1

/

of

9

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 8146-2003 English PDF (GB/T8146-2003)

GB/T 8146-2003 English PDF (GB/T8146-2003)

Regular price

$125.00

Regular price

Sale price

$125.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB/T 8146-2003: Test methods for rosin

Delivery: 9 seconds. Download (& Email) true-PDF + Invoice.

Get Quotation: Click GB/T 8146-2003 (Self-service in 1-minute)

Historical versions (Master-website): GB/T 8146-2003

Preview True-PDF (Reload/Scroll-down if blank)

GB/T 8146-2003

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 65.050

B 72

Replacing GB/T 8146-1987

Test Methods for Rosin

ISSUED ON: JUNE 17, 2003

IMPLEMENTED ON: DECEMBER 01, 2003

Issued by: General Administration of Quality Supervision, Inspection and

Quarantine

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative References ... 5

3 Determination of Colour and Appearance ... 5

4 Determination of Softening Point (Ring-and-Ball Method) ... 7

5 Determination of Acid Value ... 11

6 Determination of Unsaponifiable Matter ... 13

7 Determination of Ethanol Insoluble Matter ... 15

8 Determination of Ash... 16

Appendix A (Normative) Judgment of Crystallization Phenomenon and

Qualitative Method of Sulfur Content ... 18

Test Methods for Rosin

1 Scope

This Standard specifies the inspection methods for the colour, appearance, softening

point, acid value, unsaponifiable matter, ethanol insoluble matter, and ash of rosin.

This Standard is applicable to the inspection of rosin.

2 Normative References

The provisions in following documents become the provisions of this Standard through

reference in this Standard. For dated references, the subsequent amendments

(excluding corrigendum) or revisions do not apply to this Standard, however, parties

who reach an agreement based on this Standard are encouraged to study if the latest

versions of these documents are applicable. For undated references, the latest edition

of the referenced document applies.

GB/T 601 Chemical Reagent - Preparations of Standard Volumetric Solutions

3 Determination of Colour and Appearance

3.1 Colour grading

The colour grading of rosin uses rosin chromaticity standard blocks, each set has a

total of six glass standard colour blocks. A set of rosin chromaticity standard device No.

S20 preserved by the Institute of Chemical Industry of Forest Products CAF stipulates

as the color grading standard of rosin chromaticity standard block; the chromaticity

index of 1931 standard chromaticity system of the International Commission on

Illumination (CIE) for all grades of colours is shown in Table 1.

3.2.3 Other colorimeters

The inspection of rosin colour shall be based on the rosin chromaticity standard block

as the grading standard. It is allowed to use other colorimeters whose colorimetric

effect is equivalent to that of the chromaticity standard block after being checked by

the chromaticity standard block.

3.3 Determination of appearance

Under indoor natural light or normal lighting conditions, horizontally place one

observation surface of the sample block used to determine the colour grade made

according to 3.2.1 on an ordinary newspaper; and observe downward from the other

observation surface, if it can read the No.5 printed font clearly, it is transparent;

otherwise, it is opaque.

4 Determination of Softening Point (Ring-and-Ball

Method)

4.1 Summary of the method

Rosin has no fixed melting point and becomes soft when heated. Fill two copper rings

of specified thickness and diameter with rosin; respectively place a steel ball of

specified mass and diameter on the ironed rosin through a positioner; and then heat it

in a heating medium at a certain temperature-rise speed; then the instantaneous

temperature at which the rosin wrapped with steel ball falling a fixed distance is the

softening point of the rosin.

4.2 Apparatus

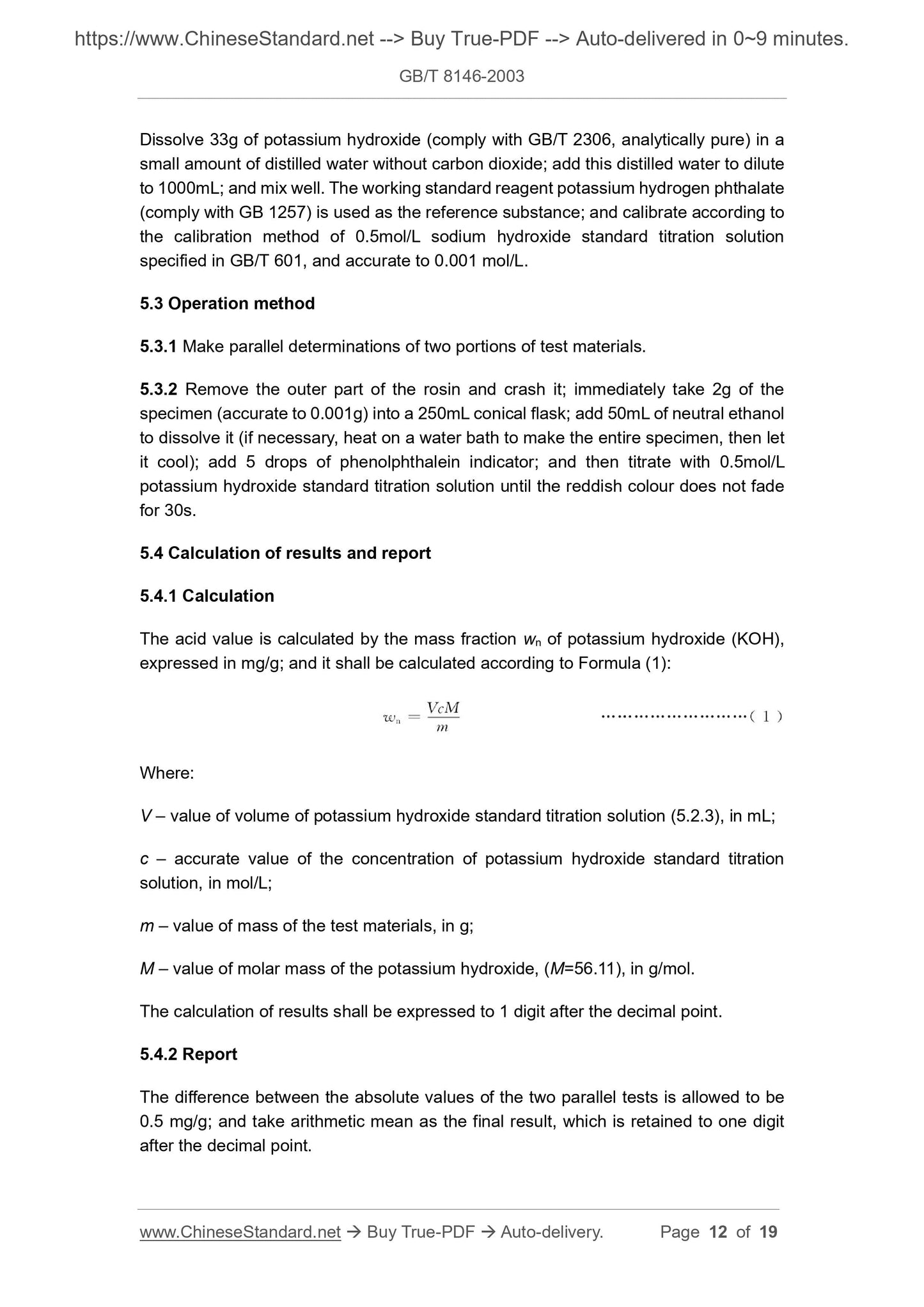

4.2.1 The softening point tester, the device is shown in Figure 1; and the main parts

are shown in Figure 2.

4.2.6 Thermometer, internal standard type, immersion height of 55mm, tail length of

100mm, scale range of 30°C~100°C, minimum graduation of 0.2°C, mercury bulb outer

diameter of 5.0mm±0.5mm, mercury bulb length of 8mm ±2mm, and total length of

380mm±10mm.

4.2.7 Beaker with the capacity of about 800 mL, the diameter of 90mm, and the height

of no less than 140mm.

4.2.8 Stirrer, generally manual stirrer is used, mechanical stirrer or electromagnetic

stirrer may also be used. When stirring, the speed shall be uniform and shall not form

a vortex, vibration or air bubbles.

4.3 Heating medium

4.3.1 Freshly boiled distilled water

Put about 800 mL of ordinary distilled water into a 1000 mL beaker and heat it to boiling;

and then cool it to 35°C below. Then it is used for the determination of rosin samples

with a softening point no greater than 80°C.

4.3.2 Glyceryl (glycerol)

It shall be analytically pure, which comply with GB/T687. It is used for the determination

of rosin samples with a softening point greater than 80°C. Repeated use shall not affect

the determination results.

4.4 Operation method

4.4.1 Once-melt specimen shall be used for two parallel determinations under the

same conditions.

4.4.2 Take about 5g of rosin and crush into a diameter of about 5mm in a container;

slowly heat it to melt at the possible lowest temperature to avoid bubbles and smoke.

Pour the molten rosin into the preheated ring on the copper plate immediately. When

the rosin is completely solidified, gently remove the copper plate. The ring shall be full

of rosin; and the surface shall be slightly raised. Use an electric iron to iron it out for

inspection. If the rosin in the ring has sunken or bubbles, it shall be remade.

4.4.3 Put the prepared specimen ring on the ring frame plate; install the steel ball

positioner on the ring; and then put the steel ball into the centre of the steel ball

positioner. Then insert the thermometer from the top cover of the ring frame; so that

the bottom of the mercury ball and the bottom surface of the ring are on the same

plane; and then put the entire ring frame into an 800mL beaker. After the above device

is completed, pour the freshly boiled distilled water into the beaker; so that the upper

surface of the ring frame plate is kept at 51mm from the water surface. After standing

for 10min; use an adjustable electric furnace or other heat source to heat the water to

Dissolve 33g of potassium hydroxide (comply with GB/T 2306, analytically pure) in a

small amount of distilled water without carbon dioxide; add this distilled water to dilute

to 1000mL; and mix well. The working standard reagent potassium hydrogen phthalate

(comply with GB 1257) is used as the reference substance; and calibrate according to

the calibration method of 0.5mol/L sodium hydroxide standard titration solution

specified in GB/T 601, and accurate to 0.001 mol/L.

5.3 Operation method

5.3.1 Make parallel determinations of two portions of test materials.

5.3.2 Remove the outer part of the rosin and crash it; immediately take 2g of the

specimen (accurate to 0.001g) into a 250mL conical flask; add 50mL of neutral ethanol

to dissolve it (if necessary, heat on a water bath to make the entire specimen, then let

it cool); add 5 drops of phenolphthalein indicator; and then titrate with 0.5mol/L

potassium hydroxide standard titration solution until the reddish colour does not fade

for 30s.

5.4 Calculation of results and report

5.4.1 Calculation

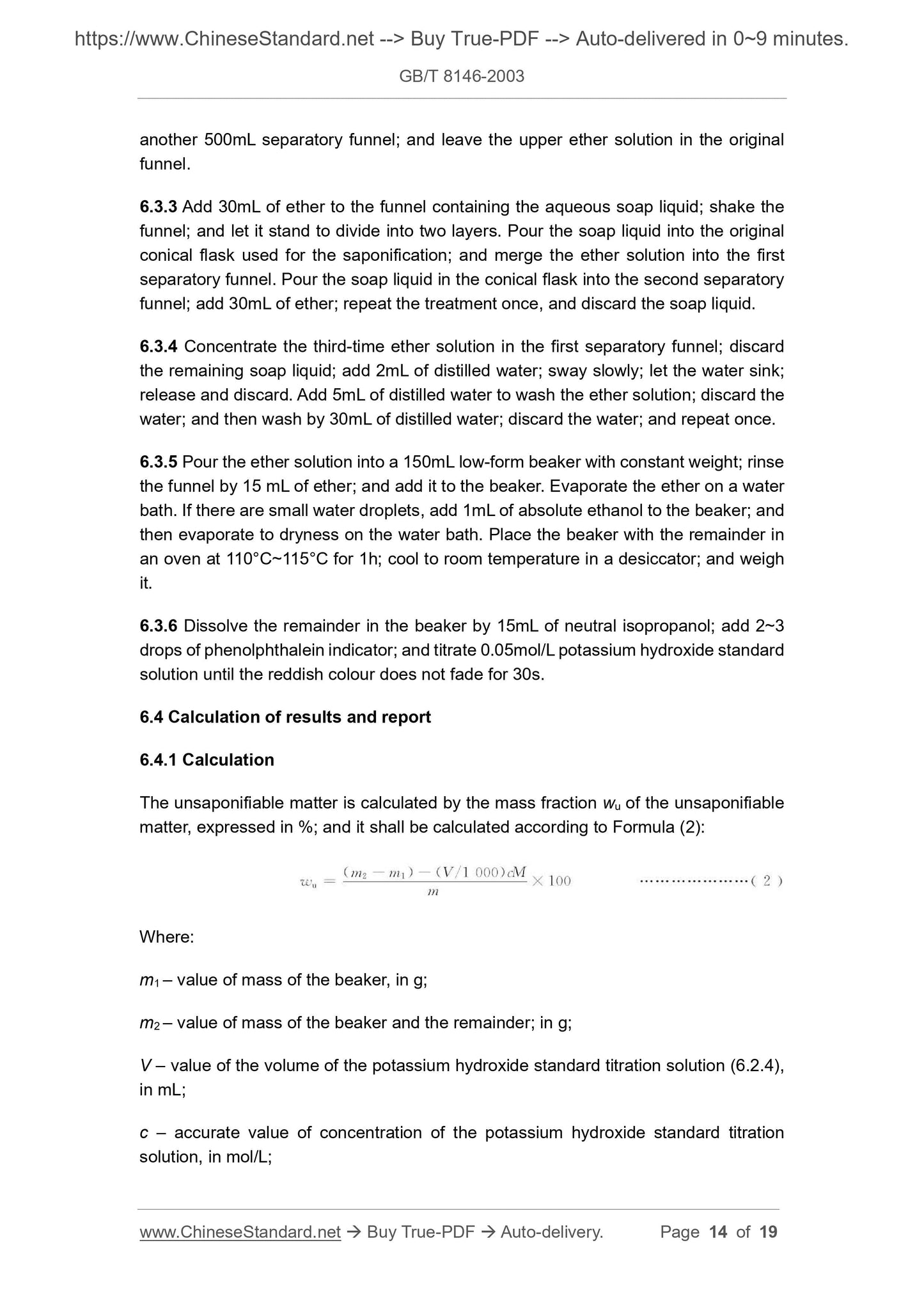

The acid value is calculated by the mass fraction wn of potassium hydroxide (KOH),

expressed in mg/g; and it shall be calculated according to Formula (1):

Where:

V – value of volume of potassium hydroxide standard titration solution (5.2.3), in mL;

c – accurate value of the concentration of potassium hydroxide standard titration

solution, in mol/L;

m – value of mass of the test materials, in g;

M – value of molar mass of the potassium hydroxide, (M=56.11), in g/mol.

The calculation of results shall be expressed to 1 digit after the decimal point.

5.4.2 Report

The difference between the absolute values of the two parallel tests is allowed to be

0.5 mg/g; and take arithmetic mean as the final result, which is retained to one digit

after the decimal point.

another 500mL separatory funnel; and leave the upper ether solution in the original

funnel.

6.3.3 Add 30mL of ether to the funnel containing the aqueous soap liquid; shake the

funnel; and let it stand to divide into two layers. Pour the soap liquid into the original

conical flask used for the saponification; and merge the ether solution into the first

separatory funnel. Pour the soap liquid in the conical flask into the second separatory

funnel; add 30mL of ether; repeat the treatment once, and discard the soap liquid.

6.3.4 Concentrate the third-time ether solution in the first separatory funnel; discard

the remaining soap liquid; add 2mL of distilled water; sway slowly; let the water sink;

release and discard. Add 5mL of distilled water to wash the ether solution; discard the

water; and then wash by 30mL of distilled water; discard the water; and repeat once.

6.3.5 Pour the ether solution into a 150mL low-form beaker with constant weight; rinse

the funnel by 15 mL of ether; and add it to the beaker. Evaporate the ether on a water

bath. If there are small water droplets, add 1mL of absolute ethanol to the beaker; and

then evaporate to dryness on the water bath. Place the beaker with the remainder in

an oven at 110°C~115°C for 1h; cool to room temperature in a desiccator; and weigh

it.

6.3.6 Dissolve the remainder in the beaker by 15mL of neutral isopropanol; add 2~3

drops of phenolphthalein indicator; and titrate 0.05mol/L potassium hydroxide standard

solution until the reddish colour does not fade for 30s.

6.4 Calculation of results and report

6.4.1 Calculation

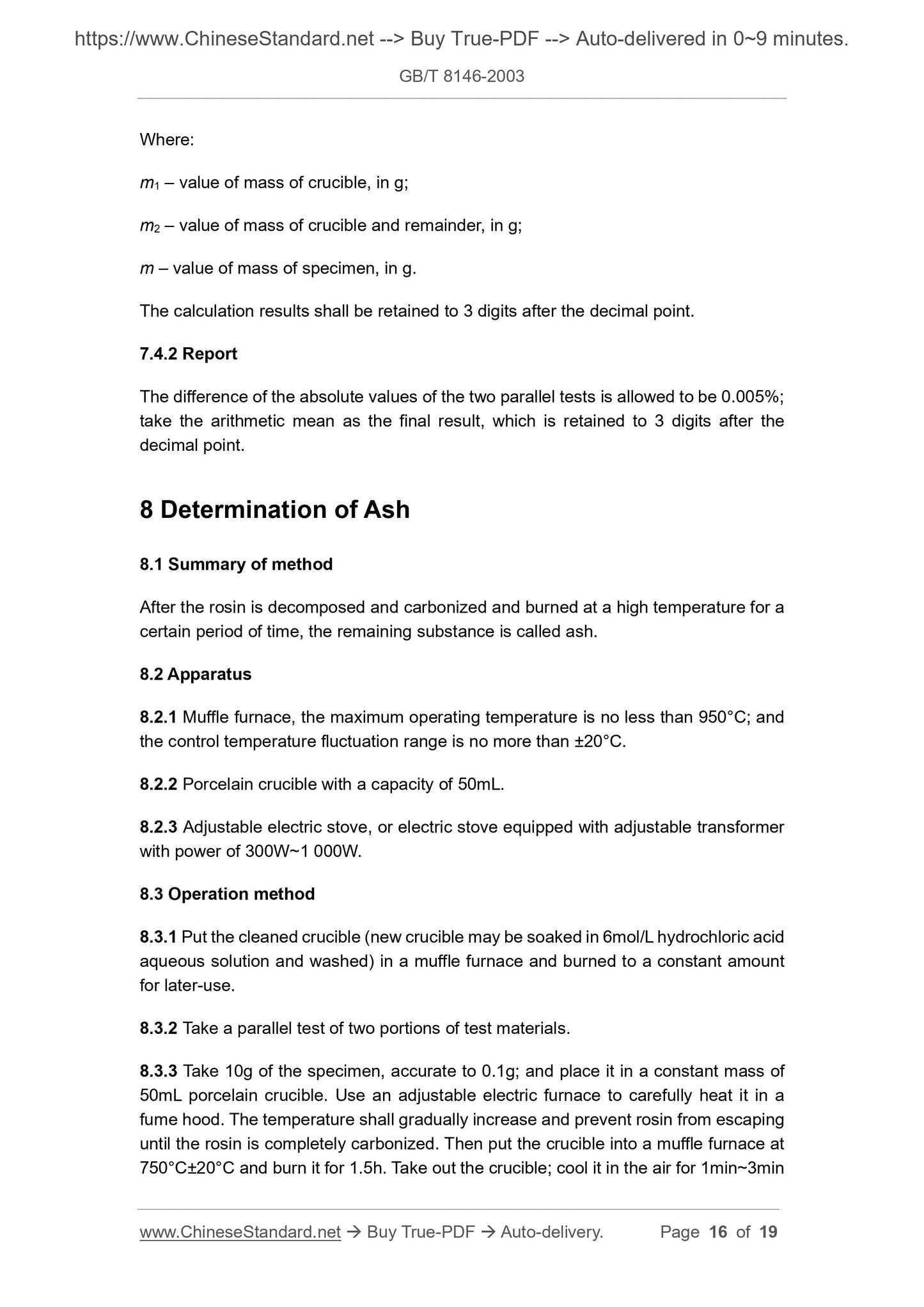

The unsaponifiable matter is calculated by the mass fraction wu of the unsaponifiable

matter, expressed in %; and it shall be calculated according to Formula (2):

Where:

m1 – value of mass of the beaker, in g;

m2 – value of mass of the beaker and the remainder; in g;

V – value of the volume of the potassium hydroxide standard titration solution (6.2.4),

in mL;

c – accurate value of concentration of the potassium hydroxide standard titration

solution, in mol/L;

Where:

m1 – value of mass of crucible, in g;

m2 – value of mass of crucible and remainder, in g;

m – value of mass of specimen, in g.

The calculation results shall be retained to 3 digits after the decimal point.

7.4.2 Report

The difference of the absolute values of the two parallel tests is allowed to be 0.005%;

take the arithmetic mean as the final result, which is retained to 3 digits after the

decimal point.

8 Determination of Ash

8.1 Summary of method

After the rosin is decomposed and carbonized and burned at a high temperature for a

certain period of time, the remaining substance is called ash.

8.2 Apparatus

8.2.1 Muffle furnace, the maximum operating temperature is no less than 950°C; and

the control temperature fluctuation range is no more than ±20°C.

8.2.2 Porcelain crucible with a capacity of 50mL.

8.2.3 Adjustable electric stove, or electric stove equipped with adjustable transformer

with power of 300W~1 000W.

8.3 Operation method

8.3.1 Put the cleaned crucible (new crucible may be soaked in 6mol/L hydrochloric acid

aqueous solution and washed) in a muffle furnace and burned to a constant amount

for later-use.

8.3.2 Take a parallel test of two portions of test materials.

8.3.3 Take 10g of the specimen, accurate to 0.1g; and place it in a constant mass of

50mL porcelain crucible. Use an adjustable electric furnace to carefully heat it in a

fume hood. The temperature shall gradually increase and prevent rosin from escaping

until the rosin is completely carbonized. Then put the crucible into a muffle furnace at

750°C±20°C and burn it for 1.5h. Take out the crucible; cool it in the air for 1min~3min

Appendix A

(Normative)

Judgment of Crystallization Phenomenon and Qualitative Method

of Sulfur Content

A.1 Judgment of rosin crystallization

Rosin crystallization is one of the physical properties of rosin, which is related to the

source and processing technology of rosin. Accurate description of the crystallization

phenomenon of rosin is a reference for measuring the quality of rosin products.

A.1.1 There are slight needle-like crystals, the nearest distance between adjacent

crystals is not less than 5mm; and they are sparsely distributed in the barrel.

A.1.2 There are slightly granular, flaky or other shaped crystals, the length or maximum

diameter is no more than 2mm, the nearest distance between adjacent crystals is no

less than 20mm; and they are sparsely distributed in the barrel.

A.1.3 If the crystallization phenomenon satisfies A.1.1 and A.1.2, it is regarded as slight

crystallization. If the crystallization phenomenon exceeds A.1.1 and A.1.2, it is

regarded as partial crystallization.

A.2 Qualitative analysis of sulfur content in rosin

A.2.1 Preparation of lead acetate test paper

A.2.1.1 30g/L lead acetate aqueous solution

Dissolve 3.5g of lead acetate trihydrate (comply with HG/T 2630, analytically pure) in

distilled water; add distilled water to 100 mL; and obtain an aqueous solution containing

30g/L lead acetate.

A.2.1.2 Lead acetate test paper

Cut ordinary filter paper into strips; soak it in 30g/L lead acetate aqueous solution; take

it out after soaking; and dry it in an indoor environment where there is no hydrogen

sulfide for later-use.

A.2.2 Operation method

Take 1.0g of rosin sample and put it into a test tube with a length of about

100mm~120mm. A lead acetate test paper moistened with distilled water is hung in the

tube. The mouth of the tube has a small notch on the periphery and is plugged with a

GB/T 8146-2003

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 65.050

B 72

Replacing GB/T 8146-1987

Test Methods for Rosin

ISSUED ON: JUNE 17, 2003

IMPLEMENTED ON: DECEMBER 01, 2003

Issued by: General Administration of Quality Supervision, Inspection and

Quarantine

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative References ... 5

3 Determination of Colour and Appearance ... 5

4 Determination of Softening Point (Ring-and-Ball Method) ... 7

5 Determination of Acid Value ... 11

6 Determination of Unsaponifiable Matter ... 13

7 Determinat...

Delivery: 9 seconds. Download (& Email) true-PDF + Invoice.

Get Quotation: Click GB/T 8146-2003 (Self-service in 1-minute)

Historical versions (Master-website): GB/T 8146-2003

Preview True-PDF (Reload/Scroll-down if blank)

GB/T 8146-2003

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 65.050

B 72

Replacing GB/T 8146-1987

Test Methods for Rosin

ISSUED ON: JUNE 17, 2003

IMPLEMENTED ON: DECEMBER 01, 2003

Issued by: General Administration of Quality Supervision, Inspection and

Quarantine

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative References ... 5

3 Determination of Colour and Appearance ... 5

4 Determination of Softening Point (Ring-and-Ball Method) ... 7

5 Determination of Acid Value ... 11

6 Determination of Unsaponifiable Matter ... 13

7 Determination of Ethanol Insoluble Matter ... 15

8 Determination of Ash... 16

Appendix A (Normative) Judgment of Crystallization Phenomenon and

Qualitative Method of Sulfur Content ... 18

Test Methods for Rosin

1 Scope

This Standard specifies the inspection methods for the colour, appearance, softening

point, acid value, unsaponifiable matter, ethanol insoluble matter, and ash of rosin.

This Standard is applicable to the inspection of rosin.

2 Normative References

The provisions in following documents become the provisions of this Standard through

reference in this Standard. For dated references, the subsequent amendments

(excluding corrigendum) or revisions do not apply to this Standard, however, parties

who reach an agreement based on this Standard are encouraged to study if the latest

versions of these documents are applicable. For undated references, the latest edition

of the referenced document applies.

GB/T 601 Chemical Reagent - Preparations of Standard Volumetric Solutions

3 Determination of Colour and Appearance

3.1 Colour grading

The colour grading of rosin uses rosin chromaticity standard blocks, each set has a

total of six glass standard colour blocks. A set of rosin chromaticity standard device No.

S20 preserved by the Institute of Chemical Industry of Forest Products CAF stipulates

as the color grading standard of rosin chromaticity standard block; the chromaticity

index of 1931 standard chromaticity system of the International Commission on

Illumination (CIE) for all grades of colours is shown in Table 1.

3.2.3 Other colorimeters

The inspection of rosin colour shall be based on the rosin chromaticity standard block

as the grading standard. It is allowed to use other colorimeters whose colorimetric

effect is equivalent to that of the chromaticity standard block after being checked by

the chromaticity standard block.

3.3 Determination of appearance

Under indoor natural light or normal lighting conditions, horizontally place one

observation surface of the sample block used to determine the colour grade made

according to 3.2.1 on an ordinary newspaper; and observe downward from the other

observation surface, if it can read the No.5 printed font clearly, it is transparent;

otherwise, it is opaque.

4 Determination of Softening Point (Ring-and-Ball

Method)

4.1 Summary of the method

Rosin has no fixed melting point and becomes soft when heated. Fill two copper rings

of specified thickness and diameter with rosin; respectively place a steel ball of

specified mass and diameter on the ironed rosin through a positioner; and then heat it

in a heating medium at a certain temperature-rise speed; then the instantaneous

temperature at which the rosin wrapped with steel ball falling a fixed distance is the

softening point of the rosin.

4.2 Apparatus

4.2.1 The softening point tester, the device is shown in Figure 1; and the main parts

are shown in Figure 2.

4.2.6 Thermometer, internal standard type, immersion height of 55mm, tail length of

100mm, scale range of 30°C~100°C, minimum graduation of 0.2°C, mercury bulb outer

diameter of 5.0mm±0.5mm, mercury bulb length of 8mm ±2mm, and total length of

380mm±10mm.

4.2.7 Beaker with the capacity of about 800 mL, the diameter of 90mm, and the height

of no less than 140mm.

4.2.8 Stirrer, generally manual stirrer is used, mechanical stirrer or electromagnetic

stirrer may also be used. When stirring, the speed shall be uniform and shall not form

a vortex, vibration or air bubbles.

4.3 Heating medium

4.3.1 Freshly boiled distilled water

Put about 800 mL of ordinary distilled water into a 1000 mL beaker and heat it to boiling;

and then cool it to 35°C below. Then it is used for the determination of rosin samples

with a softening point no greater than 80°C.

4.3.2 Glyceryl (glycerol)

It shall be analytically pure, which comply with GB/T687. It is used for the determination

of rosin samples with a softening point greater than 80°C. Repeated use shall not affect

the determination results.

4.4 Operation method

4.4.1 Once-melt specimen shall be used for two parallel determinations under the

same conditions.

4.4.2 Take about 5g of rosin and crush into a diameter of about 5mm in a container;

slowly heat it to melt at the possible lowest temperature to avoid bubbles and smoke.

Pour the molten rosin into the preheated ring on the copper plate immediately. When

the rosin is completely solidified, gently remove the copper plate. The ring shall be full

of rosin; and the surface shall be slightly raised. Use an electric iron to iron it out for

inspection. If the rosin in the ring has sunken or bubbles, it shall be remade.

4.4.3 Put the prepared specimen ring on the ring frame plate; install the steel ball

positioner on the ring; and then put the steel ball into the centre of the steel ball

positioner. Then insert the thermometer from the top cover of the ring frame; so that

the bottom of the mercury ball and the bottom surface of the ring are on the same

plane; and then put the entire ring frame into an 800mL beaker. After the above device

is completed, pour the freshly boiled distilled water into the beaker; so that the upper

surface of the ring frame plate is kept at 51mm from the water surface. After standing

for 10min; use an adjustable electric furnace or other heat source to heat the water to

Dissolve 33g of potassium hydroxide (comply with GB/T 2306, analytically pure) in a

small amount of distilled water without carbon dioxide; add this distilled water to dilute

to 1000mL; and mix well. The working standard reagent potassium hydrogen phthalate

(comply with GB 1257) is used as the reference substance; and calibrate according to

the calibration method of 0.5mol/L sodium hydroxide standard titration solution

specified in GB/T 601, and accurate to 0.001 mol/L.

5.3 Operation method

5.3.1 Make parallel determinations of two portions of test materials.

5.3.2 Remove the outer part of the rosin and crash it; immediately take 2g of the

specimen (accurate to 0.001g) into a 250mL conical flask; add 50mL of neutral ethanol

to dissolve it (if necessary, heat on a water bath to make the entire specimen, then let

it cool); add 5 drops of phenolphthalein indicator; and then titrate with 0.5mol/L

potassium hydroxide standard titration solution until the reddish colour does not fade

for 30s.

5.4 Calculation of results and report

5.4.1 Calculation

The acid value is calculated by the mass fraction wn of potassium hydroxide (KOH),

expressed in mg/g; and it shall be calculated according to Formula (1):

Where:

V – value of volume of potassium hydroxide standard titration solution (5.2.3), in mL;

c – accurate value of the concentration of potassium hydroxide standard titration

solution, in mol/L;

m – value of mass of the test materials, in g;

M – value of molar mass of the potassium hydroxide, (M=56.11), in g/mol.

The calculation of results shall be expressed to 1 digit after the decimal point.

5.4.2 Report

The difference between the absolute values of the two parallel tests is allowed to be

0.5 mg/g; and take arithmetic mean as the final result, which is retained to one digit

after the decimal point.

another 500mL separatory funnel; and leave the upper ether solution in the original

funnel.

6.3.3 Add 30mL of ether to the funnel containing the aqueous soap liquid; shake the

funnel; and let it stand to divide into two layers. Pour the soap liquid into the original

conical flask used for the saponification; and merge the ether solution into the first

separatory funnel. Pour the soap liquid in the conical flask into the second separatory

funnel; add 30mL of ether; repeat the treatment once, and discard the soap liquid.

6.3.4 Concentrate the third-time ether solution in the first separatory funnel; discard

the remaining soap liquid; add 2mL of distilled water; sway slowly; let the water sink;

release and discard. Add 5mL of distilled water to wash the ether solution; discard the

water; and then wash by 30mL of distilled water; discard the water; and repeat once.

6.3.5 Pour the ether solution into a 150mL low-form beaker with constant weight; rinse

the funnel by 15 mL of ether; and add it to the beaker. Evaporate the ether on a water

bath. If there are small water droplets, add 1mL of absolute ethanol to the beaker; and

then evaporate to dryness on the water bath. Place the beaker with the remainder in

an oven at 110°C~115°C for 1h; cool to room temperature in a desiccator; and weigh

it.

6.3.6 Dissolve the remainder in the beaker by 15mL of neutral isopropanol; add 2~3

drops of phenolphthalein indicator; and titrate 0.05mol/L potassium hydroxide standard

solution until the reddish colour does not fade for 30s.

6.4 Calculation of results and report

6.4.1 Calculation

The unsaponifiable matter is calculated by the mass fraction wu of the unsaponifiable

matter, expressed in %; and it shall be calculated according to Formula (2):

Where:

m1 – value of mass of the beaker, in g;

m2 – value of mass of the beaker and the remainder; in g;

V – value of the volume of the potassium hydroxide standard titration solution (6.2.4),

in mL;

c – accurate value of concentration of the potassium hydroxide standard titration

solution, in mol/L;

Where:

m1 – value of mass of crucible, in g;

m2 – value of mass of crucible and remainder, in g;

m – value of mass of specimen, in g.

The calculation results shall be retained to 3 digits after the decimal point.

7.4.2 Report

The difference of the absolute values of the two parallel tests is allowed to be 0.005%;

take the arithmetic mean as the final result, which is retained to 3 digits after the

decimal point.

8 Determination of Ash

8.1 Summary of method

After the rosin is decomposed and carbonized and burned at a high temperature for a

certain period of time, the remaining substance is called ash.

8.2 Apparatus

8.2.1 Muffle furnace, the maximum operating temperature is no less than 950°C; and

the control temperature fluctuation range is no more than ±20°C.

8.2.2 Porcelain crucible with a capacity of 50mL.

8.2.3 Adjustable electric stove, or electric stove equipped with adjustable transformer

with power of 300W~1 000W.

8.3 Operation method

8.3.1 Put the cleaned crucible (new crucible may be soaked in 6mol/L hydrochloric acid

aqueous solution and washed) in a muffle furnace and burned to a constant amount

for later-use.

8.3.2 Take a parallel test of two portions of test materials.

8.3.3 Take 10g of the specimen, accurate to 0.1g; and place it in a constant mass of

50mL porcelain crucible. Use an adjustable electric furnace to carefully heat it in a

fume hood. The temperature shall gradually increase and prevent rosin from escaping

until the rosin is completely carbonized. Then put the crucible into a muffle furnace at

750°C±20°C and burn it for 1.5h. Take out the crucible; cool it in the air for 1min~3min

Appendix A

(Normative)

Judgment of Crystallization Phenomenon and Qualitative Method

of Sulfur Content

A.1 Judgment of rosin crystallization

Rosin crystallization is one of the physical properties of rosin, which is related to the

source and processing technology of rosin. Accurate description of the crystallization

phenomenon of rosin is a reference for measuring the quality of rosin products.

A.1.1 There are slight needle-like crystals, the nearest distance between adjacent

crystals is not less than 5mm; and they are sparsely distributed in the barrel.

A.1.2 There are slightly granular, flaky or other shaped crystals, the length or maximum

diameter is no more than 2mm, the nearest distance between adjacent crystals is no

less than 20mm; and they are sparsely distributed in the barrel.

A.1.3 If the crystallization phenomenon satisfies A.1.1 and A.1.2, it is regarded as slight

crystallization. If the crystallization phenomenon exceeds A.1.1 and A.1.2, it is

regarded as partial crystallization.

A.2 Qualitative analysis of sulfur content in rosin

A.2.1 Preparation of lead acetate test paper

A.2.1.1 30g/L lead acetate aqueous solution

Dissolve 3.5g of lead acetate trihydrate (comply with HG/T 2630, analytically pure) in

distilled water; add distilled water to 100 mL; and obtain an aqueous solution containing

30g/L lead acetate.

A.2.1.2 Lead acetate test paper

Cut ordinary filter paper into strips; soak it in 30g/L lead acetate aqueous solution; take

it out after soaking; and dry it in an indoor environment where there is no hydrogen

sulfide for later-use.

A.2.2 Operation method

Take 1.0g of rosin sample and put it into a test tube with a length of about

100mm~120mm. A lead acetate test paper moistened with distilled water is hung in the

tube. The mouth of the tube has a small notch on the periphery and is plugged with a

GB/T 8146-2003

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 65.050

B 72

Replacing GB/T 8146-1987

Test Methods for Rosin

ISSUED ON: JUNE 17, 2003

IMPLEMENTED ON: DECEMBER 01, 2003

Issued by: General Administration of Quality Supervision, Inspection and

Quarantine

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative References ... 5

3 Determination of Colour and Appearance ... 5

4 Determination of Softening Point (Ring-and-Ball Method) ... 7

5 Determination of Acid Value ... 11

6 Determination of Unsaponifiable Matter ... 13

7 Determinat...

Share