1

/

of

6

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

GB/T 8753.1-2017 English PDF (GB/T8753.1-2017)

GB/T 8753.1-2017 English PDF (GB/T8753.1-2017)

Regular price

$110.00

Regular price

Sale price

$110.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB/T 8753.1-2017: Anodizing of aluminum and its alloys - Assessment of quality of sealed anodic oxidation coatings - Part 1: Measurement of the loss of mass after immersion in acid solution(s)

Delivery: 9 seconds. Download (& Email) true-PDF + Invoice.

Get Quotation: Click GB/T 8753.1-2017 (Self-service in 1-minute)

Historical versions (Master-website): GB/T 8753.1-2017

Preview True-PDF (Reload/Scroll-down if blank)

GB/T 8753.1-2017

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 25.220.20

H 21

Replacing GB/T 8753.1-2005, GB/T 8753.2-2005

Anodizing of aluminum and its alloys - Assessment of

quality of sealed anodic oxidation coatings - Part 1:

Measurement of the loss of mass after immersion in

acid solution(s)

ISSUED ON: MAY 31, 2017

IMPLEMENTED ON: DECEMBER 01, 2017

Issued by: General Administration of Quality Supervision, Inspection and

Quarantine of PRC;

Standardization Administration of PRC.

Table of Contents

Foreword ... 3

1 Scope ... 6

2 Normative references ... 6

3 Overview of method ... 7

4 Reagents ... 7

5 Instruments ... 8

6 Specimens ... 8

7 Test procedure ... 9

8 Test report ... 12

Anodizing of aluminum and its alloys - Assessment of

quality of sealed anodic oxidation coatings - Part 1:

Measurement of the loss of mass after immersion in

acid solution(s)

1 Scope

This part of GB/T 8753 specifies a method, for assessing the quality of sealed

anodic oxidation coatings of aluminum and aluminum alloy, through the loss of

mass, after they are etched in an acid solution.

This part applies to the assessment of the quality of the sealed anodic oxidation

coating, which is exposed to the atmosphere, for the purpose of decoration and

protection, has the ability to resist pollution, can resist environmental corrosion.

Among them, the acid etching method without nitric acid predip is suitable for

the assessment of the quality of the sealed anodic oxidation coatings for indoor

use; the acid etching method with nitric acid predip is suitable for the

assessment of the quality of the sealed anodic oxidation coatings for outdoor

use. When the test result is disputed, the phosphoric acid/chromic acid test with

nitric acid predip can be used as an arbitration test.

This part does not apply to the anodic oxidation coating, which is treated by the

following processes:

a) Hard anodic oxidation coating that is usually not sealed;

b) Anodic oxidation coating that has been sealed in a dichromate solution;

c) Anodic oxidation coating that is formed in chromic acid solution;

d) Anodic oxidation coating after hydrophobic treatment.

2 Normative references

The following documents are essential to the application of this document. For

the dated documents, only the versions with the dates indicated are applicable

to this document; for the undated documents, only the latest version (including

all the amendments) are applicable to this standard.

GB/T 6682 Water for analytical laboratory use - Specification and test

methods

GB/T 8170 Rules of rounding off for numerical values and expression and

judgement of limiting values

GB 8978 Integrated waste water discharge standard

3 Overview of method

3.1 Phosphoric chromic acid method: The specimen is pre-dipped in nitric acid

(or not), etched in a phosphoric chromic acid solution. The mass loss of the

specimen is measured, to assess the quality of the sealed anodic oxidation

coating. Phosphoric chromic acid solution dissolves the anodic oxidation

coating, prevents the corrosion of the non-anodic oxidation surface through

passivation. The nitric acid predip will increase the mass loss of poorly sealed

specimens. The phosphoric chromic acid method is a classic and stable test

method.

3.2 Phosphoric acid method: The specimen is (or is not) pre-dipped in nitric acid,

etched in a phosphoric acid solution. The mass loss of the specimen is

measured, to assess the quality of the sealed anodic oxidation coating.

Phosphoric acid solution dissolves the anodic oxidation coating; it also etches

the non-anodic oxide surface. Under the same circumstances, the mass loss of

the specimen is higher than that of the phosphoric chromic acid method. The

phosphoric acid method is a new and environmentally friendly test method.

3.3 Sodium molybdate phosphate method: The specimen is pre-dipped in nitric

acid, etched in a sodium molybdate phosphate solution. The mass loss of the

specimen is measured, to assess the quality of sealed anodic oxidation coating.

The sodium molybdate phosphate solution dissolves the anodic oxidation

coating; prevents the corrosion of the non-anodic oxidation surface through

passivation. Under the same circumstances, the mass loss of the specimen is

close to that of the phosphoric chromic acid method with nitric acid predip. The

sodium molybdate phosphate method is a new and environmentally friendly test

method.

4 Reagents

4.1 Unless otherwise stated, the reagents used in this part are all analytical

reagents, that comply with national standards or industry standards. The water

used is distilled water or deionized water of grade 3 or higher, which is specified

in GB/T 6682.

4.2 Nitric acid [ρ20 = 1.40 g/mL, HNO3 content (mass fraction): 65.0% ~ 68.0%].

anodic oxidation coating from the inner surface.

6.4 After cutting the specimen, it shall remove the burrs from the cutting edge

of the specimen.

7 Test procedure

7.1 Measurement of the anodic oxidation area of specimen

Use a vernier caliper (5.3) to measure the size of the specimen. Calculate the

anodic oxidation area A of the specimen (which retains 2 decimal places).

7.2 Degreasing

At room temperature, stir the specimen in a suitable organic solvent (such as

acetone or ethanol) for 30 s; OR wipe off the grease. When using chlorinated

solvents, such as perchloroethylene, for degreasing, the pre-drying shall be

carried out in a well-ventilated fume hood, to prevent inhalation of solvent

vapors.

7.3 Drying

First, the specimen is air-dried (pre-dried) at room temperature for 5 min. Then

it is placed upright in a preheated (60 ± 3) °C drying box. After drying for 15

minutes, then in a sealed desiccator, the specimen is placed above the silica

gel, to cool for 30 minutes.

7.4 Weighing

Weigh the specimen mass (m1) immediately, accurate to 0.1 mg.

7.5 Phosphoric chromic acid method without nitric acid predip

7.5.1 Place the specimen upright; completely immerse it in the pre-heated

phosphoric chromic acid solution (4.7), to soak for 15 min. The test temperature

is (38 ± 1) °C.

7.5.2 Remove the specimen from the test solution. First use tap water; then use

deionized water or distilled water to clean it. After drying according to 7.3,

immediately weigh the mass of the specimen (m2), accurate to 0.1 mg.

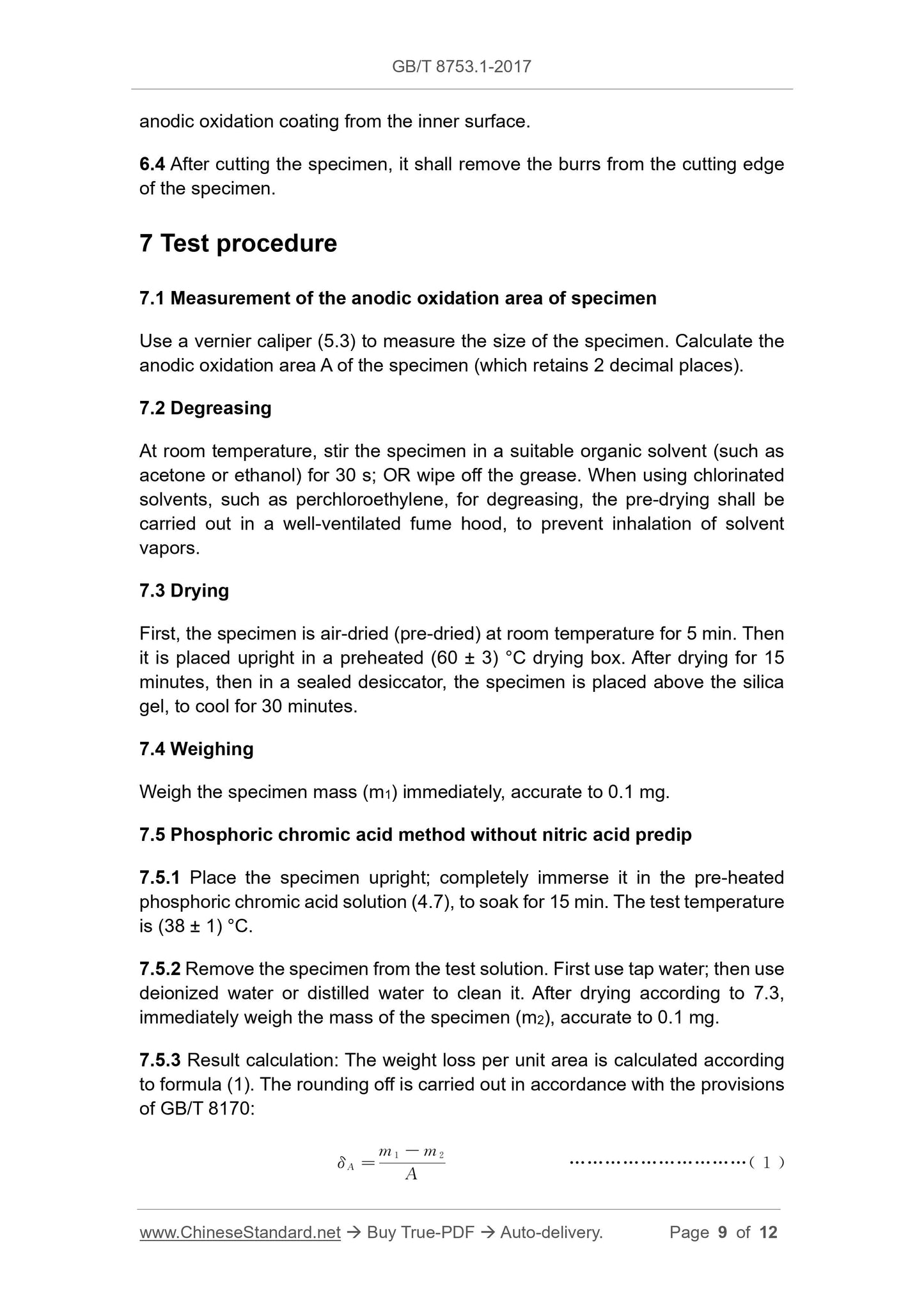

7.5.3 Result calculation: The weight loss per unit area is calculated according

to formula (1). The rounding off is carried out in accordance with the provisions

of GB/T 8170:

7.7.3 Result calculation: Calculate in accordance with the provisions of 7.5.3.

7.7.4 Phosphoric acid solution will etch the non-anodized surface of the

specimen. When the mass loss, during the test of non-anodized surface, does

not exceed 10 mg/dm2, meanwhile the non-anodized surface does not exceed

20% of the total area of specimen, the non-anodized area may not be

considered. If the above conditions are not met, the non-anodized surface of

the specimen shall be shielded. The mass loss of the shielding material, during

operation, shall not exceed 1.0 mg/dm2. For the mass loss of the non-anodized

surface, it can be determined using the alloy specimen, which is same as the

specimen.

7.8 Phosphoric acid method with nitric acid predip

7.8.1 Put the specimen upright; completely immerse it in the predip solution

(4.6), at a temperature of (19 ± 1) °C. Keep it for 10 min. Then take the specimen

out of the predip solution. First use tap water, then deionized water or distilled

water, to wash it thoroughly clean.

7.8.2 Put the specimen upright; completely immerse it in the pre-heated

phosphoric acid solution (4.8). Soak it for 13 min. The test temperature is (38 ±

1) °C.

7.8.3 Remove the specimen from the test solution. First use tap water, then

deionized water or distilled water, to wash it clean. After drying according to 7.3,

immediately weigh the mass of the specimen (m2), accurate to 0.1 mg.

7.8.4 Result calculation: Calculate in accordance with the provisions of 7.5.3.

7.9 Sodium molybdate phosphate method with nitric acid predip

7.9.1 Put the specimen upright; completely immerse it in the predip solution

(4.6), at a temperature of (19 ± 1) °C. Keep it for 10 min. Then take the specimen

out of the predip solution. First use tap water, then deionized water or distilled

water, to wash it thoroughly clean.

7.9.2 Put the specimen upright; completely immerse it in the pre-heated sodium

molybdate phosphate solution (4.9). Soak it for 15 min. The test temperature is

(38 ± 1) °C.

7.9.3 Remove the specimen from the test solution. First use tap water, then

deionized water or distilled water, to wash it clean. After drying according to 7.3,

immediately weigh the mass of the specimen (m2), accurate to 0.1 mg.

7.9.4 Result calculation: Calculate in accordance with the provisions of 7.5.3.

7.9.5 Use the sodium molybdate phosphate solution, to slightly etch the non-

GB/T 8753.1-2017

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 25.220.20

H 21

Replacing GB/T 8753.1-2005, GB/T 8753.2-2005

Anodizing of aluminum and its alloys - Assessment of

quality of sealed anodic oxidation coatings - Part 1:

Measurement of the loss of mass after immersion in

acid solution(s)

ISSUED ON: MAY 31, 2017

IMPLEMENTED ON: DECEMBER 01, 2017

Issued by: General Administration of Quality Supervision, Inspection and

Quarantine of PRC;

Standardization Administration of PRC.

Table of Contents

Foreword ... 3

1 Scope ... 6

2 Normative references ... 6

3 Overview of method ... 7

4 Reagents ... 7

5 Instruments ... 8

6 Specimens ... 8

7 Test procedure ... 9

8 Test report ... 12

Anodizing of aluminum and its alloys - Assessment of

quality of sealed anodic oxidation coatings - Part 1:

Measurement of the loss of mass after immersion in

acid solution(s)

1 Scope

This part of GB/T 8753 specifies a method, for assessing the quality of sealed

anodic oxidation coatings of aluminum and aluminum alloy, through the loss of

mass, after they are etched in an acid solution.

This part applies to the assessment of the quality of the sealed anodic oxidation

coating, which is exposed to the atmosphere, for the purpose of decoration and

protection, has the ability to resist pollution, can resist environmental corrosion.

Among them, the acid etching method without nitric acid predip is suitable for

the assessment of the quality of the sealed anodic oxidation coatings for indoor

use; the acid etching method with nitric acid predip is suitable for the

assessment of the quality of the sealed anodic oxidation coatings for outdoor

use. When the test result is disputed, the phosphoric acid/chromic acid test with

nitric acid predip can be used as an arbitration test.

This part does not apply to the anodic oxidation coating, which is treated by the

following processes:

a) Hard anodic oxidation coating that is usually not sealed;

b) Anodic oxidation coating that has been sealed in a dichromate solution;

c) Anodic oxidation coating that is formed in chromic acid solution;

d) Anodic oxidation coating after hydrophobic treatment.

2 Normative references

The following documents are essential to the application of this document. For

the dated documents, only the versions with the dates indicated are applicable

to this document; for the undated documents, only the latest version (including

all the amendments) are applicable to this standard.

GB/T 6682 Water for analytical laboratory use - Specification and test

methods

GB/T 8170 Rules of rounding off for numerical values and expression and

judgement of limiting values

GB 8978 Integrated waste water discharge standard

3 Overview of method

3.1 Phosphoric chromic acid method: The specimen is pre-dipped in nitric acid

(or not), etched in a phosphoric chromic acid solution. The mass loss of the

specimen is measured, to assess the quality of the sealed anodic oxidation

coating. Phosphoric chromic acid solution dissolves the anodic oxidation

coating, prevents the corrosion of the non-anodic oxidation surface through

passivation. The nitric acid predip will increase the mass loss of poorly sealed

specimens. The phosphoric chromic acid method is a classic and stable test

method.

3.2 Phosphoric acid method: The specimen is (or is not) pre-dipped in nitric acid,

etched in a phosphoric acid solution. The mass loss of the specimen is

measured, to assess the quality of the sealed anodic oxidation coating.

Phosphoric acid solution dissolves the anodic oxidation coating; it also etches

the non-anodic oxide surface. Under the same circumstances, the mass loss of

the specimen is higher than that of the phosphoric chromic acid method. The

phosphoric acid method is a new and environmentally friendly test method.

3.3 Sodium molybdate phosphate method: The specimen is pre-dipped in nitric

acid, etched in a sodium molybdate phosphate solution. The mass loss of the

specimen is measured, to assess the quality of sealed anodic oxidation coating.

The sodium molybdate phosphate solution dissolves the anodic oxidation

coating; prevents the corrosion of the non-anodic oxidation surface through

passivation. Under the same circumstances, the mass loss of the specimen is

close to that of the phosphoric chromic acid method with nitric acid predip. The

sodium molybdate phosphate method is a new and environmentally friendly test

method.

4 Reagents

4.1 Unless otherwise stated, the reagents used in this part are all analytical

reagents, that comply with national standards or industry standards. The water

used is distilled water or deionized water of grade 3 or higher, which is specified

in GB/T 6682.

4.2 Nitric acid [ρ20 = 1.40 g/mL, HNO3 content (mass fraction): 65.0% ~ 68.0%].

anodic oxidation coating from the inner surface.

6.4 After cutting the specimen, it shall remove the burrs from the cutting edge

of the specimen...

Delivery: 9 seconds. Download (& Email) true-PDF + Invoice.

Get Quotation: Click GB/T 8753.1-2017 (Self-service in 1-minute)

Historical versions (Master-website): GB/T 8753.1-2017

Preview True-PDF (Reload/Scroll-down if blank)

GB/T 8753.1-2017

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 25.220.20

H 21

Replacing GB/T 8753.1-2005, GB/T 8753.2-2005

Anodizing of aluminum and its alloys - Assessment of

quality of sealed anodic oxidation coatings - Part 1:

Measurement of the loss of mass after immersion in

acid solution(s)

ISSUED ON: MAY 31, 2017

IMPLEMENTED ON: DECEMBER 01, 2017

Issued by: General Administration of Quality Supervision, Inspection and

Quarantine of PRC;

Standardization Administration of PRC.

Table of Contents

Foreword ... 3

1 Scope ... 6

2 Normative references ... 6

3 Overview of method ... 7

4 Reagents ... 7

5 Instruments ... 8

6 Specimens ... 8

7 Test procedure ... 9

8 Test report ... 12

Anodizing of aluminum and its alloys - Assessment of

quality of sealed anodic oxidation coatings - Part 1:

Measurement of the loss of mass after immersion in

acid solution(s)

1 Scope

This part of GB/T 8753 specifies a method, for assessing the quality of sealed

anodic oxidation coatings of aluminum and aluminum alloy, through the loss of

mass, after they are etched in an acid solution.

This part applies to the assessment of the quality of the sealed anodic oxidation

coating, which is exposed to the atmosphere, for the purpose of decoration and

protection, has the ability to resist pollution, can resist environmental corrosion.

Among them, the acid etching method without nitric acid predip is suitable for

the assessment of the quality of the sealed anodic oxidation coatings for indoor

use; the acid etching method with nitric acid predip is suitable for the

assessment of the quality of the sealed anodic oxidation coatings for outdoor

use. When the test result is disputed, the phosphoric acid/chromic acid test with

nitric acid predip can be used as an arbitration test.

This part does not apply to the anodic oxidation coating, which is treated by the

following processes:

a) Hard anodic oxidation coating that is usually not sealed;

b) Anodic oxidation coating that has been sealed in a dichromate solution;

c) Anodic oxidation coating that is formed in chromic acid solution;

d) Anodic oxidation coating after hydrophobic treatment.

2 Normative references

The following documents are essential to the application of this document. For

the dated documents, only the versions with the dates indicated are applicable

to this document; for the undated documents, only the latest version (including

all the amendments) are applicable to this standard.

GB/T 6682 Water for analytical laboratory use - Specification and test

methods

GB/T 8170 Rules of rounding off for numerical values and expression and

judgement of limiting values

GB 8978 Integrated waste water discharge standard

3 Overview of method

3.1 Phosphoric chromic acid method: The specimen is pre-dipped in nitric acid

(or not), etched in a phosphoric chromic acid solution. The mass loss of the

specimen is measured, to assess the quality of the sealed anodic oxidation

coating. Phosphoric chromic acid solution dissolves the anodic oxidation

coating, prevents the corrosion of the non-anodic oxidation surface through

passivation. The nitric acid predip will increase the mass loss of poorly sealed

specimens. The phosphoric chromic acid method is a classic and stable test

method.

3.2 Phosphoric acid method: The specimen is (or is not) pre-dipped in nitric acid,

etched in a phosphoric acid solution. The mass loss of the specimen is

measured, to assess the quality of the sealed anodic oxidation coating.

Phosphoric acid solution dissolves the anodic oxidation coating; it also etches

the non-anodic oxide surface. Under the same circumstances, the mass loss of

the specimen is higher than that of the phosphoric chromic acid method. The

phosphoric acid method is a new and environmentally friendly test method.

3.3 Sodium molybdate phosphate method: The specimen is pre-dipped in nitric

acid, etched in a sodium molybdate phosphate solution. The mass loss of the

specimen is measured, to assess the quality of sealed anodic oxidation coating.

The sodium molybdate phosphate solution dissolves the anodic oxidation

coating; prevents the corrosion of the non-anodic oxidation surface through

passivation. Under the same circumstances, the mass loss of the specimen is

close to that of the phosphoric chromic acid method with nitric acid predip. The

sodium molybdate phosphate method is a new and environmentally friendly test

method.

4 Reagents

4.1 Unless otherwise stated, the reagents used in this part are all analytical

reagents, that comply with national standards or industry standards. The water

used is distilled water or deionized water of grade 3 or higher, which is specified

in GB/T 6682.

4.2 Nitric acid [ρ20 = 1.40 g/mL, HNO3 content (mass fraction): 65.0% ~ 68.0%].

anodic oxidation coating from the inner surface.

6.4 After cutting the specimen, it shall remove the burrs from the cutting edge

of the specimen.

7 Test procedure

7.1 Measurement of the anodic oxidation area of specimen

Use a vernier caliper (5.3) to measure the size of the specimen. Calculate the

anodic oxidation area A of the specimen (which retains 2 decimal places).

7.2 Degreasing

At room temperature, stir the specimen in a suitable organic solvent (such as

acetone or ethanol) for 30 s; OR wipe off the grease. When using chlorinated

solvents, such as perchloroethylene, for degreasing, the pre-drying shall be

carried out in a well-ventilated fume hood, to prevent inhalation of solvent

vapors.

7.3 Drying

First, the specimen is air-dried (pre-dried) at room temperature for 5 min. Then

it is placed upright in a preheated (60 ± 3) °C drying box. After drying for 15

minutes, then in a sealed desiccator, the specimen is placed above the silica

gel, to cool for 30 minutes.

7.4 Weighing

Weigh the specimen mass (m1) immediately, accurate to 0.1 mg.

7.5 Phosphoric chromic acid method without nitric acid predip

7.5.1 Place the specimen upright; completely immerse it in the pre-heated

phosphoric chromic acid solution (4.7), to soak for 15 min. The test temperature

is (38 ± 1) °C.

7.5.2 Remove the specimen from the test solution. First use tap water; then use

deionized water or distilled water to clean it. After drying according to 7.3,

immediately weigh the mass of the specimen (m2), accurate to 0.1 mg.

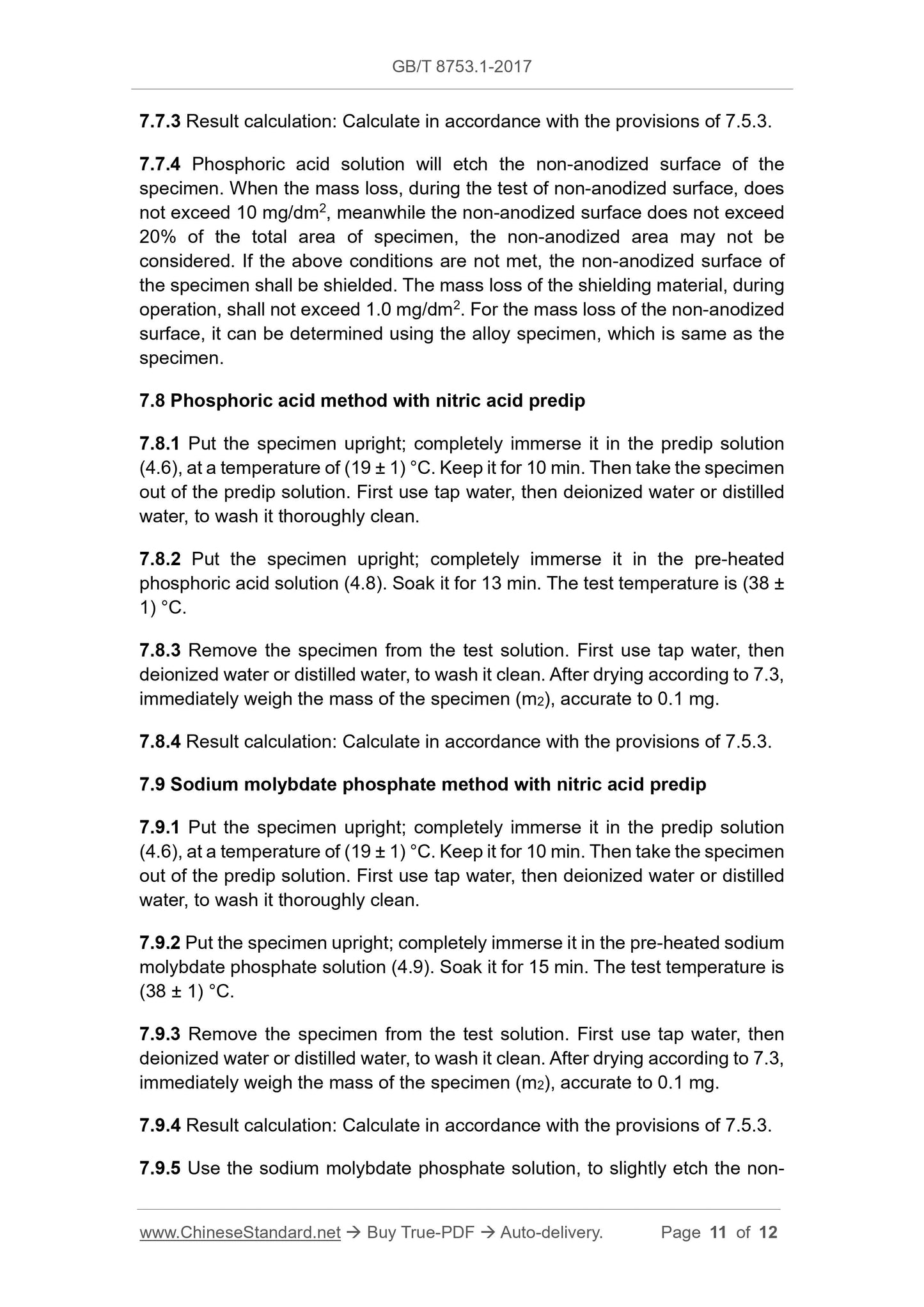

7.5.3 Result calculation: The weight loss per unit area is calculated according

to formula (1). The rounding off is carried out in accordance with the provisions

of GB/T 8170:

7.7.3 Result calculation: Calculate in accordance with the provisions of 7.5.3.

7.7.4 Phosphoric acid solution will etch the non-anodized surface of the

specimen. When the mass loss, during the test of non-anodized surface, does

not exceed 10 mg/dm2, meanwhile the non-anodized surface does not exceed

20% of the total area of specimen, the non-anodized area may not be

considered. If the above conditions are not met, the non-anodized surface of

the specimen shall be shielded. The mass loss of the shielding material, during

operation, shall not exceed 1.0 mg/dm2. For the mass loss of the non-anodized

surface, it can be determined using the alloy specimen, which is same as the

specimen.

7.8 Phosphoric acid method with nitric acid predip

7.8.1 Put the specimen upright; completely immerse it in the predip solution

(4.6), at a temperature of (19 ± 1) °C. Keep it for 10 min. Then take the specimen

out of the predip solution. First use tap water, then deionized water or distilled

water, to wash it thoroughly clean.

7.8.2 Put the specimen upright; completely immerse it in the pre-heated

phosphoric acid solution (4.8). Soak it for 13 min. The test temperature is (38 ±

1) °C.

7.8.3 Remove the specimen from the test solution. First use tap water, then

deionized water or distilled water, to wash it clean. After drying according to 7.3,

immediately weigh the mass of the specimen (m2), accurate to 0.1 mg.

7.8.4 Result calculation: Calculate in accordance with the provisions of 7.5.3.

7.9 Sodium molybdate phosphate method with nitric acid predip

7.9.1 Put the specimen upright; completely immerse it in the predip solution

(4.6), at a temperature of (19 ± 1) °C. Keep it for 10 min. Then take the specimen

out of the predip solution. First use tap water, then deionized water or distilled

water, to wash it thoroughly clean.

7.9.2 Put the specimen upright; completely immerse it in the pre-heated sodium

molybdate phosphate solution (4.9). Soak it for 15 min. The test temperature is

(38 ± 1) °C.

7.9.3 Remove the specimen from the test solution. First use tap water, then

deionized water or distilled water, to wash it clean. After drying according to 7.3,

immediately weigh the mass of the specimen (m2), accurate to 0.1 mg.

7.9.4 Result calculation: Calculate in accordance with the provisions of 7.5.3.

7.9.5 Use the sodium molybdate phosphate solution, to slightly etch the non-

GB/T 8753.1-2017

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 25.220.20

H 21

Replacing GB/T 8753.1-2005, GB/T 8753.2-2005

Anodizing of aluminum and its alloys - Assessment of

quality of sealed anodic oxidation coatings - Part 1:

Measurement of the loss of mass after immersion in

acid solution(s)

ISSUED ON: MAY 31, 2017

IMPLEMENTED ON: DECEMBER 01, 2017

Issued by: General Administration of Quality Supervision, Inspection and

Quarantine of PRC;

Standardization Administration of PRC.

Table of Contents

Foreword ... 3

1 Scope ... 6

2 Normative references ... 6

3 Overview of method ... 7

4 Reagents ... 7

5 Instruments ... 8

6 Specimens ... 8

7 Test procedure ... 9

8 Test report ... 12

Anodizing of aluminum and its alloys - Assessment of

quality of sealed anodic oxidation coatings - Part 1:

Measurement of the loss of mass after immersion in

acid solution(s)

1 Scope

This part of GB/T 8753 specifies a method, for assessing the quality of sealed

anodic oxidation coatings of aluminum and aluminum alloy, through the loss of

mass, after they are etched in an acid solution.

This part applies to the assessment of the quality of the sealed anodic oxidation

coating, which is exposed to the atmosphere, for the purpose of decoration and

protection, has the ability to resist pollution, can resist environmental corrosion.

Among them, the acid etching method without nitric acid predip is suitable for

the assessment of the quality of the sealed anodic oxidation coatings for indoor

use; the acid etching method with nitric acid predip is suitable for the

assessment of the quality of the sealed anodic oxidation coatings for outdoor

use. When the test result is disputed, the phosphoric acid/chromic acid test with

nitric acid predip can be used as an arbitration test.

This part does not apply to the anodic oxidation coating, which is treated by the

following processes:

a) Hard anodic oxidation coating that is usually not sealed;

b) Anodic oxidation coating that has been sealed in a dichromate solution;

c) Anodic oxidation coating that is formed in chromic acid solution;

d) Anodic oxidation coating after hydrophobic treatment.

2 Normative references

The following documents are essential to the application of this document. For

the dated documents, only the versions with the dates indicated are applicable

to this document; for the undated documents, only the latest version (including

all the amendments) are applicable to this standard.

GB/T 6682 Water for analytical laboratory use - Specification and test

methods

GB/T 8170 Rules of rounding off for numerical values and expression and

judgement of limiting values

GB 8978 Integrated waste water discharge standard

3 Overview of method

3.1 Phosphoric chromic acid method: The specimen is pre-dipped in nitric acid

(or not), etched in a phosphoric chromic acid solution. The mass loss of the

specimen is measured, to assess the quality of the sealed anodic oxidation

coating. Phosphoric chromic acid solution dissolves the anodic oxidation

coating, prevents the corrosion of the non-anodic oxidation surface through

passivation. The nitric acid predip will increase the mass loss of poorly sealed

specimens. The phosphoric chromic acid method is a classic and stable test

method.

3.2 Phosphoric acid method: The specimen is (or is not) pre-dipped in nitric acid,

etched in a phosphoric acid solution. The mass loss of the specimen is

measured, to assess the quality of the sealed anodic oxidation coating.

Phosphoric acid solution dissolves the anodic oxidation coating; it also etches

the non-anodic oxide surface. Under the same circumstances, the mass loss of

the specimen is higher than that of the phosphoric chromic acid method. The

phosphoric acid method is a new and environmentally friendly test method.

3.3 Sodium molybdate phosphate method: The specimen is pre-dipped in nitric

acid, etched in a sodium molybdate phosphate solution. The mass loss of the

specimen is measured, to assess the quality of sealed anodic oxidation coating.

The sodium molybdate phosphate solution dissolves the anodic oxidation

coating; prevents the corrosion of the non-anodic oxidation surface through

passivation. Under the same circumstances, the mass loss of the specimen is

close to that of the phosphoric chromic acid method with nitric acid predip. The

sodium molybdate phosphate method is a new and environmentally friendly test

method.

4 Reagents

4.1 Unless otherwise stated, the reagents used in this part are all analytical

reagents, that comply with national standards or industry standards. The water

used is distilled water or deionized water of grade 3 or higher, which is specified

in GB/T 6682.

4.2 Nitric acid [ρ20 = 1.40 g/mL, HNO3 content (mass fraction): 65.0% ~ 68.0%].

anodic oxidation coating from the inner surface.

6.4 After cutting the specimen, it shall remove the burrs from the cutting edge

of the specimen...

Share