1

/

of

12

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

HG/T 20614-2009 English PDF (HGT20614-2009)

HG/T 20614-2009 English PDF (HGT20614-2009)

Regular price

$85.00 USD

Regular price

Sale price

$85.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click HG/T 20614-2009

Historical versions: HG/T 20614-2009

Preview True-PDF (Reload/Scroll if blank)

HG/T 20614-2009: Specification for ion of steel pipe flanges, gaskets and bolting (PN designated)

HG/T 20614-2009

Chemical Industry Standard

of the People's Republic of China

HG

Replacing HG 20614-1997

Specification for Selection of Steel Pipe Flanges,

Gaskets and Bolting

(PN designated)

(PN 系列)

ISSUED ON. FEBRUARY 5, 2009

IMPLEMENTED ON. JULY 1, 2009

Issued by. Ministry of Industry and Information Technology of the People's

Republic of China

[Including Corrigendum/Modification confirmed in May 2012. Text in RED]

Contents

2. Normative References ... 3

3. Selection Specification ... 3

Appendix A (Informative) Operating Instructions of the Pipe Flange for Gaskets ... 13

1. Scope

This standard specifies the general rules for selection of the steel pipe flange, gaskets and

bolting (PN designated).

This standard is applicable to the steel pipe flange, gaskets and bolting which are

specified in the HG/T 20592 - HG/T 20613.

2. Normative References

The following provisions contained in the following standards are turned into the

provisions of this national standard by being referred in this national standard. For date

reference, the subsequent amendments to (excluding amending error in the text) or revisions

of, any of these publications do not apply. And parties to agreements based on this standard

are encouraged to investigate the possibility of applying the most recent editions of the

standards indicated below. For undated references, its latest edition referred to applies.

HG/T 20592 "Steel Pipe Flanges (PN Designated)"

HG/T 20606 "Non-metallic Flat Gaskets for use with Steel Pipe Flanges (PN

designated)"

HG/T 20607 "PTFE Envelope Gaskets for use with Steel Pipe Flanges (PN designated)"

HG/T 20609 "Metal Jacketed Gaskets for use with Steel Pipe Flanges (PN designated)"

HG/T 20610 "Spiral Wound Gaskets for use with Steel Pipe Flanges (PN designated"

HG/T 20611 "Covered Serrated Metal Gaskets for use with Steel Pipe Flanges (PN

designated)"

HG/T 20612 "Metallic Ring Joint Gaskets for use with Steel Pipe Flanges (PN

designated)"

HG/T 20613 "Bolting for use with Steel Pipe Flanges (PN designated)"

3. Selection Specification

3.0.1 Pipe Flange

1 Type and application range of the flange shall meet the requirements of the Table 3.1.4

in HG/T 20592.

2 Type and application range of the sealing surface of the flange shall meet the

requirements of Table 3.2.2 in HG/T 20592.

3 Materials for flange shall meet the requirements of Chapter 4 in HG/T 20592. As for

the forging, casting or plates for other pressure-bearing equipments, if its composition and

performance are not lower than those of the materials which are listed in Table 4.0.1 of HG/T

20592, the aforesaid ones may be used for the preparation of the flange. The maximum

allowable working pressure of the flange shall meet the requirements of the corresponding

materials which are listed in the table.

4 The maximum allowable working pressure (gauge pressure) of the flange under the

working temperature shall meet the requirements of Table 7.0.1-1 - Table 7.0.1-9 in HG/T

20592.

5 When the two flanges of the flanged joint are of different pressure-temperature rating,

the rated value of the flanged joint shall not exceed the lower one of the two.

6 Under the severe cyclic working condition, weld neck flange or integral type flange

3.0.2 Gasket

1 Type and application range of the gasket shall meet the requirements of HG/T 20606 -

HG/T 20612.

2 Type and material of gasket shall be selected according to such requirements as fluid,

working condition (pressure and temperature) as well as sealing condition of the flanged joint.

The type of the sealing surface of the flange and the surface roughness shall be correspondent

with the type and material of the gasket.

3 Seal load of the gasket shall be correspondent with such requirements as rated value of

the flange, sealing surface type, service temperature and sealing requirements of the joint.

And the material, strength as well as tightening of the bolting shall be correspondent with

such requirements as type and material of the gasket as well as sealing condition of the

flanged joint.

4 PTFE envelope gaskets shall not be used in such places that it is vacuum or the

materials for its embedding layer is easy to be corrosive. Generally, PMF type is used for it is

useful to reduce the hold-up liquid in the pipe. PFT type is used for that the nominal

dimension is larger than or equal to DN350.

5 When asbestos or flexible graphite gasket are used for the stainless steel flange and

nickel base alloy flange, content of chloride ion of the gasket material shall not

exceed50×10-6.

6 When expanded graphite material is used for the oxidative medium, maximum service

temperature shall not exceed 450 . ℃

7 Asbestos and non asbestos gasket shall not be used for the utmost or high hazardous

medium and high vacuum seal condition.

8 As PTFE flat gasket which is of the tendency to cold flow, flat face, male-female face

or tongue and groove face should be adopted for its sealing surface type.

9 As for the flange that its nominal pressure is less than or equal to PN16, such rigid

flange structural type as weld neck flange shall be adopted when such semimetal gasket or

metal ring gasket as spiral-wound gasket and metal cladding gasket are adopted.

10 The internal diameter of the nonmetallic flat gaskets and internal ring of the wound

gasket may be possibly larger than the internal diameter of the corresponding flange. If the

aforesaid internal diameter of the gasket (or internal ring) shall be flush with the internal

diameter of the flange, the following requirements shall be proposed by the user.

1) Integral type flange, welding neck flange or socket welding flange shall be

adopted;

2) The corresponding internal diameter of the flange shall be supplied as the internal

diameter of the gasket to the gasket manufactory.

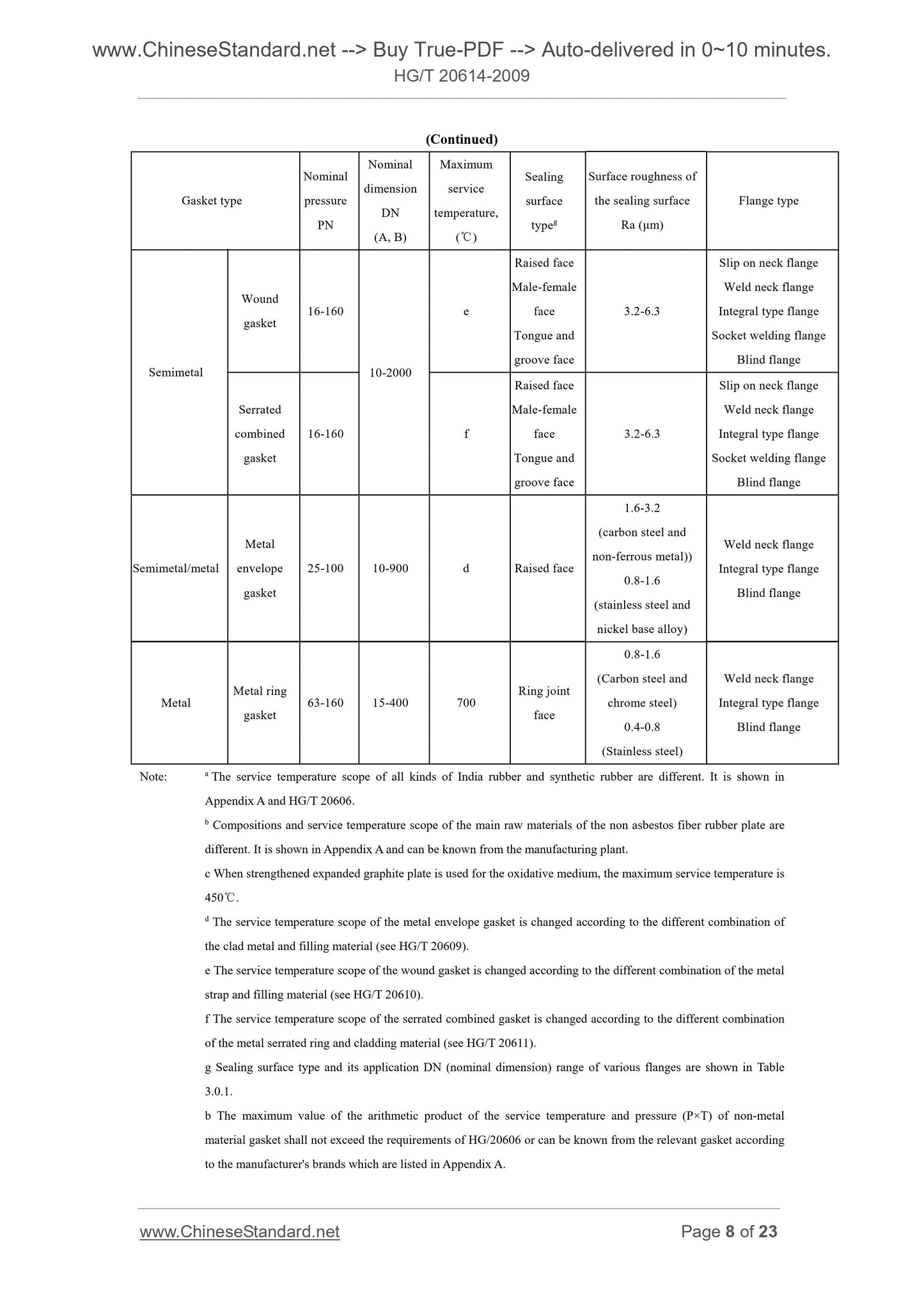

11 Selection of the gasket type is listed in Table 3.0.2.

(Continued)

Gasket type

Nominal

pressure

PN

Nominal

dimension

DN

(A, B)

Maximum

service

temperature,

( )℃

Sealing

surface

typeg

Surface roughness of

the sealing surface

Ra (μm)

Flange type

Semimetal

Wound

gasket 16-160

10-2000

Raised face

Male-female

face

Tongue and

groove face

3.2-6.3

Slip on neck flange

Weld neck flange

Integral type flange

Socket welding flange

Blind flange

Serrated

combined

gasket

16-160 f

Raised face

Male-female

face

Tongue and

groove face

3.2-6.3

Slip on neck flange

Weld neck flange

Integral type flange

Socket welding flange

Blind flange

Semimetal/metal

Metal

envelope

gasket

25-100 10-900 d Raised face

1.6-3.2

(carbon steel and

non-ferrous metal))

0.8-1.6

(stainless steel and

nickel base alloy)

Weld neck flange

Integral type flange

Blind flange

Metal Metal ring gasket 63-160 15-400 700

Ring joint

face

0.8-1.6

(Carbon steel and

chrome steel)

0.4-0.8

(Stainless steel)

Weld neck flange

Integral type flange

Blind flange

Note. a The service temperature scope of all kinds of India rubber and synthetic rubber are different. It is shown in

Appendix A and HG/T 20606.

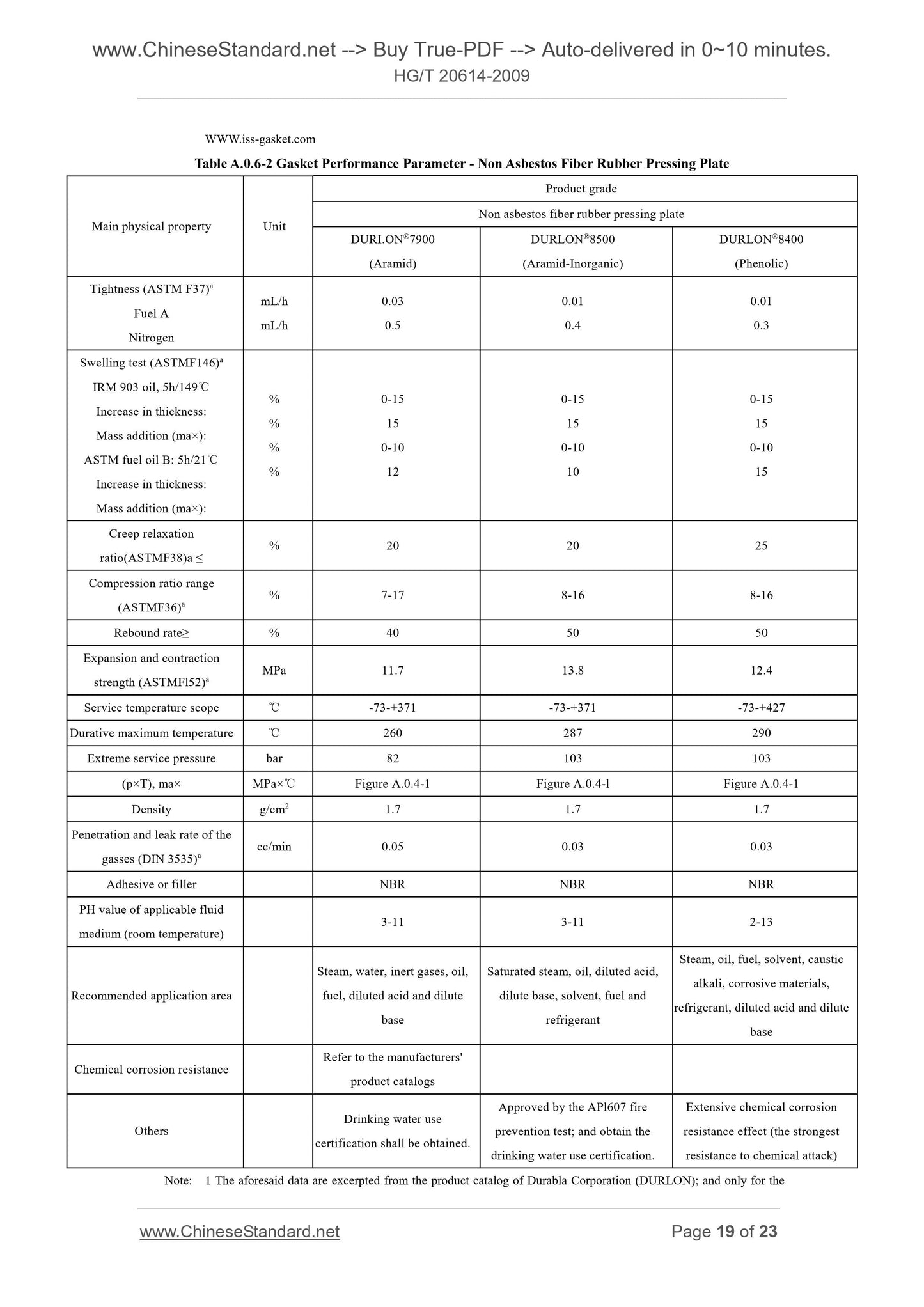

b Compositions and service temperature scope of the main raw materials of the non asbestos fiber rubber plate are

different. It is shown in Appendix A and can be known from the manufactur...

Get QUOTATION in 1-minute: Click HG/T 20614-2009

Historical versions: HG/T 20614-2009

Preview True-PDF (Reload/Scroll if blank)

HG/T 20614-2009: Specification for ion of steel pipe flanges, gaskets and bolting (PN designated)

HG/T 20614-2009

Chemical Industry Standard

of the People's Republic of China

HG

Replacing HG 20614-1997

Specification for Selection of Steel Pipe Flanges,

Gaskets and Bolting

(PN designated)

(PN 系列)

ISSUED ON. FEBRUARY 5, 2009

IMPLEMENTED ON. JULY 1, 2009

Issued by. Ministry of Industry and Information Technology of the People's

Republic of China

[Including Corrigendum/Modification confirmed in May 2012. Text in RED]

Contents

2. Normative References ... 3

3. Selection Specification ... 3

Appendix A (Informative) Operating Instructions of the Pipe Flange for Gaskets ... 13

1. Scope

This standard specifies the general rules for selection of the steel pipe flange, gaskets and

bolting (PN designated).

This standard is applicable to the steel pipe flange, gaskets and bolting which are

specified in the HG/T 20592 - HG/T 20613.

2. Normative References

The following provisions contained in the following standards are turned into the

provisions of this national standard by being referred in this national standard. For date

reference, the subsequent amendments to (excluding amending error in the text) or revisions

of, any of these publications do not apply. And parties to agreements based on this standard

are encouraged to investigate the possibility of applying the most recent editions of the

standards indicated below. For undated references, its latest edition referred to applies.

HG/T 20592 "Steel Pipe Flanges (PN Designated)"

HG/T 20606 "Non-metallic Flat Gaskets for use with Steel Pipe Flanges (PN

designated)"

HG/T 20607 "PTFE Envelope Gaskets for use with Steel Pipe Flanges (PN designated)"

HG/T 20609 "Metal Jacketed Gaskets for use with Steel Pipe Flanges (PN designated)"

HG/T 20610 "Spiral Wound Gaskets for use with Steel Pipe Flanges (PN designated"

HG/T 20611 "Covered Serrated Metal Gaskets for use with Steel Pipe Flanges (PN

designated)"

HG/T 20612 "Metallic Ring Joint Gaskets for use with Steel Pipe Flanges (PN

designated)"

HG/T 20613 "Bolting for use with Steel Pipe Flanges (PN designated)"

3. Selection Specification

3.0.1 Pipe Flange

1 Type and application range of the flange shall meet the requirements of the Table 3.1.4

in HG/T 20592.

2 Type and application range of the sealing surface of the flange shall meet the

requirements of Table 3.2.2 in HG/T 20592.

3 Materials for flange shall meet the requirements of Chapter 4 in HG/T 20592. As for

the forging, casting or plates for other pressure-bearing equipments, if its composition and

performance are not lower than those of the materials which are listed in Table 4.0.1 of HG/T

20592, the aforesaid ones may be used for the preparation of the flange. The maximum

allowable working pressure of the flange shall meet the requirements of the corresponding

materials which are listed in the table.

4 The maximum allowable working pressure (gauge pressure) of the flange under the

working temperature shall meet the requirements of Table 7.0.1-1 - Table 7.0.1-9 in HG/T

20592.

5 When the two flanges of the flanged joint are of different pressure-temperature rating,

the rated value of the flanged joint shall not exceed the lower one of the two.

6 Under the severe cyclic working condition, weld neck flange or integral type flange

3.0.2 Gasket

1 Type and application range of the gasket shall meet the requirements of HG/T 20606 -

HG/T 20612.

2 Type and material of gasket shall be selected according to such requirements as fluid,

working condition (pressure and temperature) as well as sealing condition of the flanged joint.

The type of the sealing surface of the flange and the surface roughness shall be correspondent

with the type and material of the gasket.

3 Seal load of the gasket shall be correspondent with such requirements as rated value of

the flange, sealing surface type, service temperature and sealing requirements of the joint.

And the material, strength as well as tightening of the bolting shall be correspondent with

such requirements as type and material of the gasket as well as sealing condition of the

flanged joint.

4 PTFE envelope gaskets shall not be used in such places that it is vacuum or the

materials for its embedding layer is easy to be corrosive. Generally, PMF type is used for it is

useful to reduce the hold-up liquid in the pipe. PFT type is used for that the nominal

dimension is larger than or equal to DN350.

5 When asbestos or flexible graphite gasket are used for the stainless steel flange and

nickel base alloy flange, content of chloride ion of the gasket material shall not

exceed50×10-6.

6 When expanded graphite material is used for the oxidative medium, maximum service

temperature shall not exceed 450 . ℃

7 Asbestos and non asbestos gasket shall not be used for the utmost or high hazardous

medium and high vacuum seal condition.

8 As PTFE flat gasket which is of the tendency to cold flow, flat face, male-female face

or tongue and groove face should be adopted for its sealing surface type.

9 As for the flange that its nominal pressure is less than or equal to PN16, such rigid

flange structural type as weld neck flange shall be adopted when such semimetal gasket or

metal ring gasket as spiral-wound gasket and metal cladding gasket are adopted.

10 The internal diameter of the nonmetallic flat gaskets and internal ring of the wound

gasket may be possibly larger than the internal diameter of the corresponding flange. If the

aforesaid internal diameter of the gasket (or internal ring) shall be flush with the internal

diameter of the flange, the following requirements shall be proposed by the user.

1) Integral type flange, welding neck flange or socket welding flange shall be

adopted;

2) The corresponding internal diameter of the flange shall be supplied as the internal

diameter of the gasket to the gasket manufactory.

11 Selection of the gasket type is listed in Table 3.0.2.

(Continued)

Gasket type

Nominal

pressure

PN

Nominal

dimension

DN

(A, B)

Maximum

service

temperature,

( )℃

Sealing

surface

typeg

Surface roughness of

the sealing surface

Ra (μm)

Flange type

Semimetal

Wound

gasket 16-160

10-2000

Raised face

Male-female

face

Tongue and

groove face

3.2-6.3

Slip on neck flange

Weld neck flange

Integral type flange

Socket welding flange

Blind flange

Serrated

combined

gasket

16-160 f

Raised face

Male-female

face

Tongue and

groove face

3.2-6.3

Slip on neck flange

Weld neck flange

Integral type flange

Socket welding flange

Blind flange

Semimetal/metal

Metal

envelope

gasket

25-100 10-900 d Raised face

1.6-3.2

(carbon steel and

non-ferrous metal))

0.8-1.6

(stainless steel and

nickel base alloy)

Weld neck flange

Integral type flange

Blind flange

Metal Metal ring gasket 63-160 15-400 700

Ring joint

face

0.8-1.6

(Carbon steel and

chrome steel)

0.4-0.8

(Stainless steel)

Weld neck flange

Integral type flange

Blind flange

Note. a The service temperature scope of all kinds of India rubber and synthetic rubber are different. It is shown in

Appendix A and HG/T 20606.

b Compositions and service temperature scope of the main raw materials of the non asbestos fiber rubber plate are

different. It is shown in Appendix A and can be known from the manufactur...

Share