1

/

of

6

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 5563-2013 English PDF (GB/T5563-2013)

GB/T 5563-2013 English PDF (GB/T5563-2013)

Regular price

$130.00

Regular price

Sale price

$130.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB/T 5563-2013: Rubber and plastics hoses and hose assemblies -- Hydrostatic testing

Delivery: 9 seconds. Download (& Email) true-PDF + Invoice.

Get Quotation: Click GB/T 5563-2013 (Self-service in 1-minute)

Historical versions (Master-website): GB/T 5563-2013

Preview True-PDF (Reload/Scroll-down if blank)

GB/T 5563-2013

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 23.040.70

G 42

GB/T 5563-2013 / ISO 1402:2009

Replacing GB/T 5563-2006

Rubber and plastics hoses and hose assemblies

- Hydrostatic testing

(ISO 1402:2009, IDT)

ISSUED ON: DECEMBER 31, 2013

IMPLEMENTED ON: SEPTEMBER 01, 2014

Issued by:

General Administration of Quality Supervision, Inspection

and Quarantine of the People’s Republic of China;

Standardization Administration of the People’s Republic of

China.

GB/T 5563-2013

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Terms and definitions ... 5

4 General requirements ... 5

5 Apparatus ... 5

6 Test pieces ... 6

7 Application of hydrostatic pressure ... 6

8 Hydrostatic pressure tests ... 7

9 Test report ... 13

GB/T 5563-2013

Foreword

This Standard is drafted according to the rules given in the GB/T 1.1-2009.

This Standard replaced GB/T 5563-2006 “Rubber and plastics hoses and hose

assemblies - Hydrostatic testing”. Compared with GB/T 5563-2006, the main changes

of this Standard are as follows:

- ADD the terms and determination (refer to Chapter 3);

- REVISE the Chapter 4 (refer to Chapter 5; the Chapter 4 of 2006-edition);

- ADD “When a particular hose type or size needs longer measurement, it shall be

specified in the hose product standard.” (refer to 6.2);

- ADD “Note 1: use the term ‘maximum working pressure’ instead of the

deprecated term ‘design working pressure’. ” (refer to 8.1);

- REVISE the general procedure (refer to 8.2.1, 7.2.1 in 2006-edition);

- ADD “Apply 0.07MPa of pressure for approximately 5 min after completion of the

proof pressure test. The supporting surface upon which the hose/hose assembly

rests shall be flat and smooth enough to allow the hose/hose assembly to

expand or contract without restriction. Alternatively, the hose/hose assembly

may be supported on rollers, or suspended vertically. When a section of hose is

used as a test piece, it may also be placed in a test rig in a vertical position.”

(refer to 8.2.1.1);

- ADD “For hose assemblies, measure the distance between the contact faces of

the end fittings, or select the reference marks on the hose surface near the end

of the inserted part of the fitting.” (refer to 8.2.1.2);

- ADD “The change percentage in length will be positive (+) when increase length

and negative (−) when decrease length.” (refer to 8.2.2);

- DELETE “When the fittings are pull-out, any failures caused by leakage or burst

that is 25mm apart from the fittings or within the distance that equal to the hose

outer-diameter (maximum) shall not be considered as the real hose bursting.”

(refer to 8.3, 7.3 in 2006-edition);

- ADD Figure 3, the hydrostatic test procedure specified in this Standard (refer to

Figure 3).

This Standard uses translation method and equally adopts ISO 1402:2009 “Rubber

and plastics hoses and hose assemblies - Hydrostatic testing”.

The national documents that have the consistency and correspondence with

GB/T 5563-2013

international documents which are normative references in this Standard are as

follows:

- GB/T 2941-2006 Rubber - General procedures for preparing and conditioning

test pieces for physical test methods (ISO 23529:2004, IDT);

- GB/T 7528-2011 Rubber and plastics hoses and hose assemblies - Vocabulary

(ISO 8330:2007, IDT);

- GB/T 9574-2001 Rubber and plastics hoses and hose assemblies - Ratios of

proof and burst pressure to design working pressure (ISO 7751:1991, IDT);

- GB/T 9573-2003 Rubber and plastics hoses and hose assemblies - Methods of

measurement of dimension (ISO 4671:2007, IDT).

This Standard was proposed by China Petroleum and Chemical Industry Federation.

This Standard shall be under the jurisdiction of National Technical Committee on

Rubber and Products of Standardization Administration of China.

Drafting organizations of this Standard: Luohe Letong Rubber Co., Ltd., Guangzhou

Mingjun Balflex Rubber Co., Ltd., and Shenyang Rubber Research and Design Institute.

The main drafters of this Standard: Zhong Weijiang, Zhang Jingxiang, Wang Shuli,

Zhao Hongliang, and Zhang Tong.

The historical versions replaced by this Standard are as follows:

- GB/T 5563-1985, GB/T 5563-1994, GB/T 5563-2006.

GB/T 5563-2013

Rubber and plastics hoses and hose assemblies

- Hydrostatic testing

1 Scope

This Standard specifies methods for the hydrostatic testing of rubber and plastics

hoses and hose assemblies, including methods for the determination of dimensional

stability.

2 Normative references

The following documents are essential to the application of this document. For the

dated documents, only the versions with the dates indicated are applicable to this

document; for the undated documents, only the latest version (including all the

amendments) are applicable to this standard.

ISO 4671 Rubber and plastics hoses and hose assemblies - Methods of

measurement of the dimensions of hoses and the length of hose assemblies

ISO 7751 Rubber and plastic hoses and hose assemblies - Ratios of proof and

burst pressure to design working pressure

ISO 8330 Rubber and plastics hoses and hose assemblies - Vocabulary

ISO 23529 Rubber - General procedures for preparing and conditioning test pieces

for physical test methods

3 Terms and definitions

The terms and definitions given in ISO 8330 apply to this document.

4 General requirements

Unless otherwise specified, all tests shall be carried out at standard temperature

(refer to ISO 23529).

5 Apparatus

5.1 Pressure pump

GB/T 5563-2013

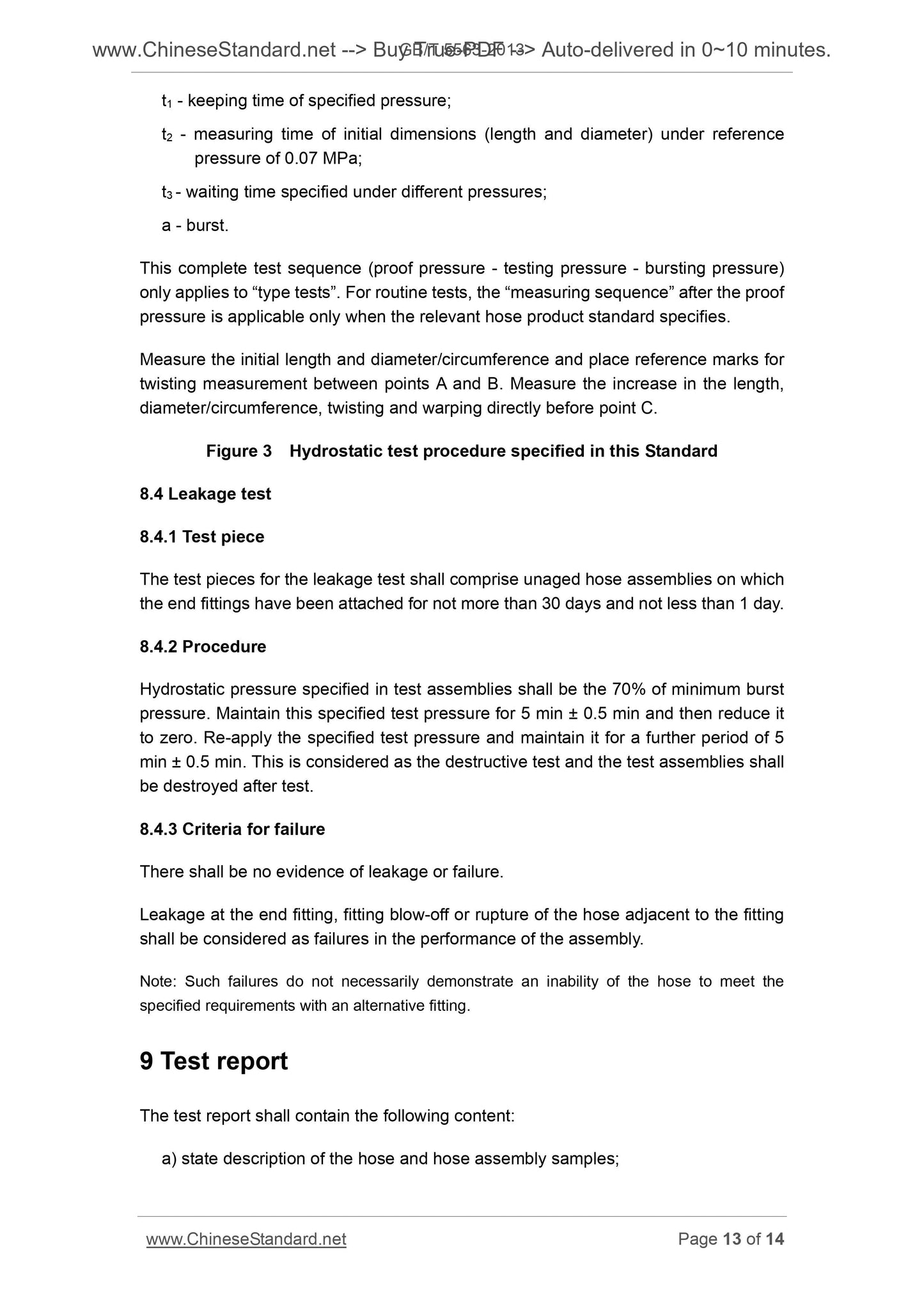

t1 - keeping time of specified pressure;

t2 - measuring time of initial dimensions (length and diameter) under reference

pressure of 0.07 MPa;

t3 - waiting time specified under different pressures;

a - burst.

This complete test sequence (proof pressure - testing pressure - bursting pressure)

only applies to “type tests”. For routine tests, the “measuring sequence” after the proof

pressure is applicable only when the relevant hose product standard specifies.

Measure the initial length and diameter/circumference and place reference marks for

twisting measurement between points A and B. Measure the increase in the length,

diameter/circumference, twisting and warping directly before point C.

Figure 3 Hydrostatic test procedure specified in this Standard

8.4 Leakage test

8.4.1 Test piece

The test pieces for the leakage test shall comprise unaged hose assemblies on which

the end fittings have been attached for not more than 30 days and not less than 1 day.

8.4.2 Procedure

Hydrostatic pressure specified in test assemblies shall be the 70% of minimum burst

pressure. Maintain this specified test pressure for 5 min ± 0.5 min and then reduce it

to zero. Re-apply the specified test pressure and maintain it for a further period of 5

min ± 0.5 min. This is considered as the destructive test and the test assemblies shall

be destroyed after test.

8.4.3 Criteria for failure

There shall be no evidence of leakage or failure.

Leakage at the end fitting, fitting blow-off or rupture of the hose adjacent to the fitting

shall be considered as failures in the performance of the assembly.

Note: Such failures do not necessarily demonstrate an inability of the hose to meet the

specified requirements with an alternative fitting.

9 Test report

The test report shall contain the following content:

a) state description of the hose and hose assembly samples;

GB/T 5563-2013

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 23.040.70

G 42

GB/T 5563-2013 / ISO 1402:2009

Replacing GB/T 5563-2006

Rubber and plastics hoses and hose assemblies

- Hydrostatic testing

(ISO 1402:2009, IDT)

ISSUED ON: DECEMBER 31, 2013

IMPLEMENTED ON: SEPTEMBER 01, 2014

Issued by:

General Administration of Quality Supervision, Inspection

and Quarantine of the People’s Republic of China;

Standardization Administration of the People’s Republic of

China.

GB/T 5563-2013

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Terms and definitions ... 5

4 General requirements ... 5

5 Apparatus ... 5

6 Test pieces ... 6

7 Application of hydrostatic pressure ... 6

8 Hydrostatic pressure tests ... 7

9 Test report ... 13

GB/T 5563-2013

Foreword

This Standard is drafted according to the rules given in the GB/T 1.1-2009.

This Standard replaced GB/T 5563-2006 “Rubber and plastics hoses and hose

assemblies - Hydrostatic testing”. Compared with GB/T 5563-2006, the main changes

of this Standard are as follows:

- ADD the terms and determination (refer to Chapter 3);

- REVISE the Chapter 4 (refer to Chapter 5; the Chapter 4 of 2006-edition);

- ADD “When a particular hose type or size needs longer measurement, it shall be

specified in the hose product standard.” (refer to 6.2);

- ADD “Note 1: use the term ‘maximum working pressure’ instead of the

deprecated term ‘design working pressure’. ” (refer to 8.1);

- REVISE the general procedure (refer to 8.2.1, 7.2.1 in 2006-edition);

- ADD “Apply 0.07MPa of pressure for approximately 5 min after completion of the

proof pressure test. The supporting surface upon which the hose/hose assembly

rests shall be flat and smooth enough to allow the hose/hose assembly to

expand or contract without restriction. Alternatively, the hose/hose assembly

may be supported on rollers, or suspended vertically. When a section of hose is

used as a test piece, it may also be placed in a test rig in a vertical position.”

(refer to 8.2.1.1);

- ADD “For hose assemblies, measure the distance between the contact faces of

the end fittings, or select the reference marks on the hose surface near the end

of the inserted part of the fitting.” (refer to 8.2.1.2);

- ADD “The change percentage in length will be positive (+) when increase length

and negative (−) when decrease length.” (refer to 8.2.2);

- DELETE “When the fittings are pull-out, any failures caused by leakage or burst

that is 25mm apart from the fittings or within the distance that equal to the hose

outer-diameter (maximum) shall not be considered as the real hose bursting.”

(refer to 8.3, 7.3 in 2006-edition);

- ADD Figure 3, the hydrostatic test procedure specified in this Standard (refer to

Figure 3).

This Standard uses translation method and equally adopts ISO 1402:2009 “Rubber

and plastics hoses and hose assemblies - Hydrostatic testing”.

The national documents that have the consistency and correspondence with

GB/T 5563-2013

international documents which are normative references in this Standard are as

follows:

- GB/T 2941-2006 Rubber - General procedures for preparing and conditioning

test pieces for physical test methods (ISO 23529:2004, IDT);

- GB/T 7528-2011 Rubber and plastics hoses and hose assemblies - Vocabulary

(ISO 8330:2007, IDT);

- GB/T 9574-2001 Rubber and plastics hoses and hose assemblies - Ratios of

proof and burst pressure to design working pressure (ISO 7751:1991, IDT);

- GB/T 9573-2003 Rubber and plastics hoses and hose assemblies - Methods of

measurement of dimension (ISO 4671:2007, IDT).

This Standard was proposed by China Petroleum and Chemical Industry Federation.

This Standard shall be under the jurisdiction of National Technical Committee on

Rubber and Products of Standardization Administration of China.

Drafting organizations of this Standard: Luohe Letong Rubber Co., Ltd., Guangzhou

Mingjun Balflex Rubber Co., Ltd., and Shenyang Rubber Research and Design Institute.

The main drafters of this Standard: Zhong Weijiang, Zhang Jingxiang, Wang Shuli,

Zhao Hongliang, and Zhang Tong.

The historical versions replaced by this Standard are as follows:

- GB/T 5563-1985, GB/T 5563-1994, GB/T 5563-2006.

GB/T 5563-2013

Rubber and plastics hoses and hose assemblies

- Hydrostatic testing

1 Scope

This Standard specifies methods for the hydrostatic testing of rubber and plastics

hoses and hose assemblies, including methods for the determination of dimensional

stability.

2 Normative references

The following documents are essential to the application of this document. For the

dated documents, only the versions with the dates indicated are applicable to this

document; for the undated documents, only the latest version (including all the

amendments) are applicable to this standard.

ISO 4671 Rubber and plastics hoses and hose assemblies - Methods of

measurement of the dimensions of hoses and the length of hose assemblies

ISO 7751 Rubber and plastic hoses and hose assemblies - Ratios of proof and

burst pressure to design working pressure

ISO 8330 Rubber and plastics hoses and hose assemblies - Vocabulary

ISO 23529 Rubber - General procedures for preparing and conditioning test pieces

for physical test methods

3 Terms and definitions

The terms and definitions given in ISO 8330 apply to this document.

4 General requirements

Unless otherwise specified, all tests shall be carried out at standard temperature

(refer to ISO 23529).

5 Apparatus

5.1 Pressure pump

GB/T 5563-2013

t1 - keeping time of specified pressure;

t2 - measuring time of initial dimensions (length and diameter) under reference

pressure of 0.07 MPa;

t3 - waiting time specified under different pressures;

a - burst.

This complete test sequence (proof pressure - testing pressure - bursting pressure)

only applies to “type tests”. For routine tests, the “measuring sequence” after the proof

pressure is applicable only when the relevant hose product standard specifies.

Measure the initial length and diameter/circumference and place reference marks for

twisting measurement between points A and B. Measure the increase in the length,

diameter/circumference, twisting and warping directly before point C.

Figure 3 Hydrostatic test procedure specified in this Standard

8.4 Leakage test

8.4.1 Test piece

The test pieces for the leakage t...

Delivery: 9 seconds. Download (& Email) true-PDF + Invoice.

Get Quotation: Click GB/T 5563-2013 (Self-service in 1-minute)

Historical versions (Master-website): GB/T 5563-2013

Preview True-PDF (Reload/Scroll-down if blank)

GB/T 5563-2013

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 23.040.70

G 42

GB/T 5563-2013 / ISO 1402:2009

Replacing GB/T 5563-2006

Rubber and plastics hoses and hose assemblies

- Hydrostatic testing

(ISO 1402:2009, IDT)

ISSUED ON: DECEMBER 31, 2013

IMPLEMENTED ON: SEPTEMBER 01, 2014

Issued by:

General Administration of Quality Supervision, Inspection

and Quarantine of the People’s Republic of China;

Standardization Administration of the People’s Republic of

China.

GB/T 5563-2013

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Terms and definitions ... 5

4 General requirements ... 5

5 Apparatus ... 5

6 Test pieces ... 6

7 Application of hydrostatic pressure ... 6

8 Hydrostatic pressure tests ... 7

9 Test report ... 13

GB/T 5563-2013

Foreword

This Standard is drafted according to the rules given in the GB/T 1.1-2009.

This Standard replaced GB/T 5563-2006 “Rubber and plastics hoses and hose

assemblies - Hydrostatic testing”. Compared with GB/T 5563-2006, the main changes

of this Standard are as follows:

- ADD the terms and determination (refer to Chapter 3);

- REVISE the Chapter 4 (refer to Chapter 5; the Chapter 4 of 2006-edition);

- ADD “When a particular hose type or size needs longer measurement, it shall be

specified in the hose product standard.” (refer to 6.2);

- ADD “Note 1: use the term ‘maximum working pressure’ instead of the

deprecated term ‘design working pressure’. ” (refer to 8.1);

- REVISE the general procedure (refer to 8.2.1, 7.2.1 in 2006-edition);

- ADD “Apply 0.07MPa of pressure for approximately 5 min after completion of the

proof pressure test. The supporting surface upon which the hose/hose assembly

rests shall be flat and smooth enough to allow the hose/hose assembly to

expand or contract without restriction. Alternatively, the hose/hose assembly

may be supported on rollers, or suspended vertically. When a section of hose is

used as a test piece, it may also be placed in a test rig in a vertical position.”

(refer to 8.2.1.1);

- ADD “For hose assemblies, measure the distance between the contact faces of

the end fittings, or select the reference marks on the hose surface near the end

of the inserted part of the fitting.” (refer to 8.2.1.2);

- ADD “The change percentage in length will be positive (+) when increase length

and negative (−) when decrease length.” (refer to 8.2.2);

- DELETE “When the fittings are pull-out, any failures caused by leakage or burst

that is 25mm apart from the fittings or within the distance that equal to the hose

outer-diameter (maximum) shall not be considered as the real hose bursting.”

(refer to 8.3, 7.3 in 2006-edition);

- ADD Figure 3, the hydrostatic test procedure specified in this Standard (refer to

Figure 3).

This Standard uses translation method and equally adopts ISO 1402:2009 “Rubber

and plastics hoses and hose assemblies - Hydrostatic testing”.

The national documents that have the consistency and correspondence with

GB/T 5563-2013

international documents which are normative references in this Standard are as

follows:

- GB/T 2941-2006 Rubber - General procedures for preparing and conditioning

test pieces for physical test methods (ISO 23529:2004, IDT);

- GB/T 7528-2011 Rubber and plastics hoses and hose assemblies - Vocabulary

(ISO 8330:2007, IDT);

- GB/T 9574-2001 Rubber and plastics hoses and hose assemblies - Ratios of

proof and burst pressure to design working pressure (ISO 7751:1991, IDT);

- GB/T 9573-2003 Rubber and plastics hoses and hose assemblies - Methods of

measurement of dimension (ISO 4671:2007, IDT).

This Standard was proposed by China Petroleum and Chemical Industry Federation.

This Standard shall be under the jurisdiction of National Technical Committee on

Rubber and Products of Standardization Administration of China.

Drafting organizations of this Standard: Luohe Letong Rubber Co., Ltd., Guangzhou

Mingjun Balflex Rubber Co., Ltd., and Shenyang Rubber Research and Design Institute.

The main drafters of this Standard: Zhong Weijiang, Zhang Jingxiang, Wang Shuli,

Zhao Hongliang, and Zhang Tong.

The historical versions replaced by this Standard are as follows:

- GB/T 5563-1985, GB/T 5563-1994, GB/T 5563-2006.

GB/T 5563-2013

Rubber and plastics hoses and hose assemblies

- Hydrostatic testing

1 Scope

This Standard specifies methods for the hydrostatic testing of rubber and plastics

hoses and hose assemblies, including methods for the determination of dimensional

stability.

2 Normative references

The following documents are essential to the application of this document. For the

dated documents, only the versions with the dates indicated are applicable to this

document; for the undated documents, only the latest version (including all the

amendments) are applicable to this standard.

ISO 4671 Rubber and plastics hoses and hose assemblies - Methods of

measurement of the dimensions of hoses and the length of hose assemblies

ISO 7751 Rubber and plastic hoses and hose assemblies - Ratios of proof and

burst pressure to design working pressure

ISO 8330 Rubber and plastics hoses and hose assemblies - Vocabulary

ISO 23529 Rubber - General procedures for preparing and conditioning test pieces

for physical test methods

3 Terms and definitions

The terms and definitions given in ISO 8330 apply to this document.

4 General requirements

Unless otherwise specified, all tests shall be carried out at standard temperature

(refer to ISO 23529).

5 Apparatus

5.1 Pressure pump

GB/T 5563-2013

t1 - keeping time of specified pressure;

t2 - measuring time of initial dimensions (length and diameter) under reference

pressure of 0.07 MPa;

t3 - waiting time specified under different pressures;

a - burst.

This complete test sequence (proof pressure - testing pressure - bursting pressure)

only applies to “type tests”. For routine tests, the “measuring sequence” after the proof

pressure is applicable only when the relevant hose product standard specifies.

Measure the initial length and diameter/circumference and place reference marks for

twisting measurement between points A and B. Measure the increase in the length,

diameter/circumference, twisting and warping directly before point C.

Figure 3 Hydrostatic test procedure specified in this Standard

8.4 Leakage test

8.4.1 Test piece

The test pieces for the leakage test shall comprise unaged hose assemblies on which

the end fittings have been attached for not more than 30 days and not less than 1 day.

8.4.2 Procedure

Hydrostatic pressure specified in test assemblies shall be the 70% of minimum burst

pressure. Maintain this specified test pressure for 5 min ± 0.5 min and then reduce it

to zero. Re-apply the specified test pressure and maintain it for a further period of 5

min ± 0.5 min. This is considered as the destructive test and the test assemblies shall

be destroyed after test.

8.4.3 Criteria for failure

There shall be no evidence of leakage or failure.

Leakage at the end fitting, fitting blow-off or rupture of the hose adjacent to the fitting

shall be considered as failures in the performance of the assembly.

Note: Such failures do not necessarily demonstrate an inability of the hose to meet the

specified requirements with an alternative fitting.

9 Test report

The test report shall contain the following content:

a) state description of the hose and hose assembly samples;

GB/T 5563-2013

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 23.040.70

G 42

GB/T 5563-2013 / ISO 1402:2009

Replacing GB/T 5563-2006

Rubber and plastics hoses and hose assemblies

- Hydrostatic testing

(ISO 1402:2009, IDT)

ISSUED ON: DECEMBER 31, 2013

IMPLEMENTED ON: SEPTEMBER 01, 2014

Issued by:

General Administration of Quality Supervision, Inspection

and Quarantine of the People’s Republic of China;

Standardization Administration of the People’s Republic of

China.

GB/T 5563-2013

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Terms and definitions ... 5

4 General requirements ... 5

5 Apparatus ... 5

6 Test pieces ... 6

7 Application of hydrostatic pressure ... 6

8 Hydrostatic pressure tests ... 7

9 Test report ... 13

GB/T 5563-2013

Foreword

This Standard is drafted according to the rules given in the GB/T 1.1-2009.

This Standard replaced GB/T 5563-2006 “Rubber and plastics hoses and hose

assemblies - Hydrostatic testing”. Compared with GB/T 5563-2006, the main changes

of this Standard are as follows:

- ADD the terms and determination (refer to Chapter 3);

- REVISE the Chapter 4 (refer to Chapter 5; the Chapter 4 of 2006-edition);

- ADD “When a particular hose type or size needs longer measurement, it shall be

specified in the hose product standard.” (refer to 6.2);

- ADD “Note 1: use the term ‘maximum working pressure’ instead of the

deprecated term ‘design working pressure’. ” (refer to 8.1);

- REVISE the general procedure (refer to 8.2.1, 7.2.1 in 2006-edition);

- ADD “Apply 0.07MPa of pressure for approximately 5 min after completion of the

proof pressure test. The supporting surface upon which the hose/hose assembly

rests shall be flat and smooth enough to allow the hose/hose assembly to

expand or contract without restriction. Alternatively, the hose/hose assembly

may be supported on rollers, or suspended vertically. When a section of hose is

used as a test piece, it may also be placed in a test rig in a vertical position.”

(refer to 8.2.1.1);

- ADD “For hose assemblies, measure the distance between the contact faces of

the end fittings, or select the reference marks on the hose surface near the end

of the inserted part of the fitting.” (refer to 8.2.1.2);

- ADD “The change percentage in length will be positive (+) when increase length

and negative (−) when decrease length.” (refer to 8.2.2);

- DELETE “When the fittings are pull-out, any failures caused by leakage or burst

that is 25mm apart from the fittings or within the distance that equal to the hose

outer-diameter (maximum) shall not be considered as the real hose bursting.”

(refer to 8.3, 7.3 in 2006-edition);

- ADD Figure 3, the hydrostatic test procedure specified in this Standard (refer to

Figure 3).

This Standard uses translation method and equally adopts ISO 1402:2009 “Rubber

and plastics hoses and hose assemblies - Hydrostatic testing”.

The national documents that have the consistency and correspondence with

GB/T 5563-2013

international documents which are normative references in this Standard are as

follows:

- GB/T 2941-2006 Rubber - General procedures for preparing and conditioning

test pieces for physical test methods (ISO 23529:2004, IDT);

- GB/T 7528-2011 Rubber and plastics hoses and hose assemblies - Vocabulary

(ISO 8330:2007, IDT);

- GB/T 9574-2001 Rubber and plastics hoses and hose assemblies - Ratios of

proof and burst pressure to design working pressure (ISO 7751:1991, IDT);

- GB/T 9573-2003 Rubber and plastics hoses and hose assemblies - Methods of

measurement of dimension (ISO 4671:2007, IDT).

This Standard was proposed by China Petroleum and Chemical Industry Federation.

This Standard shall be under the jurisdiction of National Technical Committee on

Rubber and Products of Standardization Administration of China.

Drafting organizations of this Standard: Luohe Letong Rubber Co., Ltd., Guangzhou

Mingjun Balflex Rubber Co., Ltd., and Shenyang Rubber Research and Design Institute.

The main drafters of this Standard: Zhong Weijiang, Zhang Jingxiang, Wang Shuli,

Zhao Hongliang, and Zhang Tong.

The historical versions replaced by this Standard are as follows:

- GB/T 5563-1985, GB/T 5563-1994, GB/T 5563-2006.

GB/T 5563-2013

Rubber and plastics hoses and hose assemblies

- Hydrostatic testing

1 Scope

This Standard specifies methods for the hydrostatic testing of rubber and plastics

hoses and hose assemblies, including methods for the determination of dimensional

stability.

2 Normative references

The following documents are essential to the application of this document. For the

dated documents, only the versions with the dates indicated are applicable to this

document; for the undated documents, only the latest version (including all the

amendments) are applicable to this standard.

ISO 4671 Rubber and plastics hoses and hose assemblies - Methods of

measurement of the dimensions of hoses and the length of hose assemblies

ISO 7751 Rubber and plastic hoses and hose assemblies - Ratios of proof and

burst pressure to design working pressure

ISO 8330 Rubber and plastics hoses and hose assemblies - Vocabulary

ISO 23529 Rubber - General procedures for preparing and conditioning test pieces

for physical test methods

3 Terms and definitions

The terms and definitions given in ISO 8330 apply to this document.

4 General requirements

Unless otherwise specified, all tests shall be carried out at standard temperature

(refer to ISO 23529).

5 Apparatus

5.1 Pressure pump

GB/T 5563-2013

t1 - keeping time of specified pressure;

t2 - measuring time of initial dimensions (length and diameter) under reference

pressure of 0.07 MPa;

t3 - waiting time specified under different pressures;

a - burst.

This complete test sequence (proof pressure - testing pressure - bursting pressure)

only applies to “type tests”. For routine tests, the “measuring sequence” after the proof

pressure is applicable only when the relevant hose product standard specifies.

Measure the initial length and diameter/circumference and place reference marks for

twisting measurement between points A and B. Measure the increase in the length,

diameter/circumference, twisting and warping directly before point C.

Figure 3 Hydrostatic test procedure specified in this Standard

8.4 Leakage test

8.4.1 Test piece

The test pieces for the leakage t...

Share