pipe, in millimeters (mm).

7.6.2 Flarin...

Share