1

/

of

7

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

HG/T 20611-2009 English PDF (HG/T20611-2009)

HG/T 20611-2009 English PDF (HG/T20611-2009)

Regular price

$75.00 USD

Regular price

Sale price

$75.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click HG/T 20611-2009

Historical versions: HG/T 20611-2009

Preview True-PDF (Reload/Scroll if blank)

HG/T 20611-2009: Covered serrated metal gaskets for use with steel pipe flanges (PN designated)

HG/T 20611-2009

Chemical Industry Standard

of the People's Republic of China

HG

Replacing HG 20611-1997

Covered Serrated Metal Gaskets for use with Steel

Pipe Flanges

(PN designated)

(PN系列)

ISSUED ON. FEBRUARY 5, 2009

IMPLEMENTED ON. JULY 1, 2009

Issued by. Ministry of Industry and Information Technology of the People's

Republic of China

Contents

1. Scope ... 3

2. Normative References ... 3

3. General Provisions ... 3

3.1 Type and Code Name ... 3

3.2 Nominal Pressure and Nominal Dimension ... 4

3.3 Usage of Gaskets ... 4

3.4 Materials ... 5

4. Dimension ... 5

5. Technical Requirements ... 8

6. Inspection ... 9

7. Labeling... 9

1. Scope

This standard specifies the type, dimension, technical requirements, labeling and

marking of covered serrated metal gaskets for steel pipe flanges (PN designated).

This standard is applicable to covered serrated metal gaskets for steel pipe flanges

specified in HG/T 20592 whose nominal pressure is PN16~PN160.

2. Normative References

The following standards contain provisions which, through reference in this text,

constitute provisions of this national standard. For dated reference, subsequent amendments

(excluding amending error in the text) to, or revisions of, any of these publications do not

apply. However, parties to agreement based on this standard are encouraged to research

whether the latest editions of these references are applied or not. For undated references, the

latest edition of the normative document is applicable to this national standard.

"Hot-rolled Plain Carbon and Low Alloy Structural Steel Sheets and Strips" GB/T 912

"Hot Rolled Stainless Steel Plate Sheets and Strips” GB/T 4237"Cold Rolled Stainless

Steel Plate Sheets and Strips” GB/T 3280

"Steel Pipe Flanges (PN designated)" HG/T 20592

“Specification for Selection of Steel Pipe Flanges, Gaskets and Bolting (PN designated)”

HG/T 20614

"Specification for Flexible Graphite Plates" TB/T 7758.2

"PTFE Sheers" QB/T 3625

3. General Provisions

3.1 Type and Code Name

The type, code name, section form and applicable flange sealing surface of gaskets shall meet

the provisions of Table 3.1.

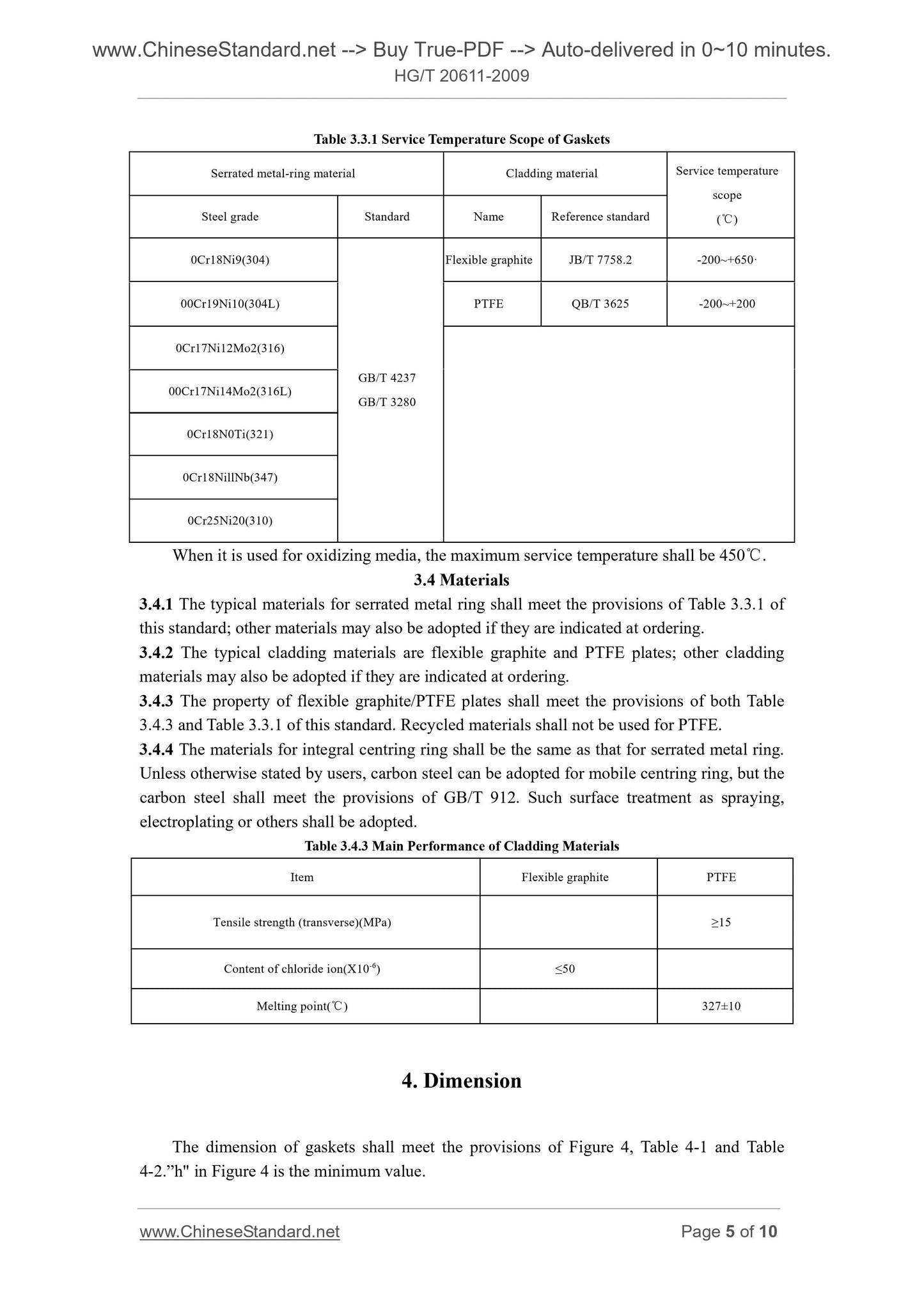

Table 3.3.1 Service Temperature Scope of Gaskets

Serrated metal-ring material Cladding material Service temperature

scope

( )℃ Steel grade Standard Name Reference standard

0Cr18Ni9(304)

GB/T 4237

GB/T 3280

Flexible graphite JB/T 7758.2 -200~+650·

00Cr19Ni10(304L) PTFE QB/T 3625 -200~+200

0Cr17Ni12Mo2(316)

00Cr17Ni14Mo2(316L)

0Cr18N0Ti(321)

0Cr18NillNb(347)

0Cr25Ni20(310)

When it is used for oxidizing media, the maximum service temperature shall be 450 . ℃

3.4 Materials

3.4.1 The typical materials for serrated metal ring shall meet the provisions of Table 3.3.1 of

this standard; other materials may also be adopted if they are indicated at ordering.

3.4.2 The typical cladding materials are flexible graphite and PTFE plates; other cladding

materials may also be adopted if they are indicated at ordering.

3.4.3 The property of flexible graphite/PTFE plates shall meet the provisions of both Table

3.4.3 and Table 3.3.1 of this standard. Recycled materials shall not be used for PTFE.

3.4.4 The materials for integral centring ring shall be the same as that for serrated metal ring.

Unless otherwise stated by users, carbon steel can be adopted for mobile centring ring, but the

carbon steel shall meet the provisions of GB/T 912. Such surface treatment as spraying,

electroplating or others shall be adopted.

Table 3.4.3 Main Performance of Cladding Materials

Item Flexible graphite PTFE

Tensile strength (transverse)(MPa) ≥15

Content of chloride ion(X10-6) ≤50

Melting point( )℃ 327±10

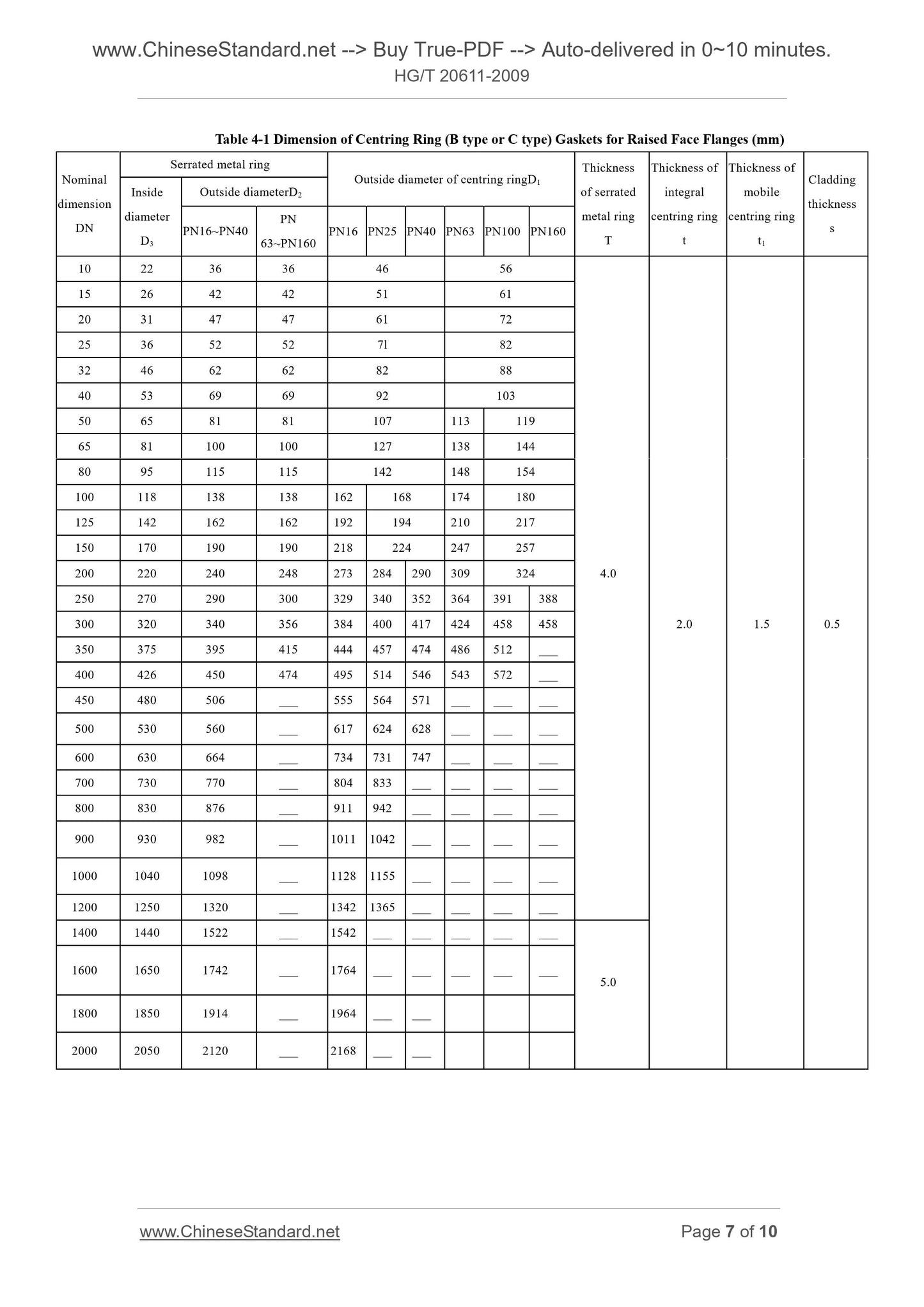

4. Dimension

The dimension of gaskets shall meet the provisions of Figure 4, Table 4-1 and Table

4-2.”h" in Figure 4 is the minimum value.

Table 4-1 Dimension of Centring Ring (B type or C type) Gaskets for Raised Face Flanges (mm)

Nominal

dimension

DN

Serrated metal ring

Outside diameter of centring ringD1

Thickness

of serrated

metal ring

Thickness of

integral

centring ring

Thickness of

mobile

centring ring

t1

Cladding

thickness

Inside

diameter

D3

Outside diameterD2

PN16~PN40 PN 63~PN160 PN16 PN25 PN40 PN63 PN100 PN160

10 22 36 36 46 56

15 26 42 42 51 61

20 31 47 47 61 72

25 36 52 52 7l 82

32 46 62 62 82 88

40 53 69 69 92 103

50 65 81 81 107 113 119

65 81 100 100 127 138 144

80 95 115 115 142 148 154

100 118 138 138 162 168 174 180

125 142 162 162 192 194 210 217

150 170 190 190 218 224 247 257

200 220 240 248 273 284 290 309 324 4.0

250 270 290 300 329 340 352 364 391 388

300 320 340 356 384 400 417 424 458 458 2.0 1.5 0.5

350 375 395 415 444 457 474 486 512 ___

400 426 450 474 495 514 546 543 572 ___

450 480 506 ___ 555 564 571 ___ ___ ___

500 530 560 ___ 617 624 628 ___ ___ ___

600 630 664 ___ 734 731 747 ___ ___ ___

700 730 770 ___ 804 833 ___ ___ ___ ___

800 830 876 ___ 911 942 ___ ___ ___ ___

900 930 982 ___ 1011 1042 ___ ___ ___ ___

1000 1040 1098 ___ 1128 1155 ___ ___ ___ ___

1200 1250 1320 ___ 1342 1365 ___ ___ ___ ___

1400 1440 1522 ___ 1542 ___ ___ ___ ___ ___

1600 1650 1742 ___ 1764 ___ ___ ___ ___ ___ 5.0

1800 1850 1914 ___ 1964 ___ ___

2000 2050 2120 ___ 2168 ___ ___

1 Generally, the serrated metal ring is integrally constructed. If weld structure is adopted,

the following requirements shall be complied with.

1) Get approval from the users;

2) Complete penetration type shall be adopted as welding seam structure; there shall

be no more than two soldered joints and stress-relief heat treatment shall be carried out

after welding;

3) Before covering the cladding, the serrated form and dimension of the weld part

shall be in accordance with other parts.

2 The planeness of serrated metal ring shall be no bigger than 1/100 of the outside

diameter of the gasket.

3 The cladding materials shall be fixed firmly on the serrated metal ring so that they

won't scale off during the transportation or assembly process. The adhesive used shall have no

corrosion to the metallic materials. There shall be no more than two scabbed joints, if

overlapping is adopted, the overlap section shall be connected through bias cutting; if abutting

is adopted, a thinner cladding material shall be covered at the seam crossing.

4 There shall be proper clearance between the centering groove between the mobile

centering ring and serrated metal ring so that when it expands at heating, it will not disturb

movement. Welding method may be adopted for mobile centering ring.

5.0.4 Performance

The performance of gaskets shall meet the relevant provisions specified by users.

6. Inspection

6.0.1 The material, dimension, appearance and manufacture of gaskets shall be compliant to

the provisions of this standard.

6.0.2 Other inspection requirements may be determined through negotiating with the

producers at ordering.

7. Labeling

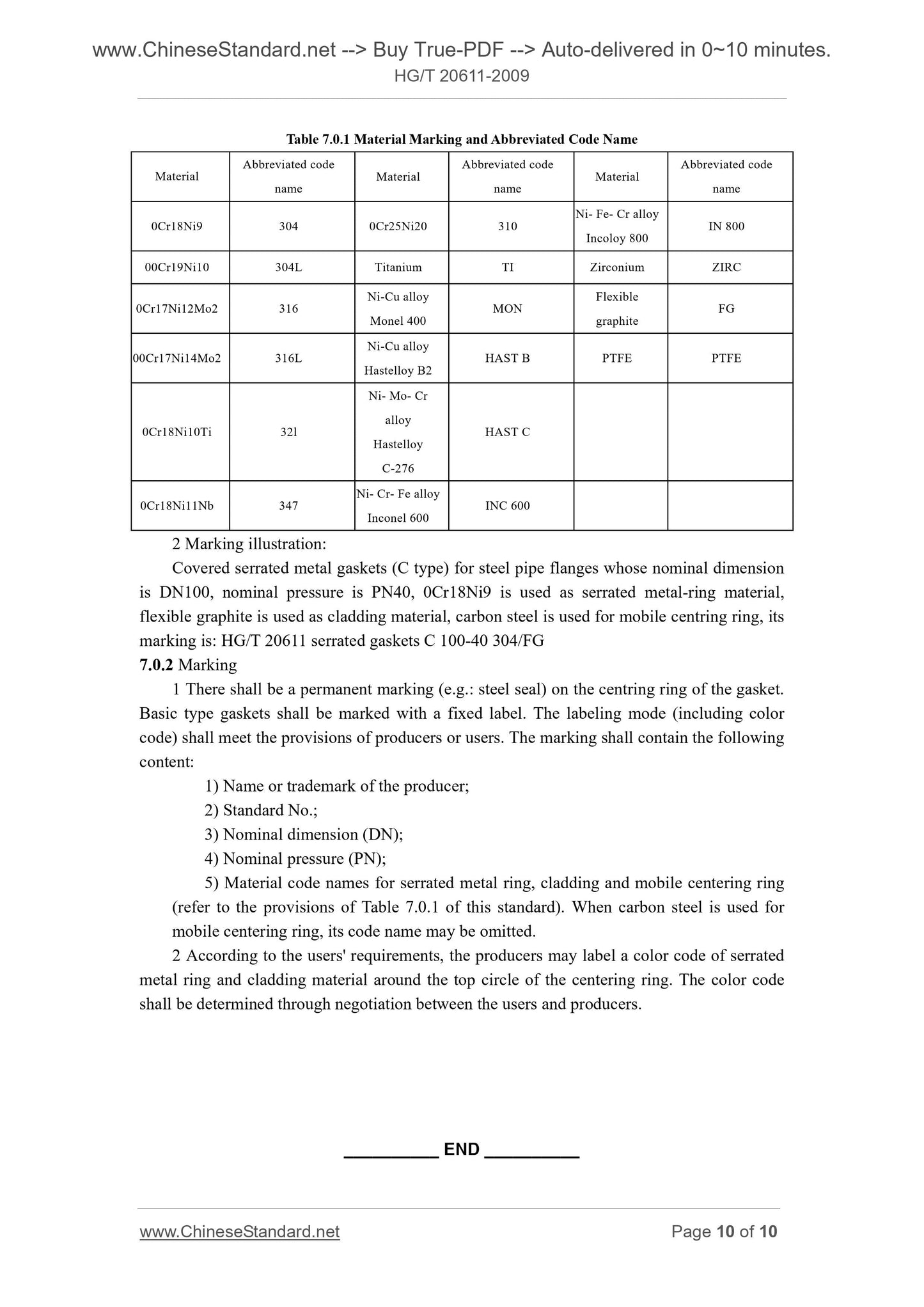

7.0.1 Labeling and illustration

1 The gasket shall be labeled according to the following provisions.

1) Standard name;

2) Gasket type (refer to the provisions of Table 3.1 of this standard);

3) Nominal dimension (DN);

4) Nominal pressure (PN);

5) Material code names for serrated metal ring, cladding and mobile centering ring

(refer to the provisions of Table 7.0.1). When carbon steel...

Get QUOTATION in 1-minute: Click HG/T 20611-2009

Historical versions: HG/T 20611-2009

Preview True-PDF (Reload/Scroll if blank)

HG/T 20611-2009: Covered serrated metal gaskets for use with steel pipe flanges (PN designated)

HG/T 20611-2009

Chemical Industry Standard

of the People's Republic of China

HG

Replacing HG 20611-1997

Covered Serrated Metal Gaskets for use with Steel

Pipe Flanges

(PN designated)

(PN系列)

ISSUED ON. FEBRUARY 5, 2009

IMPLEMENTED ON. JULY 1, 2009

Issued by. Ministry of Industry and Information Technology of the People's

Republic of China

Contents

1. Scope ... 3

2. Normative References ... 3

3. General Provisions ... 3

3.1 Type and Code Name ... 3

3.2 Nominal Pressure and Nominal Dimension ... 4

3.3 Usage of Gaskets ... 4

3.4 Materials ... 5

4. Dimension ... 5

5. Technical Requirements ... 8

6. Inspection ... 9

7. Labeling... 9

1. Scope

This standard specifies the type, dimension, technical requirements, labeling and

marking of covered serrated metal gaskets for steel pipe flanges (PN designated).

This standard is applicable to covered serrated metal gaskets for steel pipe flanges

specified in HG/T 20592 whose nominal pressure is PN16~PN160.

2. Normative References

The following standards contain provisions which, through reference in this text,

constitute provisions of this national standard. For dated reference, subsequent amendments

(excluding amending error in the text) to, or revisions of, any of these publications do not

apply. However, parties to agreement based on this standard are encouraged to research

whether the latest editions of these references are applied or not. For undated references, the

latest edition of the normative document is applicable to this national standard.

"Hot-rolled Plain Carbon and Low Alloy Structural Steel Sheets and Strips" GB/T 912

"Hot Rolled Stainless Steel Plate Sheets and Strips” GB/T 4237"Cold Rolled Stainless

Steel Plate Sheets and Strips” GB/T 3280

"Steel Pipe Flanges (PN designated)" HG/T 20592

“Specification for Selection of Steel Pipe Flanges, Gaskets and Bolting (PN designated)”

HG/T 20614

"Specification for Flexible Graphite Plates" TB/T 7758.2

"PTFE Sheers" QB/T 3625

3. General Provisions

3.1 Type and Code Name

The type, code name, section form and applicable flange sealing surface of gaskets shall meet

the provisions of Table 3.1.

Table 3.3.1 Service Temperature Scope of Gaskets

Serrated metal-ring material Cladding material Service temperature

scope

( )℃ Steel grade Standard Name Reference standard

0Cr18Ni9(304)

GB/T 4237

GB/T 3280

Flexible graphite JB/T 7758.2 -200~+650·

00Cr19Ni10(304L) PTFE QB/T 3625 -200~+200

0Cr17Ni12Mo2(316)

00Cr17Ni14Mo2(316L)

0Cr18N0Ti(321)

0Cr18NillNb(347)

0Cr25Ni20(310)

When it is used for oxidizing media, the maximum service temperature shall be 450 . ℃

3.4 Materials

3.4.1 The typical materials for serrated metal ring shall meet the provisions of Table 3.3.1 of

this standard; other materials may also be adopted if they are indicated at ordering.

3.4.2 The typical cladding materials are flexible graphite and PTFE plates; other cladding

materials may also be adopted if they are indicated at ordering.

3.4.3 The property of flexible graphite/PTFE plates shall meet the provisions of both Table

3.4.3 and Table 3.3.1 of this standard. Recycled materials shall not be used for PTFE.

3.4.4 The materials for integral centring ring shall be the same as that for serrated metal ring.

Unless otherwise stated by users, carbon steel can be adopted for mobile centring ring, but the

carbon steel shall meet the provisions of GB/T 912. Such surface treatment as spraying,

electroplating or others shall be adopted.

Table 3.4.3 Main Performance of Cladding Materials

Item Flexible graphite PTFE

Tensile strength (transverse)(MPa) ≥15

Content of chloride ion(X10-6) ≤50

Melting point( )℃ 327±10

4. Dimension

The dimension of gaskets shall meet the provisions of Figure 4, Table 4-1 and Table

4-2.”h" in Figure 4 is the minimum value.

Table 4-1 Dimension of Centring Ring (B type or C type) Gaskets for Raised Face Flanges (mm)

Nominal

dimension

DN

Serrated metal ring

Outside diameter of centring ringD1

Thickness

of serrated

metal ring

Thickness of

integral

centring ring

Thickness of

mobile

centring ring

t1

Cladding

thickness

Inside

diameter

D3

Outside diameterD2

PN16~PN40 PN 63~PN160 PN16 PN25 PN40 PN63 PN100 PN160

10 22 36 36 46 56

15 26 42 42 51 61

20 31 47 47 61 72

25 36 52 52 7l 82

32 46 62 62 82 88

40 53 69 69 92 103

50 65 81 81 107 113 119

65 81 100 100 127 138 144

80 95 115 115 142 148 154

100 118 138 138 162 168 174 180

125 142 162 162 192 194 210 217

150 170 190 190 218 224 247 257

200 220 240 248 273 284 290 309 324 4.0

250 270 290 300 329 340 352 364 391 388

300 320 340 356 384 400 417 424 458 458 2.0 1.5 0.5

350 375 395 415 444 457 474 486 512 ___

400 426 450 474 495 514 546 543 572 ___

450 480 506 ___ 555 564 571 ___ ___ ___

500 530 560 ___ 617 624 628 ___ ___ ___

600 630 664 ___ 734 731 747 ___ ___ ___

700 730 770 ___ 804 833 ___ ___ ___ ___

800 830 876 ___ 911 942 ___ ___ ___ ___

900 930 982 ___ 1011 1042 ___ ___ ___ ___

1000 1040 1098 ___ 1128 1155 ___ ___ ___ ___

1200 1250 1320 ___ 1342 1365 ___ ___ ___ ___

1400 1440 1522 ___ 1542 ___ ___ ___ ___ ___

1600 1650 1742 ___ 1764 ___ ___ ___ ___ ___ 5.0

1800 1850 1914 ___ 1964 ___ ___

2000 2050 2120 ___ 2168 ___ ___

1 Generally, the serrated metal ring is integrally constructed. If weld structure is adopted,

the following requirements shall be complied with.

1) Get approval from the users;

2) Complete penetration type shall be adopted as welding seam structure; there shall

be no more than two soldered joints and stress-relief heat treatment shall be carried out

after welding;

3) Before covering the cladding, the serrated form and dimension of the weld part

shall be in accordance with other parts.

2 The planeness of serrated metal ring shall be no bigger than 1/100 of the outside

diameter of the gasket.

3 The cladding materials shall be fixed firmly on the serrated metal ring so that they

won't scale off during the transportation or assembly process. The adhesive used shall have no

corrosion to the metallic materials. There shall be no more than two scabbed joints, if

overlapping is adopted, the overlap section shall be connected through bias cutting; if abutting

is adopted, a thinner cladding material shall be covered at the seam crossing.

4 There shall be proper clearance between the centering groove between the mobile

centering ring and serrated metal ring so that when it expands at heating, it will not disturb

movement. Welding method may be adopted for mobile centering ring.

5.0.4 Performance

The performance of gaskets shall meet the relevant provisions specified by users.

6. Inspection

6.0.1 The material, dimension, appearance and manufacture of gaskets shall be compliant to

the provisions of this standard.

6.0.2 Other inspection requirements may be determined through negotiating with the

producers at ordering.

7. Labeling

7.0.1 Labeling and illustration

1 The gasket shall be labeled according to the following provisions.

1) Standard name;

2) Gasket type (refer to the provisions of Table 3.1 of this standard);

3) Nominal dimension (DN);

4) Nominal pressure (PN);

5) Material code names for serrated metal ring, cladding and mobile centering ring

(refer to the provisions of Table 7.0.1). When carbon steel...

Share