1

/

of

6

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 7964-2020 English PDF (GB/T7964-2020)

GB/T 7964-2020 English PDF (GB/T7964-2020)

Regular price

$145.00

Regular price

Sale price

$145.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB/T 7964-2020: Sintered Metal Materials (Excluding Hardmetal) - Tension Testing at Room Temperature

Delivery: 9 seconds. Download (& Email) true-PDF + Invoice.

Get Quotation: Click GB/T 7964-2020 (Self-service in 1-minute)

Historical versions (Master-website): GB/T 7964-2020

Preview True-PDF (Reload/Scroll-down if blank)

GB/T 7964-2020

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.160

H 22

Replacing GB/T 7964-1987

Sintered Metal Materials (Excluding Hardmetal)

– Tension Testing at Room Temperature

ISSUED ON: MARCH 06, 2006

IMPLEMENTED ON: FEBRUARY 01, 2021

Issued by: State Administration for Market Regulation;

Standardization Administration of PRC.

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative References ... 5

3 Principle ... 5

4 Symbols and Instructions ... 6

5 Specimen ... 7

6 Test Device ... 7

7 Test Procedures ... 7

8 Calculation of Test Results ... 8

9 Numerical Rounding-off ... 10

10 Test Report ... 11

Appendix A (Informative) Comparison List between Old and New Symbols .. 12

Foreword

This Standard was drafted as per the rules specified in GB/T 1.1-2009.

This Standard replaced GB/T 7964-1987 Sintered Metal Materials (Excluding

Hardmetal) -Tension Testing at Room Temperature.

Compared with GB/T 7964-1987, this Standard made the major technical changes as

follows besides the editorial modifications:

--- Change "yield point" into "yield strength"; change "yield stress" into "specified

plastic elongation strength"; and change "elongation" into "elongation after

break" (see Clause 1 of this Edition; Clause 1 of 1987 Edition);

--- Add normative references (see Clause 2 of this Edition);

--- Modify "record the corresponding load, deformation or draw the stress-strain

diagram (load-elongation diagram), measure mechanical properties" into "record

the corresponding load and deformation by the computer to obtain the load-

elongation diagram, and calculate the mechanical properties" (see Clause 3 of

this Edition; Clause 2 of 1987 Edition);

--- Modify the expressions and corresponding instructions of the used symbols (see

Clause 4 of this Edition; Chapter 1 of 1987 Edition);

--- Modify "performed in accordance with GB/T 7963-1987 Sintered Metal Materials

(Excluding Hardmetal) - Tensile Test Pieces" into "sample preparation and

requirements shall be performed in accordance with the provisions of GB/T

7963" (see Clause 5 of this Edition; Clause 3 of 1987 Edition);

--- Modify the part of the testing machine into "the testing machine of any system

used for tensile testing, the accuracy should be Level-1 or better, and be tested

according to GB/T 16825.1" (see 6.1 of this Edition; 4.1 of 1987 Edition);

---Confirm that the accuracy requirement of the extensometer is Level-1 or better

(see 6.3 of this Edition; 4.3 of 1987 Edition);

--- Modify the "accuracy 0.02mm" of the size measuring instrument into "accuracy

0.01mm" (see 6.4 of this Edition; 4.4 of 1987 Edition);

--- Modify "measurement accuracy 0.02mm" into "measurement accuracy 0.01mm"

(see 7.1.1 of this Edition; 5.1.1 of 1987 Edition);

--- Modify the rate control mode (see 7.2 of this Edition; 5.2 of 1987 Edition);

Sintered Metal Materials (Excluding Hardmetal)

– Tension Testing at Room Temperature

1 Scope

This Standard specifies the room temperature tensile test method for sintered metal

materials, including principles, symbols and instructions, specimens, test device, test

procedures, calculation of test results, numerical rounding-off and test reports.

This Standard is applicable to the determination of the yield strength, specified plastic

elongation strength, tensile strength, elongation after break, and reduction of area for

machined or non-machined sintered metal materials (excluding hardmetal).

2 Normative References

The following documents are essential to the application of this document. For the

dated documents, only the versions with the dates indicated are applicable to this

document; for the undated documents, only the latest version (including all the

amendments) are applicable to this document.

GB/T 7963 Sintered Metal Materials, Excluding Hardmetals - Tensile Test Pieces

GB/T 16825.1 Verification of Static Uniaxial Testing Machines - Part 1 :

Tension/Compression Testing Machines - Verification and Calibration of the Force-

Measuring System

3 Principle

Put the specimen in the appropriate position of the fixture; start the testing machine;

make the specimen continuously and uniformly bear the tensile stress till break under

the specified tensile speed; and record the corresponding load and deformation by the

computer to obtain the load-elongation diagram; and calculate the mechanical

properties.

5 Specimen

The preparation and requirements of the specimens shall be carried out in accordance

with the provisions of GB/T 7963.

6 Test Device

6.1 Testing machine

The testing machine of any system used for tensile testing shall have an accuracy of

Level-1 or better; and shall be tested in accordance with GB/T 16825.1. The testing

machine shall have sufficient rigidity and shall not cause instability within its tensile

load range.

6.2 Fixture

Choose a suitable specimen clamping device. The wedge chuck and collar chuck are

usually used to transfer the load applied by the testing machine to the specimen. The

axis of the specimen shall coincide with the center of the chuck of the testing machine.

6.3 Extensometer

The accuracy of the extensometer shall be Level-1 or better.

6.4 Size measuring instrument

Use a suitable instrument for measuring the specimen size, with an accuracy of 0.01

mm.

7 Test Procedures

7.1 Measuring specimen size

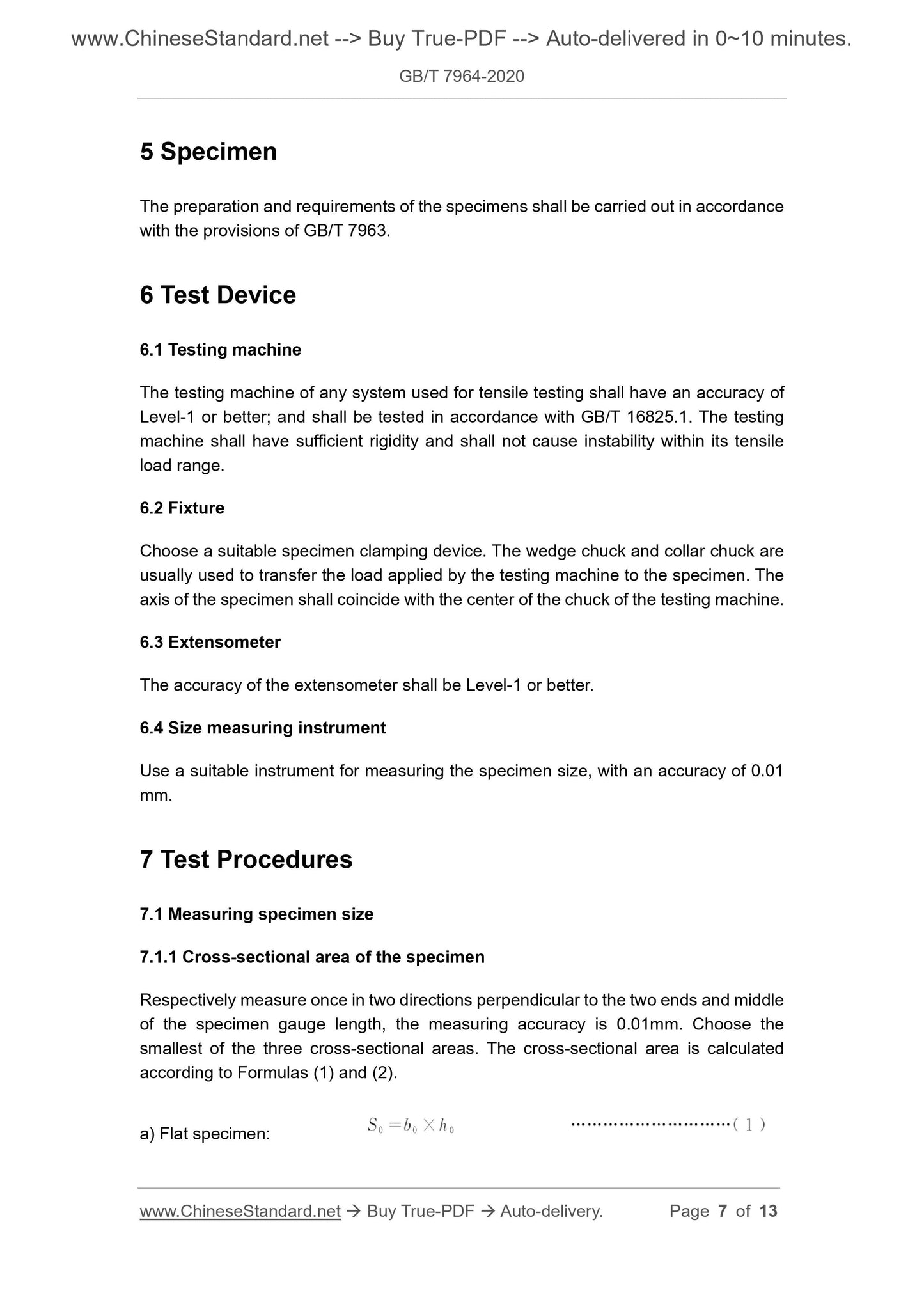

7.1.1 Cross-sectional area of the specimen

Respectively measure once in two directions perpendicular to the two ends and middle

of the specimen gauge length, the measuring accuracy is 0.01mm. Choose the

smallest of the three cross-sectional areas. The cross-sectional area is calculated

according to Formulas (1) and (2).

a) Flat specimen:

b) Cylindrical specimen:

7.1.2 Specimen gauge length

The original specimen has a gauge length of 25.0mm and a marking accuracy of

±0.1mm.

7.2 Test speed

According to the characteristics of the testing machine, the specimen material and the

purpose of the test, unless otherwise specified in the relevant material standards or

agreements, the tensile test speed shall meet the following requirements:

--- When measuring the tensile yield strength, the strain rate shall not exceed

0.0008s-1;

--- When measuring the tensile strength, the strain rate shall not exceed 0.0024s-1.

NOTE: For the beam displacement control testing machine, it is allowed to set a speed

equivalent to the above required strain rate. When using beam displacement control, the test

rate is calculated as per the following formula:

8 Calculation of Test Results

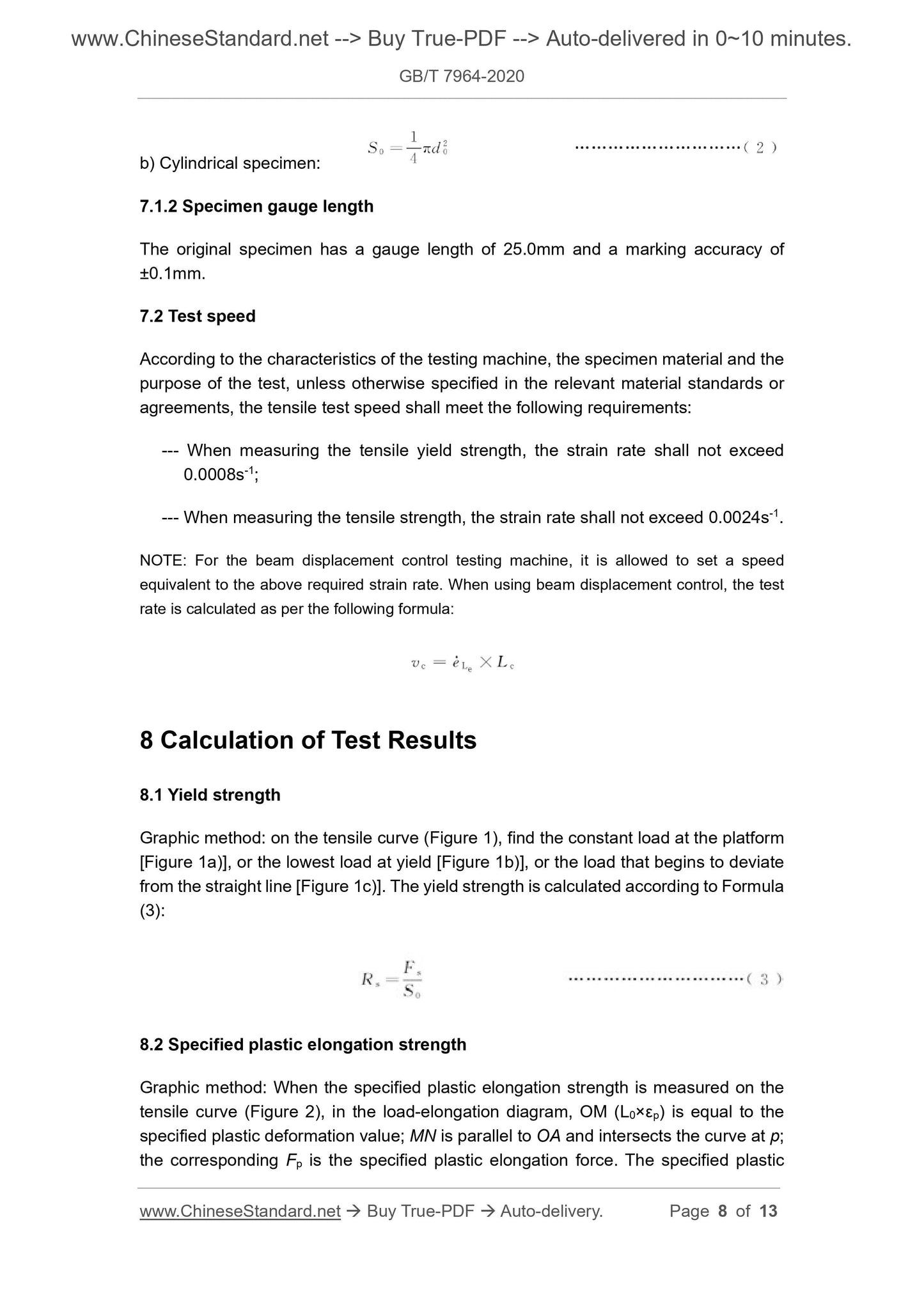

8.1 Yield strength

Graphic method: on the tensile curve (Figure 1), find the constant load at the platform

[Figure 1a)], or the lowest load at yield [Figure 1b)], or the load that begins to deviate

from the straight line [Figure 1c)]. The yield strength is calculated according to Formula

(3):

8.2 Specified plastic elongation strength

Graphic method: When the specified plastic elongation strength is measured on the

tensile curve (Figure 2), in the load-elongation diagram, OM (L0×εp) is equal to the

specified plastic deformation value; MN is parallel to OA and intersects the curve at p;

the corresponding Fp is the specified plastic elongation force. The specified plastic

GB/T 7964-2020

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.160

H 22

Replacing GB/T 7964-1987

Sintered Metal Materials (Excluding Hardmetal)

– Tension Testing at Room Temperature

ISSUED ON: MARCH 06, 2006

IMPLEMENTED ON: FEBRUARY 01, 2021

Issued by: State Administration for Market Regulation;

Standardization Administration of PRC.

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative References ... 5

3 Principle ... 5

4 Symbols and Instructions ... 6

5 Specimen ... 7

6 Test Device ... 7

7 Test Procedures ... 7

8 Calculation of Test Results ... 8

9 Numerical Rounding-off ... 10

10 Test Report ... 11

Appendix A (Informative) Comparison List between Old and New Symbols .. 12

Foreword

This Standard was drafted as per the rules specified in GB/T 1.1-2009.

This Standard replaced GB/T 7964-1987 Sintered Metal Materials (Excluding

Hardmetal) -Tension Testing at Room Temperature.

Compared with GB/T 7964-1987, this Standard made the major technical changes as

follows besides the editorial modifications:

--- Change "yield point" into "yield strength"; change "yield stress" into "specified

plastic elongation strength"; and change "elongation" into "elongation after

break" (see Clause 1 of this Edition; Clause 1 of 1987 Edition);

--- Add normative references (see Clause 2 of this Edition);

--- Modify "record the corresponding load, deformation or draw the stress-strain

diagram (load-elongation diagram), measure mechanical properties" into "record

the corresponding load and deformation by the computer to obtain the load-

elongation diagram, and calculate the mechanical properties" (see Clause 3 of

this Edition; Clause 2 of 1987 Edition);

--- Modify the expressions and corresponding instructions of the used symbols (see

Clause 4 of this Edition; Chapter 1 of 1987 Edition);

--- Modify "performed in accordance with GB/T 7963-1987 Sintered Metal Materials

(Excluding Hardmetal) - Tensile Test Pieces" into "sample preparation and

requirements shall be performed in accordance with the provisions of GB/T

7963" (see Clause 5 of this Edition; Clause 3 of 1987 Edition);

--- Modify the part of the testing machine into "the testing machine of any system

used for tensile testing, the accuracy should be Level-1 or better, and be tested

according to GB/T 16825.1" (see 6.1 of this Edition; 4.1 of 1987 Edition);

---Confirm that the accuracy requirement of the extensometer is Level-1 or better

(see 6.3 of this Edition; 4.3 of 1987 Edition);

--- Modify the "accuracy 0.02mm" of the size measuring instrument into "accuracy

0.01mm" (see 6.4 of this Edition; 4.4 of 1987 Edition);

--- Modify "measurement accuracy 0.02mm" into "measurement accuracy 0.01mm"

(see 7.1.1 of this Edition; 5.1.1 of 1987 Edition);

--- Modify the rate control mode (see 7.2 of this Edition; 5.2 of 1987 Edition);

Sintered Metal Materials (Excluding Hardmetal)

– Tension Testing at Room Temperature

1 Scope

This Standard specifies the room temperature tensile test method for sintered metal

materials, including principles, symbols and instructions, specimens, test device, test

procedures, calculation of test results, numerical rounding-off and test reports.

This Standard is applicable to the determination of the yield strength, specified plastic

elongation strength, tensile strength, elongation after break, and reduction of area for

machined or non-machined sintered metal materials (excluding hardmetal).

2 Normative References

The following documents are essential to the application of this document. For the

dated documents, only the versions with the dates indicated are applicable to this

document; for the undated documents, only the latest version (including all the

amendments) are applicable to this document.

GB/T 7963 Sintered Metal Materials, Excluding Hardmetals - Tensile Test Pieces

GB/T 16825.1 Verification of Static Uniaxial Testing Machines - Part 1 :

Tension/Compression Testing Machines - Verification and Calibration of the Force-

Measuring System

3 Principle

Put the specimen in the appropriate position of the fixture; start the testing machine;

make the specimen continuously and uniformly bear the tensile stress till break under

the specified tensile speed; and record the corresponding load and deformation by the

computer to obtain the load-elongation diagram; and calculate the mechanical

properties.

5 Specimen

The preparation and requirements of the specimens shall be carried out in accordance

with the provisions of GB/T 7963.

6 Test Device

6.1 Testing machine

The testing machine of any system used for tensile testing shall have an accuracy of

Level-1 or better; and shall be tested in accordance with GB/T 16825.1. The testing

machine shall have sufficient rigidity and shall not cause instability within its tensile

load range.

6.2 Fixture

Choose a suitable specimen clamping device. The wedge chuck and collar chuck are

usually used to transfer the load applied by the testing machine to the specimen. The

axis of the specimen shall coincide with the center of the chuck of the testing machine.

6.3 Extensometer

The accuracy of the extensometer shall be Level-1 or better.

6.4 Size measuring instrument

Use a suitable instrument for measuring the specimen size, with an accuracy of 0.01

mm.

7 Test Procedures

7.1 Measuring specimen size

7.1.1 Cross-sectional area of the specimen

Respectively measure once in two directions perpendicular to the two ends and middle

of the specimen gauge length, the measuring accuracy is 0.01mm. Choose the

smallest of the three cross-sectional areas. The cross-sectional area is calculated

according to Formulas (1) and (2).

a) Flat specimen:

b) Cylindrical specimen:

7.1.2 Specimen gauge length

The original specimen has a gauge length of 25.0mm and a marking accuracy of

±0.1mm.

7.2 Test speed

According to the characteristics of the testing machine, the specimen material and the

purpose of the test, unless otherwise specified in the relevant material standards or

agreements, the tensile test speed shall meet the following requirements:

--- When measuring the tensile yield strength, the strain rate shall not exceed

0.0008s-1;

--- When measuring the tensile strength, the strain rate shall not exceed 0.0024s-1.

NOTE: For the beam displacement control testing machine, it is allowed to set a speed

equivalent to the above required strain rate. When using beam displacement control, the test

rate is calculated as per the following formula:

8 Calculation of Test Results

8.1 Yield strength

Graphic method: on the tensile curve (Figure 1), find the constant load at the platform

[Figure 1a)], or the lo...

Delivery: 9 seconds. Download (& Email) true-PDF + Invoice.

Get Quotation: Click GB/T 7964-2020 (Self-service in 1-minute)

Historical versions (Master-website): GB/T 7964-2020

Preview True-PDF (Reload/Scroll-down if blank)

GB/T 7964-2020

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.160

H 22

Replacing GB/T 7964-1987

Sintered Metal Materials (Excluding Hardmetal)

– Tension Testing at Room Temperature

ISSUED ON: MARCH 06, 2006

IMPLEMENTED ON: FEBRUARY 01, 2021

Issued by: State Administration for Market Regulation;

Standardization Administration of PRC.

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative References ... 5

3 Principle ... 5

4 Symbols and Instructions ... 6

5 Specimen ... 7

6 Test Device ... 7

7 Test Procedures ... 7

8 Calculation of Test Results ... 8

9 Numerical Rounding-off ... 10

10 Test Report ... 11

Appendix A (Informative) Comparison List between Old and New Symbols .. 12

Foreword

This Standard was drafted as per the rules specified in GB/T 1.1-2009.

This Standard replaced GB/T 7964-1987 Sintered Metal Materials (Excluding

Hardmetal) -Tension Testing at Room Temperature.

Compared with GB/T 7964-1987, this Standard made the major technical changes as

follows besides the editorial modifications:

--- Change "yield point" into "yield strength"; change "yield stress" into "specified

plastic elongation strength"; and change "elongation" into "elongation after

break" (see Clause 1 of this Edition; Clause 1 of 1987 Edition);

--- Add normative references (see Clause 2 of this Edition);

--- Modify "record the corresponding load, deformation or draw the stress-strain

diagram (load-elongation diagram), measure mechanical properties" into "record

the corresponding load and deformation by the computer to obtain the load-

elongation diagram, and calculate the mechanical properties" (see Clause 3 of

this Edition; Clause 2 of 1987 Edition);

--- Modify the expressions and corresponding instructions of the used symbols (see

Clause 4 of this Edition; Chapter 1 of 1987 Edition);

--- Modify "performed in accordance with GB/T 7963-1987 Sintered Metal Materials

(Excluding Hardmetal) - Tensile Test Pieces" into "sample preparation and

requirements shall be performed in accordance with the provisions of GB/T

7963" (see Clause 5 of this Edition; Clause 3 of 1987 Edition);

--- Modify the part of the testing machine into "the testing machine of any system

used for tensile testing, the accuracy should be Level-1 or better, and be tested

according to GB/T 16825.1" (see 6.1 of this Edition; 4.1 of 1987 Edition);

---Confirm that the accuracy requirement of the extensometer is Level-1 or better

(see 6.3 of this Edition; 4.3 of 1987 Edition);

--- Modify the "accuracy 0.02mm" of the size measuring instrument into "accuracy

0.01mm" (see 6.4 of this Edition; 4.4 of 1987 Edition);

--- Modify "measurement accuracy 0.02mm" into "measurement accuracy 0.01mm"

(see 7.1.1 of this Edition; 5.1.1 of 1987 Edition);

--- Modify the rate control mode (see 7.2 of this Edition; 5.2 of 1987 Edition);

Sintered Metal Materials (Excluding Hardmetal)

– Tension Testing at Room Temperature

1 Scope

This Standard specifies the room temperature tensile test method for sintered metal

materials, including principles, symbols and instructions, specimens, test device, test

procedures, calculation of test results, numerical rounding-off and test reports.

This Standard is applicable to the determination of the yield strength, specified plastic

elongation strength, tensile strength, elongation after break, and reduction of area for

machined or non-machined sintered metal materials (excluding hardmetal).

2 Normative References

The following documents are essential to the application of this document. For the

dated documents, only the versions with the dates indicated are applicable to this

document; for the undated documents, only the latest version (including all the

amendments) are applicable to this document.

GB/T 7963 Sintered Metal Materials, Excluding Hardmetals - Tensile Test Pieces

GB/T 16825.1 Verification of Static Uniaxial Testing Machines - Part 1 :

Tension/Compression Testing Machines - Verification and Calibration of the Force-

Measuring System

3 Principle

Put the specimen in the appropriate position of the fixture; start the testing machine;

make the specimen continuously and uniformly bear the tensile stress till break under

the specified tensile speed; and record the corresponding load and deformation by the

computer to obtain the load-elongation diagram; and calculate the mechanical

properties.

5 Specimen

The preparation and requirements of the specimens shall be carried out in accordance

with the provisions of GB/T 7963.

6 Test Device

6.1 Testing machine

The testing machine of any system used for tensile testing shall have an accuracy of

Level-1 or better; and shall be tested in accordance with GB/T 16825.1. The testing

machine shall have sufficient rigidity and shall not cause instability within its tensile

load range.

6.2 Fixture

Choose a suitable specimen clamping device. The wedge chuck and collar chuck are

usually used to transfer the load applied by the testing machine to the specimen. The

axis of the specimen shall coincide with the center of the chuck of the testing machine.

6.3 Extensometer

The accuracy of the extensometer shall be Level-1 or better.

6.4 Size measuring instrument

Use a suitable instrument for measuring the specimen size, with an accuracy of 0.01

mm.

7 Test Procedures

7.1 Measuring specimen size

7.1.1 Cross-sectional area of the specimen

Respectively measure once in two directions perpendicular to the two ends and middle

of the specimen gauge length, the measuring accuracy is 0.01mm. Choose the

smallest of the three cross-sectional areas. The cross-sectional area is calculated

according to Formulas (1) and (2).

a) Flat specimen:

b) Cylindrical specimen:

7.1.2 Specimen gauge length

The original specimen has a gauge length of 25.0mm and a marking accuracy of

±0.1mm.

7.2 Test speed

According to the characteristics of the testing machine, the specimen material and the

purpose of the test, unless otherwise specified in the relevant material standards or

agreements, the tensile test speed shall meet the following requirements:

--- When measuring the tensile yield strength, the strain rate shall not exceed

0.0008s-1;

--- When measuring the tensile strength, the strain rate shall not exceed 0.0024s-1.

NOTE: For the beam displacement control testing machine, it is allowed to set a speed

equivalent to the above required strain rate. When using beam displacement control, the test

rate is calculated as per the following formula:

8 Calculation of Test Results

8.1 Yield strength

Graphic method: on the tensile curve (Figure 1), find the constant load at the platform

[Figure 1a)], or the lowest load at yield [Figure 1b)], or the load that begins to deviate

from the straight line [Figure 1c)]. The yield strength is calculated according to Formula

(3):

8.2 Specified plastic elongation strength

Graphic method: When the specified plastic elongation strength is measured on the

tensile curve (Figure 2), in the load-elongation diagram, OM (L0×εp) is equal to the

specified plastic deformation value; MN is parallel to OA and intersects the curve at p;

the corresponding Fp is the specified plastic elongation force. The specified plastic

GB/T 7964-2020

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.160

H 22

Replacing GB/T 7964-1987

Sintered Metal Materials (Excluding Hardmetal)

– Tension Testing at Room Temperature

ISSUED ON: MARCH 06, 2006

IMPLEMENTED ON: FEBRUARY 01, 2021

Issued by: State Administration for Market Regulation;

Standardization Administration of PRC.

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative References ... 5

3 Principle ... 5

4 Symbols and Instructions ... 6

5 Specimen ... 7

6 Test Device ... 7

7 Test Procedures ... 7

8 Calculation of Test Results ... 8

9 Numerical Rounding-off ... 10

10 Test Report ... 11

Appendix A (Informative) Comparison List between Old and New Symbols .. 12

Foreword

This Standard was drafted as per the rules specified in GB/T 1.1-2009.

This Standard replaced GB/T 7964-1987 Sintered Metal Materials (Excluding

Hardmetal) -Tension Testing at Room Temperature.

Compared with GB/T 7964-1987, this Standard made the major technical changes as

follows besides the editorial modifications:

--- Change "yield point" into "yield strength"; change "yield stress" into "specified

plastic elongation strength"; and change "elongation" into "elongation after

break" (see Clause 1 of this Edition; Clause 1 of 1987 Edition);

--- Add normative references (see Clause 2 of this Edition);

--- Modify "record the corresponding load, deformation or draw the stress-strain

diagram (load-elongation diagram), measure mechanical properties" into "record

the corresponding load and deformation by the computer to obtain the load-

elongation diagram, and calculate the mechanical properties" (see Clause 3 of

this Edition; Clause 2 of 1987 Edition);

--- Modify the expressions and corresponding instructions of the used symbols (see

Clause 4 of this Edition; Chapter 1 of 1987 Edition);

--- Modify "performed in accordance with GB/T 7963-1987 Sintered Metal Materials

(Excluding Hardmetal) - Tensile Test Pieces" into "sample preparation and

requirements shall be performed in accordance with the provisions of GB/T

7963" (see Clause 5 of this Edition; Clause 3 of 1987 Edition);

--- Modify the part of the testing machine into "the testing machine of any system

used for tensile testing, the accuracy should be Level-1 or better, and be tested

according to GB/T 16825.1" (see 6.1 of this Edition; 4.1 of 1987 Edition);

---Confirm that the accuracy requirement of the extensometer is Level-1 or better

(see 6.3 of this Edition; 4.3 of 1987 Edition);

--- Modify the "accuracy 0.02mm" of the size measuring instrument into "accuracy

0.01mm" (see 6.4 of this Edition; 4.4 of 1987 Edition);

--- Modify "measurement accuracy 0.02mm" into "measurement accuracy 0.01mm"

(see 7.1.1 of this Edition; 5.1.1 of 1987 Edition);

--- Modify the rate control mode (see 7.2 of this Edition; 5.2 of 1987 Edition);

Sintered Metal Materials (Excluding Hardmetal)

– Tension Testing at Room Temperature

1 Scope

This Standard specifies the room temperature tensile test method for sintered metal

materials, including principles, symbols and instructions, specimens, test device, test

procedures, calculation of test results, numerical rounding-off and test reports.

This Standard is applicable to the determination of the yield strength, specified plastic

elongation strength, tensile strength, elongation after break, and reduction of area for

machined or non-machined sintered metal materials (excluding hardmetal).

2 Normative References

The following documents are essential to the application of this document. For the

dated documents, only the versions with the dates indicated are applicable to this

document; for the undated documents, only the latest version (including all the

amendments) are applicable to this document.

GB/T 7963 Sintered Metal Materials, Excluding Hardmetals - Tensile Test Pieces

GB/T 16825.1 Verification of Static Uniaxial Testing Machines - Part 1 :

Tension/Compression Testing Machines - Verification and Calibration of the Force-

Measuring System

3 Principle

Put the specimen in the appropriate position of the fixture; start the testing machine;

make the specimen continuously and uniformly bear the tensile stress till break under

the specified tensile speed; and record the corresponding load and deformation by the

computer to obtain the load-elongation diagram; and calculate the mechanical

properties.

5 Specimen

The preparation and requirements of the specimens shall be carried out in accordance

with the provisions of GB/T 7963.

6 Test Device

6.1 Testing machine

The testing machine of any system used for tensile testing shall have an accuracy of

Level-1 or better; and shall be tested in accordance with GB/T 16825.1. The testing

machine shall have sufficient rigidity and shall not cause instability within its tensile

load range.

6.2 Fixture

Choose a suitable specimen clamping device. The wedge chuck and collar chuck are

usually used to transfer the load applied by the testing machine to the specimen. The

axis of the specimen shall coincide with the center of the chuck of the testing machine.

6.3 Extensometer

The accuracy of the extensometer shall be Level-1 or better.

6.4 Size measuring instrument

Use a suitable instrument for measuring the specimen size, with an accuracy of 0.01

mm.

7 Test Procedures

7.1 Measuring specimen size

7.1.1 Cross-sectional area of the specimen

Respectively measure once in two directions perpendicular to the two ends and middle

of the specimen gauge length, the measuring accuracy is 0.01mm. Choose the

smallest of the three cross-sectional areas. The cross-sectional area is calculated

according to Formulas (1) and (2).

a) Flat specimen:

b) Cylindrical specimen:

7.1.2 Specimen gauge length

The original specimen has a gauge length of 25.0mm and a marking accuracy of

±0.1mm.

7.2 Test speed

According to the characteristics of the testing machine, the specimen material and the

purpose of the test, unless otherwise specified in the relevant material standards or

agreements, the tensile test speed shall meet the following requirements:

--- When measuring the tensile yield strength, the strain rate shall not exceed

0.0008s-1;

--- When measuring the tensile strength, the strain rate shall not exceed 0.0024s-1.

NOTE: For the beam displacement control testing machine, it is allowed to set a speed

equivalent to the above required strain rate. When using beam displacement control, the test

rate is calculated as per the following formula:

8 Calculation of Test Results

8.1 Yield strength

Graphic method: on the tensile curve (Figure 1), find the constant load at the platform

[Figure 1a)], or the lo...

Share