1

/

of

9

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 43252-2023 English PDF (GB/T43252-2023)

GB/T 43252-2023 English PDF (GB/T43252-2023)

Regular price

$320.00

Regular price

Sale price

$320.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB/T 43252-2023: Test methods of energy consumption and range for fuel cell electric vehicles

Delivery: 9 seconds. Download (& Email) true-PDF + Invoice.

Get Quotation: Click GB/T 43252-2023 (Self-service in 1-minute)

Historical versions (Master-website): GB/T 43252-2023

Preview True-PDF (Reload/Scroll-down if blank)

GB/T 43252-2023

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 43.120

CCS T 47

Test methods of energy consumption and range for fuel cell

electric vehicles

ISSUED ON: NOVEMBER 27, 2023

IMPLEMENTED ON: NOVEMBER 27, 2023

Issued by: State Administration for Market Regulation;

Standardization Administration of the People’s Republic of China.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Terms and definitions ... 5

4 Measurement parameter, unit, accuracy and resolution ... 5

5 Test conditions ... 5

5.1 Test vehicle conditions ... 5

5.2 Ambient temperature conditions and vehicle immersion requirements ... 6

5.3 Driving mode selection ... 6

5.4 Vehicle load setting ... 6

5.5 Test tolerance requirements ... 6

6 Classification of test vehicles ... 8

7 Test methods ... 8

7.1 Shortening method ... 8

7.2 Run-through method ... 10

Appendix A (Normative) Hydrogenation technical specifications ... 13

A.1 Hydrogenation before vehicle testing ... 13

A.2 Hydrogenation after vehicle testing ... 14

A.3 Measurement of internal pressure of hydrogen tank after vehicle test ... 14

Appendix B (Normative) Type-A vehicle data processing method ... 16

B.1 Energy change of REESS ... 16

B.2 Hydrogen consumption ... 16

B.3 Vehicle driving range ... 16

B.4 Data processing requirements ... 17

Appendix C (Normative) Type-B vehicle data processing method ... 18

C.1 Fuel cell vehicle power system structure diagram ... 18

C.2 Test data processing for externally rechargeable fuel cell electric vehicles ... 19

C.3 Test data processing for non-externally rechargeable fuel cell electric vehicles ... 21

C.4 Data processing requirements ... 23

Bibliography ... 24

Test methods of energy consumption and range for fuel cell

electric vehicles

1 Scope

This document describes the test method for measuring the energy consumption and

range for fuel cell electric vehicles on a chassis dynamometer.

This document applies to Category-M and Category-N fuel cell electric vehicles

(hereinafter referred to as “vehicles”) that use compressed gaseous hydrogen.

2 Normative references

The following documents are referred to in the text in such a way that some or all of

their content constitutes requirements of this document. For dated references, only the

version corresponding to that date is applicable to this document; for undated references,

the latest version (including all amendments) is applicable to this document.

GB/T 8170, Rules of rounding off for numerical values and expression and judgment

of limiting values

GB 18352.6-2016, Limits and measurement methods for emissions from light-duty

vehicles (CHINA 6)

GB/T 18386.1-2021, Test methods for energy consumption and range of electric

vehicles - Part 1: Light-duty vehicles

GB/T 18386.2-2022, Test methods for energy consumption and range of electric

vehicles - Part 2: Heavy-duty commercial vehicles

GB/T 24548, Fuel cell electric vehicles - Terminology

GB/T 27840-2021, Fuel consumption test methods for heavy-duty commercial

vehicles

GB/T 37244, Fuel specification for proton exchange membrane fuel cell vehicles -

Hydrogen

GB/T 38146.1, China automotive test cycle - Part 1: Light-duty vehicles

GB/T 38146.2, China automotive test cycle - Part 2: Heavy-duty commercial

vehicles

-- Make the viscosity of the lubricating oil for mechanical moving parts and the tire

pressure comply with the regulations of the vehicle manufacturer;

-- Run-in the transmission system and tires according to the requirements of the vehicle

manufacturer's instructions, and drive at least 300 km using the fuel cell power

system installed on the test vehicle;

-- Except for the equipment necessary for testing and the daily operating parts of the

vehicle, turn off the lighting devices and auxiliary devices that use electricity on the

vehicle;

-- Make the fuel used in the vehicle complies with the provisions of GB/T 37244.

5.2 Ambient temperature conditions and vehicle immersion requirements

The laboratory temperature shall be set to 23 °C with an allowable deviation of ±5 °C.

The temperature in the immersion area shall be set to 23 °C, with an allowable deviation

of ±3 °C, and the immersion time shall be no less than 2 hours.

5.3 Driving mode selection

The driving mode shall be set according to the selection of C.2 driving mode in GB/T

18386.1-2021.

5.4 Vehicle load setting

5.4.1 Determination of driving resistance and simulation on chassis dynamometer:

Category-M1, Category-N1 , as well as Category-M2 with a maximum design total mass

not exceeding 3 500 kg, shall comply with the provisions of Appendix CC of GB

18352.6-2016; the chassis dynamometer settings of other types of vehicles shall comply

with the provisions of Appendix C of GB/T 27840-2021, where the additional mass of

city buses is 65% of the maximum design loading mass.

5.4.2 If the driving resistance curve is provided by the vehicle manufacturer, a test

report, a calculation report or other relevant information shall be provided and inspected

by a testing agency to ensure the reliability of the test results.

5.5 Test tolerance requirements

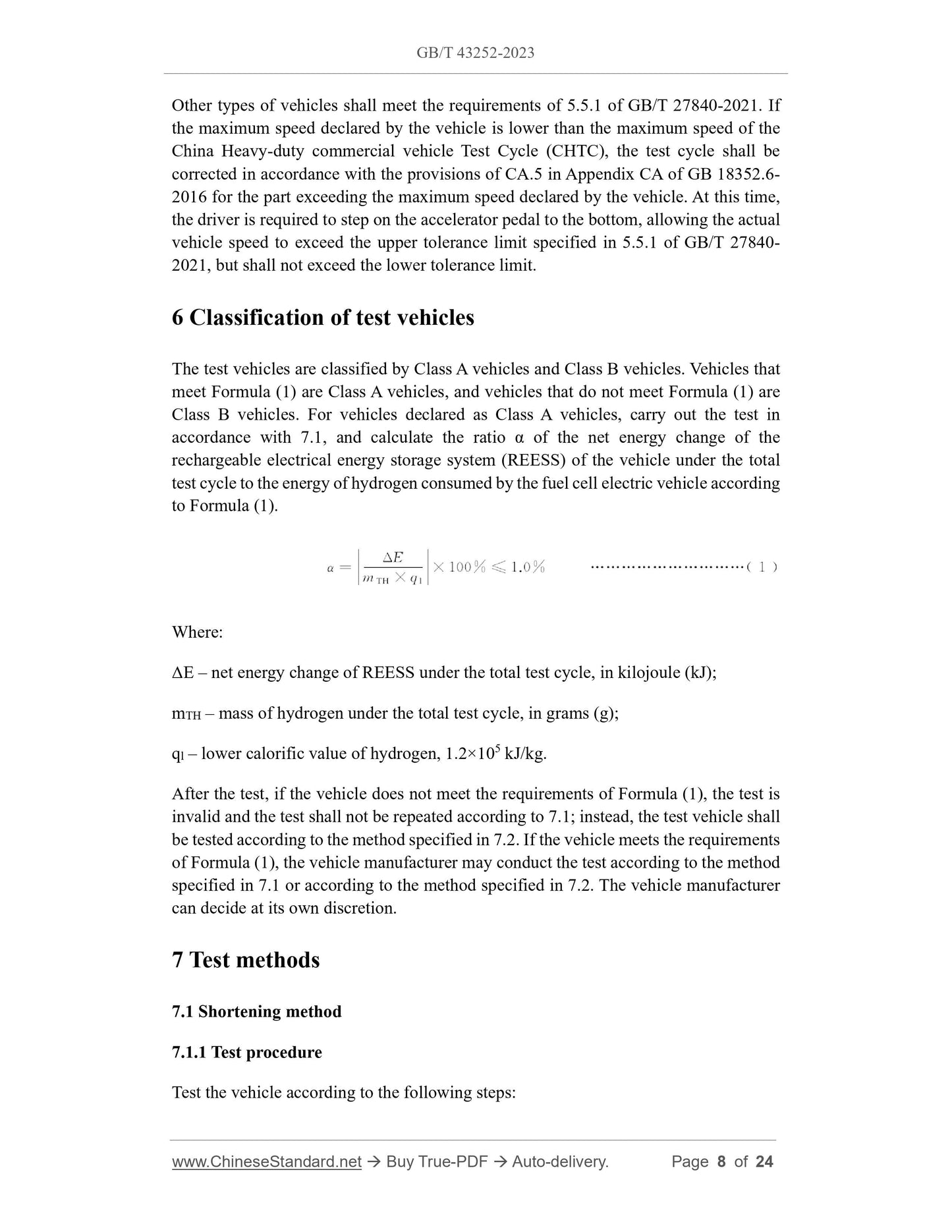

The schematic diagram of the reference curve, speed tolerance and time tolerance of

the test process is shown in Figure 1.

Other types of vehicles shall meet the requirements of 5.5.1 of GB/T 27840-2021. If

the maximum speed declared by the vehicle is lower than the maximum speed of the

China Heavy-duty commercial vehicle Test Cycle (CHTC), the test cycle shall be

corrected in accordance with the provisions of CA.5 in Appendix CA of GB 18352.6-

2016 for the part exceeding the maximum speed declared by the vehicle. At this time,

the driver is required to step on the accelerator pedal to the bottom, allowing the actual

vehicle speed to exceed the upper tolerance limit specified in 5.5.1 of GB/T 27840-

2021, but shall not exceed the lower tolerance limit.

6 Classification of test vehicles

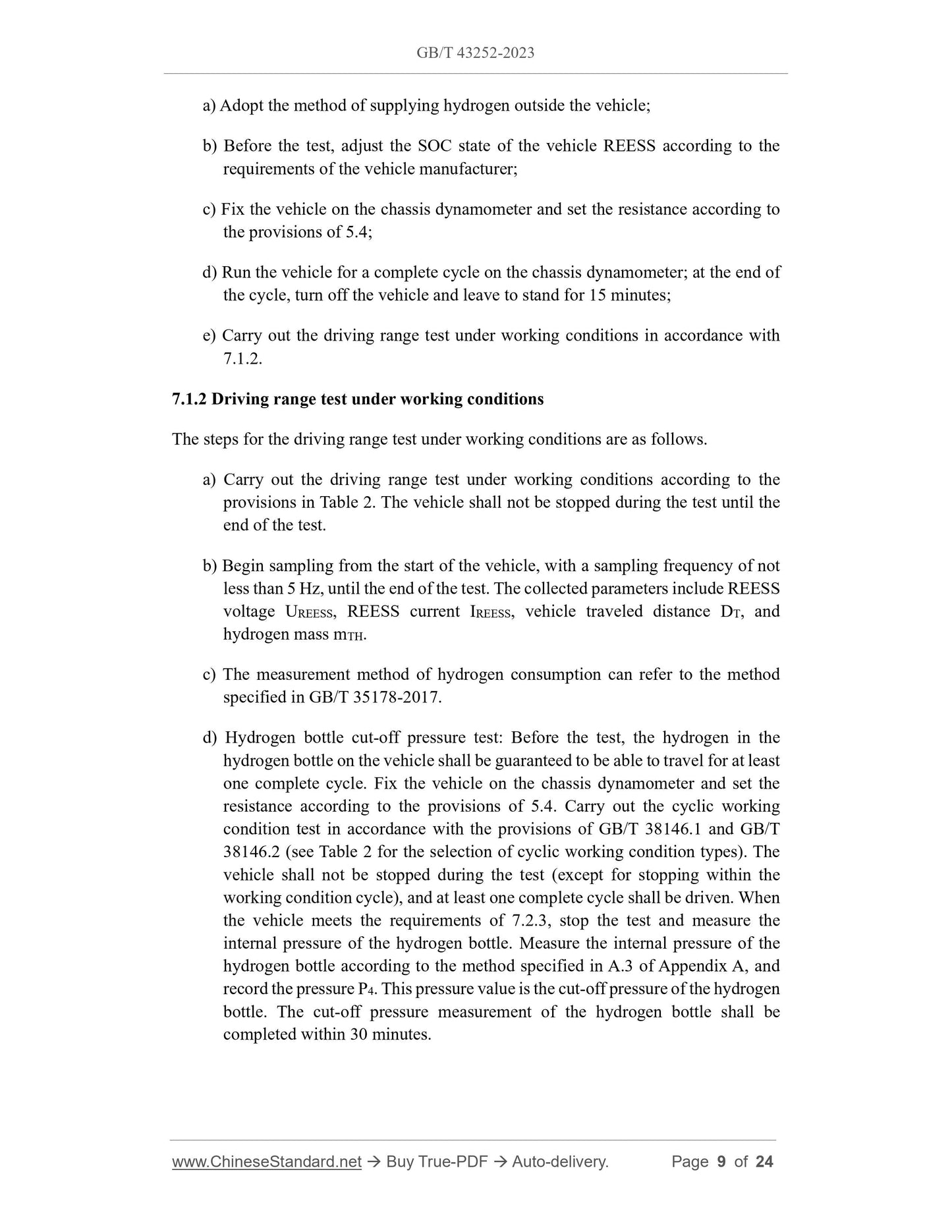

The test vehicles are classified by Class A vehicles and Class B vehicles. Vehicles that

meet Formula (1) are Class A vehicles, and vehicles that do not meet Formula (1) are

Class B vehicles. For vehicles declared as Class A vehicles, carry out the test in

accordance with 7.1, and calculate the ratio α of the net energy change of the

rechargeable electrical energy storage system (REESS) of the vehicle under the total

test cycle to the energy of hydrogen consumed by the fuel cell electric vehicle according

to Formula (1).

Where:

ΔE – net energy change of REESS under the total test cycle, in kilojoule (kJ);

mTH – mass of hydrogen under the total test cycle, in grams (g);

ql – lower calorific value of hydrogen, 1.2×105 kJ/kg.

After the test, if the vehicle does not meet the requirements of Formula (1), the test is

invalid and the test shall not be repeated according to 7.1; instead, the test vehicle shall

be tested according to the method specified in 7.2. If the vehicle meets the requirements

of Formula (1), the vehicle manufacturer may conduct the test according to the method

specified in 7.1 or according to the method specified in 7.2. The vehicle manufacturer

can decide at its own discretion.

7 Test methods

7.1 Shortening method

7.1.1 Test procedure

Test the vehicle according to the following steps:

a) Adopt the method of supplying hydrogen outside the vehicle;

b) Before the test, adjust the SOC state of the vehicle REESS according to the

requirements of the vehicle manufacturer;

c) Fix the vehicle on the chassis dynamometer and set the resistance according to

the provisions of 5.4;

d) Run the vehicle for a complete cycle on the chassis dynamometer; at the end of

the cycle, turn off the vehicle and leave to stand for 15 minutes;

e) Carry out the driving range test under working conditions in accordance with

7.1.2.

7.1.2 Driving range test under working conditions

The steps for the driving range test under working conditions are as follows.

a) Carry out the driving range test under working conditions according to the

provisions in Table 2. The vehicle shall not be stopped during the test until the

end of the test.

b) Begin sampling from the start of the vehicle, with a sampling frequency of not

less than 5 Hz, until the end of the test. The collected parameters include REESS

voltage UREESS, REESS current IREESS, vehicle traveled distance DT, and

hydrogen mass mTH.

c) The measurement method of hydrogen consumption can refer to the method

specified in GB/T 35178-2017.

d) Hydrogen bottle cut-off pressure test: Before the test, the hydrogen in the

hydrogen bottle on the vehicle shall be guaranteed to be able to travel for at least

one complete cycle. Fix the vehicle on the chassis dynamometer and set the

resistance according to the provisions of 5.4. Carry out the cyclic working

condition test in accordance with the provisions of GB/T 38146.1 and GB/T

38146.2 (see Table 2 for the selection of cyclic working condition types). The

vehicle shall not be stopped during the test (except for stopping within the

working condition cycle), and at least one complete cycle shall be driven. When

the vehicle meets the requirements of 7.2.3, stop the test and measure the

internal pressure of the hydrogen bottle. Measure the internal pressure of the

hydrogen bottle according to the method specified in A.3 of Appendix A, and

record the pressure P4. This pressure value is the cut-off pressure of the hydrogen

bottle. The cut-off pressure measurement of the hydrogen bottle shall be

completed within 30 minutes.

18386.2-2022, and measure and record the energy E from the power grid; for

non-externally rechargeable fuel cell electric vehicles, proceed to step f).

f) Move the vehicle to the hydrogenation unit, add hydrogen according to the

provisions of A.2 and calculate the mass of hydrogen mTH. Keep four significant

figures after the decimal point of the calculation result (round off).

Except for step b) and step c), between any two steps, if the vehicle needs to move:

-- For Category-M1, Category-N1, as well as Category-M2 with a maximum design

total mass not exceeding 3 500 kg, it is not allowed to use the power on the

vehicle to move the vehicle to the next test location, and the regeneration

braking system shall be turned off;

-- For other types of vehicles, the use of on-board power is allowed. The vehicle is

required to travel at a speed not exceeding 30 km/h or the speed limit of the

factory area, and move between the two test locations as evenly as possible. The

shift distance of the vehicle between the two test locations each time shall not

exceed 3 km.

7.2.2 Driving range test under working conditions

The steps for the driving range test under working conditions are as follows.

a) Carry out the driving range test under working conditions according to the

provisions of Table 3; do not step the test until the range specified in 7.2.3 is

reached.

b) Unless otherwise specified, the number of stops during the working condition

test cycle shall not exceed 3 times (stops outside the operating cycle), and the

total cumulative stop time shall not exceed 15 minutes. During the stop period,

turn off the test bench fan, and do not use an external power supply to charge

the vehicle.

c) Begin sampling from the start of the vehicle, with a sampling frequency of not

less than 5 Hz, until the end of the test. The collected parameters include the fuel

cell stack voltage UFC, the fuel cell stack current IFC, the REESS voltage UREESS,

the REESS current IREESS, and the distance D traveled by the vehicle (the

measured value is rounded to an integer, and this distance is the driving range

measured by the working condition method); at the same time, record the time

used in hours (h) and minutes (min).

Note: For vehicles of which the fuel cell stack voltage UFC and fuel cell stack current

IFC cannot be measured directly, measure the voltage and current at the output

of the DC/DC converter, and then convert the power of the fuel cell stack. The

DC/DC converter conversion efficiency is 97.0%.

e) Based on T2 and P2, refer to the temperature-pressure method in Appendix A of

GB/T 35178-2017 to calculate the mass m1 of hydrogen carried by the vehicle

before the test.

A.2 Hydrogenation after vehicle testing

After the test, hydrogenation and calculation of the mass of hydrogen consumed shall

be carried out according to the following steps:

a) Connect the vehicle to the same hydrogenation unit used before the test; record

the ambient temperature T3 of the vehicle; open the stop valve V1; add a small

amount (no more than 0.05 kg) of hydrogen to the vehicle through the buffer

tank; record the mass of hydrogen added m2 (m2 may be 0 here) through the

mass flow meter; close the stop valve V1; record the internal pressure P3 of the

hydrogen bottle after the pressure is balanced;

b) Based on T3 and P3, refer to the temperature-pressure method in Appendix A of

GB/T 35178-2017 to calculate the mass m3 of hydrogen carried by the vehicle

at this time;

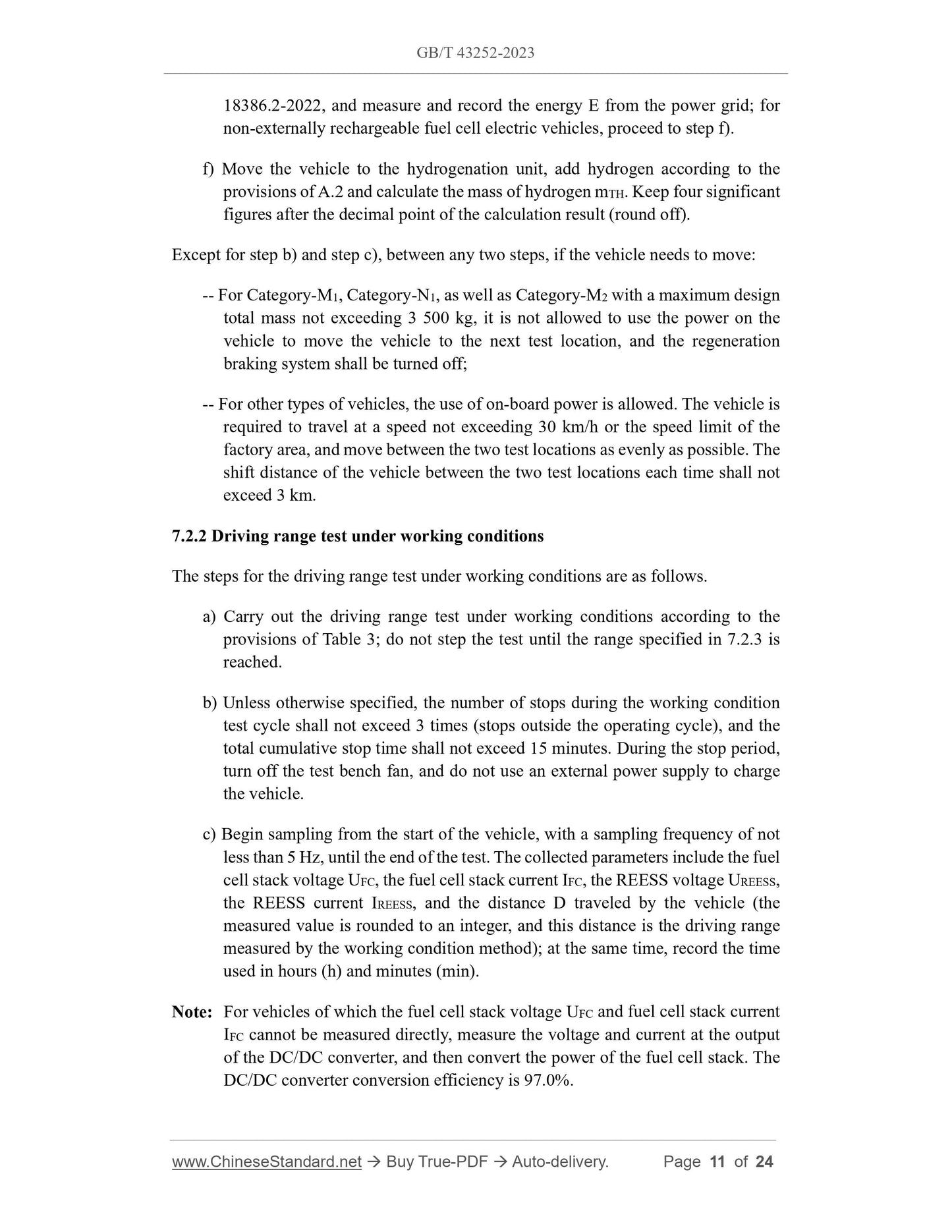

c) Calculate the mass of hydrogen mTH consumed in the test according to Formula

(A.1).

For externally rechargeable fuel cell electric vehicles, post-test hydrogenation shall be

completed within 30 minutes after the energy storage device is charged; for non-

externally rechargeable fuel cell electric vehicles, the above post-test hydrogenation

process needs to be completed within 30 minutes after the end of the test.

A.3 Measurement of internal pressure of hydrogen tank after vehicle test

After the test, the pressure in the hydrogen cylinder shall be measured in the following

way:

a) Adjust the pressure of the hydrogen source to be higher than the internal pressure

of the hydrogen cylinder, and connect the vehicle to the pressure measuring

device, as shown in Figure A.2;

b) Make sure the mass of hydrogen entering the hydrogen bottle is no more than

0.05 kg, close the stop valve in time, and record the pressure P4 after the pressure...

Delivery: 9 seconds. Download (& Email) true-PDF + Invoice.

Get Quotation: Click GB/T 43252-2023 (Self-service in 1-minute)

Historical versions (Master-website): GB/T 43252-2023

Preview True-PDF (Reload/Scroll-down if blank)

GB/T 43252-2023

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 43.120

CCS T 47

Test methods of energy consumption and range for fuel cell

electric vehicles

ISSUED ON: NOVEMBER 27, 2023

IMPLEMENTED ON: NOVEMBER 27, 2023

Issued by: State Administration for Market Regulation;

Standardization Administration of the People’s Republic of China.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Terms and definitions ... 5

4 Measurement parameter, unit, accuracy and resolution ... 5

5 Test conditions ... 5

5.1 Test vehicle conditions ... 5

5.2 Ambient temperature conditions and vehicle immersion requirements ... 6

5.3 Driving mode selection ... 6

5.4 Vehicle load setting ... 6

5.5 Test tolerance requirements ... 6

6 Classification of test vehicles ... 8

7 Test methods ... 8

7.1 Shortening method ... 8

7.2 Run-through method ... 10

Appendix A (Normative) Hydrogenation technical specifications ... 13

A.1 Hydrogenation before vehicle testing ... 13

A.2 Hydrogenation after vehicle testing ... 14

A.3 Measurement of internal pressure of hydrogen tank after vehicle test ... 14

Appendix B (Normative) Type-A vehicle data processing method ... 16

B.1 Energy change of REESS ... 16

B.2 Hydrogen consumption ... 16

B.3 Vehicle driving range ... 16

B.4 Data processing requirements ... 17

Appendix C (Normative) Type-B vehicle data processing method ... 18

C.1 Fuel cell vehicle power system structure diagram ... 18

C.2 Test data processing for externally rechargeable fuel cell electric vehicles ... 19

C.3 Test data processing for non-externally rechargeable fuel cell electric vehicles ... 21

C.4 Data processing requirements ... 23

Bibliography ... 24

Test methods of energy consumption and range for fuel cell

electric vehicles

1 Scope

This document describes the test method for measuring the energy consumption and

range for fuel cell electric vehicles on a chassis dynamometer.

This document applies to Category-M and Category-N fuel cell electric vehicles

(hereinafter referred to as “vehicles”) that use compressed gaseous hydrogen.

2 Normative references

The following documents are referred to in the text in such a way that some or all of

their content constitutes requirements of this document. For dated references, only the

version corresponding to that date is applicable to this document; for undated references,

the latest version (including all amendments) is applicable to this document.

GB/T 8170, Rules of rounding off for numerical values and expression and judgment

of limiting values

GB 18352.6-2016, Limits and measurement methods for emissions from light-duty

vehicles (CHINA 6)

GB/T 18386.1-2021, Test methods for energy consumption and range of electric

vehicles - Part 1: Light-duty vehicles

GB/T 18386.2-2022, Test methods for energy consumption and range of electric

vehicles - Part 2: Heavy-duty commercial vehicles

GB/T 24548, Fuel cell electric vehicles - Terminology

GB/T 27840-2021, Fuel consumption test methods for heavy-duty commercial

vehicles

GB/T 37244, Fuel specification for proton exchange membrane fuel cell vehicles -

Hydrogen

GB/T 38146.1, China automotive test cycle - Part 1: Light-duty vehicles

GB/T 38146.2, China automotive test cycle - Part 2: Heavy-duty commercial

vehicles

-- Make the viscosity of the lubricating oil for mechanical moving parts and the tire

pressure comply with the regulations of the vehicle manufacturer;

-- Run-in the transmission system and tires according to the requirements of the vehicle

manufacturer's instructions, and drive at least 300 km using the fuel cell power

system installed on the test vehicle;

-- Except for the equipment necessary for testing and the daily operating parts of the

vehicle, turn off the lighting devices and auxiliary devices that use electricity on the

vehicle;

-- Make the fuel used in the vehicle complies with the provisions of GB/T 37244.

5.2 Ambient temperature conditions and vehicle immersion requirements

The laboratory temperature shall be set to 23 °C with an allowable deviation of ±5 °C.

The temperature in the immersion area shall be set to 23 °C, with an allowable deviation

of ±3 °C, and the immersion time shall be no less than 2 hours.

5.3 Driving mode selection

The driving mode shall be set according to the selection of C.2 driving mode in GB/T

18386.1-2021.

5.4 Vehicle load setting

5.4.1 Determination of driving resistance and simulation on chassis dynamometer:

Category-M1, Category-N1 , as well as Category-M2 with a maximum design total mass

not exceeding 3 500 kg, shall comply with the provisions of Appendix CC of GB

18352.6-2016; the chassis dynamometer settings of other types of vehicles shall comply

with the provisions of Appendix C of GB/T 27840-2021, where the additional mass of

city buses is 65% of the maximum design loading mass.

5.4.2 If the driving resistance curve is provided by the vehicle manufacturer, a test

report, a calculation report or other relevant information shall be provided and inspected

by a testing agency to ensure the reliability of the test results.

5.5 Test tolerance requirements

The schematic diagram of the reference curve, speed tolerance and time tolerance of

the test process is shown in Figure 1.

Other types of vehicles shall meet the requirements of 5.5.1 of GB/T 27840-2021. If

the maximum speed declared by the vehicle is lower than the maximum speed of the

China Heavy-duty commercial vehicle Test Cycle (CHTC), the test cycle shall be

corrected in accordance with the provisions of CA.5 in Appendix CA of GB 18352.6-

2016 for the part exceeding the maximum speed declared by the vehicle. At this time,

the driver is required to step on the accelerator pedal to the bottom, allowing the actual

vehicle speed to exceed the upper tolerance limit specified in 5.5.1 of GB/T 27840-

2021, but shall not exceed the lower tolerance limit.

6 Classification of test vehicles

The test vehicles are classified by Class A vehicles and Class B vehicles. Vehicles that

meet Formula (1) are Class A vehicles, and vehicles that do not meet Formula (1) are

Class B vehicles. For vehicles declared as Class A vehicles, carry out the test in

accordance with 7.1, and calculate the ratio α of the net energy change of the

rechargeable electrical energy storage system (REESS) of the vehicle under the total

test cycle to the energy of hydrogen consumed by the fuel cell electric vehicle according

to Formula (1).

Where:

ΔE – net energy change of REESS under the total test cycle, in kilojoule (kJ);

mTH – mass of hydrogen under the total test cycle, in grams (g);

ql – lower calorific value of hydrogen, 1.2×105 kJ/kg.

After the test, if the vehicle does not meet the requirements of Formula (1), the test is

invalid and the test shall not be repeated according to 7.1; instead, the test vehicle shall

be tested according to the method specified in 7.2. If the vehicle meets the requirements

of Formula (1), the vehicle manufacturer may conduct the test according to the method

specified in 7.1 or according to the method specified in 7.2. The vehicle manufacturer

can decide at its own discretion.

7 Test methods

7.1 Shortening method

7.1.1 Test procedure

Test the vehicle according to the following steps:

a) Adopt the method of supplying hydrogen outside the vehicle;

b) Before the test, adjust the SOC state of the vehicle REESS according to the

requirements of the vehicle manufacturer;

c) Fix the vehicle on the chassis dynamometer and set the resistance according to

the provisions of 5.4;

d) Run the vehicle for a complete cycle on the chassis dynamometer; at the end of

the cycle, turn off the vehicle and leave to stand for 15 minutes;

e) Carry out the driving range test under working conditions in accordance with

7.1.2.

7.1.2 Driving range test under working conditions

The steps for the driving range test under working conditions are as follows.

a) Carry out the driving range test under working conditions according to the

provisions in Table 2. The vehicle shall not be stopped during the test until the

end of the test.

b) Begin sampling from the start of the vehicle, with a sampling frequency of not

less than 5 Hz, until the end of the test. The collected parameters include REESS

voltage UREESS, REESS current IREESS, vehicle traveled distance DT, and

hydrogen mass mTH.

c) The measurement method of hydrogen consumption can refer to the method

specified in GB/T 35178-2017.

d) Hydrogen bottle cut-off pressure test: Before the test, the hydrogen in the

hydrogen bottle on the vehicle shall be guaranteed to be able to travel for at least

one complete cycle. Fix the vehicle on the chassis dynamometer and set the

resistance according to the provisions of 5.4. Carry out the cyclic working

condition test in accordance with the provisions of GB/T 38146.1 and GB/T

38146.2 (see Table 2 for the selection of cyclic working condition types). The

vehicle shall not be stopped during the test (except for stopping within the

working condition cycle), and at least one complete cycle shall be driven. When

the vehicle meets the requirements of 7.2.3, stop the test and measure the

internal pressure of the hydrogen bottle. Measure the internal pressure of the

hydrogen bottle according to the method specified in A.3 of Appendix A, and

record the pressure P4. This pressure value is the cut-off pressure of the hydrogen

bottle. The cut-off pressure measurement of the hydrogen bottle shall be

completed within 30 minutes.

18386.2-2022, and measure and record the energy E from the power grid; for

non-externally rechargeable fuel cell electric vehicles, proceed to step f).

f) Move the vehicle to the hydrogenation unit, add hydrogen according to the

provisions of A.2 and calculate the mass of hydrogen mTH. Keep four significant

figures after the decimal point of the calculation result (round off).

Except for step b) and step c), between any two steps, if the vehicle needs to move:

-- For Category-M1, Category-N1, as well as Category-M2 with a maximum design

total mass not exceeding 3 500 kg, it is not allowed to use the power on the

vehicle to move the vehicle to the next test location, and the regeneration

braking system shall be turned off;

-- For other types of vehicles, the use of on-board power is allowed. The vehicle is

required to travel at a speed not exceeding 30 km/h or the speed limit of the

factory area, and move between the two test locations as evenly as possible. The

shift distance of the vehicle between the two test locations each time shall not

exceed 3 km.

7.2.2 Driving range test under working conditions

The steps for the driving range test under working conditions are as follows.

a) Carry out the driving range test under working conditions according to the

provisions of Table 3; do not step the test until the range specified in 7.2.3 is

reached.

b) Unless otherwise specified, the number of stops during the working condition

test cycle shall not exceed 3 times (stops outside the operating cycle), and the

total cumulative stop time shall not exceed 15 minutes. During the stop period,

turn off the test bench fan, and do not use an external power supply to charge

the vehicle.

c) Begin sampling from the start of the vehicle, with a sampling frequency of not

less than 5 Hz, until the end of the test. The collected parameters include the fuel

cell stack voltage UFC, the fuel cell stack current IFC, the REESS voltage UREESS,

the REESS current IREESS, and the distance D traveled by the vehicle (the

measured value is rounded to an integer, and this distance is the driving range

measured by the working condition method); at the same time, record the time

used in hours (h) and minutes (min).

Note: For vehicles of which the fuel cell stack voltage UFC and fuel cell stack current

IFC cannot be measured directly, measure the voltage and current at the output

of the DC/DC converter, and then convert the power of the fuel cell stack. The

DC/DC converter conversion efficiency is 97.0%.

e) Based on T2 and P2, refer to the temperature-pressure method in Appendix A of

GB/T 35178-2017 to calculate the mass m1 of hydrogen carried by the vehicle

before the test.

A.2 Hydrogenation after vehicle testing

After the test, hydrogenation and calculation of the mass of hydrogen consumed shall

be carried out according to the following steps:

a) Connect the vehicle to the same hydrogenation unit used before the test; record

the ambient temperature T3 of the vehicle; open the stop valve V1; add a small

amount (no more than 0.05 kg) of hydrogen to the vehicle through the buffer

tank; record the mass of hydrogen added m2 (m2 may be 0 here) through the

mass flow meter; close the stop valve V1; record the internal pressure P3 of the

hydrogen bottle after the pressure is balanced;

b) Based on T3 and P3, refer to the temperature-pressure method in Appendix A of

GB/T 35178-2017 to calculate the mass m3 of hydrogen carried by the vehicle

at this time;

c) Calculate the mass of hydrogen mTH consumed in the test according to Formula

(A.1).

For externally rechargeable fuel cell electric vehicles, post-test hydrogenation shall be

completed within 30 minutes after the energy storage device is charged; for non-

externally rechargeable fuel cell electric vehicles, the above post-test hydrogenation

process needs to be completed within 30 minutes after the end of the test.

A.3 Measurement of internal pressure of hydrogen tank after vehicle test

After the test, the pressure in the hydrogen cylinder shall be measured in the following

way:

a) Adjust the pressure of the hydrogen source to be higher than the internal pressure

of the hydrogen cylinder, and connect the vehicle to the pressure measuring

device, as shown in Figure A.2;

b) Make sure the mass of hydrogen entering the hydrogen bottle is no more than

0.05 kg, close the stop valve in time, and record the pressure P4 after the pressure...

Share