1

/

of

5

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

HG/T 20609-2009 English PDF (HG/T20609-2009)

HG/T 20609-2009 English PDF (HG/T20609-2009)

Regular price

$70.00

Regular price

Sale price

$70.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

HG/T 20609-2009: Metal jacketed gaskets for use with steel pipe flanges (PN designated)

Delivery: 9 seconds. Download (& Email) true-PDF + Invoice.

Get Quotation: Click HG/T 20609-2009 (Self-service in 1-minute)

Historical versions (Master-website): HG/T 20609-2009

Preview True-PDF (Reload/Scroll-down if blank)

HG/T 20609-2009

Chemical Industry Standard

of the People's Republic of China

HG

Replacing HG 20609-1997

Metal Jacketed Gaskets for use with Steel Pipe

Flanges

(PN Designated)

(PN系列)

ISSUED ON. FEBRUARY 5, 2006

IMPLEMENTED ON. JULY 1, 2006

Issued by. Ministry of Industry and Information Technology of the People’s

Republic of China

Contents

1. Scope ... 3

2. Normative references ... 3

3. Service conditions of the gaskets ... 3

4. Gasket pattern and dimension ... 4

5. Technical requirement ... 5

6. Marking and Packaging ... 7

1. Scope

This national standard specifies pattern, dimension, and technical requirement and

marking of metal jacketed gaskets for use with steel pipe flanges (PN designated).

This Standard is applicable to metal jacketed gaskets for use with steel pipe flange with

raised face in nominal pressure of PN25~PN100 specified in HG/T 20592.

Note. the use of the asbestos-contained material shall comply with requirements of relevant laws and regulations. When

the production and use are containing asbestos material gasket, protective measures shall be adopted, so as to ensure not

endanger the person health.

2. Normative references

The following standards contain provisions which, through reference in this text,

constitute provisions of this Standard. For dated reference, subsequent amendments

(excluding content of corrigenda) to, or revisions of, any of these publications do not apply.

However, Parties to agreements biased on this Code are encouraged to investigate the

possibility of applying the most recent editions of the standards indicated below. For undated

references, the latest edition of the normative document referred to applies.

"Metallic Materials--Bend Test" GB/T 232

"Hot-rolled Quality Carbon Structural Steel Sheets and Strips" GB/T 710

"Sheet of Copper and Copper Alloy" GB/T 2040

"Continuously Hot-dip Zinc-coated Steel Sheet and Strip" GB/T 2518

"Cold Rolled Stainless Steel Plate Sheet and Strip" GB/T 3280

"Wrought Aluminium and Aluminium Alloy Plates, sheets and Strips for General

Engineering" GB/T 3880

"Compressed Asbestos Fibre Jointing" GB/T 3985

"Metallic Envelope Gaskets for Pipe Flanges" GB/T 15601

"Steel Pipe Flanges (PN designed)" HG/T 20592

"Specification for selection of Steel Pipe Flanges, Gaskets and Bolting (PN designated)"

HG/T 20614

"Specifications of Flexible Graphite Sheets" JB/T 7758.2

3. Service conditions of the gaskets

3.0.1 The maximum operating temperature of the metal jacketed material shall be in

accordance with those specified in Table 3.0.1.

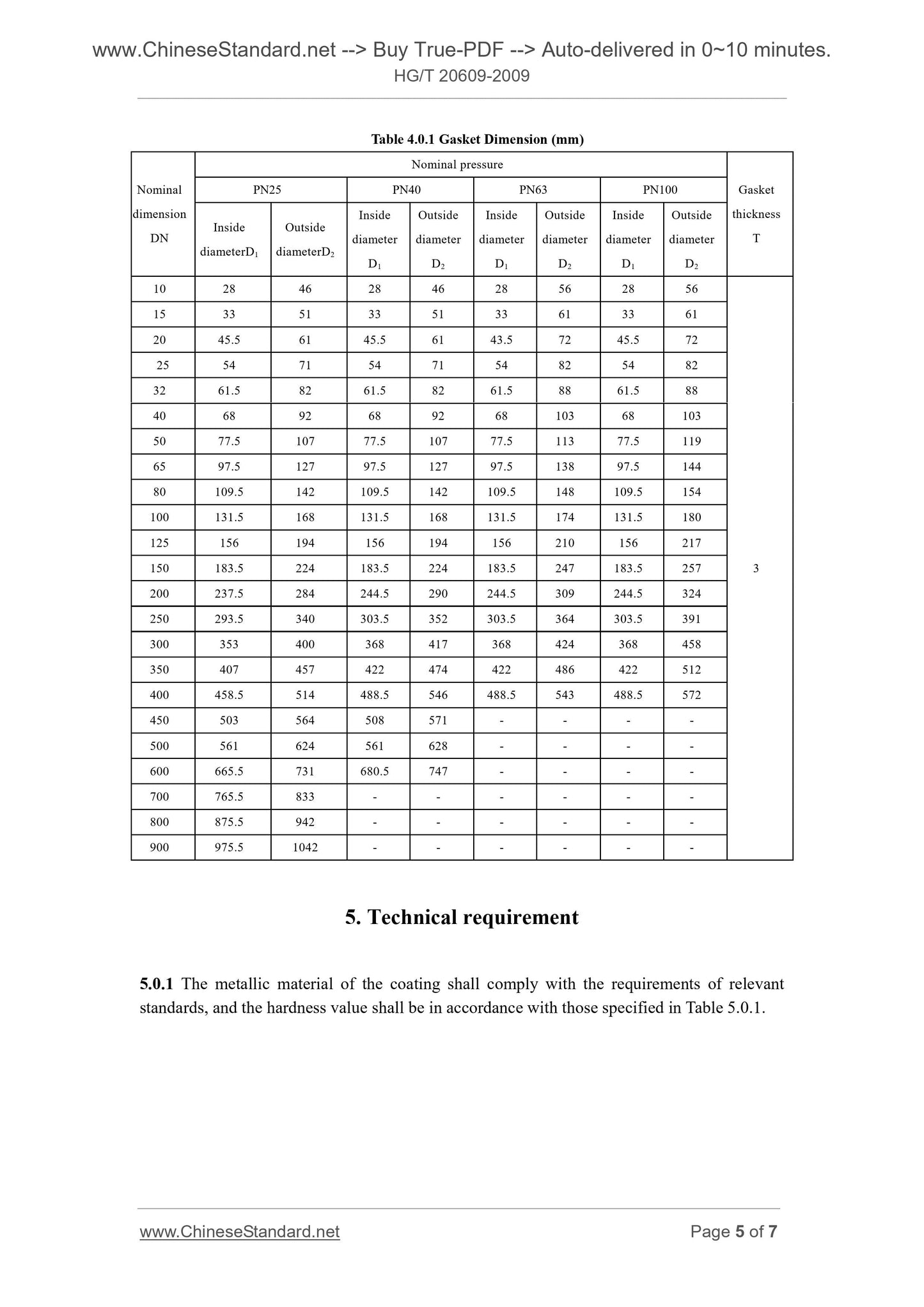

Table 4.0.1 Gasket Dimension (mm)

Nominal

dimension

DN

Nominal pressure

Gasket

thickness

PN25 PN40 PN63 PN100

Inside

diameterD1

Outside

diameterD2

Inside

diameter

D1

Outside

diameter

D2

Inside

diameter

D1

Outside

diameter

D2

Inside

diameter

D1

Outside

diameter

D2

10 28 46 28 46 28 56 28 56

15 33 51 33 51 33 61 33 61

20 45.5 61 45.5 61 43.5 72 45.5 72

25 54 71 54 71 54 82 54 82

32 61.5 82 61.5 82 61.5 88 61.5 88

40 68 92 68 92 68 103 68 103

50 77.5 107 77.5 107 77.5 113 77.5 119

65 97.5 127 97.5 127 97.5 138 97.5 144

80 109.5 142 109.5 142 109.5 148 109.5 154

100 131.5 168 131.5 168 131.5 174 131.5 180

125 156 194 156 194 156 210 156 217

150 183.5 224 183.5 224 183.5 247 183.5 257

200 237.5 284 244.5 290 244.5 309 244.5 324

250 293.5 340 303.5 352 303.5 364 303.5 391

300 353 400 368 417 368 424 368 458

350 407 457 422 474 422 486 422 512

400 458.5 514 488.5 546 488.5 543 488.5 572

450 503 564 508 571 - - - -

500 561 624 561 628 - - - -

600 665.5 731 680.5 747 - - - -

700 765.5 833 - - - - - -

800 875.5 942 - - - - - -

900 975.5 1042 - - - - - -

5. Technical requirement

5.0.1 The metallic material of the coating shall comply with the requirements of relevant

standards, and the hardness value shall be in accordance with those specified in Table 5.0.1.

6. Marking and Packaging

6.0.1 The gaskets shall be packed respectively according to the specifications and materials

and a conformity certificate of production quality test shall be attached at delivery. Each

gasket shall be labeled with the contents specified in Article 6.0.2.

6.0.2 Labeling content.

1 Standard No. (HG/T 20609)

2 Nominal dimension DN

3 Nominal pressure PN

4 Code name of the metallic material for clad (see the provisions in Table 3.0.1 of this

standard).

5 Filling material

6.0.3 Marking illustration.

Nominal dimension. DN500, nominal pressure. PN25, metal cladding material.

0Cr18Ni9, filling material. XB450 paronite metal jacketed gasket, it shall be labeled as. HG/T

20609 metal jacketed gasket 500-25 304/XB450

HG/T 20609-2009

Chemical Industry Standard

of the People's Republic of China

HG

Replacing HG 20609-1997

Metal Jacketed Gaskets for use with Steel Pipe

Flanges

(PN Designated)

(PN系列)

ISSUED ON. FEBRUARY 5, 2006

IMPLEMENTED ON. JULY 1, 2006

Issued by. Ministry of Industry and Information Technology of the People’s

Republic of China

Contents

1. Scope ... 3

2. Normative references ... 3

3. Service conditions of the gaskets ... 3

4. Gasket pattern and dimension ... 4

5. Technical requirement ... 5

6. Marking and Packaging ... 7

1. Scope

This national standard specifies pattern, dimension, and technical requirement and

marking of metal jacketed gaskets for use with steel pipe flanges (PN designated).

This Standard is applicable to metal jacketed gaskets for use with steel pipe flange with

raised face in nominal pressure of PN25~PN100 specified in HG/T 20592.

Note. the use of the asbestos-contained material shall comply with requirements of relevant laws and regulations. When

the production and use are containing asbestos material gasket, protective measures shall be adopted, so as to ensure not

endanger the person health.

2. Normative references

The following standards contain provisions which, through reference in this text,

constitute provisions of this Standard. For dated reference, subsequent amendments

(excluding content of corrigenda) to, or revisions of, any of these publications do not apply.

However, Parties to agreements biased on this Code are encouraged to investigate the

possibility of applying the most recent editions of the standards indicated below. For undated

references, the latest edition of the normative document referred to applies.

"Metallic Materials--Bend Test" GB/T 232

"Hot-rolled Quality Carbon Structural Steel Sheets and Strips" GB/T 710

"Sheet of Copper and Copper Alloy" GB/T 2040

"Continuously Hot-dip Zinc-coated Steel Sheet and Strip" GB/T 2518

"Cold Rolled Stainless Steel Plate Sheet and Strip" GB/T 3280

"Wrought Aluminium and Aluminium Alloy Plates, sheets and Strips for General

Engineering" GB/T 3880

"Compressed Asbestos Fibre Jointing" GB/T 3985

"Metallic Envelope Gaskets for Pipe Flanges" GB/T 15601

"Steel Pipe Flanges (PN designed)" HG/T 20592

"Specification for selection of Steel Pipe Flanges, Gaskets and Bolting (PN designated)"

HG/T 20614

"Specifications of Flexible Graphite Sheets" JB/T 7758.2

3. Service conditions of the gaskets

3.0.1 The maximum operating temperature of the metal jacketed material shall be in

accordance with those specified in Table 3.0.1.

Table 4.0.1 Gasket Dimension (mm)

Nominal

dimension

DN

Nominal pressure

Gasket

thickness

PN25 PN40 PN63 PN100

Inside

diameterD1

Outside

diameterD2

Inside

diameter

D1

Outside

diameter

D2

Inside

diameter

D1

Outside

diameter

D2

Inside

diameter

D1

Outside

diameter

D2

10 28 46 28 46 28 56 28 56

15 33 51 33 51 33 61 33 61

20 45.5 61 45.5 61 43.5 72 45.5 72

25 54 71 54 71 54 82 54 82

32 61.5 82 61.5 82 61.5 88 61.5 88

40 68 92 68 92 68 103 68 103

50 77.5 107 77.5 107 77.5 113 77.5 119

65 97.5 127 97.5 127 97.5 138 97.5 144

80 109.5 142 109.5 142 109.5 148 109.5 154

100 131.5 168 131.5 168 131.5 174 131.5 180

125 156 194 156 194 156 210 156 217

150 183.5 224 183.5 224 183.5 247 183.5 257

200 237.5 284 244.5 290 244.5 309 244.5 324

250 293.5 340 303.5 352 303.5 364 303.5 391

300 353 400 368 417 368 424 368 458

350 407 457 422 474 422 486 422 512

400 458.5 514 488.5 546 488.5 543 488.5 572

450 503 564 508 571 - - - -

500 561 624 561 628 - - - -

600 665.5 731 680.5 747 - - - -

700 765.5 833 - - - - - -

800 875.5 942 - - - - - -

900 975.5 1042 - - - - - -

5. Technical requirement

5.0.1 The metallic material of the coating shall comply with the requirements of relevant

standards, and the hardness value shall be in accordance with those specified in Table 5.0.1.

6. Marking and Packaging

6.0.1 The gaskets shall be packed respectively according to the specifications and materials

and a conformity certificate of production quality test shall be attached at delivery. Each

gasket shall be labeled with the contents specified in Article 6.0.2.

6.0.2 Labeling content.

1 Standard No. (HG/T 20609)

2 Nominal dimension DN

3 Nominal pressure PN

4 Code name of the metallic material for clad (see the provisions in Table 3.0.1 of this

standard).

5 Filling material

6.0.3 Marking illustration.

Nominal dimension. DN500, nominal pressure. PN25, metal cladding material.

0Cr18Ni9, filling material. XB450 paronite metal jacketed gasket, it shall be labeled as. HG/T

20609 metal jacketed gasket 500-25 304/XB450

Delivery: 9 seconds. Download (& Email) true-PDF + Invoice.

Get Quotation: Click HG/T 20609-2009 (Self-service in 1-minute)

Historical versions (Master-website): HG/T 20609-2009

Preview True-PDF (Reload/Scroll-down if blank)

HG/T 20609-2009

Chemical Industry Standard

of the People's Republic of China

HG

Replacing HG 20609-1997

Metal Jacketed Gaskets for use with Steel Pipe

Flanges

(PN Designated)

(PN系列)

ISSUED ON. FEBRUARY 5, 2006

IMPLEMENTED ON. JULY 1, 2006

Issued by. Ministry of Industry and Information Technology of the People’s

Republic of China

Contents

1. Scope ... 3

2. Normative references ... 3

3. Service conditions of the gaskets ... 3

4. Gasket pattern and dimension ... 4

5. Technical requirement ... 5

6. Marking and Packaging ... 7

1. Scope

This national standard specifies pattern, dimension, and technical requirement and

marking of metal jacketed gaskets for use with steel pipe flanges (PN designated).

This Standard is applicable to metal jacketed gaskets for use with steel pipe flange with

raised face in nominal pressure of PN25~PN100 specified in HG/T 20592.

Note. the use of the asbestos-contained material shall comply with requirements of relevant laws and regulations. When

the production and use are containing asbestos material gasket, protective measures shall be adopted, so as to ensure not

endanger the person health.

2. Normative references

The following standards contain provisions which, through reference in this text,

constitute provisions of this Standard. For dated reference, subsequent amendments

(excluding content of corrigenda) to, or revisions of, any of these publications do not apply.

However, Parties to agreements biased on this Code are encouraged to investigate the

possibility of applying the most recent editions of the standards indicated below. For undated

references, the latest edition of the normative document referred to applies.

"Metallic Materials--Bend Test" GB/T 232

"Hot-rolled Quality Carbon Structural Steel Sheets and Strips" GB/T 710

"Sheet of Copper and Copper Alloy" GB/T 2040

"Continuously Hot-dip Zinc-coated Steel Sheet and Strip" GB/T 2518

"Cold Rolled Stainless Steel Plate Sheet and Strip" GB/T 3280

"Wrought Aluminium and Aluminium Alloy Plates, sheets and Strips for General

Engineering" GB/T 3880

"Compressed Asbestos Fibre Jointing" GB/T 3985

"Metallic Envelope Gaskets for Pipe Flanges" GB/T 15601

"Steel Pipe Flanges (PN designed)" HG/T 20592

"Specification for selection of Steel Pipe Flanges, Gaskets and Bolting (PN designated)"

HG/T 20614

"Specifications of Flexible Graphite Sheets" JB/T 7758.2

3. Service conditions of the gaskets

3.0.1 The maximum operating temperature of the metal jacketed material shall be in

accordance with those specified in Table 3.0.1.

Table 4.0.1 Gasket Dimension (mm)

Nominal

dimension

DN

Nominal pressure

Gasket

thickness

PN25 PN40 PN63 PN100

Inside

diameterD1

Outside

diameterD2

Inside

diameter

D1

Outside

diameter

D2

Inside

diameter

D1

Outside

diameter

D2

Inside

diameter

D1

Outside

diameter

D2

10 28 46 28 46 28 56 28 56

15 33 51 33 51 33 61 33 61

20 45.5 61 45.5 61 43.5 72 45.5 72

25 54 71 54 71 54 82 54 82

32 61.5 82 61.5 82 61.5 88 61.5 88

40 68 92 68 92 68 103 68 103

50 77.5 107 77.5 107 77.5 113 77.5 119

65 97.5 127 97.5 127 97.5 138 97.5 144

80 109.5 142 109.5 142 109.5 148 109.5 154

100 131.5 168 131.5 168 131.5 174 131.5 180

125 156 194 156 194 156 210 156 217

150 183.5 224 183.5 224 183.5 247 183.5 257

200 237.5 284 244.5 290 244.5 309 244.5 324

250 293.5 340 303.5 352 303.5 364 303.5 391

300 353 400 368 417 368 424 368 458

350 407 457 422 474 422 486 422 512

400 458.5 514 488.5 546 488.5 543 488.5 572

450 503 564 508 571 - - - -

500 561 624 561 628 - - - -

600 665.5 731 680.5 747 - - - -

700 765.5 833 - - - - - -

800 875.5 942 - - - - - -

900 975.5 1042 - - - - - -

5. Technical requirement

5.0.1 The metallic material of the coating shall comply with the requirements of relevant

standards, and the hardness value shall be in accordance with those specified in Table 5.0.1.

6. Marking and Packaging

6.0.1 The gaskets shall be packed respectively according to the specifications and materials

and a conformity certificate of production quality test shall be attached at delivery. Each

gasket shall be labeled with the contents specified in Article 6.0.2.

6.0.2 Labeling content.

1 Standard No. (HG/T 20609)

2 Nominal dimension DN

3 Nominal pressure PN

4 Code name of the metallic material for clad (see the provisions in Table 3.0.1 of this

standard).

5 Filling material

6.0.3 Marking illustration.

Nominal dimension. DN500, nominal pressure. PN25, metal cladding material.

0Cr18Ni9, filling material. XB450 paronite metal jacketed gasket, it shall be labeled as. HG/T

20609 metal jacketed gasket 500-25 304/XB450

HG/T 20609-2009

Chemical Industry Standard

of the People's Republic of China

HG

Replacing HG 20609-1997

Metal Jacketed Gaskets for use with Steel Pipe

Flanges

(PN Designated)

(PN系列)

ISSUED ON. FEBRUARY 5, 2006

IMPLEMENTED ON. JULY 1, 2006

Issued by. Ministry of Industry and Information Technology of the People’s

Republic of China

Contents

1. Scope ... 3

2. Normative references ... 3

3. Service conditions of the gaskets ... 3

4. Gasket pattern and dimension ... 4

5. Technical requirement ... 5

6. Marking and Packaging ... 7

1. Scope

This national standard specifies pattern, dimension, and technical requirement and

marking of metal jacketed gaskets for use with steel pipe flanges (PN designated).

This Standard is applicable to metal jacketed gaskets for use with steel pipe flange with

raised face in nominal pressure of PN25~PN100 specified in HG/T 20592.

Note. the use of the asbestos-contained material shall comply with requirements of relevant laws and regulations. When

the production and use are containing asbestos material gasket, protective measures shall be adopted, so as to ensure not

endanger the person health.

2. Normative references

The following standards contain provisions which, through reference in this text,

constitute provisions of this Standard. For dated reference, subsequent amendments

(excluding content of corrigenda) to, or revisions of, any of these publications do not apply.

However, Parties to agreements biased on this Code are encouraged to investigate the

possibility of applying the most recent editions of the standards indicated below. For undated

references, the latest edition of the normative document referred to applies.

"Metallic Materials--Bend Test" GB/T 232

"Hot-rolled Quality Carbon Structural Steel Sheets and Strips" GB/T 710

"Sheet of Copper and Copper Alloy" GB/T 2040

"Continuously Hot-dip Zinc-coated Steel Sheet and Strip" GB/T 2518

"Cold Rolled Stainless Steel Plate Sheet and Strip" GB/T 3280

"Wrought Aluminium and Aluminium Alloy Plates, sheets and Strips for General

Engineering" GB/T 3880

"Compressed Asbestos Fibre Jointing" GB/T 3985

"Metallic Envelope Gaskets for Pipe Flanges" GB/T 15601

"Steel Pipe Flanges (PN designed)" HG/T 20592

"Specification for selection of Steel Pipe Flanges, Gaskets and Bolting (PN designated)"

HG/T 20614

"Specifications of Flexible Graphite Sheets" JB/T 7758.2

3. Service conditions of the gaskets

3.0.1 The maximum operating temperature of the metal jacketed material shall be in

accordance with those specified in Table 3.0.1.

Table 4.0.1 Gasket Dimension (mm)

Nominal

dimension

DN

Nominal pressure

Gasket

thickness

PN25 PN40 PN63 PN100

Inside

diameterD1

Outside

diameterD2

Inside

diameter

D1

Outside

diameter

D2

Inside

diameter

D1

Outside

diameter

D2

Inside

diameter

D1

Outside

diameter

D2

10 28 46 28 46 28 56 28 56

15 33 51 33 51 33 61 33 61

20 45.5 61 45.5 61 43.5 72 45.5 72

25 54 71 54 71 54 82 54 82

32 61.5 82 61.5 82 61.5 88 61.5 88

40 68 92 68 92 68 103 68 103

50 77.5 107 77.5 107 77.5 113 77.5 119

65 97.5 127 97.5 127 97.5 138 97.5 144

80 109.5 142 109.5 142 109.5 148 109.5 154

100 131.5 168 131.5 168 131.5 174 131.5 180

125 156 194 156 194 156 210 156 217

150 183.5 224 183.5 224 183.5 247 183.5 257

200 237.5 284 244.5 290 244.5 309 244.5 324

250 293.5 340 303.5 352 303.5 364 303.5 391

300 353 400 368 417 368 424 368 458

350 407 457 422 474 422 486 422 512

400 458.5 514 488.5 546 488.5 543 488.5 572

450 503 564 508 571 - - - -

500 561 624 561 628 - - - -

600 665.5 731 680.5 747 - - - -

700 765.5 833 - - - - - -

800 875.5 942 - - - - - -

900 975.5 1042 - - - - - -

5. Technical requirement

5.0.1 The metallic material of the coating shall comply with the requirements of relevant

standards, and the hardness value shall be in accordance with those specified in Table 5.0.1.

6. Marking and Packaging

6.0.1 The gaskets shall be packed respectively according to the specifications and materials

and a conformity certificate of production quality test shall be attached at delivery. Each

gasket shall be labeled with the contents specified in Article 6.0.2.

6.0.2 Labeling content.

1 Standard No. (HG/T 20609)

2 Nominal dimension DN

3 Nominal pressure PN

4 Code name of the metallic material for clad (see the provisions in Table 3.0.1 of this

standard).

5 Filling material

6.0.3 Marking illustration.

Nominal dimension. DN500, nominal pressure. PN25, metal cladding material.

0Cr18Ni9, filling material. XB450 paronite metal jacketed gasket, it shall be labeled as. HG/T

20609 metal jacketed gasket 500-25 304/XB450

Share