1

/

of

6

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 8721-2019 English PDF (GB/T8721-2019)

GB/T 8721-2019 English PDF (GB/T8721-2019)

Regular price

$150.00

Regular price

Sale price

$150.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB/T 8721-2019: The test method for tensile strength of carbon materials

Delivery: 9 seconds. Download (& Email) true-PDF + Invoice.

Get Quotation: Click GB/T 8721-2019 (Self-service in 1-minute)

Historical versions (Master-website): GB/T 8721-2019

Preview True-PDF (Reload/Scroll-down if blank)

GB T 8721-2019

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 29.050

Q 50

Replacing GBT 8721-2009

The test method for tensile strength of carbon

materials

ISSUED ON: JUNE 04, 2019

IMPLEMENTED ON: MAY 01, 2020

Issued by: State Administration for Market Regulation;

Standardization Administration of the People’s Republic of

China.

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Principle ... 5

4 Instruments and apparatuses ... 5

5 Sample ... 6

6 Test steps ... 7

7 Result calculation ... 7

8 Test report ... 8

Appendix A (Informative) Test fixture ... 9

References ... 14

Foreword

This Standard was drafted in accordance with the rules given in GB/T 1.1-2009.

This Standard replaces GB/T 8721-2009, Method for the determination of

tensile strength of carbonaceous materials; compared with GB/T 8721-2009,

the major technical changes of this Standard are as follows:

-- Modify the scope description (see Chapter 1, Chapter 1 of version 2009);

-- Modify the technical requirements of the material testing machine (see 4.1,

4.1 of version 2009);

-- Delete the standard fixture and replace with the test fixture (see 4.2, 4.2 of

version 2009);

-- Add technical requirements for vernier calipers (see 4.3);

-- Delete the sample quantity requirement (see 5.2 of version 2009);

-- Modify the sample processing method (see 5.2, 5.3 of version 2009);

-- Add appearance requirements for processed samples (see 5.3);

-- Delete the requirement that “machining accuracy is implemented in

accordance with the provisions of GB/T 1427” (see 5.4 of version 2009);

-- Add technical requirements of “ensuring alignment of the centerlines of all

joints” in the test (see 6.3);

-- Add Appendix A Test fixture (see Appendix A).

This Standard was proposed by China Iron and Steel Industry Association.

This Standard shall be under the jurisdiction of National Technical Committee

183 on Iron and Steel of Standardization Administration of China (SAC/TC 183).

The drafting organizations of this Standard: Sinosteel Advanced Materials

(Zhejiang) Co., Ltd., Shandong Basan Graphite New Material Plant, Kaifeng

Carbon Co., Ltd China PingMei ShenMa Group, Changzhou Xinneng Material

Inspection and Testing Co., Ltd., Sinosteel Anshan Research Institute of

Thermo-energy Co., Ltd., China Metallurgical Information and Standardization

Institute.

The drafters of this Standard: Yang Hui, Xu Hanchun, Mao Yuzhen, Tang

Yonggui, Wan Jianmin, Liu Bingqiang, Xu Jianping, Wang Wei, Zheng Jingxu,

Du Aifang, Wang Zhiqiang.

The test method for tensile strength of carbon

materials

1 Scope

This Standard specifies the determination principle, instruments and

apparatuses, samples, test steps and result calculation for tensile strength of

carbon materials.

This Standard applies to the determination of tensile strength of carbon

materials at room temperature.

2 Normative references

The following documents are indispensable for the application of this document.

For dated references, only the dated version applies to this document. For

undated references, the latest edition (including all amendments) applies to this

document.

GB/T 1427, Sample method of carbon material

GB/T 8170, Rules of rounding off for numerical values and expression and

judgment of limiting values

3 Principle

Tensile strength is the maximum load that a unit cross-section can withstand

when the material is subjected to a single tensile force.

4 Instruments and apparatuses

4.1 Material testing machine: the sensing accuracy is better than 1%; the

recommended maximum load of the sample is at least 10% ~ 90% of the sensor

range.

4.2 Test fixture: it consists of precision chain and other mechanical parts; the

recommended fixtures are shown in Appendix A. Other similar fixtures that

achieve the same function are also suitable.

4.3 Vernier caliper: measuring range of 0 mm ~ 200 mm, accuracy of 0.02 mm.

4.4 Micrometer: measuring range of 0 mm ~ 25 mm, accuracy of 0.01 mm.

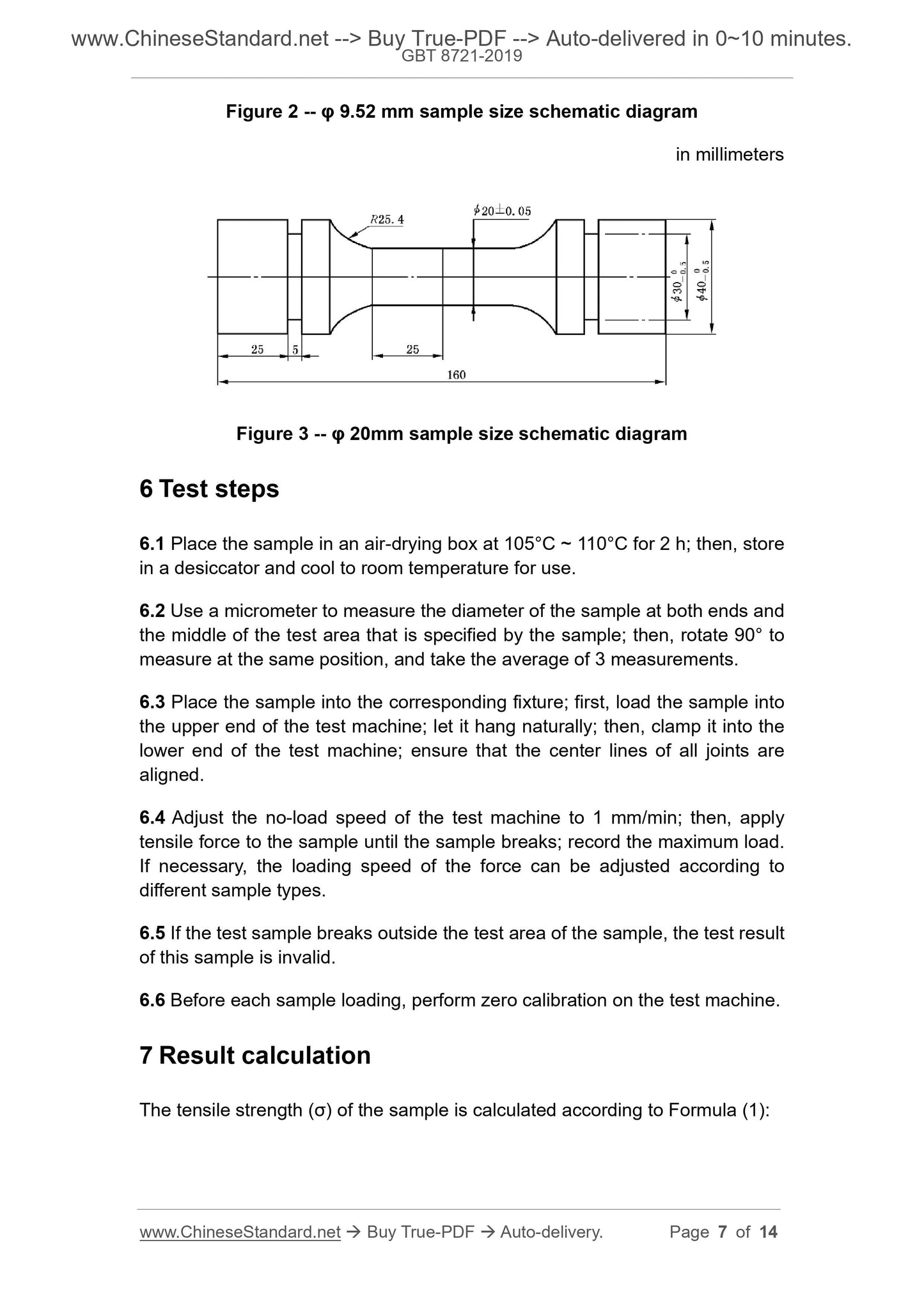

Figure 2 -- φ 9.52 mm sample size schematic diagram

in millimeters

Figure 3 -- φ 20mm sample size schematic diagram

6 Test steps

6.1 Place the sample in an air-drying box at 105°C ~ 110°C for 2 h; then, store

in a desiccator and cool to room temperature for use.

6.2 Use a micrometer to measure the diameter of the sample at both ends and

the middle of the test area that is specified by the sample; then, rotate 90° to

measure at the same position, and take the average of 3 measurements.

6.3 Place the sample into the corresponding fixture; first, load the sample into

the upper end of the test machine; let it hang naturally; then, clamp it into the

lower end of the test machine; ensure that the center lines of all joints are

aligned.

6.4 Adjust the no-load speed of the test machine to 1 mm/min; then, apply

tensile force to the sample until the sample breaks; record the maximum load.

If necessary, the loading speed of the force can be adjusted according to

different sample types.

6.5 If the test sample breaks outside the test area of the sample, the test result

of this sample is invalid.

6.6 Before each sample loading, perform zero calibration on the test machine.

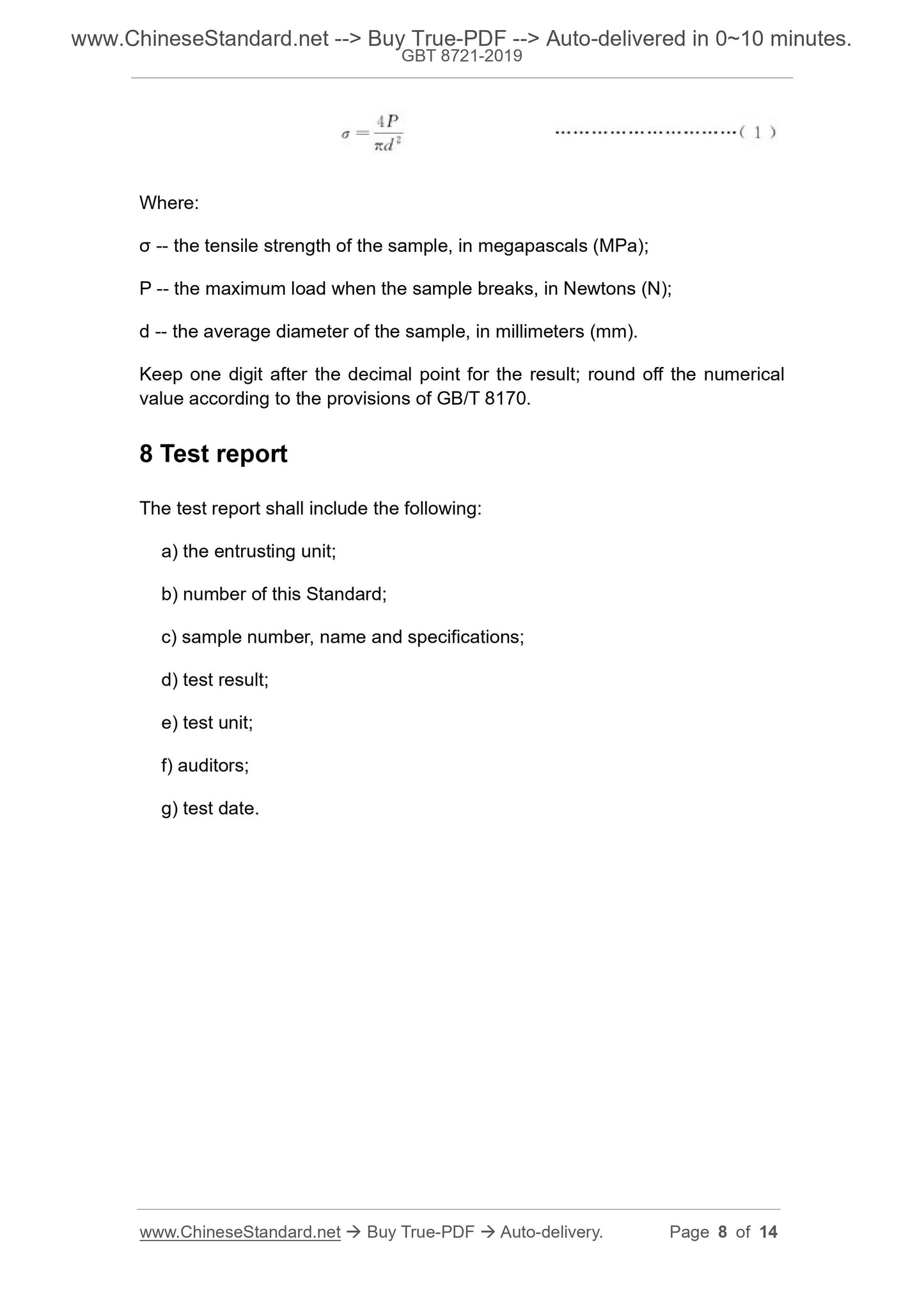

7 Result calculation

The tensile strength (σ) of the sample is calculated according to Formula (1):

Where:

σ -- the tensile strength of the sample, in megapascals (MPa);

P -- the maximum load when the sample breaks, in Newtons (N);

d -- the average diameter of the sample, in millimeters (mm).

Keep one digit after the decimal point for the result; round off the numerical

value according to the provisions of GB/T 8170.

8 Test report

The test report shall include the following:

a) the entrusting unit;

b) number of this Standard;

c) sample number, name and specifications;

d) test result;

e) test unit;

f) auditors;

g) test date.

GB T 8721-2019

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 29.050

Q 50

Replacing GBT 8721-2009

The test method for tensile strength of carbon

materials

ISSUED ON: JUNE 04, 2019

IMPLEMENTED ON: MAY 01, 2020

Issued by: State Administration for Market Regulation;

Standardization Administration of the People’s Republic of

China.

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Principle ... 5

4 Instruments and apparatuses ... 5

5 Sample ... 6

6 Test steps ... 7

7 Result calculation ... 7

8 Test report ... 8

Appendix A (Informative) Test fixture ... 9

References ... 14

Foreword

This Standard was drafted in accordance with the rules given in GB/T 1.1-2009.

This Standard replaces GB/T 8721-2009, Method for the determination of

tensile strength of carbonaceous materials; compared with GB/T 8721-2009,

the major technical changes of this Standard are as follows:

-- Modify the scope description (see Chapter 1, Chapter 1 of version 2009);

-- Modify the technical requirements of the material testing machine (see 4.1,

4.1 of version 2009);

-- Delete the standard fixture and replace with the test fixture (see 4.2, 4.2 of

version 2009);

-- Add technical requirements for vernier calipers (see 4.3);

-- Delete the sample quantity requirement (see 5.2 of version 2009);

-- Modify the sample processing method (see 5.2, 5.3 of version 2009);

-- Add appearance requirements for processed samples (see 5.3);

-- Delete the requirement that “machining accuracy is implemented in

accordance with the provisions of GB/T 1427” (see 5.4 of version 2009);

-- Add technical requirements of “ensuring alignment of the centerlines of all

joints” in the test (see 6.3);

-- Add Appendix A Test fixture (see Appendix A).

This Standard was proposed by China Iron and Steel Industry Association.

This Standard shall be under the jurisdiction of National Technical Committee

183 on Iron and Steel of Standardization Administration of China (SAC/TC 183).

The drafting organizations of this Standard: Sinosteel Advanced Materials

(Zhejiang) Co., Ltd., Shandong Basan Graphite New Material Plant, Kaifeng

Carbon Co., Ltd China PingMei ShenMa Group, Changzhou Xinneng Material

Inspection and Testing Co., Ltd., Sinosteel Anshan Research Institute of

Thermo-energy Co., Ltd., China Metallurgical Information and Standardization

Institute.

The drafters of this Standard: Yang Hui, Xu Hanchun, Mao Yuzhen, Tang

Yonggui, Wan Jianmin, Liu Bingqiang, Xu Jianping, Wang Wei, Zheng Jingxu,

Du Aifang, Wang Zhiqiang.

The test method for tensile strength of carbon

materials

1 Scope

This Standard specifies the determination principle, instruments and

apparatuses, samples, test steps and result calculation for tensile strength of

carbon materials.

This Standard applies to the determination of tensile strength of carbon

materials at room temperature.

2 Normative references

The following documents are indispensable for the application of this document.

For dated references, only the dated version applies to this document. For

undated references, the latest edition (including all amendments) applies to this

document.

GB/T 1427, Sample method of carbon material

GB/T 8170, Rules of rounding off for numerical values and expression and

judgment of limiting values

3 Principle

Tensile strength is the maximum load that a unit cross-section can withstand

when the material is subjected to a single tensile force.

4 Instruments and apparatuses

4.1 Material testing machine: the sensing accuracy is better than 1%; the

recommended maximum load of the sample is at least 10% ~ 90% of the sensor

range.

4.2 Test fixture: it consists of precision chain and other mechanical parts; the

recommended fixtures are shown in Appendix A. Other similar fixtures that

achieve the same function are also suitable.

4.3 Vernier caliper: measuring range of 0 mm ~ 200 mm, accuracy of 0.02 mm.

4.4 Micrometer: measuring range of 0 mm ~ 25 mm, accuracy of 0.01 mm.

Figure 2 -- φ 9.52 mm sample size schematic diagram

in millimeters

Figure 3 -- φ 20mm sample size schematic diagram

6 Test steps

6.1 Place the sample in an air-drying box at 105°C ~ 110°C for 2 h; then, store

in a desiccator and cool to room temperature for use.

6.2 Use a micrometer to measure the diameter of the sample at both ends and

the middle of the test area that is specified by the sample; then, rotate 90° to

measure at the same position, and take the average of 3 measurements.

6.3 Place the sample into the corresponding fixture; first, load the sample into

the upper end of the test machine; let it hang naturally; then, clamp it into the

lower end of the test machine; ensure that the center lines of all joints are

aligned.

6.4 Adjust the no-load speed of the test machine to 1 mm/min; then, apply

tensile force to the sample until the sample breaks; record the maximum load.

If necessary, the loading speed of the force can be adjusted according to

different sample types.

6.5 If the test sample breaks outside the test area of the sample, the test result

of this sample is invalid.

6.6 Before each sample loading, perform zero calibration on the test machine.

7 Result calculation

The tensile strength (σ) of the sample is calculated according to Formula (1):

Where:

σ -- the tensile strength of the sample, in megapascals (MPa);

P -- the maximum load when the sample breaks, in Newtons (N);

d -- the average diameter of the sample, in millimeters (mm).

Keep one digit after the decimal point for the result; round off the numerical

value according to the provisions of GB/T 8170.

8 Test report

The test report shall include the following:

a) the entrusting unit;

b) number of this Standard;

c) sample number, name and specifications;

d) test result;

e) test unit;

f) auditors;

g) test date.

Delivery: 9 seconds. Download (& Email) true-PDF + Invoice.

Get Quotation: Click GB/T 8721-2019 (Self-service in 1-minute)

Historical versions (Master-website): GB/T 8721-2019

Preview True-PDF (Reload/Scroll-down if blank)

GB T 8721-2019

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 29.050

Q 50

Replacing GBT 8721-2009

The test method for tensile strength of carbon

materials

ISSUED ON: JUNE 04, 2019

IMPLEMENTED ON: MAY 01, 2020

Issued by: State Administration for Market Regulation;

Standardization Administration of the People’s Republic of

China.

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Principle ... 5

4 Instruments and apparatuses ... 5

5 Sample ... 6

6 Test steps ... 7

7 Result calculation ... 7

8 Test report ... 8

Appendix A (Informative) Test fixture ... 9

References ... 14

Foreword

This Standard was drafted in accordance with the rules given in GB/T 1.1-2009.

This Standard replaces GB/T 8721-2009, Method for the determination of

tensile strength of carbonaceous materials; compared with GB/T 8721-2009,

the major technical changes of this Standard are as follows:

-- Modify the scope description (see Chapter 1, Chapter 1 of version 2009);

-- Modify the technical requirements of the material testing machine (see 4.1,

4.1 of version 2009);

-- Delete the standard fixture and replace with the test fixture (see 4.2, 4.2 of

version 2009);

-- Add technical requirements for vernier calipers (see 4.3);

-- Delete the sample quantity requirement (see 5.2 of version 2009);

-- Modify the sample processing method (see 5.2, 5.3 of version 2009);

-- Add appearance requirements for processed samples (see 5.3);

-- Delete the requirement that “machining accuracy is implemented in

accordance with the provisions of GB/T 1427” (see 5.4 of version 2009);

-- Add technical requirements of “ensuring alignment of the centerlines of all

joints” in the test (see 6.3);

-- Add Appendix A Test fixture (see Appendix A).

This Standard was proposed by China Iron and Steel Industry Association.

This Standard shall be under the jurisdiction of National Technical Committee

183 on Iron and Steel of Standardization Administration of China (SAC/TC 183).

The drafting organizations of this Standard: Sinosteel Advanced Materials

(Zhejiang) Co., Ltd., Shandong Basan Graphite New Material Plant, Kaifeng

Carbon Co., Ltd China PingMei ShenMa Group, Changzhou Xinneng Material

Inspection and Testing Co., Ltd., Sinosteel Anshan Research Institute of

Thermo-energy Co., Ltd., China Metallurgical Information and Standardization

Institute.

The drafters of this Standard: Yang Hui, Xu Hanchun, Mao Yuzhen, Tang

Yonggui, Wan Jianmin, Liu Bingqiang, Xu Jianping, Wang Wei, Zheng Jingxu,

Du Aifang, Wang Zhiqiang.

The test method for tensile strength of carbon

materials

1 Scope

This Standard specifies the determination principle, instruments and

apparatuses, samples, test steps and result calculation for tensile strength of

carbon materials.

This Standard applies to the determination of tensile strength of carbon

materials at room temperature.

2 Normative references

The following documents are indispensable for the application of this document.

For dated references, only the dated version applies to this document. For

undated references, the latest edition (including all amendments) applies to this

document.

GB/T 1427, Sample method of carbon material

GB/T 8170, Rules of rounding off for numerical values and expression and

judgment of limiting values

3 Principle

Tensile strength is the maximum load that a unit cross-section can withstand

when the material is subjected to a single tensile force.

4 Instruments and apparatuses

4.1 Material testing machine: the sensing accuracy is better than 1%; the

recommended maximum load of the sample is at least 10% ~ 90% of the sensor

range.

4.2 Test fixture: it consists of precision chain and other mechanical parts; the

recommended fixtures are shown in Appendix A. Other similar fixtures that

achieve the same function are also suitable.

4.3 Vernier caliper: measuring range of 0 mm ~ 200 mm, accuracy of 0.02 mm.

4.4 Micrometer: measuring range of 0 mm ~ 25 mm, accuracy of 0.01 mm.

Figure 2 -- φ 9.52 mm sample size schematic diagram

in millimeters

Figure 3 -- φ 20mm sample size schematic diagram

6 Test steps

6.1 Place the sample in an air-drying box at 105°C ~ 110°C for 2 h; then, store

in a desiccator and cool to room temperature for use.

6.2 Use a micrometer to measure the diameter of the sample at both ends and

the middle of the test area that is specified by the sample; then, rotate 90° to

measure at the same position, and take the average of 3 measurements.

6.3 Place the sample into the corresponding fixture; first, load the sample into

the upper end of the test machine; let it hang naturally; then, clamp it into the

lower end of the test machine; ensure that the center lines of all joints are

aligned.

6.4 Adjust the no-load speed of the test machine to 1 mm/min; then, apply

tensile force to the sample until the sample breaks; record the maximum load.

If necessary, the loading speed of the force can be adjusted according to

different sample types.

6.5 If the test sample breaks outside the test area of the sample, the test result

of this sample is invalid.

6.6 Before each sample loading, perform zero calibration on the test machine.

7 Result calculation

The tensile strength (σ) of the sample is calculated according to Formula (1):

Where:

σ -- the tensile strength of the sample, in megapascals (MPa);

P -- the maximum load when the sample breaks, in Newtons (N);

d -- the average diameter of the sample, in millimeters (mm).

Keep one digit after the decimal point for the result; round off the numerical

value according to the provisions of GB/T 8170.

8 Test report

The test report shall include the following:

a) the entrusting unit;

b) number of this Standard;

c) sample number, name and specifications;

d) test result;

e) test unit;

f) auditors;

g) test date.

GB T 8721-2019

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 29.050

Q 50

Replacing GBT 8721-2009

The test method for tensile strength of carbon

materials

ISSUED ON: JUNE 04, 2019

IMPLEMENTED ON: MAY 01, 2020

Issued by: State Administration for Market Regulation;

Standardization Administration of the People’s Republic of

China.

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Principle ... 5

4 Instruments and apparatuses ... 5

5 Sample ... 6

6 Test steps ... 7

7 Result calculation ... 7

8 Test report ... 8

Appendix A (Informative) Test fixture ... 9

References ... 14

Foreword

This Standard was drafted in accordance with the rules given in GB/T 1.1-2009.

This Standard replaces GB/T 8721-2009, Method for the determination of

tensile strength of carbonaceous materials; compared with GB/T 8721-2009,

the major technical changes of this Standard are as follows:

-- Modify the scope description (see Chapter 1, Chapter 1 of version 2009);

-- Modify the technical requirements of the material testing machine (see 4.1,

4.1 of version 2009);

-- Delete the standard fixture and replace with the test fixture (see 4.2, 4.2 of

version 2009);

-- Add technical requirements for vernier calipers (see 4.3);

-- Delete the sample quantity requirement (see 5.2 of version 2009);

-- Modify the sample processing method (see 5.2, 5.3 of version 2009);

-- Add appearance requirements for processed samples (see 5.3);

-- Delete the requirement that “machining accuracy is implemented in

accordance with the provisions of GB/T 1427” (see 5.4 of version 2009);

-- Add technical requirements of “ensuring alignment of the centerlines of all

joints” in the test (see 6.3);

-- Add Appendix A Test fixture (see Appendix A).

This Standard was proposed by China Iron and Steel Industry Association.

This Standard shall be under the jurisdiction of National Technical Committee

183 on Iron and Steel of Standardization Administration of China (SAC/TC 183).

The drafting organizations of this Standard: Sinosteel Advanced Materials

(Zhejiang) Co., Ltd., Shandong Basan Graphite New Material Plant, Kaifeng

Carbon Co., Ltd China PingMei ShenMa Group, Changzhou Xinneng Material

Inspection and Testing Co., Ltd., Sinosteel Anshan Research Institute of

Thermo-energy Co., Ltd., China Metallurgical Information and Standardization

Institute.

The drafters of this Standard: Yang Hui, Xu Hanchun, Mao Yuzhen, Tang

Yonggui, Wan Jianmin, Liu Bingqiang, Xu Jianping, Wang Wei, Zheng Jingxu,

Du Aifang, Wang Zhiqiang.

The test method for tensile strength of carbon

materials

1 Scope

This Standard specifies the determination principle, instruments and

apparatuses, samples, test steps and result calculation for tensile strength of

carbon materials.

This Standard applies to the determination of tensile strength of carbon

materials at room temperature.

2 Normative references

The following documents are indispensable for the application of this document.

For dated references, only the dated version applies to this document. For

undated references, the latest edition (including all amendments) applies to this

document.

GB/T 1427, Sample method of carbon material

GB/T 8170, Rules of rounding off for numerical values and expression and

judgment of limiting values

3 Principle

Tensile strength is the maximum load that a unit cross-section can withstand

when the material is subjected to a single tensile force.

4 Instruments and apparatuses

4.1 Material testing machine: the sensing accuracy is better than 1%; the

recommended maximum load of the sample is at least 10% ~ 90% of the sensor

range.

4.2 Test fixture: it consists of precision chain and other mechanical parts; the

recommended fixtures are shown in Appendix A. Other similar fixtures that

achieve the same function are also suitable.

4.3 Vernier caliper: measuring range of 0 mm ~ 200 mm, accuracy of 0.02 mm.

4.4 Micrometer: measuring range of 0 mm ~ 25 mm, accuracy of 0.01 mm.

Figure 2 -- φ 9.52 mm sample size schematic diagram

in millimeters

Figure 3 -- φ 20mm sample size schematic diagram

6 Test steps

6.1 Place the sample in an air-drying box at 105°C ~ 110°C for 2 h; then, store

in a desiccator and cool to room temperature for use.

6.2 Use a micrometer to measure the diameter of the sample at both ends and

the middle of the test area that is specified by the sample; then, rotate 90° to

measure at the same position, and take the average of 3 measurements.

6.3 Place the sample into the corresponding fixture; first, load the sample into

the upper end of the test machine; let it hang naturally; then, clamp it into the

lower end of the test machine; ensure that the center lines of all joints are

aligned.

6.4 Adjust the no-load speed of the test machine to 1 mm/min; then, apply

tensile force to the sample until the sample breaks; record the maximum load.

If necessary, the loading speed of the force can be adjusted according to

different sample types.

6.5 If the test sample breaks outside the test area of the sample, the test result

of this sample is invalid.

6.6 Before each sample loading, perform zero calibration on the test machine.

7 Result calculation

The tensile strength (σ) of the sample is calculated according to Formula (1):

Where:

σ -- the tensile strength of the sample, in megapascals (MPa);

P -- the maximum load when the sample breaks, in Newtons (N);

d -- the average diameter of the sample, in millimeters (mm).

Keep one digit after the decimal point for the result; round off the numerical

value according to the provisions of GB/T 8170.

8 Test report

The test report shall include the following:

a) the entrusting unit;

b) number of this Standard;

c) sample number, name and specifications;

d) test result;

e) test unit;

f) auditors;

g) test date.

Share