1

/

of

7

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

GB/T 40799-2021 English PDF (GBT40799-2021)

GB/T 40799-2021 English PDF (GBT40799-2021)

Regular price

$230.00 USD

Regular price

Sale price

$230.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click GB/T 40799-2021

Historical versions: GB/T 40799-2021

Preview True-PDF (Reload/Scroll if blank)

GB/T 40799-2021: Machining process -- Test methods for essential energy efficiency data

GB/T 40799-2021

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 25.020

CCS J 30

GB 40799-2021

Machining process - Test methods for essential energy

efficiency data

ISSUED ON: OCTOBER 11, 2021

IMPLEMENTED ON: MAY 01, 2022

Issued by: State Administration for Market Regulation;

Standardization Administration of the People’s Republic of China.

Table of Contents

FOREWORD ... 3

1 Scope ... 4

2 Normative references ... 4

3 Terms and definitions... 4

4 Scope of essential energy efficiency data ... 6

5 Test method and calculation ... 6

Appendix A (Informative) Application example of essential energy efficiency data test

in the machining process ... 12

Machining process - Test methods for essential energy

efficiency data

1 Scope

This document specifies the test and calculation methods for essential energy efficiency

data in the machining process.

This document applies to the test of essential energy efficiency data in the machining

process of metal cutting machine tools during machining.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this

document and are indispensable for its application. For dated references, only the

version corresponding to that date is applicable to this document; for undated references,

the latest version (including all amendments) is applicable to this document.

GB/T 4863, General terminology of machine-building technology

GB/T 6477, Metal-cutting machine tools - Terminology

3 Terms and definitions

Terms and definitions determined by GB/T 4863, GB/T 6477, and the following ones

are applicable to this document.

3.1

machining process

The part or entire process for a machine tool to complete the machining of a workpiece.

3.2

standby

The state where the general power supply of the machine tool is turned on, and all other

systems of the machine tool used to support machining, except the spindle and the feed

system, are running.

3.3

idling

The state, in standby, where the spindle system or feed system of the machine tool is

turned on, and the spindle system or feed system is in the state where there is no cutting

load.

3.4

cutting

The running state where the machine tool is cutting and machining the workpiece.

3.5

standby power

The input power when the machine tool is in standby (3.2).

3.6

idling power

The input power when the machine tool is in idling (3.3).

3.7

cutting power

The input power when the machine tool is in cutting (3.4).

3.8

material removal power

The power increased for the machine tool to remove material.

3.9

energy consumption in standby period

The energy consumed by the machine tool in standby (3.2).

3.10

energy consumption in idling period

The energy consumed by the machine tool in idling (3.3).

3.11

energy consumption in cutting period

2) Idling power test: Turn on the machine tool spindle system or feed system, and

record the tested power value; the stable operation time in idling stable is

greater than 3/f, and the idling power is based on the partial power data after

stable operation in the idling state or the average value of all power data; the

idling power test should include all the idling states involved in the machining

process.

3) Cutting power test: Record the input power value of the machine tool in the

whole process from when the machine tool touches the workpiece to when the

tool leaves the workpiece surface. The cutting power is based on the average

value of the input power in the whole process. At the same time, the workpiece

information, tool information and cutting parameters corresponding to the

cutting process should be recorded.

5.2.2 Energy consumption test

Install an electric energy tester at the power input end of the machine tool. After the

machine tool is turned on, record the energy consumption values corresponding to the

start time and end time of each running state of the machine tool.

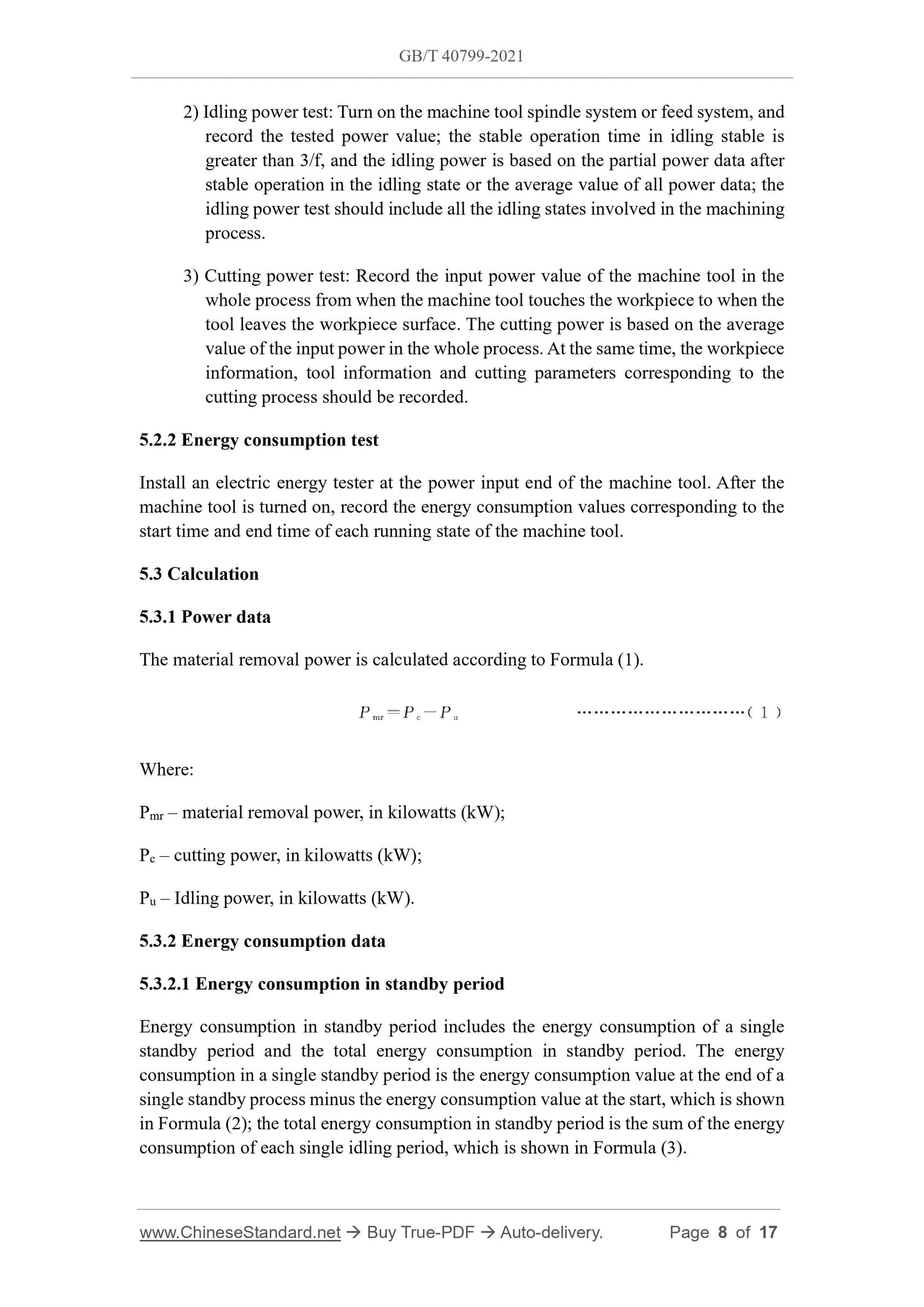

5.3 Calculation

5.3.1 Power data

The material removal power is calculated according to Formula (1).

Where:

Pmr – material removal power, in kilowatts (kW);

Pc – cutting power, in kilowatts (kW);

Pu – Idling power, in kilowatts (kW).

5.3.2 Energy consumption data

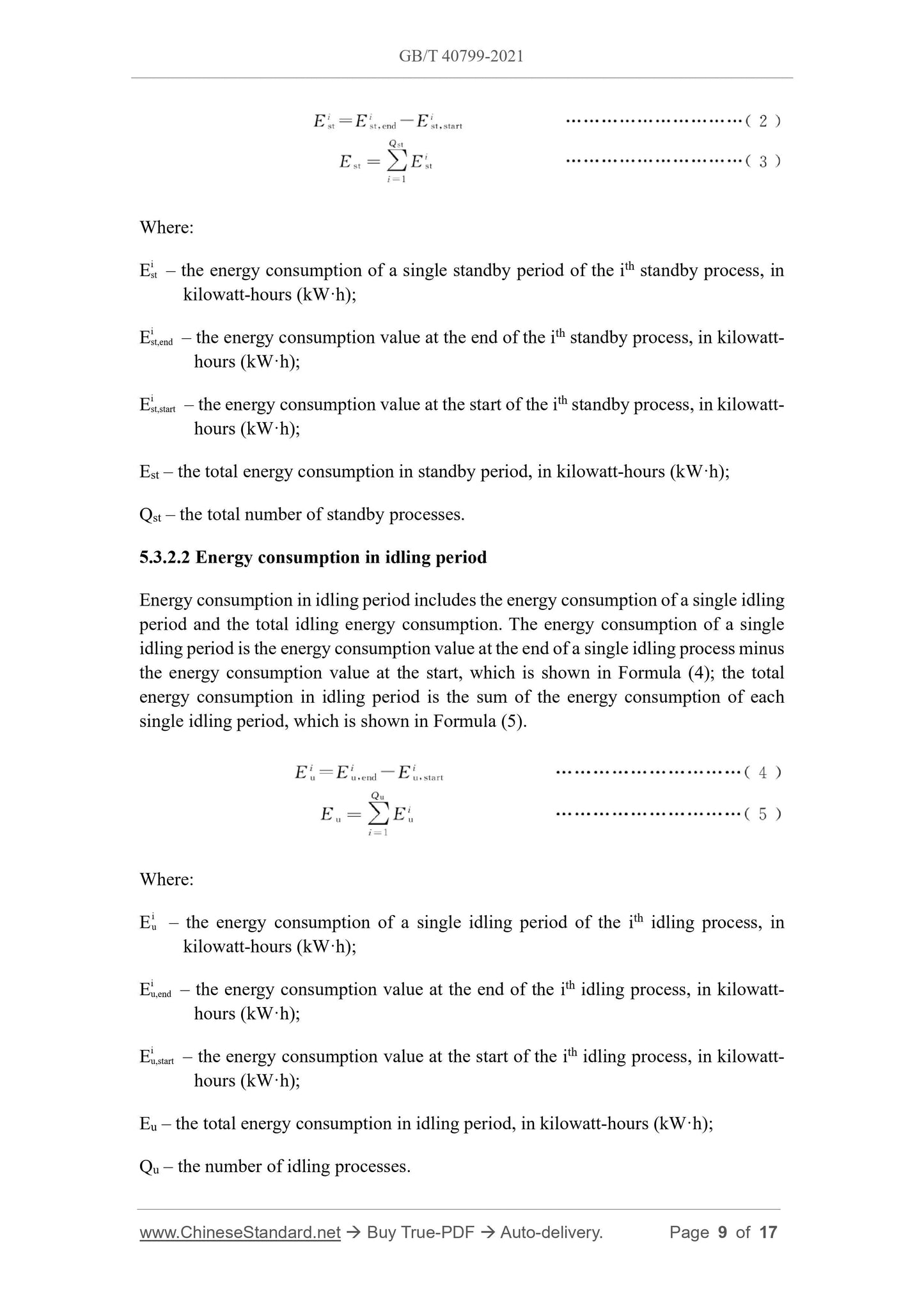

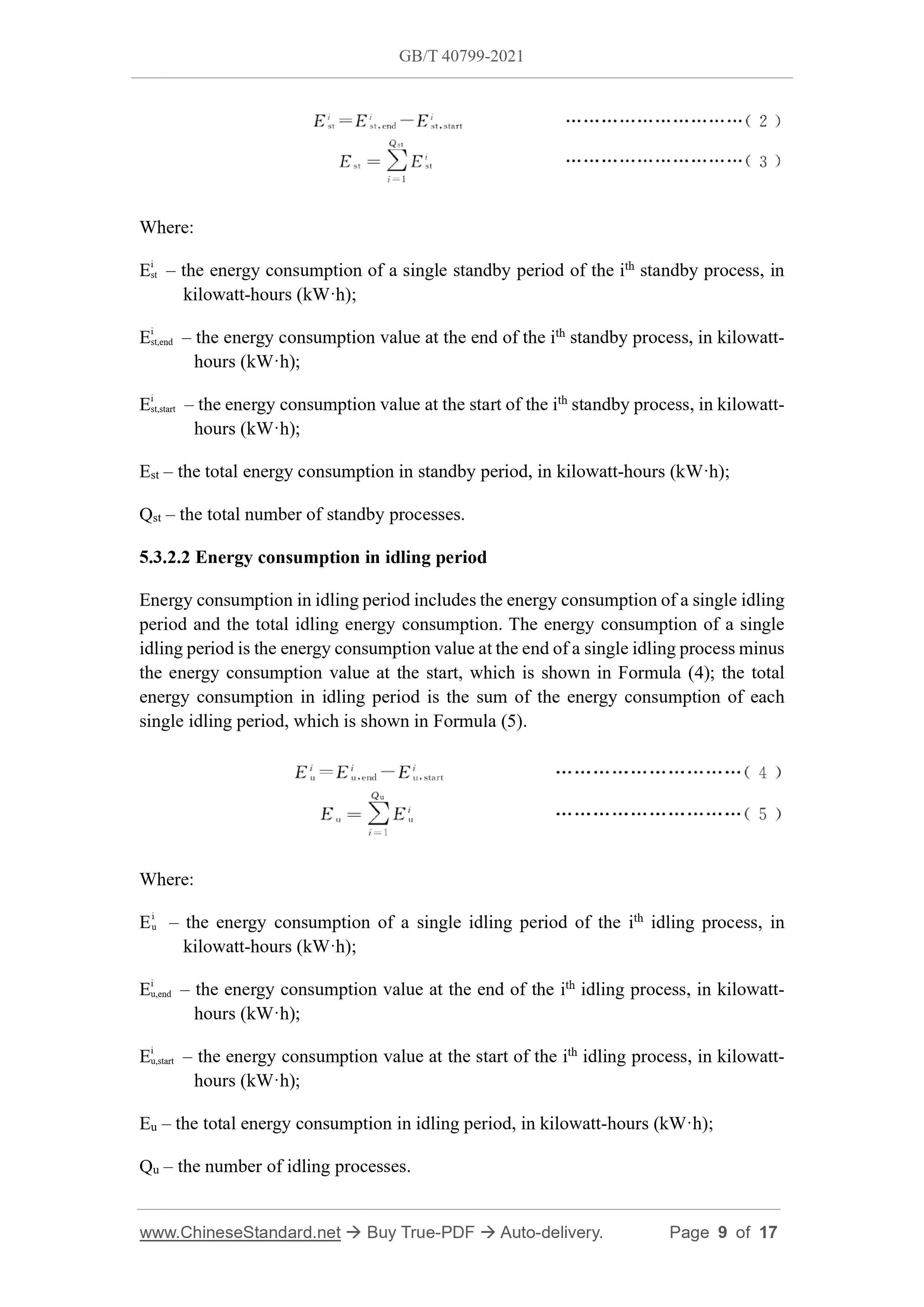

5.3.2.1 Energy consumption in standby period

Energy consumption in standby period includes the energy consumption of a single

standby period and the total energy consumption in standby period. The energy

consumption in a single standby period is the energy consumption value at the end of a

single standby process minus the energy consumption value at the start, which is shown

in Formula (2); the total energy consumption in standby period is the sum of the energy

consumption of each single idling period, which is shown in Formula (3).

Where:

Ei st – the energy consumption of a single standby period of the ith standby process, in

kilowatt-hours (kW·h);

Ei st,end – the energy consumption value at the end of the ith standby process, in kilowatt-

hours (kW·h);

Ei st,start – the energy consumption value at the start of the ith standby process, in kilowatt-

hours (kW·h);

Est – the total energy consumption in standby period, in kilowatt-hours (kW·h);

Qst – the total number of standby processes.

5.3.2.2 Energy consumption in idling period

Energy consumption in idling period includes the energy consumption of a single idling

period and the total idling energy consumption. The energy consumption of a single

idling period is the energy consumption value at the end of a single idling process minus

the energy consumption value at the start, which is shown in Formula (4); the total

energy consumption in idling period is the sum of the energy consumption of each

single idling period, which is shown in Formula (5).

Where:

Ei u – the energy consumption of a single idling period of the ith idling process, in

kilowatt-hours (kW·h);

Ei u,end – the energy consumption value at the end of the ith idling process, in kilowatt-

hours (kW·h);

Ei u,start – the energy consumption value at the start of the ith idling process, in kilowatt-

hours (kW·h);

Eu – the total energy consumption in idling period, in kilowatt-hours (kW·h);

Qu – the number of idling processes.

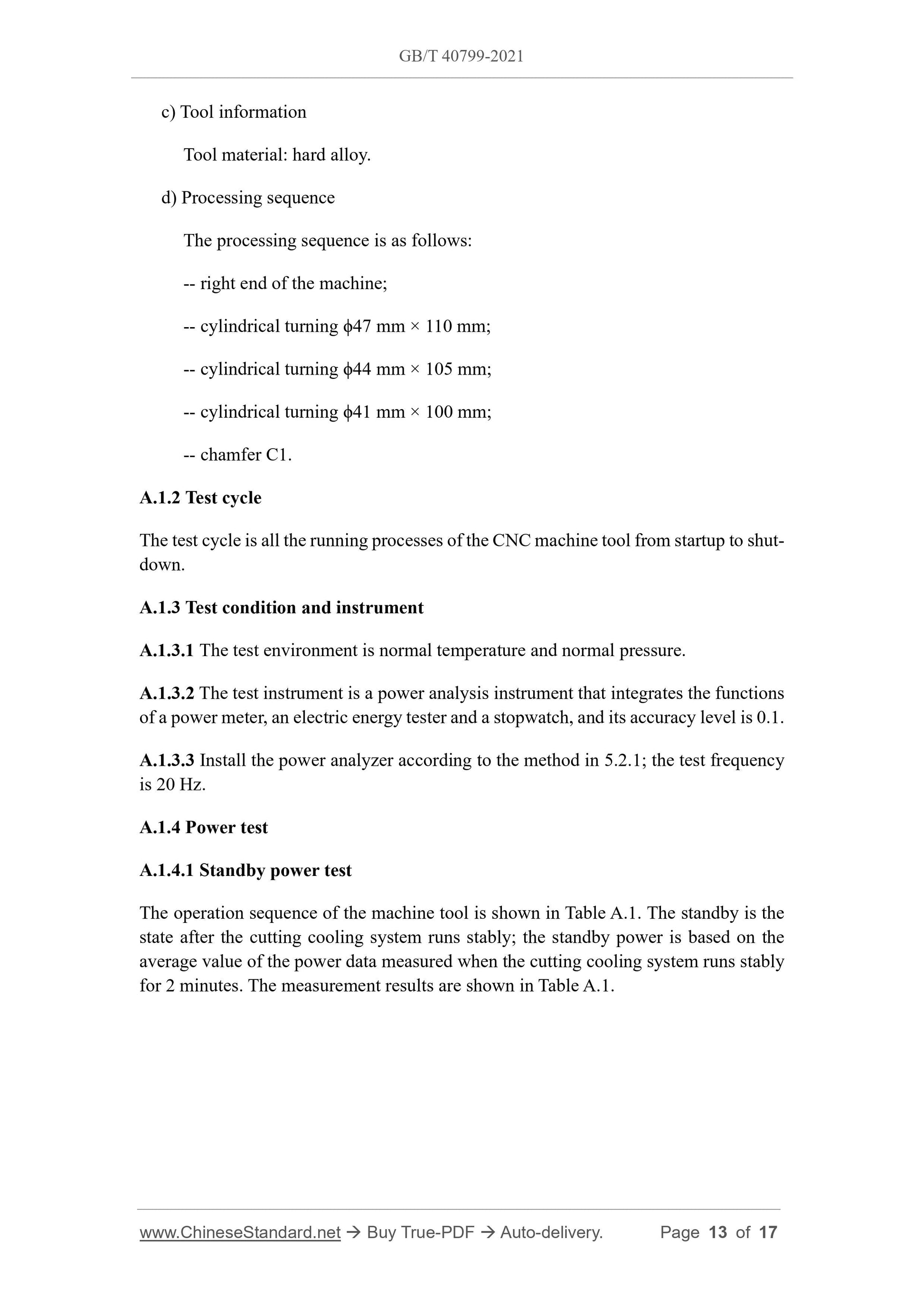

c) Tool information

Tool material: hard alloy.

d) Processing sequence

The processing sequence is as follows:

-- right end of the machine;

-- cylindrical turning ϕ47 mm × 110 mm;

-- cylindrical turning ϕ44 mm × 105 mm;

-- cylindrical turning ϕ41 mm × 100 mm;

-- chamfer C1.

A.1.2 Test cycle

The test cycle is all the running processes of the CNC machine tool from startup to shut-

down.

A.1.3 Test condition and instrument

A.1.3.1 The test environment is normal temperature and normal pressure.

A.1.3.2 The test instrument is a power analysis instrument that integrates the functions

of a power meter, an electric energy tester and a stopwatch, and its accuracy level is 0.1.

A.1.3.3 Install the power analyzer according to the method in 5.2.1; the test frequency

is 20 Hz.

A.1.4 Power test

A.1.4.1 Standby power test

The operation sequence of the machine tool is shown in Table A.1. The standby is the

state after the cutting cooling system runs stably; the standby power is based on the

average value of the power data measured when the cutting cooling system runs stably

for 2 minutes. The measurement results are shown in ...

Get QUOTATION in 1-minute: Click GB/T 40799-2021

Historical versions: GB/T 40799-2021

Preview True-PDF (Reload/Scroll if blank)

GB/T 40799-2021: Machining process -- Test methods for essential energy efficiency data

GB/T 40799-2021

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 25.020

CCS J 30

GB 40799-2021

Machining process - Test methods for essential energy

efficiency data

ISSUED ON: OCTOBER 11, 2021

IMPLEMENTED ON: MAY 01, 2022

Issued by: State Administration for Market Regulation;

Standardization Administration of the People’s Republic of China.

Table of Contents

FOREWORD ... 3

1 Scope ... 4

2 Normative references ... 4

3 Terms and definitions... 4

4 Scope of essential energy efficiency data ... 6

5 Test method and calculation ... 6

Appendix A (Informative) Application example of essential energy efficiency data test

in the machining process ... 12

Machining process - Test methods for essential energy

efficiency data

1 Scope

This document specifies the test and calculation methods for essential energy efficiency

data in the machining process.

This document applies to the test of essential energy efficiency data in the machining

process of metal cutting machine tools during machining.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this

document and are indispensable for its application. For dated references, only the

version corresponding to that date is applicable to this document; for undated references,

the latest version (including all amendments) is applicable to this document.

GB/T 4863, General terminology of machine-building technology

GB/T 6477, Metal-cutting machine tools - Terminology

3 Terms and definitions

Terms and definitions determined by GB/T 4863, GB/T 6477, and the following ones

are applicable to this document.

3.1

machining process

The part or entire process for a machine tool to complete the machining of a workpiece.

3.2

standby

The state where the general power supply of the machine tool is turned on, and all other

systems of the machine tool used to support machining, except the spindle and the feed

system, are running.

3.3

idling

The state, in standby, where the spindle system or feed system of the machine tool is

turned on, and the spindle system or feed system is in the state where there is no cutting

load.

3.4

cutting

The running state where the machine tool is cutting and machining the workpiece.

3.5

standby power

The input power when the machine tool is in standby (3.2).

3.6

idling power

The input power when the machine tool is in idling (3.3).

3.7

cutting power

The input power when the machine tool is in cutting (3.4).

3.8

material removal power

The power increased for the machine tool to remove material.

3.9

energy consumption in standby period

The energy consumed by the machine tool in standby (3.2).

3.10

energy consumption in idling period

The energy consumed by the machine tool in idling (3.3).

3.11

energy consumption in cutting period

2) Idling power test: Turn on the machine tool spindle system or feed system, and

record the tested power value; the stable operation time in idling stable is

greater than 3/f, and the idling power is based on the partial power data after

stable operation in the idling state or the average value of all power data; the

idling power test should include all the idling states involved in the machining

process.

3) Cutting power test: Record the input power value of the machine tool in the

whole process from when the machine tool touches the workpiece to when the

tool leaves the workpiece surface. The cutting power is based on the average

value of the input power in the whole process. At the same time, the workpiece

information, tool information and cutting parameters corresponding to the

cutting process should be recorded.

5.2.2 Energy consumption test

Install an electric energy tester at the power input end of the machine tool. After the

machine tool is turned on, record the energy consumption values corresponding to the

start time and end time of each running state of the machine tool.

5.3 Calculation

5.3.1 Power data

The material removal power is calculated according to Formula (1).

Where:

Pmr – material removal power, in kilowatts (kW);

Pc – cutting power, in kilowatts (kW);

Pu – Idling power, in kilowatts (kW).

5.3.2 Energy consumption data

5.3.2.1 Energy consumption in standby period

Energy consumption in standby period includes the energy consumption of a single

standby period and the total energy consumption in standby period. The energy

consumption in a single standby period is the energy consumption value at the end of a

single standby process minus the energy consumption value at the start, which is shown

in Formula (2); the total energy consumption in standby period is the sum of the energy

consumption of each single idling period, which is shown in Formula (3).

Where:

Ei st – the energy consumption of a single standby period of the ith standby process, in

kilowatt-hours (kW·h);

Ei st,end – the energy consumption value at the end of the ith standby process, in kilowatt-

hours (kW·h);

Ei st,start – the energy consumption value at the start of the ith standby process, in kilowatt-

hours (kW·h);

Est – the total energy consumption in standby period, in kilowatt-hours (kW·h);

Qst – the total number of standby processes.

5.3.2.2 Energy consumption in idling period

Energy consumption in idling period includes the energy consumption of a single idling

period and the total idling energy consumption. The energy consumption of a single

idling period is the energy consumption value at the end of a single idling process minus

the energy consumption value at the start, which is shown in Formula (4); the total

energy consumption in idling period is the sum of the energy consumption of each

single idling period, which is shown in Formula (5).

Where:

Ei u – the energy consumption of a single idling period of the ith idling process, in

kilowatt-hours (kW·h);

Ei u,end – the energy consumption value at the end of the ith idling process, in kilowatt-

hours (kW·h);

Ei u,start – the energy consumption value at the start of the ith idling process, in kilowatt-

hours (kW·h);

Eu – the total energy consumption in idling period, in kilowatt-hours (kW·h);

Qu – the number of idling processes.

c) Tool information

Tool material: hard alloy.

d) Processing sequence

The processing sequence is as follows:

-- right end of the machine;

-- cylindrical turning ϕ47 mm × 110 mm;

-- cylindrical turning ϕ44 mm × 105 mm;

-- cylindrical turning ϕ41 mm × 100 mm;

-- chamfer C1.

A.1.2 Test cycle

The test cycle is all the running processes of the CNC machine tool from startup to shut-

down.

A.1.3 Test condition and instrument

A.1.3.1 The test environment is normal temperature and normal pressure.

A.1.3.2 The test instrument is a power analysis instrument that integrates the functions

of a power meter, an electric energy tester and a stopwatch, and its accuracy level is 0.1.

A.1.3.3 Install the power analyzer according to the method in 5.2.1; the test frequency

is 20 Hz.

A.1.4 Power test

A.1.4.1 Standby power test

The operation sequence of the machine tool is shown in Table A.1. The standby is the

state after the cutting cooling system runs stably; the standby power is based on the

average value of the power data measured when the cutting cooling system runs stably

for 2 minutes. The measurement results are shown in ...

Share