1

/

of

7

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

GB/T 9286-1998 English PDF (GB/T9286-1998)

GB/T 9286-1998 English PDF (GB/T9286-1998)

Regular price

$85.00

Regular price

Sale price

$85.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

GB/T 9286-1998: Paints and varnishes--Cross cut test for films

Delivery: 9 seconds. Download (and Email) true-PDF + Invoice.Get Quotation: Click GB/T 9286-1998 (Self-service in 1-minute)

Newer / historical versions: GB/T 9286-1998

Preview True-PDF

Scope

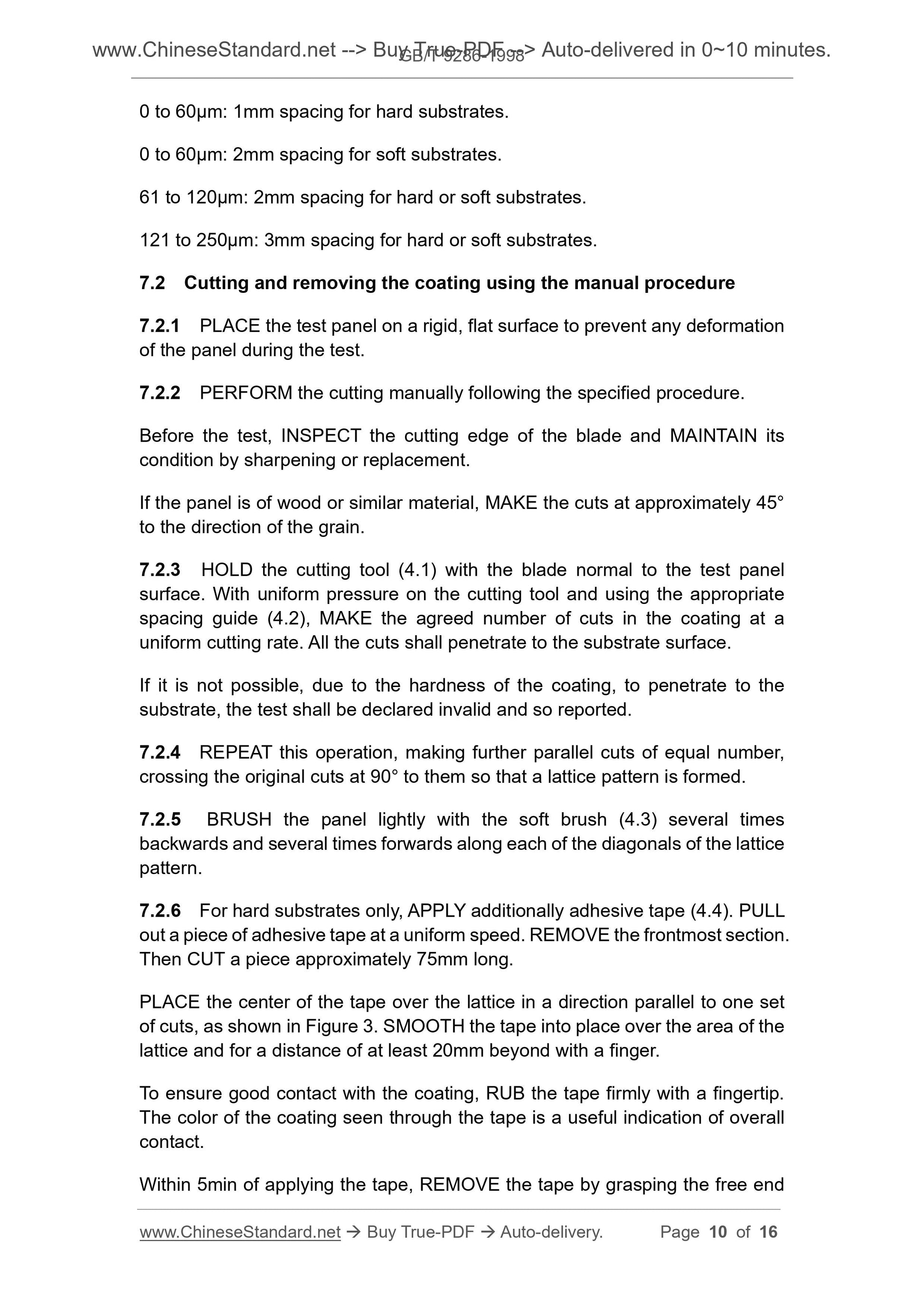

1.1 This Standard specifies a test method for assessing the resistance of paint coatings to separation from substrates when a right-angle lattice pattern is cut into the coating, penetrating through to the substrate. The property measured by this empirical test procedure depends, among other factors, on the adhesion of the coating to either the preceding coat or the substrate. This procedure is not to be regarded, however, as a means of measuring adhesion.NOTE 1. Although the test is primarily intended for use in the laboratory, the test is also suitable for field testing.

1.2 The method described may be applied either as a pass/fail test or, where circumstances are appropriate, as a six-step classification test (SEE 8.3). When applied to a multi-coat system, assessment of the resistance to separation of individual layers of the coating from each other may be made.

1.3 The test may be carried out on finished objects and/or on specially prepared test specimens.

Although the method is applicable to paint on hard (steel) and soft (wood and plaster) substrates, these different substrates need a different test procedure (SEE clause 7).

The method is not suitable for coatings of total thickness greater than 250μm or for textured coatings.

NOTE 2. The method, when applied to coatings designed to give a rough patterned surface, will give results which will show too much variation.

Basic Data

| Standard ID | GB/T 9286-1998 (GB/T9286-1998) |

| Description (Translated English) | Paints and varnishes--Cross cut test for films |

| Sector / Industry | National Standard (Recommended) |

| Classification of Chinese Standard | G50 |

| Classification of International Standard | 87.04 |

| Word Count Estimation | 9,969 |

| Date of Issue | 11/4/1998 |

| Date of Implementation | 6/1/1999 |

| Older Standard (superseded by this standard) | GB/T 9286-1988 |

| Quoted Standard | GB/T 1727-1992; GB 3186-1982 (1989); GB/T 9271-1988; GB 9278-1988; GB/T 13452.2-1992 |

| Adopted Standard | ISO 2409-1992, MOD |

| Summary | This standard specifies a test method in the grid pattern cutting at right angles to penetrate the coating to the substrate to evaluate the coating from the substrate from the resistance. In this empirical test procedure measured performance, except for the channel depending on the coating or paint adhesion to the substrate, but also depends on various other factors, it can not be measured in this test is considered as belonging to the program a method of focus. |

Share