1

/

of

5

PayPal, credit cards. Download editable-PDF & invoice in 1 second!

GB/T 40342-2021 English PDF (GB/T40342-2021)

GB/T 40342-2021 English PDF (GB/T40342-2021)

Regular price

$110.00 USD

Regular price

Sale price

$110.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get Quotation: Click GB/T 40342-2021 (Self-service in 1-minute)

Historical versions (Master-website): GB/T 40342-2021

Preview True-PDF (Reload/Scroll-down if blank)

GB/T 40342-2021: Method for determination of aluminum content in hot dipped zinc-aluminum alloy coating on steel wire

GB/T 40342-2021

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.140.65

CCS H 12

Method for determination of aluminum content in hot

dipped zinc-aluminum alloy coating on steel wire

ISSUED ON: AUGUST 20, 2021

IMPLEMENTED ON: MARCH 1, 2022

Issued by: State Administration for Market Regulation;

Standardization Administration of PRC.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Terms and definitions ... 5

4 Principle... 5

5 Reagents ... 5

6 Analysis steps ... 6

7 Calculation of analysis results ... 8

8 Precision... 8

9 Quality assurance and control ... 9

10 Test report ... 9

Method for determination of aluminum content in hot

dipped zinc-aluminum alloy coating on steel wire

Warning -- The personnel using this document shall have practical experience

in formal laboratory work. This document does not indicate all possible safety

issues. The user is responsible for taking appropriate safety and health

measures and ensuring compliance with the conditions stipulated by relevant

national laws and regulations.

1 Scope

This document specifies the principle, reagents, analysis steps, the calculation of

analysis results, the calculation of precision, methods of quality assurance and control,

and contents of test reports of the chemical titration method for determining aluminum

content in hot dipped zinc-aluminum alloy coating on steel wire.

This document is applicable to the determination of aluminum content in hot dipped

zinc-aluminum alloy coating on steel wire. The measurement range of aluminum

content is 2.5%~30%.

2 Normative references

The following documents are essential to the application of this document. For the

dated documents, only the versions with the dates indicated are applicable to this

document; for the undated documents, only the latest version (including all the

amendments) is applicable to this standard.

GB/T 601 Chemical reagent -- Preparations of reference titration solutions

GB/T 1839 Test method for gravimetric determination of the mass per unit area of

galvanized coatings on steel products

GB/T 6682 Water for analytical laboratory use -- Specification and test methods

GB/T 8170 Rules of rounding off for numerical values and expression and

judgement of limiting values

3 Terms and definitions

There are no terms and definitions that need to be defined in this document.

4 Principle

Add an excess of EDTA standard solution to the weakly acidic solution to form

complexes with iron, zinc, copper and other elements. Then, in the presence of acetic

acid, boil all aluminum to form a complex; use xylenol orange as an indicator; and use

lead nitrate standard solution to back-titrate an excess of EDTA. Add fluoride to de-

mask Al-EDTA; release the same amount of EDTA as aluminum; and titrate with lead

nitrate standard titration solution; then, calculate the mass fraction of aluminum.

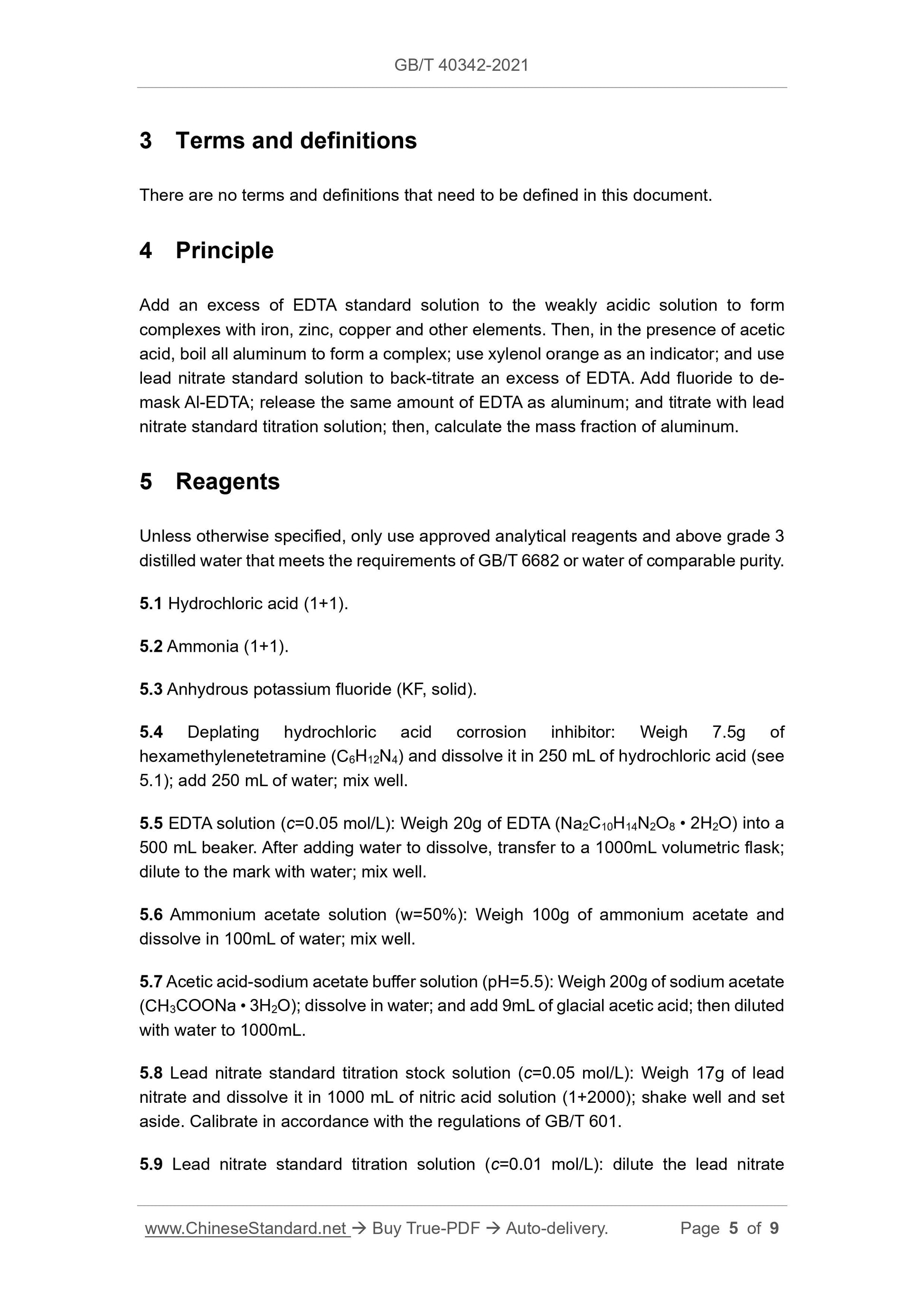

5 Reagents

Unless otherwise specified, only use approved analytical reagents and above grade 3

distilled water that meets the requirements of GB/T 6682 or water of comparable purity.

5.1 Hydrochloric acid (1+1).

5.2 Ammonia (1+1).

5.3 Anhydrous potassium fluoride (KF, solid).

5.4 Deplating hydrochloric acid corrosion inhibitor: Weigh 7.5g of

hexamethylenetetramine (C6H12N4) and dissolve it in 250 mL of hydrochloric acid (see

5.1); add 250 mL of water; mix well.

5.5 EDTA solution (c=0.05 mol/L): Weigh 20g of EDTA (Na2C10H14N2O8 • 2H2O) into a

500 mL beaker. After adding water to dissolve, transfer to a 1000mL volumetric flask;

dilute to the mark with water; mix well.

5.6 Ammonium acetate solution (w=50%): Weigh 100g of ammonium acetate and

dissolve in 100mL of water; mix well.

5.7 Acetic acid-sodium acetate buffer solution (pH=5.5): Weigh 200g of sodium acetate

(CH3COONa • 3H2O); dissolve in water; and add 9mL of glacial acetic acid; then diluted

with water to 1000mL.

5.8 Lead nitrate standard titration stock solution (c=0.05 mol/L): Weigh 17g of lead

nitrate and dissolve it in 1000 mL of nitric acid solution (1+2000); shake well and set

aside. Calibrate in accordance with the regulations of GB/T 601.

5.9 Lead nitrate standard titration solution (c=0.01 mol/L): dilute the lead nitrate

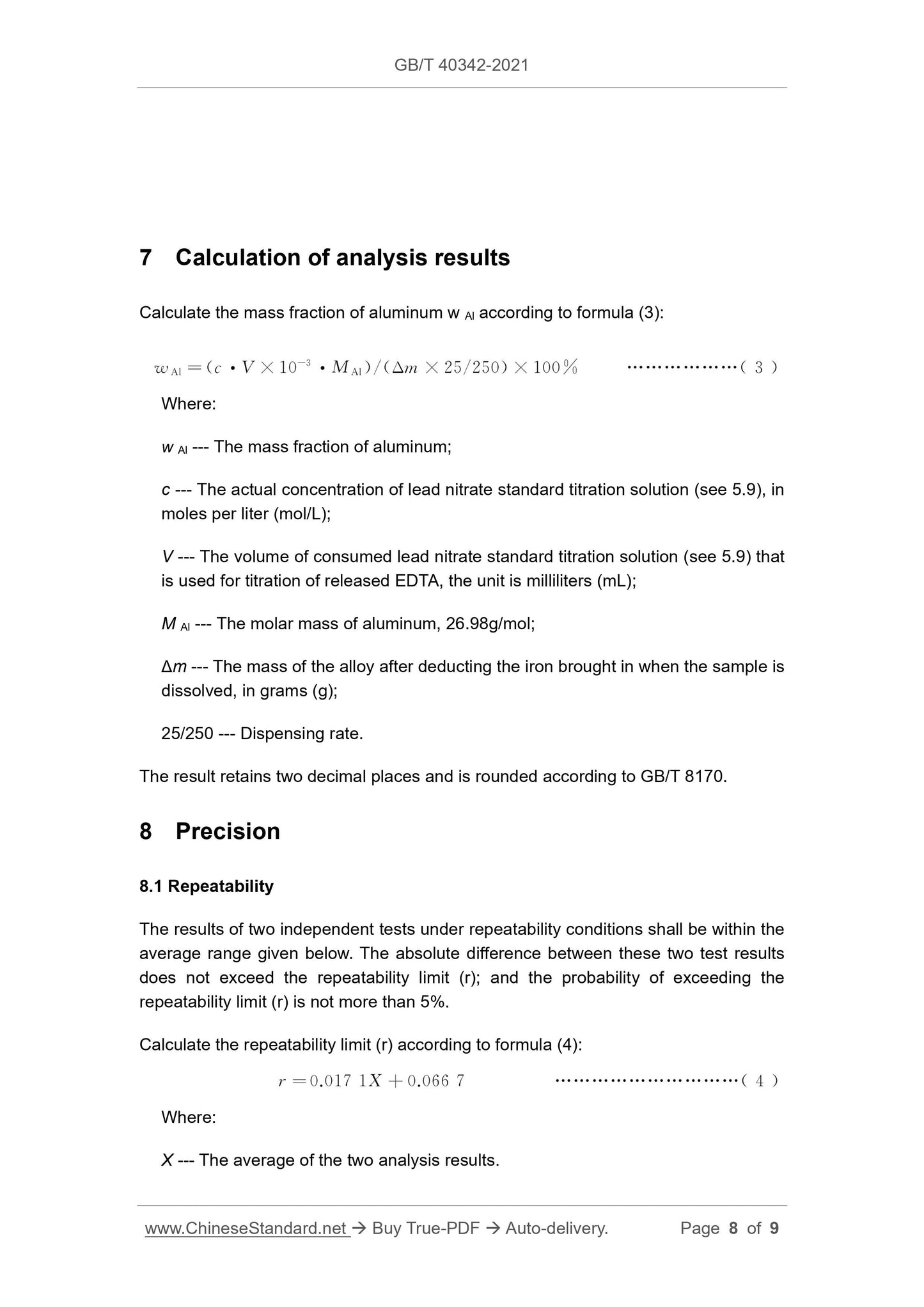

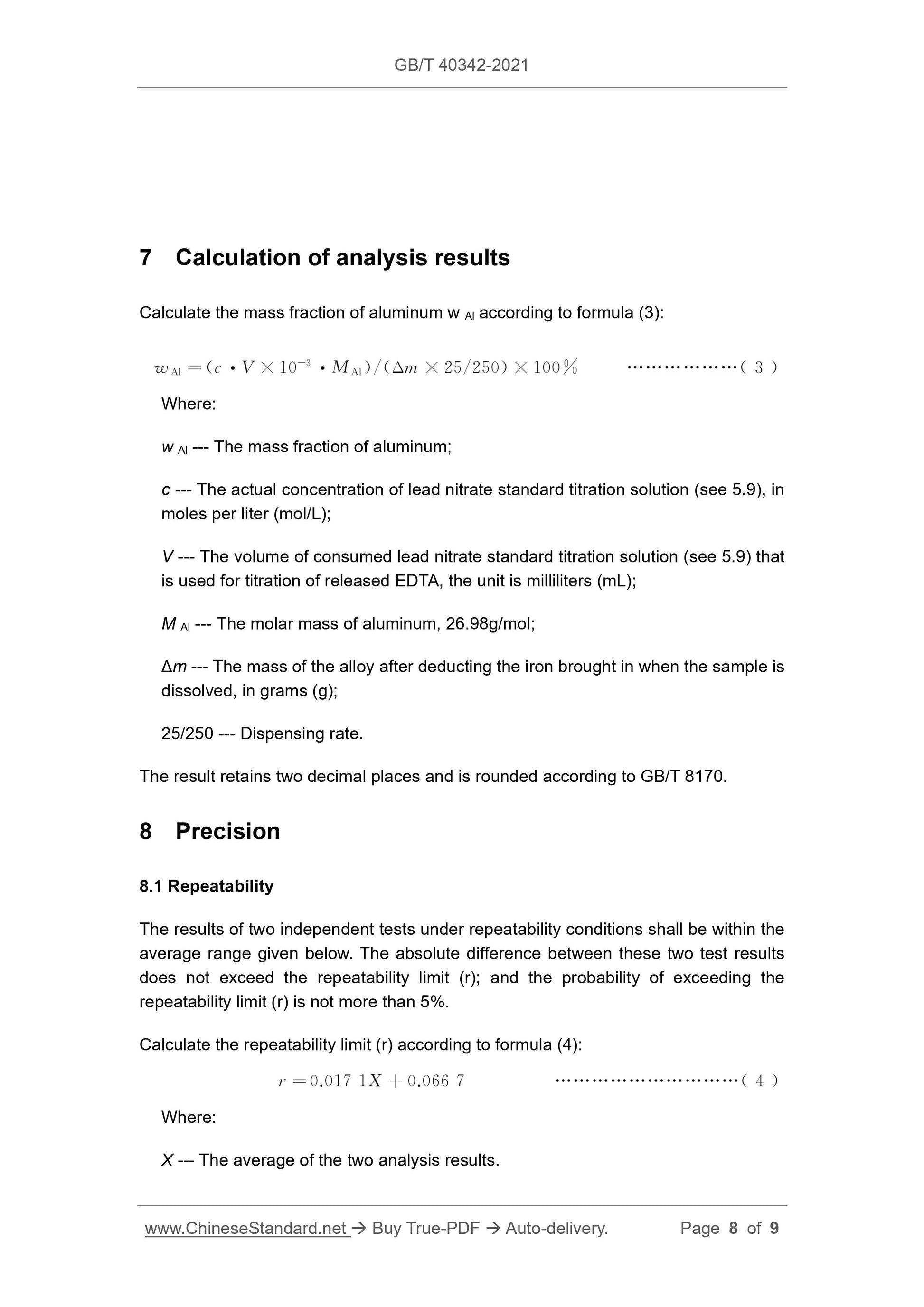

7 Calculation of analysis results

Calculate the mass fraction of aluminum w Al according to formula (3):

Where:

w Al --- The mass fraction of aluminum;

c --- The actual concentration of lead nitrate standard titration solution (see 5.9), in

moles per liter (mol/L);

V --- The volume of consumed lead nitrate standard titration solution (see 5.9) that

is used for titration of released EDTA, the unit is milliliters (mL);

M Al --- The molar mass of aluminum, 26.98g/mol;

Δm --- The mass of the alloy after deducting the iron brought in when the sample is

dissolved, in grams (g);

25/250 --- Dispensing rate.

The result retains two decimal places and is rounded according to GB/T 8170.

8 Precision

8.1 Repeatability

The results of two independent tests under repeatability conditions shall be within the

average range given below. The absolute difference between these two test results

does not exceed the repeatability limit (r); and the probability of exceeding the

repeatability limit (r) is not more than 5%.

Calculate the repeatability limit (r) according to formula (4):

Where:

X --- The average of the two analysis results.

GB/T 40342-2021

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.140.65

CCS H 12

Method for determination of aluminum content in hot

dipped zinc-aluminum alloy coating on steel wire

ISSUED ON: AUGUST 20, 2021

IMPLEMENTED ON: MARCH 1, 2022

Issued by: State Administration for Market Regulation;

Standardization Administration of PRC.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Terms and definitions ... 5

4 Principle... 5

5 Reagents ... 5

6 Analysis steps ... 6

7 Calculation of analysis results ... 8

8 Precision... 8

9 Quality assurance and control ... 9

10 Test report ... 9

Method for determination of aluminum content in hot

dipped zinc-aluminum alloy coating on steel wire

Warning -- The personnel using this document shall have practical experience

in formal laboratory work. This document does not indicate all possible safety

issues. The user is responsible for taking appropriate safety and health

measures and ensuring compliance with the conditions stipulated by relevant

national laws and regulations.

1 Scope

This document specifies the principle, reagents, analysis steps, the calculation of

analysis results, the calculation of precision, methods of quality assurance and control,

and contents of test reports of the chemical titration method for determining aluminum

content in hot dipped zinc-aluminum alloy coating on steel wire.

This document is applicable to the determination of aluminum content in hot dipped

zinc-aluminum alloy coating on steel wire. The measurement range of aluminum

content is 2.5%~30%.

2 Normative references

The following documents are essential to the application of this document. For the

dated documents, only the versions with the dates indicated are applicable to this

document; for the undated documents, only the latest version (including all the

amendments) is applicable to this standard.

GB/T 601 Chemical reagent -- Preparations of reference titration solutions

GB/T 1839 Test method for gravimetric determination of the mass per unit area of

galvanized coatings on steel products

GB/T 6682 Water for analytical laboratory use -- Specification and test methods

GB/T 8170 Rules of rounding off for numerical values and expression and

judgement of limiting values

3 Terms and definitions

There are no terms and definitions that need to be defined in this document.

4 Principle

Add an excess of EDTA standard solution to the weakly acidic solution to form

complexes with iron, zinc, copper and other elements. Then, in the presence of acetic

acid, boil all aluminum to form a complex; use xylenol orange as an indicator; and use

lead nitrate standard solution to back-titrate an excess of EDTA. Add fluoride to de-

mask Al-EDTA; release the same amount of EDTA as aluminum; and titrate with lead

nitrate standard titration solution; then, calculate the mass fraction of aluminum.

5 Reagents

Unless otherwise specified, only use approved analytical reagents and above grade 3

distilled water that meets the requirements of GB/T 6682 or water of comparable purity.

5.1 Hydrochloric acid (1+1).

5.2 Ammonia (1+1).

5.3 Anhydrous potassium fluoride (KF, solid).

5.4 Deplating hydrochloric acid corrosion inhibitor: Weigh 7.5g of

hexamethylenetetramine (C6H12N4) and dissolve it in 250 mL of hydrochloric acid (see

5.1); add 250 mL of water; mix well.

5.5 EDTA solution (c=0.05 mol/L): Weigh 20g of EDTA (Na2C10H14N2O8 • 2H2O) into a

500 mL beaker. After adding water to dissolve, transfer to a 1000mL volumetric flask;

dilute to the mark with water; mix well.

5.6 Ammonium acetate solution (w=50%): Weigh 100g of ammonium acetate and

dissolve in 100mL of water; mix well.

5.7 Acetic acid-sodium acetate buffer solution (pH=5.5): Weigh 200g of sodium acetate

(CH3COONa • 3H2O); dissolve in water; and add 9mL of glacial acetic acid; then diluted

with water to 1000mL.

5.8 Lead nitrate standard titration stock solution (c=0.05 mol/L): Weigh 17g of lead

nitrate and dissolve it in 1000 mL of nitric acid solution (1+2000); shake well and set

aside. Calibrate in accordance with the regulations of GB/T 601.

5.9 Lead nitrate standard titration solution (c=0.01 mol/L): dilute the lead nitrate

7 Calculation of analysis results

Calculate the mass fraction of aluminum w Al according to formula (3):

Where:

w Al --- The mass fraction of aluminum;

c --- The actual concentration of lead nitrate standard titration solution (see 5.9), in

moles per liter (mol/L);

V --- The volume of consumed lead nitrate standard titration solution (see 5.9) that

is used for titration of released EDTA, the unit is milliliters (mL);

M Al --- The molar mass of aluminum, 26.98g/mol;

Δm --- The mass of the alloy after deducting the iron brought in when the sample is

dissolved, in grams (g);

25/250 --- Dispensing rate.

The result retains two decimal places and is rounded according to GB/T 8170.

8 Precision

8.1 Repeatability

The results of two independent tests under repeatability conditions shall be within the

average range given below. The absolute difference between these two test results

does not exceed the repeatability limit (r); and the probability of exceeding the

repeatability limit (r) is not more than 5%.

Calculate the repeatability limit (r) according to formula (4):

Where:

X --- The average of the two analysis results.

Get Quotation: Click GB/T 40342-2021 (Self-service in 1-minute)

Historical versions (Master-website): GB/T 40342-2021

Preview True-PDF (Reload/Scroll-down if blank)

GB/T 40342-2021: Method for determination of aluminum content in hot dipped zinc-aluminum alloy coating on steel wire

GB/T 40342-2021

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.140.65

CCS H 12

Method for determination of aluminum content in hot

dipped zinc-aluminum alloy coating on steel wire

ISSUED ON: AUGUST 20, 2021

IMPLEMENTED ON: MARCH 1, 2022

Issued by: State Administration for Market Regulation;

Standardization Administration of PRC.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Terms and definitions ... 5

4 Principle... 5

5 Reagents ... 5

6 Analysis steps ... 6

7 Calculation of analysis results ... 8

8 Precision... 8

9 Quality assurance and control ... 9

10 Test report ... 9

Method for determination of aluminum content in hot

dipped zinc-aluminum alloy coating on steel wire

Warning -- The personnel using this document shall have practical experience

in formal laboratory work. This document does not indicate all possible safety

issues. The user is responsible for taking appropriate safety and health

measures and ensuring compliance with the conditions stipulated by relevant

national laws and regulations.

1 Scope

This document specifies the principle, reagents, analysis steps, the calculation of

analysis results, the calculation of precision, methods of quality assurance and control,

and contents of test reports of the chemical titration method for determining aluminum

content in hot dipped zinc-aluminum alloy coating on steel wire.

This document is applicable to the determination of aluminum content in hot dipped

zinc-aluminum alloy coating on steel wire. The measurement range of aluminum

content is 2.5%~30%.

2 Normative references

The following documents are essential to the application of this document. For the

dated documents, only the versions with the dates indicated are applicable to this

document; for the undated documents, only the latest version (including all the

amendments) is applicable to this standard.

GB/T 601 Chemical reagent -- Preparations of reference titration solutions

GB/T 1839 Test method for gravimetric determination of the mass per unit area of

galvanized coatings on steel products

GB/T 6682 Water for analytical laboratory use -- Specification and test methods

GB/T 8170 Rules of rounding off for numerical values and expression and

judgement of limiting values

3 Terms and definitions

There are no terms and definitions that need to be defined in this document.

4 Principle

Add an excess of EDTA standard solution to the weakly acidic solution to form

complexes with iron, zinc, copper and other elements. Then, in the presence of acetic

acid, boil all aluminum to form a complex; use xylenol orange as an indicator; and use

lead nitrate standard solution to back-titrate an excess of EDTA. Add fluoride to de-

mask Al-EDTA; release the same amount of EDTA as aluminum; and titrate with lead

nitrate standard titration solution; then, calculate the mass fraction of aluminum.

5 Reagents

Unless otherwise specified, only use approved analytical reagents and above grade 3

distilled water that meets the requirements of GB/T 6682 or water of comparable purity.

5.1 Hydrochloric acid (1+1).

5.2 Ammonia (1+1).

5.3 Anhydrous potassium fluoride (KF, solid).

5.4 Deplating hydrochloric acid corrosion inhibitor: Weigh 7.5g of

hexamethylenetetramine (C6H12N4) and dissolve it in 250 mL of hydrochloric acid (see

5.1); add 250 mL of water; mix well.

5.5 EDTA solution (c=0.05 mol/L): Weigh 20g of EDTA (Na2C10H14N2O8 • 2H2O) into a

500 mL beaker. After adding water to dissolve, transfer to a 1000mL volumetric flask;

dilute to the mark with water; mix well.

5.6 Ammonium acetate solution (w=50%): Weigh 100g of ammonium acetate and

dissolve in 100mL of water; mix well.

5.7 Acetic acid-sodium acetate buffer solution (pH=5.5): Weigh 200g of sodium acetate

(CH3COONa • 3H2O); dissolve in water; and add 9mL of glacial acetic acid; then diluted

with water to 1000mL.

5.8 Lead nitrate standard titration stock solution (c=0.05 mol/L): Weigh 17g of lead

nitrate and dissolve it in 1000 mL of nitric acid solution (1+2000); shake well and set

aside. Calibrate in accordance with the regulations of GB/T 601.

5.9 Lead nitrate standard titration solution (c=0.01 mol/L): dilute the lead nitrate

7 Calculation of analysis results

Calculate the mass fraction of aluminum w Al according to formula (3):

Where:

w Al --- The mass fraction of aluminum;

c --- The actual concentration of lead nitrate standard titration solution (see 5.9), in

moles per liter (mol/L);

V --- The volume of consumed lead nitrate standard titration solution (see 5.9) that

is used for titration of released EDTA, the unit is milliliters (mL);

M Al --- The molar mass of aluminum, 26.98g/mol;

Δm --- The mass of the alloy after deducting the iron brought in when the sample is

dissolved, in grams (g);

25/250 --- Dispensing rate.

The result retains two decimal places and is rounded according to GB/T 8170.

8 Precision

8.1 Repeatability

The results of two independent tests under repeatability conditions shall be within the

average range given below. The absolute difference between these two test results

does not exceed the repeatability limit (r); and the probability of exceeding the

repeatability limit (r) is not more than 5%.

Calculate the repeatability limit (r) according to formula (4):

Where:

X --- The average of the two analysis results.

GB/T 40342-2021

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.140.65

CCS H 12

Method for determination of aluminum content in hot

dipped zinc-aluminum alloy coating on steel wire

ISSUED ON: AUGUST 20, 2021

IMPLEMENTED ON: MARCH 1, 2022

Issued by: State Administration for Market Regulation;

Standardization Administration of PRC.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Terms and definitions ... 5

4 Principle... 5

5 Reagents ... 5

6 Analysis steps ... 6

7 Calculation of analysis results ... 8

8 Precision... 8

9 Quality assurance and control ... 9

10 Test report ... 9

Method for determination of aluminum content in hot

dipped zinc-aluminum alloy coating on steel wire

Warning -- The personnel using this document shall have practical experience

in formal laboratory work. This document does not indicate all possible safety

issues. The user is responsible for taking appropriate safety and health

measures and ensuring compliance with the conditions stipulated by relevant

national laws and regulations.

1 Scope

This document specifies the principle, reagents, analysis steps, the calculation of

analysis results, the calculation of precision, methods of quality assurance and control,

and contents of test reports of the chemical titration method for determining aluminum

content in hot dipped zinc-aluminum alloy coating on steel wire.

This document is applicable to the determination of aluminum content in hot dipped

zinc-aluminum alloy coating on steel wire. The measurement range of aluminum

content is 2.5%~30%.

2 Normative references

The following documents are essential to the application of this document. For the

dated documents, only the versions with the dates indicated are applicable to this

document; for the undated documents, only the latest version (including all the

amendments) is applicable to this standard.

GB/T 601 Chemical reagent -- Preparations of reference titration solutions

GB/T 1839 Test method for gravimetric determination of the mass per unit area of

galvanized coatings on steel products

GB/T 6682 Water for analytical laboratory use -- Specification and test methods

GB/T 8170 Rules of rounding off for numerical values and expression and

judgement of limiting values

3 Terms and definitions

There are no terms and definitions that need to be defined in this document.

4 Principle

Add an excess of EDTA standard solution to the weakly acidic solution to form

complexes with iron, zinc, copper and other elements. Then, in the presence of acetic

acid, boil all aluminum to form a complex; use xylenol orange as an indicator; and use

lead nitrate standard solution to back-titrate an excess of EDTA. Add fluoride to de-

mask Al-EDTA; release the same amount of EDTA as aluminum; and titrate with lead

nitrate standard titration solution; then, calculate the mass fraction of aluminum.

5 Reagents

Unless otherwise specified, only use approved analytical reagents and above grade 3

distilled water that meets the requirements of GB/T 6682 or water of comparable purity.

5.1 Hydrochloric acid (1+1).

5.2 Ammonia (1+1).

5.3 Anhydrous potassium fluoride (KF, solid).

5.4 Deplating hydrochloric acid corrosion inhibitor: Weigh 7.5g of

hexamethylenetetramine (C6H12N4) and dissolve it in 250 mL of hydrochloric acid (see

5.1); add 250 mL of water; mix well.

5.5 EDTA solution (c=0.05 mol/L): Weigh 20g of EDTA (Na2C10H14N2O8 • 2H2O) into a

500 mL beaker. After adding water to dissolve, transfer to a 1000mL volumetric flask;

dilute to the mark with water; mix well.

5.6 Ammonium acetate solution (w=50%): Weigh 100g of ammonium acetate and

dissolve in 100mL of water; mix well.

5.7 Acetic acid-sodium acetate buffer solution (pH=5.5): Weigh 200g of sodium acetate

(CH3COONa • 3H2O); dissolve in water; and add 9mL of glacial acetic acid; then diluted

with water to 1000mL.

5.8 Lead nitrate standard titration stock solution (c=0.05 mol/L): Weigh 17g of lead

nitrate and dissolve it in 1000 mL of nitric acid solution (1+2000); shake well and set

aside. Calibrate in accordance with the regulations of GB/T 601.

5.9 Lead nitrate standard titration solution (c=0.01 mol/L): dilute the lead nitrate

7 Calculation of analysis results

Calculate the mass fraction of aluminum w Al according to formula (3):

Where:

w Al --- The mass fraction of aluminum;

c --- The actual concentration of lead nitrate standard titration solution (see 5.9), in

moles per liter (mol/L);

V --- The volume of consumed lead nitrate standard titration solution (see 5.9) that

is used for titration of released EDTA, the unit is milliliters (mL);

M Al --- The molar mass of aluminum, 26.98g/mol;

Δm --- The mass of the alloy after deducting the iron brought in when the sample is

dissolved, in grams (g);

25/250 --- Dispensing rate.

The result retains two decimal places and is rounded according to GB/T 8170.

8 Precision

8.1 Repeatability

The results of two independent tests under repeatability conditions shall be within the

average range given below. The absolute difference between these two test results

does not exceed the repeatability limit (r); and the probability of exceeding the

repeatability limit (r) is not more than 5%.

Calculate the repeatability limit (r) according to formula (4):

Where:

X --- The average of the two analysis results.

Share