1

/

of

4

PayPal, credit cards. Download editable-PDF & invoice in 1 second!

GB/T 959.1-2017 English PDF (GBT959.1-2017)

GB/T 959.1-2017 English PDF (GBT959.1-2017)

Regular price

$115.00 USD

Regular price

Sale price

$115.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click GB/T 959.1-2017

Historical versions: GB/T 959.1-2017

Preview True-PDF (Reload/Scroll if blank)

GB/T 959.1-2017: Specifications for retaining rings -- Circlips

GB/T 959.1-2017

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 21.060.30

J 13

Replacing GB/T 959.1-1986

Specifications for Retaining Rings – Circlips

ISSUED ON. JULY 12, 2017

IMPLEMENTED ON. FEBRUARY 1, 2018

Issued by. General Administration of Quality Supervision, Inspection and

Quarantine of the People's Republic of China;

Standardization Administration of the People's Republic of

China.

3. No action is required - Full-copy of this standard will be automatically and

immediately delivered to your EMAIL address in 0~60 minutes.

Table of Contents

Foreword ... 3

1 Application Scope ... 5

2 Normative References ... 5

3 Materials ... 5

4 Properties ... 6

5 Surface Treatment ... 7

6 Test Methods ... 7

7 Surface Defects ... 11

8 Acceptance Inspection ... 11

9 Marking and Packaging ... 12

Annex A (Normative) Technical Requirements for Steels C67S and C75S

... 13

Foreword

This Part belongs to the serial standards under the national standard “Retaining Rings”.

The series include.

-- GB/T 893, Retaining Rings for Bores;

-- GB/T 894, Retaining Rings for Shaft;

-- GB/T 896, “E” Rings;

-- GB/T 959.1, Specifications for Retaining Rings – Circlips.

This Part is Part 1 of GB/T 959.

This Part was drafted in accordance with the rules given in GB/T 1.1-2009.

This Part replaces GB/T 959.1-1986, Specifications for Ring – Circlips. Compared with

GB/T 959.1-1986, the major changes of this Part are as follows.

-- the material designations 70, C67S and C75S are added and it is specified that

the materials of retaining rings are to be determined by the manufacturer (see

Article 3);

-- it adds for heat treatment. d1 > 200 mm ~ 300 mm; hardness 390 HV ~ 470 HV;

40 HRC ~ 47 HRC (see Table 2);

-- it adds bending test for retaining rings for bores and shafts (see 4.1 and 6.1);

-- it adds conical deformation test for retaining rings for bores and shafts (see 4.2

and 6.2);

-- it modifies the technical requirements and methods for resilience test of retaining

rings for bores and shafts (see 4.4 and 6.4);

-- it deletes zinc plating passivation, adds surface phosphating treatment and

surface corrosion resistance and specifies that the surface treatment of retaining

rings is to be determined by the manufacturer (see Article 5 and 6.6);

-- it adds dimensions, properties and acceptable quality levels (AQL) of retaining

rings (see Table 6 and Table 7).

This Part was proposed by China Machinery Industry Federation.

This Part shall be under the jurisdiction of the National Standardization Technical

Committee on Fasteners (SAC/TC 85).

The responsible drafting organization of this Part. China Productivity Centre for

Machinery.

Specifications for Retaining Rings – Circlips

1 Application Scope

This Part of GB/T 959 specifies the specifications for retaining rings for bores and

shafts and “E” rings.

This Part applies to retaining rings for bores and shafts and “E” rings as specified by

the national Standards, as well as other standard and non-standard retaining ring

products.

2 Normative References

The following referenced documents are indispensable for the application of this

document. For dated references, only the edition dated applies to this document. For

undated references, the latest edition of the referenced documents (including all

amendments) applies to This Standard.

GB/T 90.1, Fasteners – Acceptance Inspection

GB/T 90.2, Fasteners – Marking and Packaging

GB/T 1222, Spring Steels

GB/T 4357, Cold-drawn Non-alloy Steel Wire for Springs

GB/T 10125, Corrosion tests in Artificial Atmospheres – Salt Spray Tests

GB/T 11376, Phosphate Conversion Coatings for Metals

JB/T 3411.47, Pincer for Assembly Spring Thrust Collar on Shaft – Dimensions

JB/T 3411.48, Pincer for Assembly Spring Thrust Collar in Hole – Dimensions

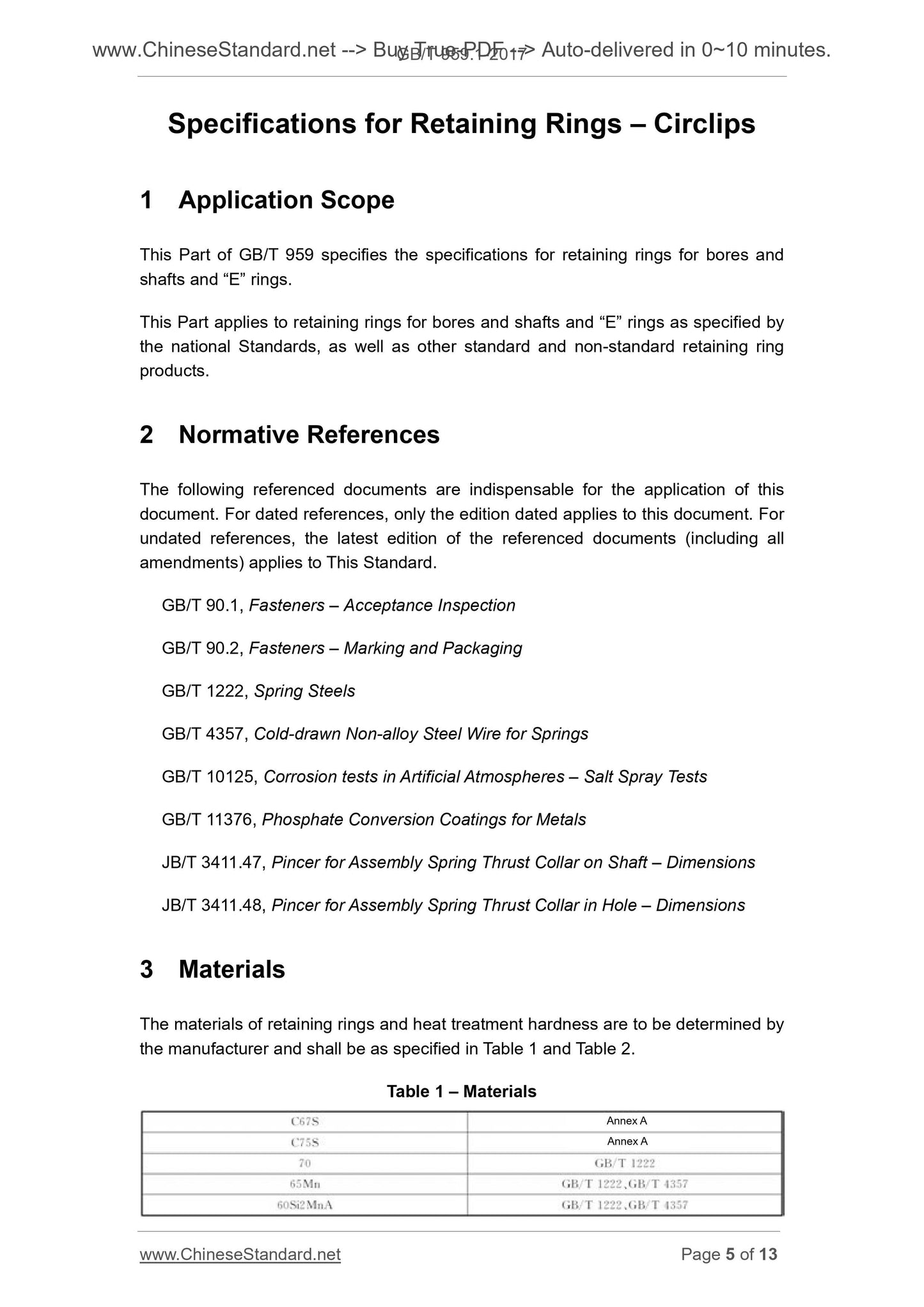

3 Materials

The materials of retaining rings and heat treatment hardness are to be determined by

the manufacturer and shall be as specified in Table 1 and Table 2.

Table 1 – Materials

Annex A

Annex A

Get QUOTATION in 1-minute: Click GB/T 959.1-2017

Historical versions: GB/T 959.1-2017

Preview True-PDF (Reload/Scroll if blank)

GB/T 959.1-2017: Specifications for retaining rings -- Circlips

GB/T 959.1-2017

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 21.060.30

J 13

Replacing GB/T 959.1-1986

Specifications for Retaining Rings – Circlips

ISSUED ON. JULY 12, 2017

IMPLEMENTED ON. FEBRUARY 1, 2018

Issued by. General Administration of Quality Supervision, Inspection and

Quarantine of the People's Republic of China;

Standardization Administration of the People's Republic of

China.

3. No action is required - Full-copy of this standard will be automatically and

immediately delivered to your EMAIL address in 0~60 minutes.

Table of Contents

Foreword ... 3

1 Application Scope ... 5

2 Normative References ... 5

3 Materials ... 5

4 Properties ... 6

5 Surface Treatment ... 7

6 Test Methods ... 7

7 Surface Defects ... 11

8 Acceptance Inspection ... 11

9 Marking and Packaging ... 12

Annex A (Normative) Technical Requirements for Steels C67S and C75S

... 13

Foreword

This Part belongs to the serial standards under the national standard “Retaining Rings”.

The series include.

-- GB/T 893, Retaining Rings for Bores;

-- GB/T 894, Retaining Rings for Shaft;

-- GB/T 896, “E” Rings;

-- GB/T 959.1, Specifications for Retaining Rings – Circlips.

This Part is Part 1 of GB/T 959.

This Part was drafted in accordance with the rules given in GB/T 1.1-2009.

This Part replaces GB/T 959.1-1986, Specifications for Ring – Circlips. Compared with

GB/T 959.1-1986, the major changes of this Part are as follows.

-- the material designations 70, C67S and C75S are added and it is specified that

the materials of retaining rings are to be determined by the manufacturer (see

Article 3);

-- it adds for heat treatment. d1 > 200 mm ~ 300 mm; hardness 390 HV ~ 470 HV;

40 HRC ~ 47 HRC (see Table 2);

-- it adds bending test for retaining rings for bores and shafts (see 4.1 and 6.1);

-- it adds conical deformation test for retaining rings for bores and shafts (see 4.2

and 6.2);

-- it modifies the technical requirements and methods for resilience test of retaining

rings for bores and shafts (see 4.4 and 6.4);

-- it deletes zinc plating passivation, adds surface phosphating treatment and

surface corrosion resistance and specifies that the surface treatment of retaining

rings is to be determined by the manufacturer (see Article 5 and 6.6);

-- it adds dimensions, properties and acceptable quality levels (AQL) of retaining

rings (see Table 6 and Table 7).

This Part was proposed by China Machinery Industry Federation.

This Part shall be under the jurisdiction of the National Standardization Technical

Committee on Fasteners (SAC/TC 85).

The responsible drafting organization of this Part. China Productivity Centre for

Machinery.

Specifications for Retaining Rings – Circlips

1 Application Scope

This Part of GB/T 959 specifies the specifications for retaining rings for bores and

shafts and “E” rings.

This Part applies to retaining rings for bores and shafts and “E” rings as specified by

the national Standards, as well as other standard and non-standard retaining ring

products.

2 Normative References

The following referenced documents are indispensable for the application of this

document. For dated references, only the edition dated applies to this document. For

undated references, the latest edition of the referenced documents (including all

amendments) applies to This Standard.

GB/T 90.1, Fasteners – Acceptance Inspection

GB/T 90.2, Fasteners – Marking and Packaging

GB/T 1222, Spring Steels

GB/T 4357, Cold-drawn Non-alloy Steel Wire for Springs

GB/T 10125, Corrosion tests in Artificial Atmospheres – Salt Spray Tests

GB/T 11376, Phosphate Conversion Coatings for Metals

JB/T 3411.47, Pincer for Assembly Spring Thrust Collar on Shaft – Dimensions

JB/T 3411.48, Pincer for Assembly Spring Thrust Collar in Hole – Dimensions

3 Materials

The materials of retaining rings and heat treatment hardness are to be determined by

the manufacturer and shall be as specified in Table 1 and Table 2.

Table 1 – Materials

Annex A

Annex A

Share