1

/

of

6

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

GB/T 40508-2021 English PDF (GBT40508-2021)

GB/T 40508-2021 English PDF (GBT40508-2021)

Regular price

$170.00 USD

Regular price

Sale price

$170.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click GB/T 40508-2021

Historical versions: GB/T 40508-2021

Preview True-PDF (Reload/Scroll if blank)

GB/T 40508-2021: Determination of tar and dust concentrations in biomass-based synthetic gas

GB/T 40508-2021

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 27.010

CCS F 01

Determination of tar and dust concentrations in

biomass-based synthetic gas

ISSUED ON: AUGUST 20, 2021

IMPLEMENTED ON: MARCH 01, 2022

Issued by: State Administration for Market Regulation;

Standardization Administration of the People’s Republic of

China.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Terms and definitions ... 4

4 Determination method ... 5

5 Result calculation ... 9

6 Repeatability ... 10

Appendix A (Normative) Conversion method of gas volume under standard

conditions ... 11

Determination of tar and dust concentrations in

biomass-based synthetic gas

1 Scope

This document specifies the determination method, result calculation and

repeatability requirements of tar and dust concentrations in biomass-based

synthetic gas.

This document applies to combustible gases which are produced from raw

materials, such as biomass wastes of agricultural sources, forestry sources,

industrial sources, and domestic sources, through thermo-chemical conversion

methods such as pyrolysis or gasification.

2 Normative references

The following documents are normatively referenced in this document and are

indispensable for its application. For dated references, only the version

corresponding to that date is applicable to this document; for undated

references, the latest version (including all amendments) is applicable to this

document.

GB/T 1914-2017, Chemical analytical filter paper

GB/T 12206-2006, Testing method to determine the calorific values of town

gas

GB/T 12208-2008, Test methods of components and impurities of the

manufactured gas

3 Terms and definitions

The following terms and definitions are applicable to this document.

3.1

biomass-based synthetic gas

Combustible gas which is produced by biomass raw materials through thermo-

chemical conversion methods such as pyrolysis or gasification.

3.2

4.2.10 Vacuum drying oven: the temperature control range is from room

temperature to 200 °C; the temperature control accuracy is ±1 °C; the vacuum

degree range is 0 kPa ~ 98 kPa.

4.2.11 Buchner funnel: the inner diameter is 80 mm.

4.2.12 Filter bottle: the volume is 1 000 mL.

4.2.13 Dryer: it contains color-changing silica gel or granular anhydrous calcium

chloride.

4.2.14 Drying dish: the diameter is 150 mm.

4.2.15 Round-bottom flask: the volume is 250 mL; the bottleneck has a standard

grinding mouth whose diameter is 24/29.

4.3 Sampling requirements and procedures

4.3.1 Sampling requirements

4.3.1.1 Sampling position and requirements: the gas sampling position and

requirements shall be implemented in accordance with 5.3.1 of GB/T 12208-

2008.

4.3.1.2 The gas production equipment shall be in a stable operating state during

sampling; the equipment operating parameters shall be stable and the types of

raw materials shall be unchanged during the test.

4.3.1.3 If the gas pressure at the sampling point is lower than the atmospheric

pressure, a vacuum controllable suction pump should be connected after the

wet gas flow meter, so as to ensure that the gas can pass through the sampling

device smoothly. The gas after the volume measured by the wet gas flow meter

shall be discharged to an open outdoor area to avoid possible safety risks.

4.3.2 Sampling procedures

4.3.2.1 Add 150 mL ~ 200 mL of trichloromethane to the 6 gas washing bottles;

place all the gas washing bottles in the cooling pool. The height of the ice-water

mixture in the cooling pool shall be higher than the height of the solvent in the

gas washing bottles. It shall be ensured that the cooling pool is always in a state

of coexistence of ice and water during the sampling process. Connect the

sampling device according to Figure 1; check the air tightness of the device;

confirm that the air tightness of the device is good; record the wet gas flow

meter reading V1.

4.3.2.2 Open the sampling valve; adjust the gas flow rate to 5 L/min ~ 10 L/min;

record the sampled gas average temperature (t1), gas pressure (p1) and

atmospheric pressure (p).

dripping speed in the rotary evaporator is about 0.25 drops/s, stop the rotary

evaporator.

4.4.2.3 Transfer the filtrate from the filter bottle to the flask in batches; repeat

4.4.2.2; use about 30 mL of trichloromethane to clean the filter bottle twice;

transfer all the cleaning solvents to the flask for rotary evaporation.

4.4.2.4 When the dripping speed of the liquid in the rotary evaporator is about

0.25 drops/s, continue the rotary evaporation for 30 minutes and then end it; if

a small amount of moisture is still observed in the flask, add about 20 mL of

trichloromethane to the flask.

4.4.2.5 Repeat 4.4.2.4 until no moisture can be observed in the flask.

4.4.2.6 Remove the flask and put it in a desiccator to cool to room temperature;

then, weigh it. The reading is accurate to 0.1 mg; the weighed mass m3 is used

as the basis for calculation of the result. If the mass of the obtained tar is less

than 100 mg, the tar mass result of this time shall be converted to adjust the

gas sampling volume, so as to the to ensure that the tar mass measured by

subsequent tests is greater than 100 mg. The result of the last test shall prevail.

4.4.3 Determination of dust concentration

4.4.3.1 Transfer the filter cake and filter paper to a clean and dry dish of a known

mass of m4.

4.4.3.2 Place the drying dish in a vacuum drying oven for 12 hours. Set the

temperature of the drying oven to 80 °C. After removing the drying dish, put it

in a desiccator and cool to room temperature before weighing. The reading is

accurate to 0.1 mg.

4.4.3.3 Carry out inspection drying, for 0.5 h each time, until the difference

between the last two weighing results does not exceed 0.3 mg. Use the mass

m5 of the last weighing as the basis for calculation of the results.

4.4.3.4 If the mass of the obtained dust is less than 100 mg, the dust mass

result of this time shall be converted to adjust the gas sampling volume, so as

to ensure that the dust mass measured by subsequent tests is greater than 100

mg. The result of the last test shall prevail.

5 Result calculation

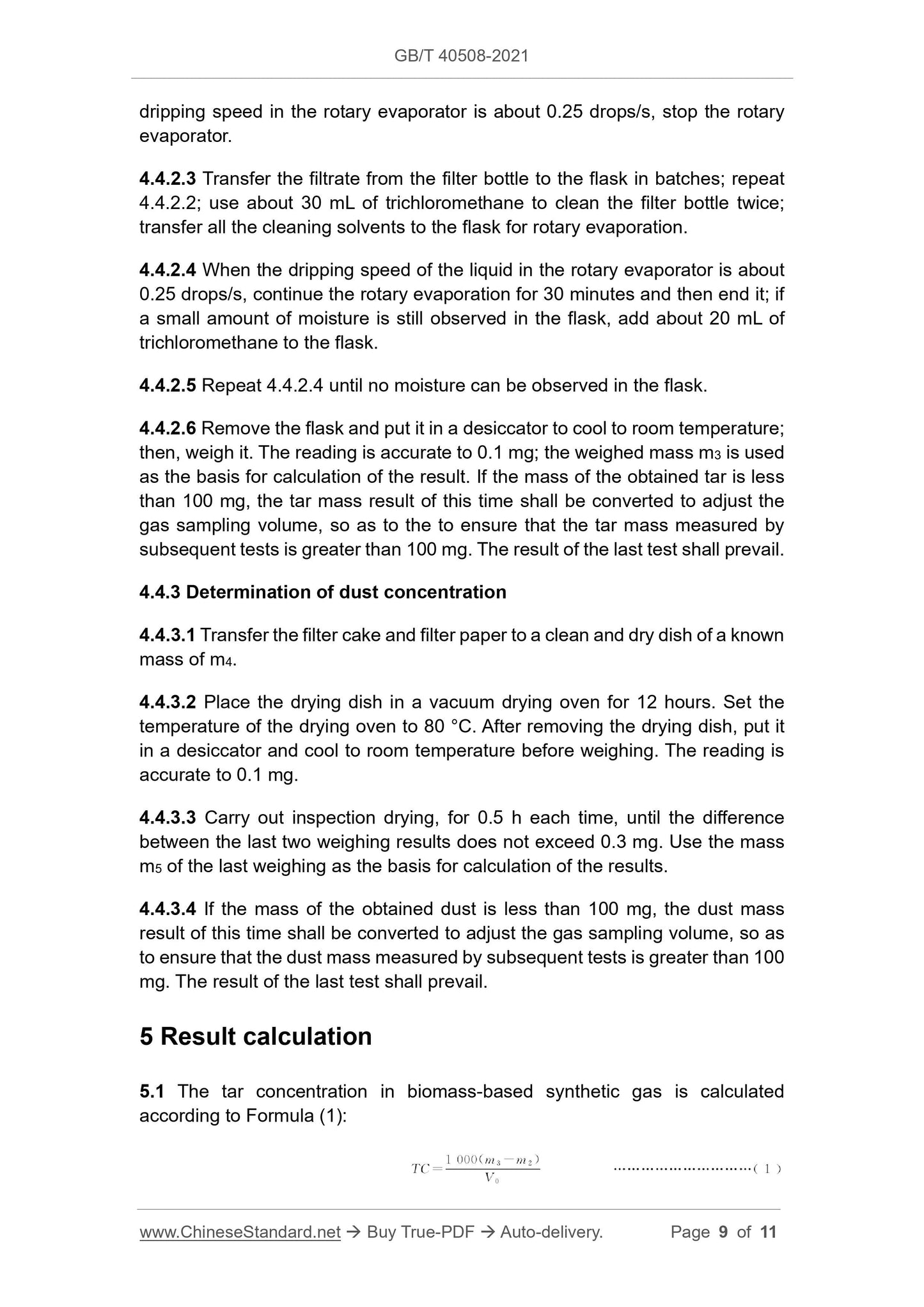

5.1 The tar concentration in biomass-based synthetic gas is calculated

according to Formula (1):

Where:

TC – the tar concentration in biomass-based synthetic gas, in milligrams per

cubic meter (mg/m3);

m2 – the mass of the 250 mL flask, in milligrams (mg);

m3 – the sum of mass of the 250 mL flask and tar, in milligrams (mg);

V0 – the value of gas volume under standard conditions [calculated according

to Formula (A.1) in Appendix A], in liters (L).

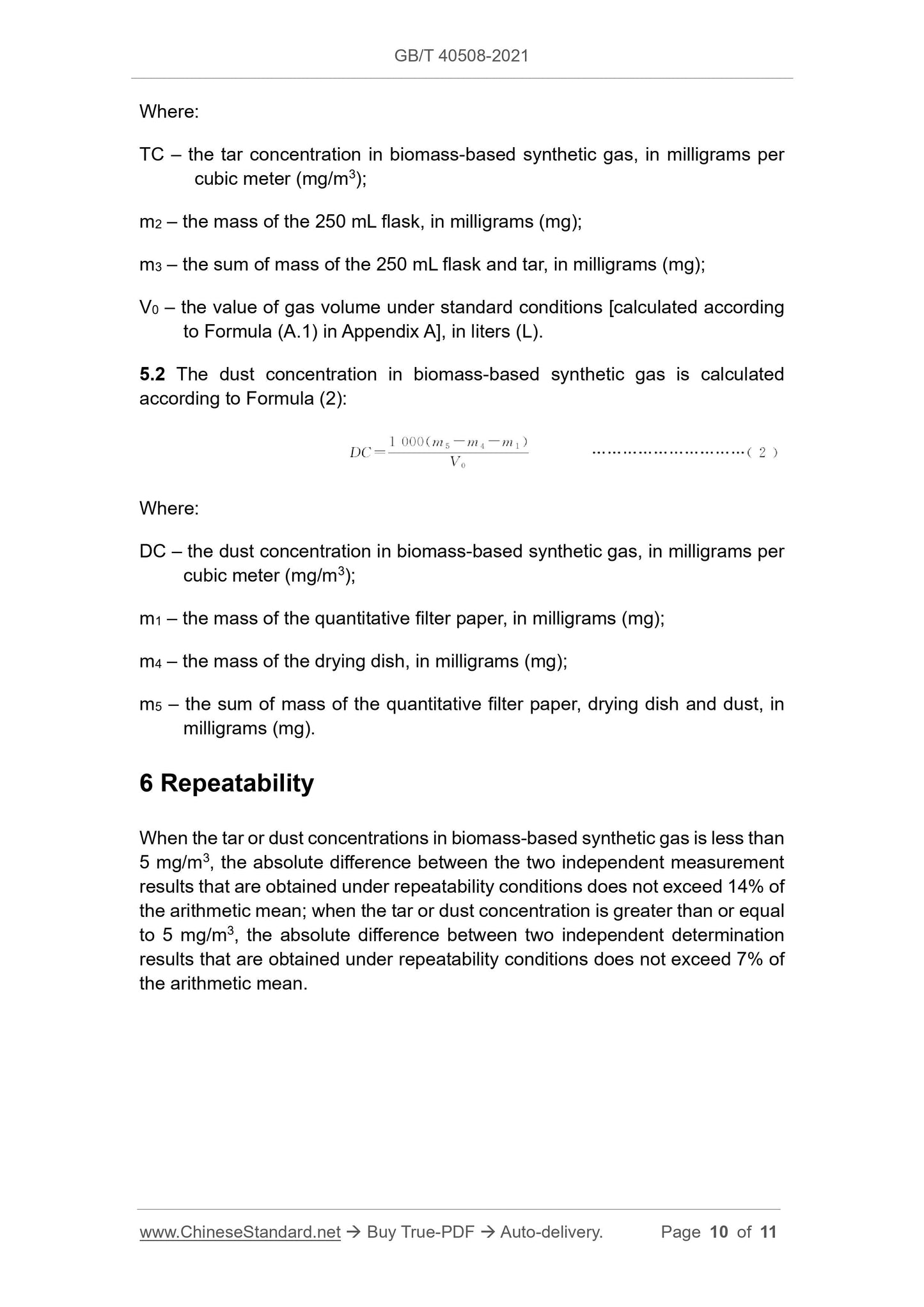

5.2 The dust concentration in biomass-based synthetic gas is calculated

according to Formula (2):

Where:

DC – the dust concentration in biomass-based synthetic gas, in milligrams per

cubic meter (mg/m3);

m1 – the mass of the quantitative filter paper, in milligrams (mg);

m4 – the mass of the drying dish, in milligrams (mg);

m5 – the sum of mass of the quantitative filter paper, drying dish and dust, in

milligrams (mg).

6 Repeatability

When the tar or dust concentrations in biomass-based synthetic gas is less than

5 mg/m3, the absolute difference between the two independent measurement

results that are obtained under repeatability conditions does not exceed 14% of

the arithmetic mean; when the tar...

Get QUOTATION in 1-minute: Click GB/T 40508-2021

Historical versions: GB/T 40508-2021

Preview True-PDF (Reload/Scroll if blank)

GB/T 40508-2021: Determination of tar and dust concentrations in biomass-based synthetic gas

GB/T 40508-2021

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 27.010

CCS F 01

Determination of tar and dust concentrations in

biomass-based synthetic gas

ISSUED ON: AUGUST 20, 2021

IMPLEMENTED ON: MARCH 01, 2022

Issued by: State Administration for Market Regulation;

Standardization Administration of the People’s Republic of

China.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Terms and definitions ... 4

4 Determination method ... 5

5 Result calculation ... 9

6 Repeatability ... 10

Appendix A (Normative) Conversion method of gas volume under standard

conditions ... 11

Determination of tar and dust concentrations in

biomass-based synthetic gas

1 Scope

This document specifies the determination method, result calculation and

repeatability requirements of tar and dust concentrations in biomass-based

synthetic gas.

This document applies to combustible gases which are produced from raw

materials, such as biomass wastes of agricultural sources, forestry sources,

industrial sources, and domestic sources, through thermo-chemical conversion

methods such as pyrolysis or gasification.

2 Normative references

The following documents are normatively referenced in this document and are

indispensable for its application. For dated references, only the version

corresponding to that date is applicable to this document; for undated

references, the latest version (including all amendments) is applicable to this

document.

GB/T 1914-2017, Chemical analytical filter paper

GB/T 12206-2006, Testing method to determine the calorific values of town

gas

GB/T 12208-2008, Test methods of components and impurities of the

manufactured gas

3 Terms and definitions

The following terms and definitions are applicable to this document.

3.1

biomass-based synthetic gas

Combustible gas which is produced by biomass raw materials through thermo-

chemical conversion methods such as pyrolysis or gasification.

3.2

4.2.10 Vacuum drying oven: the temperature control range is from room

temperature to 200 °C; the temperature control accuracy is ±1 °C; the vacuum

degree range is 0 kPa ~ 98 kPa.

4.2.11 Buchner funnel: the inner diameter is 80 mm.

4.2.12 Filter bottle: the volume is 1 000 mL.

4.2.13 Dryer: it contains color-changing silica gel or granular anhydrous calcium

chloride.

4.2.14 Drying dish: the diameter is 150 mm.

4.2.15 Round-bottom flask: the volume is 250 mL; the bottleneck has a standard

grinding mouth whose diameter is 24/29.

4.3 Sampling requirements and procedures

4.3.1 Sampling requirements

4.3.1.1 Sampling position and requirements: the gas sampling position and

requirements shall be implemented in accordance with 5.3.1 of GB/T 12208-

2008.

4.3.1.2 The gas production equipment shall be in a stable operating state during

sampling; the equipment operating parameters shall be stable and the types of

raw materials shall be unchanged during the test.

4.3.1.3 If the gas pressure at the sampling point is lower than the atmospheric

pressure, a vacuum controllable suction pump should be connected after the

wet gas flow meter, so as to ensure that the gas can pass through the sampling

device smoothly. The gas after the volume measured by the wet gas flow meter

shall be discharged to an open outdoor area to avoid possible safety risks.

4.3.2 Sampling procedures

4.3.2.1 Add 150 mL ~ 200 mL of trichloromethane to the 6 gas washing bottles;

place all the gas washing bottles in the cooling pool. The height of the ice-water

mixture in the cooling pool shall be higher than the height of the solvent in the

gas washing bottles. It shall be ensured that the cooling pool is always in a state

of coexistence of ice and water during the sampling process. Connect the

sampling device according to Figure 1; check the air tightness of the device;

confirm that the air tightness of the device is good; record the wet gas flow

meter reading V1.

4.3.2.2 Open the sampling valve; adjust the gas flow rate to 5 L/min ~ 10 L/min;

record the sampled gas average temperature (t1), gas pressure (p1) and

atmospheric pressure (p).

dripping speed in the rotary evaporator is about 0.25 drops/s, stop the rotary

evaporator.

4.4.2.3 Transfer the filtrate from the filter bottle to the flask in batches; repeat

4.4.2.2; use about 30 mL of trichloromethane to clean the filter bottle twice;

transfer all the cleaning solvents to the flask for rotary evaporation.

4.4.2.4 When the dripping speed of the liquid in the rotary evaporator is about

0.25 drops/s, continue the rotary evaporation for 30 minutes and then end it; if

a small amount of moisture is still observed in the flask, add about 20 mL of

trichloromethane to the flask.

4.4.2.5 Repeat 4.4.2.4 until no moisture can be observed in the flask.

4.4.2.6 Remove the flask and put it in a desiccator to cool to room temperature;

then, weigh it. The reading is accurate to 0.1 mg; the weighed mass m3 is used

as the basis for calculation of the result. If the mass of the obtained tar is less

than 100 mg, the tar mass result of this time shall be converted to adjust the

gas sampling volume, so as to the to ensure that the tar mass measured by

subsequent tests is greater than 100 mg. The result of the last test shall prevail.

4.4.3 Determination of dust concentration

4.4.3.1 Transfer the filter cake and filter paper to a clean and dry dish of a known

mass of m4.

4.4.3.2 Place the drying dish in a vacuum drying oven for 12 hours. Set the

temperature of the drying oven to 80 °C. After removing the drying dish, put it

in a desiccator and cool to room temperature before weighing. The reading is

accurate to 0.1 mg.

4.4.3.3 Carry out inspection drying, for 0.5 h each time, until the difference

between the last two weighing results does not exceed 0.3 mg. Use the mass

m5 of the last weighing as the basis for calculation of the results.

4.4.3.4 If the mass of the obtained dust is less than 100 mg, the dust mass

result of this time shall be converted to adjust the gas sampling volume, so as

to ensure that the dust mass measured by subsequent tests is greater than 100

mg. The result of the last test shall prevail.

5 Result calculation

5.1 The tar concentration in biomass-based synthetic gas is calculated

according to Formula (1):

Where:

TC – the tar concentration in biomass-based synthetic gas, in milligrams per

cubic meter (mg/m3);

m2 – the mass of the 250 mL flask, in milligrams (mg);

m3 – the sum of mass of the 250 mL flask and tar, in milligrams (mg);

V0 – the value of gas volume under standard conditions [calculated according

to Formula (A.1) in Appendix A], in liters (L).

5.2 The dust concentration in biomass-based synthetic gas is calculated

according to Formula (2):

Where:

DC – the dust concentration in biomass-based synthetic gas, in milligrams per

cubic meter (mg/m3);

m1 – the mass of the quantitative filter paper, in milligrams (mg);

m4 – the mass of the drying dish, in milligrams (mg);

m5 – the sum of mass of the quantitative filter paper, drying dish and dust, in

milligrams (mg).

6 Repeatability

When the tar or dust concentrations in biomass-based synthetic gas is less than

5 mg/m3, the absolute difference between the two independent measurement

results that are obtained under repeatability conditions does not exceed 14% of

the arithmetic mean; when the tar...

Share