1

/

of

6

PayPal, credit cards. Download editable-PDF & invoice in 1 second!

GB/T 41750-2022 English PDF (GBT41750-2022)

GB/T 41750-2022 English PDF (GBT41750-2022)

Regular price

$170.00 USD

Regular price

Sale price

$170.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click GB/T 41750-2022

Historical versions: GB/T 41750-2022

Preview True-PDF (Reload/Scroll if blank)

GB/T 41750-2022: Titanium and titanium alloy square and rectangular tubes

GB/T 41750-2022

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.150.50

CCS H 64

Titanium and titanium alloy square and rectangular tubes

ISSUED ON: OCTOBER 12, 2022

IMPLEMENTED ON: MAY 1, 2023

Issued by: State Administration for Market Regulation;

Standardization Administration of PRC.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Terms and definitions ... 5

4 Categories ... 5

5 Technical requirements ... 6

6 Test method ... 8

7 Inspection rules ... 9

8 Marking, packaging, transportation, storage, and accompanying documents ... 11

9 Order form contents ... 12

Titanium and titanium alloy square and rectangular tubes

1 Scope

This document specifies the classification, technical requirements, test methods,

inspection rules, marking, packaging, transportation, storage, accompanying

documents, and order form contents of titanium and titanium alloy square and

rectangular tubes.

This document applies to titanium and titanium alloy square tubes and rectangular tubes.

2 Normative references

The following documents contain the provisions which, through normative reference in

this document, constitute the essential provisions of this document. For the dated

referenced documents, only the versions with the indicated dates are applicable to this

document; for the undated referenced documents, only the latest version (including all

the amendments) is applicable to this document.

GB/T 228.1 Metallic materials - Tensile testing - Part 1: Method of test at room

temperature

GB/T 3620.1 Designation and composition of titanium and titanium alloys

GB/T 3620.2 Titanium and titanium alloys. Permissible variations of chemical

composition for wrought product analysis

GB/T 3621 Titanium and titanium alloy plate and sheet

GB/T 4698 (all parts) Methods for chemical analysis of titanium sponge, titanium

and titanium alloys

GB/T 6611 Terminology and metallographs for titanium and titanium alloys

GB/T 8180 Wrought titanium and titanium alloy products packing, marking,

transporting and storing

GB/T 38982 Method of measuring shape and dimension for wrought titanium and

titanium alloy products

NB/T 47013.5-2015 Nondestructive testing of pressure equipment - Part 5: Penetrant

testing

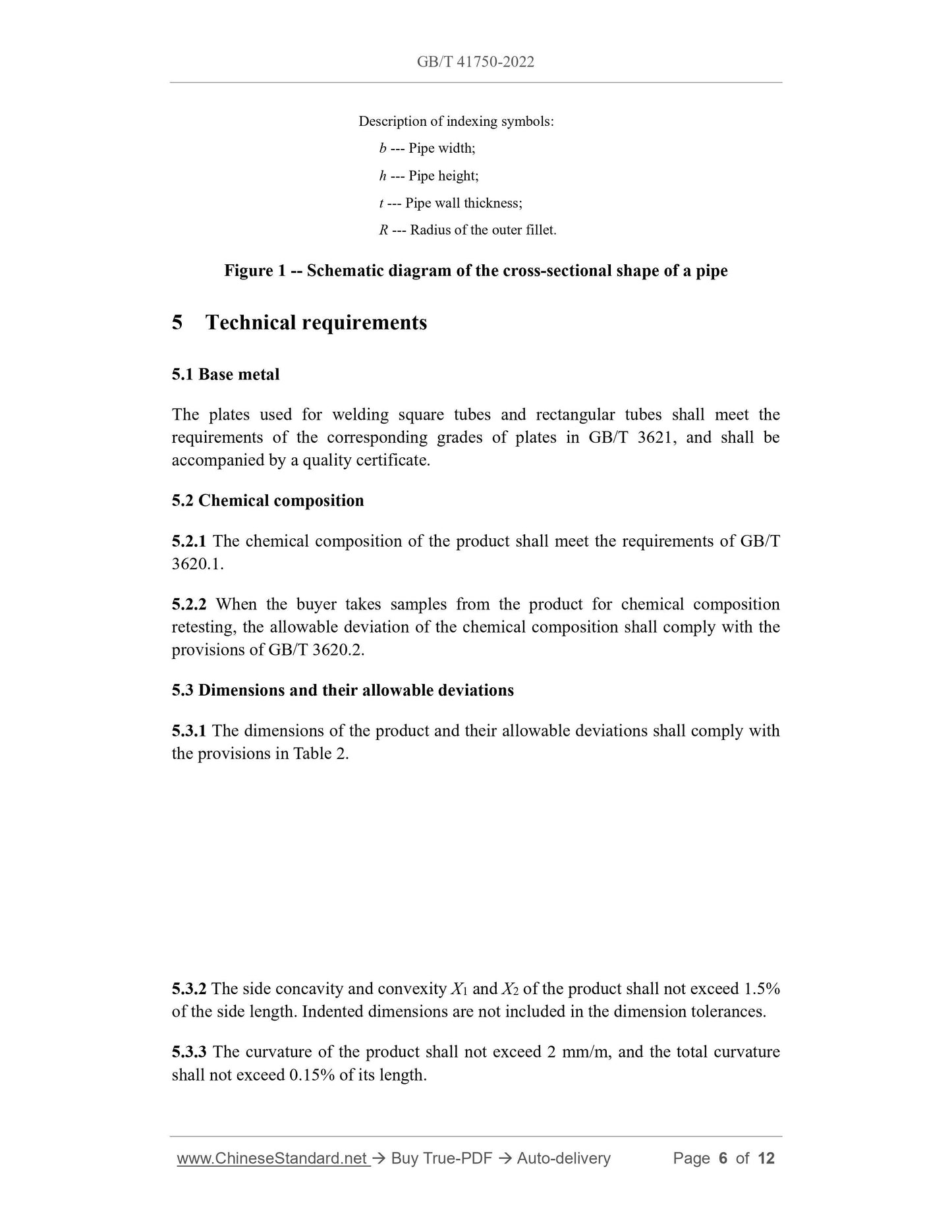

Description of indexing symbols:

b --- Pipe width;

h --- Pipe height;

t --- Pipe wall thickness;

R --- Radius of the outer fillet.

Figure 1 -- Schematic diagram of the cross-sectional shape of a pipe

5 Technical requirements

5.1 Base metal

The plates used for welding square tubes and rectangular tubes shall meet the

requirements of the corresponding grades of plates in GB/T 3621, and shall be

accompanied by a quality certificate.

5.2 Chemical composition

5.2.1 The chemical composition of the product shall meet the requirements of GB/T

3620.1.

5.2.2 When the buyer takes samples from the product for chemical composition

retesting, the allowable deviation of the chemical composition shall comply with the

provisions of GB/T 3620.2.

5.3 Dimensions and their allowable deviations

5.3.1 The dimensions of the product and their allowable deviations shall comply with

the provisions in Table 2.

5.3.2 The side concavity and convexity X1 and X2 of the product shall not exceed 1.5%

of the side length. Indented dimensions are not included in the dimension tolerances.

5.3.3 The curvature of the product shall not exceed 2 mm/m, and the total curvature

shall not exceed 0.15% of its length.

6.3 Tensile properties

The test of the tensile properties of the product at room temperature shall be carried out

according to the method specified in GB/T 228.1.

6.4 Penetration test

The penetration test of the product shall be carried out according to the method specified

in NB/T 47013.5-2015.

6.5 Appearance quality

The test of the appearance quality of the product shall be carried out by visual inspection.

7 Inspection rules

7.1 Inspection and acceptance

7.1.1 Products shall be inspected by the supplier or a third party.

7.1.2 The buyer can inspect the received products according to the provisions of this

document. When the inspection results are inconsistent with the provisions of this

document or the purchase order, it shall be reported to the supplier in written form, and

the supplier and the buyer shall negotiate to resolve it. Objections pertaining to

dimensions and their allowable deviations, penetration test and appearance quality shall

be raised within one month from the date of receipt of the product; objections pertaining

to chemical composition and tensile properties shall be raised within three months from

the date of receipt of the product. If arbitration is required, the supply and demand

parties shall sample jointly on the demand side, or it shall be negotiated by the supply

and demand parties.

7.2 Batching

double samples shall be taken from this batch of products for repeated inspection. If

there is still an unqualified sample in the repeated inspection, the batch of products shall

be judged as unqualified. However, the supplier can inspect the pipes one by one, and

the qualified ones can be delivered in batches again.

8 Marking, packaging, transportation, storage, and

accompanying documents

8.1 Marking

8.1.1 Product marking

Labels or tags shall be attached to the products that have passed the inspection, and the

following contents shall be indicated at least on them:

a) The name and trademark of the manufacturer;

b) Grade;

c) Specifications;

d) State;

e) Batch number;

f) Number of this document.

8.1.2 Packaging marks

The packaging marks of the products shall comply with the provisions of GB/T 8180.

8.2 Packaging, transportation, and storage

The packaging, transportation, and storage of the products shall comply with the

provisions of GB/T 8180.

8.3 Accompanying documents

Each batch of products shall be attached with accompanying documents, which shall

not only include supplier information, product information, serial number of this

document, date of manufacture or date of packaging, but also include:

a) Quality certificate, the contents are as follows:

Product name, grade, specification, and state;

Get QUOTATION in 1-minute: Click GB/T 41750-2022

Historical versions: GB/T 41750-2022

Preview True-PDF (Reload/Scroll if blank)

GB/T 41750-2022: Titanium and titanium alloy square and rectangular tubes

GB/T 41750-2022

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.150.50

CCS H 64

Titanium and titanium alloy square and rectangular tubes

ISSUED ON: OCTOBER 12, 2022

IMPLEMENTED ON: MAY 1, 2023

Issued by: State Administration for Market Regulation;

Standardization Administration of PRC.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Terms and definitions ... 5

4 Categories ... 5

5 Technical requirements ... 6

6 Test method ... 8

7 Inspection rules ... 9

8 Marking, packaging, transportation, storage, and accompanying documents ... 11

9 Order form contents ... 12

Titanium and titanium alloy square and rectangular tubes

1 Scope

This document specifies the classification, technical requirements, test methods,

inspection rules, marking, packaging, transportation, storage, accompanying

documents, and order form contents of titanium and titanium alloy square and

rectangular tubes.

This document applies to titanium and titanium alloy square tubes and rectangular tubes.

2 Normative references

The following documents contain the provisions which, through normative reference in

this document, constitute the essential provisions of this document. For the dated

referenced documents, only the versions with the indicated dates are applicable to this

document; for the undated referenced documents, only the latest version (including all

the amendments) is applicable to this document.

GB/T 228.1 Metallic materials - Tensile testing - Part 1: Method of test at room

temperature

GB/T 3620.1 Designation and composition of titanium and titanium alloys

GB/T 3620.2 Titanium and titanium alloys. Permissible variations of chemical

composition for wrought product analysis

GB/T 3621 Titanium and titanium alloy plate and sheet

GB/T 4698 (all parts) Methods for chemical analysis of titanium sponge, titanium

and titanium alloys

GB/T 6611 Terminology and metallographs for titanium and titanium alloys

GB/T 8180 Wrought titanium and titanium alloy products packing, marking,

transporting and storing

GB/T 38982 Method of measuring shape and dimension for wrought titanium and

titanium alloy products

NB/T 47013.5-2015 Nondestructive testing of pressure equipment - Part 5: Penetrant

testing

Description of indexing symbols:

b --- Pipe width;

h --- Pipe height;

t --- Pipe wall thickness;

R --- Radius of the outer fillet.

Figure 1 -- Schematic diagram of the cross-sectional shape of a pipe

5 Technical requirements

5.1 Base metal

The plates used for welding square tubes and rectangular tubes shall meet the

requirements of the corresponding grades of plates in GB/T 3621, and shall be

accompanied by a quality certificate.

5.2 Chemical composition

5.2.1 The chemical composition of the product shall meet the requirements of GB/T

3620.1.

5.2.2 When the buyer takes samples from the product for chemical composition

retesting, the allowable deviation of the chemical composition shall comply with the

provisions of GB/T 3620.2.

5.3 Dimensions and their allowable deviations

5.3.1 The dimensions of the product and their allowable deviations shall comply with

the provisions in Table 2.

5.3.2 The side concavity and convexity X1 and X2 of the product shall not exceed 1.5%

of the side length. Indented dimensions are not included in the dimension tolerances.

5.3.3 The curvature of the product shall not exceed 2 mm/m, and the total curvature

shall not exceed 0.15% of its length.

6.3 Tensile properties

The test of the tensile properties of the product at room temperature shall be carried out

according to the method specified in GB/T 228.1.

6.4 Penetration test

The penetration test of the product shall be carried out according to the method specified

in NB/T 47013.5-2015.

6.5 Appearance quality

The test of the appearance quality of the product shall be carried out by visual inspection.

7 Inspection rules

7.1 Inspection and acceptance

7.1.1 Products shall be inspected by the supplier or a third party.

7.1.2 The buyer can inspect the received products according to the provisions of this

document. When the inspection results are inconsistent with the provisions of this

document or the purchase order, it shall be reported to the supplier in written form, and

the supplier and the buyer shall negotiate to resolve it. Objections pertaining to

dimensions and their allowable deviations, penetration test and appearance quality shall

be raised within one month from the date of receipt of the product; objections pertaining

to chemical composition and tensile properties shall be raised within three months from

the date of receipt of the product. If arbitration is required, the supply and demand

parties shall sample jointly on the demand side, or it shall be negotiated by the supply

and demand parties.

7.2 Batching

double samples shall be taken from this batch of products for repeated inspection. If

there is still an unqualified sample in the repeated inspection, the batch of products shall

be judged as unqualified. However, the supplier can inspect the pipes one by one, and

the qualified ones can be delivered in batches again.

8 Marking, packaging, transportation, storage, and

accompanying documents

8.1 Marking

8.1.1 Product marking

Labels or tags shall be attached to the products that have passed the inspection, and the

following contents shall be indicated at least on them:

a) The name and trademark of the manufacturer;

b) Grade;

c) Specifications;

d) State;

e) Batch number;

f) Number of this document.

8.1.2 Packaging marks

The packaging marks of the products shall comply with the provisions of GB/T 8180.

8.2 Packaging, transportation, and storage

The packaging, transportation, and storage of the products shall comply with the

provisions of GB/T 8180.

8.3 Accompanying documents

Each batch of products shall be attached with accompanying documents, which shall

not only include supplier information, product information, serial number of this

document, date of manufacture or date of packaging, but also include:

a) Quality certificate, the contents are as follows:

Product name, grade, specification, and state;

Share