1

/

of

9

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

HG/T 20627-2009 English PDF (HGT20627-2009)

HG/T 20627-2009 English PDF (HGT20627-2009)

Regular price

$85.00 USD

Regular price

Sale price

$85.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click HG/T 20627-2009

Historical versions: HG/T 20627-2009

Preview True-PDF (Reload/Scroll if blank)

HG/T 20627-2009: Non-metallic flat gaskets for use with steel pipe flanges (Class designated)

HG/T 20627-2009

Chemical Industry Standard

of the People's Republic of China

HG

Replacing HG 20627-1997, HG 20629-1997

Non-metallic Flat Gaskets for Use with Steel Pipe Flanges

(Class Designated)

(Class)系列

ISSUED ON. FEBRUARY 5, 2009

IMPLEMENTED ON. JULY 1, 2009

Issued by. Ministry of Industry and Information Technology of the People’s

Republic of China

Contents

1. Scope ... 3

2. Normative references ... 3

3. Material and working conditions ... 3

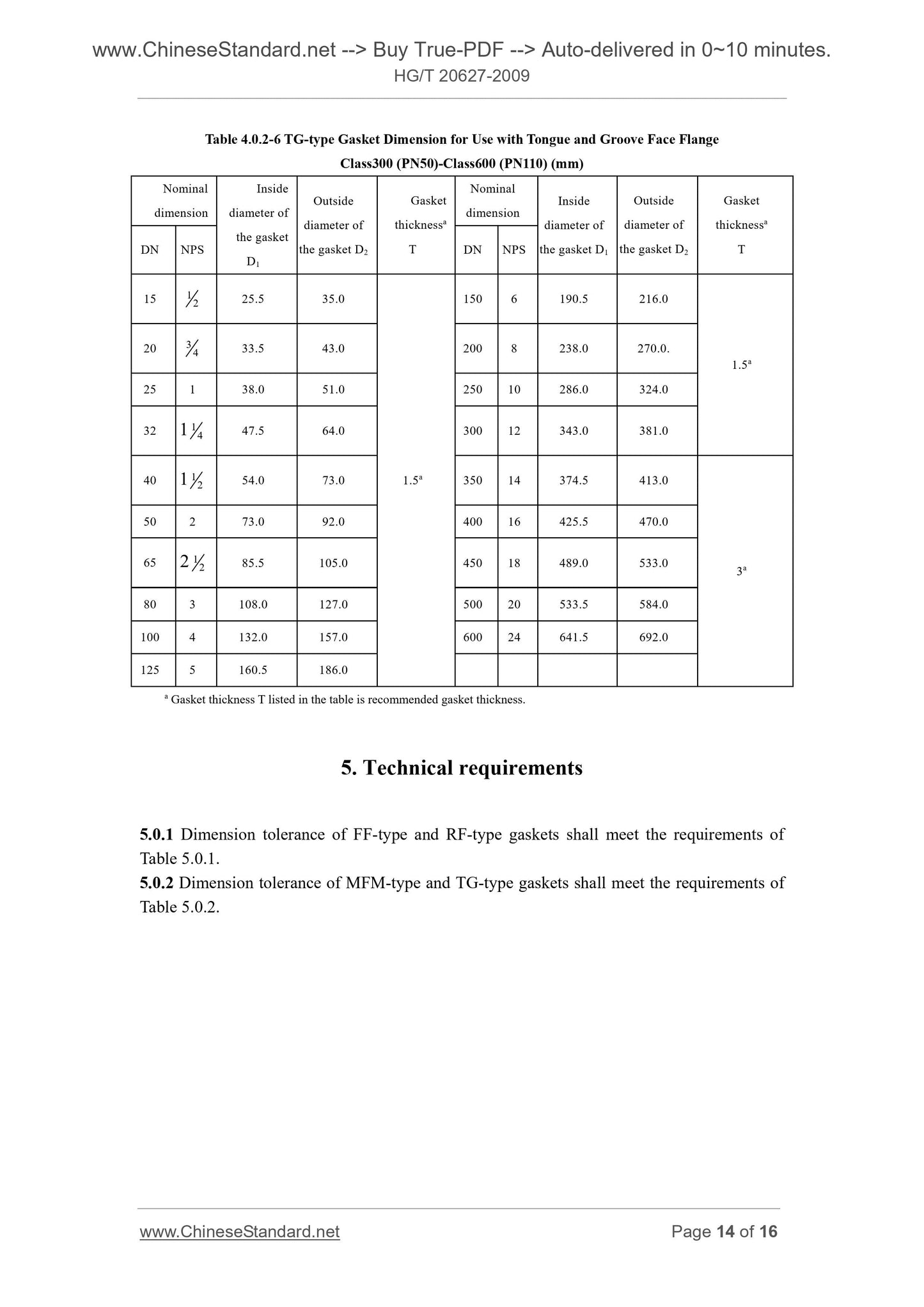

4. Gasket type and dimension ... 6

5. Technical requirements ... 14

6. Marking illustration ... 15

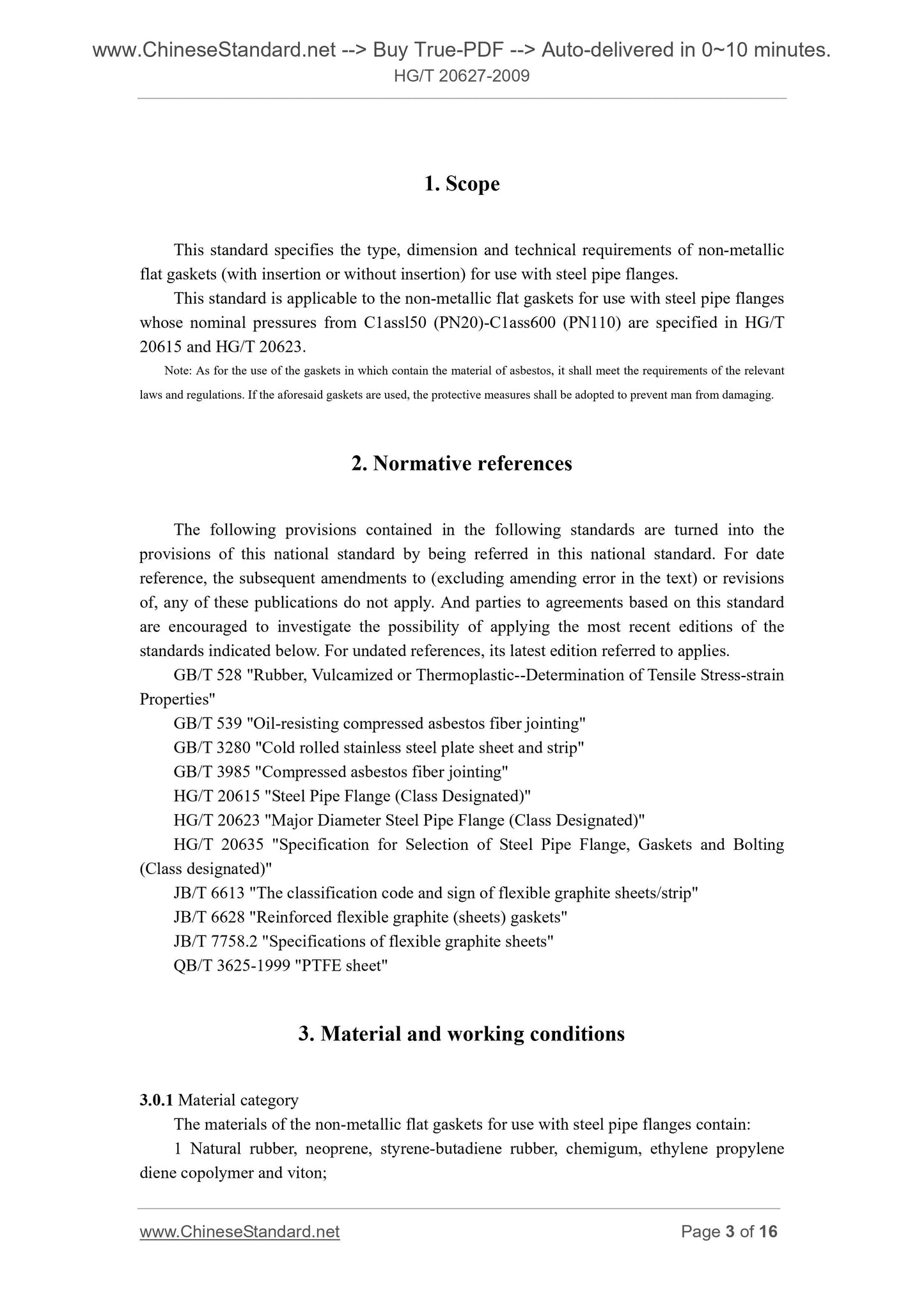

1. Scope

This standard specifies the type, dimension and technical requirements of non-metallic

flat gaskets (with insertion or without insertion) for use with steel pipe flanges.

This standard is applicable to the non-metallic flat gaskets for use with steel pipe flanges

whose nominal pressures from C1assl50 (PN20)-C1ass600 (PN110) are specified in HG/T

20615 and HG/T 20623.

Note. As for the use of the gaskets in which contain the material of asbestos, it shall meet the requirements of the relevant

laws and regulations. If the aforesaid gaskets are used, the protective measures shall be adopted to prevent man from damaging.

2. Normative references

The following provisions contained in the following standards are turned into the

provisions of this national standard by being referred in this national standard. For date

reference, the subsequent amendments to (excluding amending error in the text) or revisions

of, any of these publications do not apply. And parties to agreements based on this standard

are encouraged to investigate the possibility of applying the most recent editions of the

standards indicated below. For undated references, its latest edition referred to applies.

GB/T 528 "Rubber, Vulcamized or Thermoplastic--Determination of Tensile Stress-strain

Properties"

GB/T 539 "Oil-resisting compressed asbestos fiber jointing"

GB/T 3280 "Cold rolled stainless steel plate sheet and strip"

GB/T 3985 "Compressed asbestos fiber jointing"

HG/T 20615 "Steel Pipe Flange (Class Designated)"

HG/T 20623 "Major Diameter Steel Pipe Flange (Class Designated)"

HG/T 20635 "Specification for Selection of Steel Pipe Flange, Gaskets and Bolting

(Class designated)"

JB/T 6613 "The classification code and sign of flexible graphite sheets/strip"

JB/T 6628 "Reinforced flexible graphite (sheets) gaskets"

JB/T 7758.2 "Specifications of flexible graphite sheets"

QB/T 3625-1999 "PTFE sheet"

3. Material and working conditions

3.0.1 Material category

The materials of the non-metallic flat gaskets for use with steel pipe flanges contain.

1 Natural rubber, neoprene, styrene-butadiene rubber, chemigum, ethylene propylene

diene copolymer and viton;

manufacturer's brand shall be indicated. The applicable pressure, temperature and maximum

(P×T) value of the gaskets shall be determined according to the working condition.

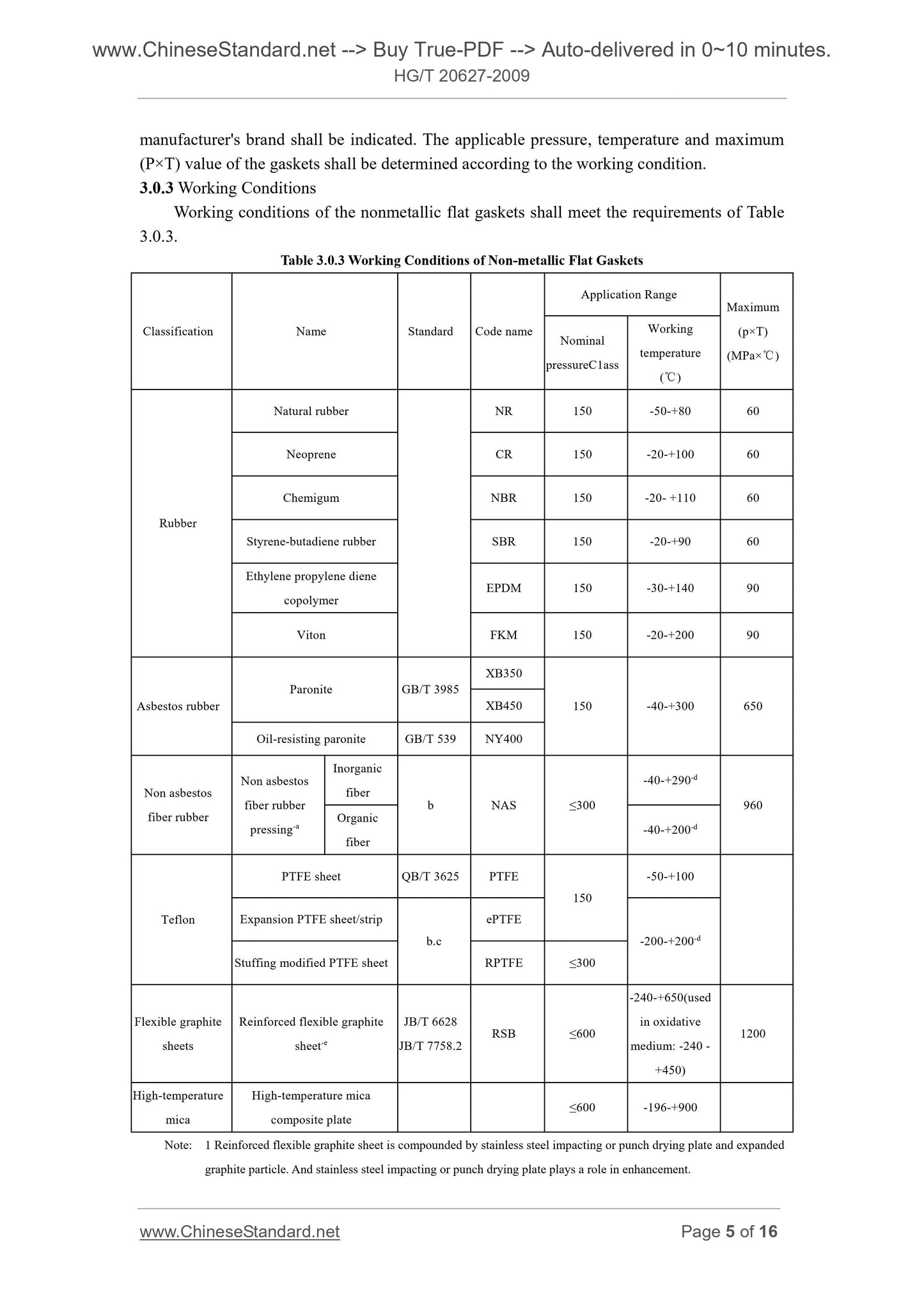

3.0.3 Working Conditions

Working conditions of the nonmetallic flat gaskets shall meet the requirements of Table

3.0.3.

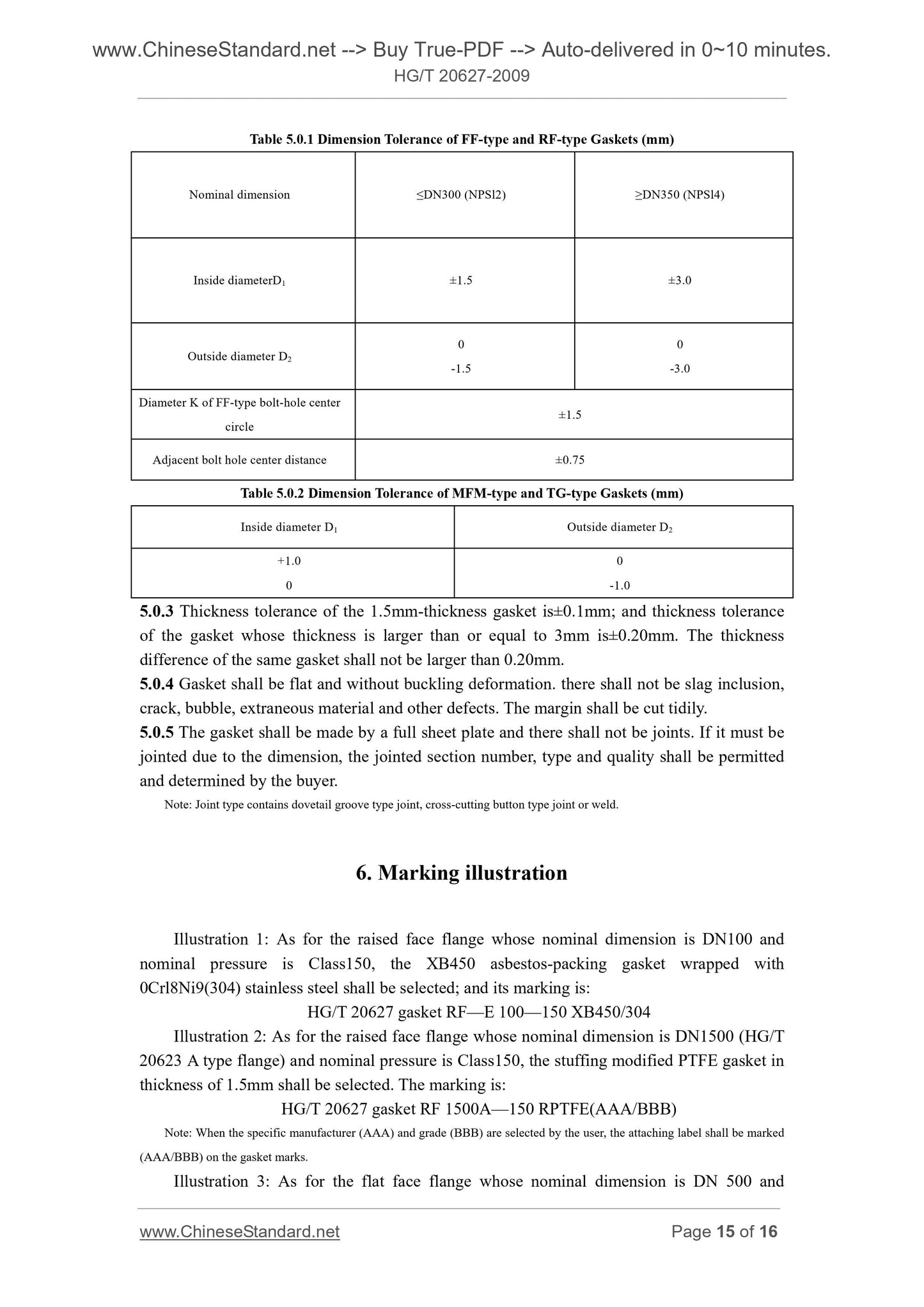

Table 3.0.3 Working Conditions of Non-metallic Flat Gaskets

Classification Name Standard Code name

Application Range

Maximum

(p×T)

(MPa×℃)

Nominal

pressureC1ass

Working

temperature

(℃)

Rubber

Natural rubber

NR 150 -50-+80 60

Neoprene CR 150 -20-+100 60

Chemigum NBR 150 -20- +110 60

Styrene-butadiene rubber SBR 150 -20-+90 60

Ethylene propylene diene

copolymer EPDM 150 -30-+140 90

Viton FKM 150 -20-+200 90

Asbestos rubber

Paronite GB/T 3985

XB350

150 -40-+300 650 XB450

Oil-resisting paronite GB/T 539 NY400

Non asbestos

fiber rubber

Non asbestos

fiber rubber

pressing-a

Inorganic

fiber

b NAS ≤300

-40-+290-d

Organic

fiber -40-+200

-d

Teflon

PTFE sheet QB/T 3625 PTFE

-50-+100

Expansion PTFE sheet/strip

b.c

ePTFE

-200-+200-d

Stuffing modified PTFE sheet RPTFE ≤300

Flexible graphite

sheets

Reinforced flexible graphite

sheet-e

JB/T 6628

JB/T 7758.2 RSB ≤600

-240-+650(used

in oxidative

medium. -240 -

+450)

High-temperature

mica

High-temperature mica

composite plate ≤600 -196-+900

Note. 1 Reinforced flexible graphite sheet is compounded by stainless steel impacting or punch drying plate and expanded

graphite particle. And stainless steel impacting or punch drying plate plays a role in enhancement.

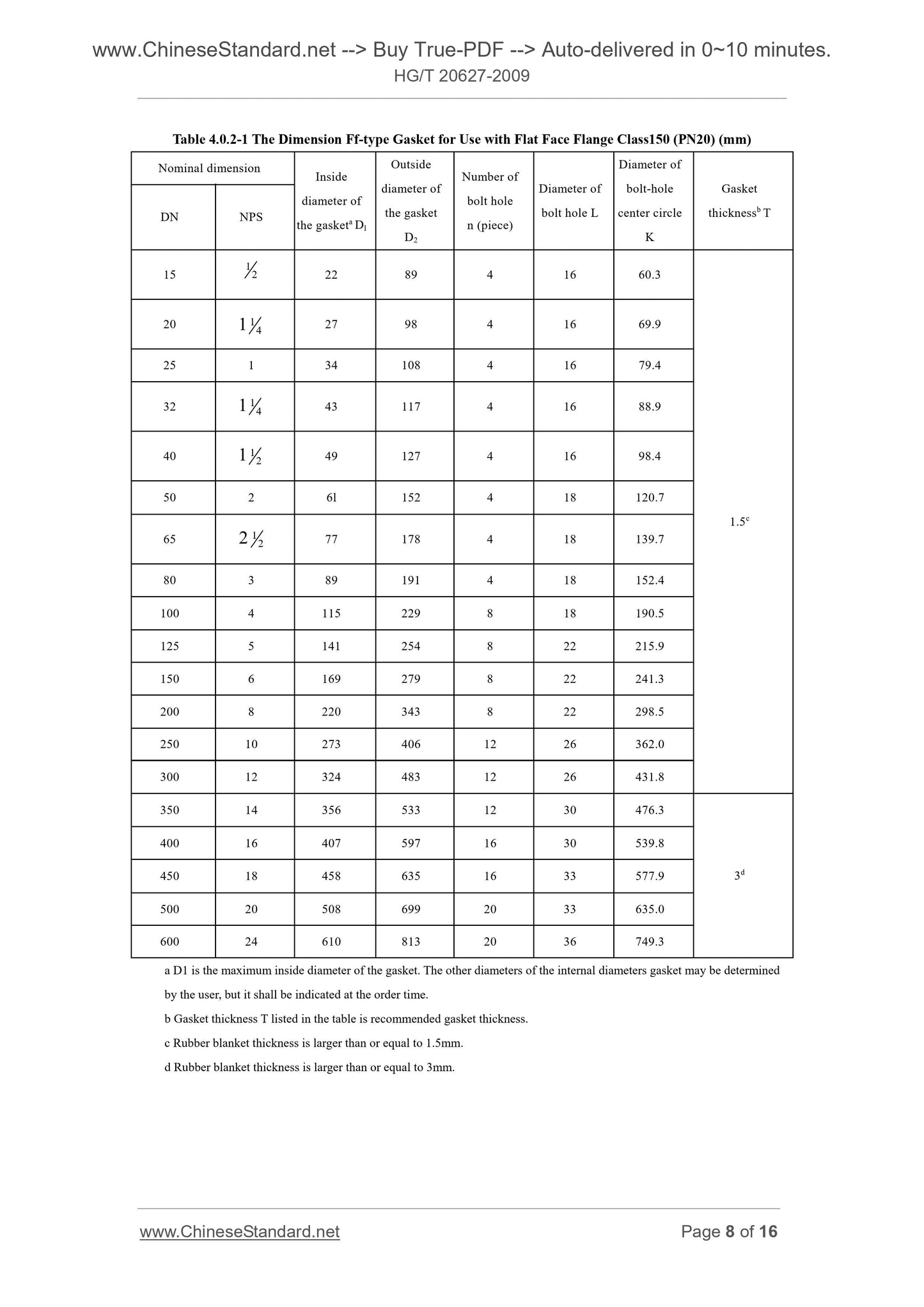

Table 4.0.2-1 The Dimension Ff-type Gasket for Use with Flat Face Flange Class150 (PN20) (mm)

Nominal dimension Inside

diameter of

the gasketa Dl

Outside

diameter of

the gasket

D2

Number of

bolt hole

n (piece)

Diameter of

bolt hole L

Diameter of

bolt-hole

center circle

Gasket

thicknessb T DN NPS

15 21 22 89 4 16 60.3

1.5c

20 411 27 98 4 16 69.9

25 1 34 108 4 16 79.4

32 411 43 117 4 16 88.9

40 211 49 127 4 16 98.4

50 2 6l 152 4 18 120.7

65 212 77 178 4 18 139.7

80 3 89 191 4 18 152.4

100 4 115 229 8 18 190.5

125 5 141 254 8 22 215.9

150 6 169 279 8 22 241.3

200 8 220 343 8 22 298.5

250 10 273 406 12 26 362.0

300 12 324 483 12 26 431.8

350 14 356 533 12 30 476.3

3d

400 16 407 597 16 30 539.8

450 18 458 635 16 33 577.9

500 20 508 699 20 33 635.0

600 24 610 813 20 36 749.3

a D1 is the maximum inside diameter of the gasket. The other diameters of the internal diameters gasket may be determined

by the user, but it shall be indicated at the order time.

b Gasket thickness T listed in the table is recommended gasket thickness.

c Rubber blanket thickness is larger than or equal to 1.5mm.

d Rubber blanket thickness is larger than or equal to 3mm.

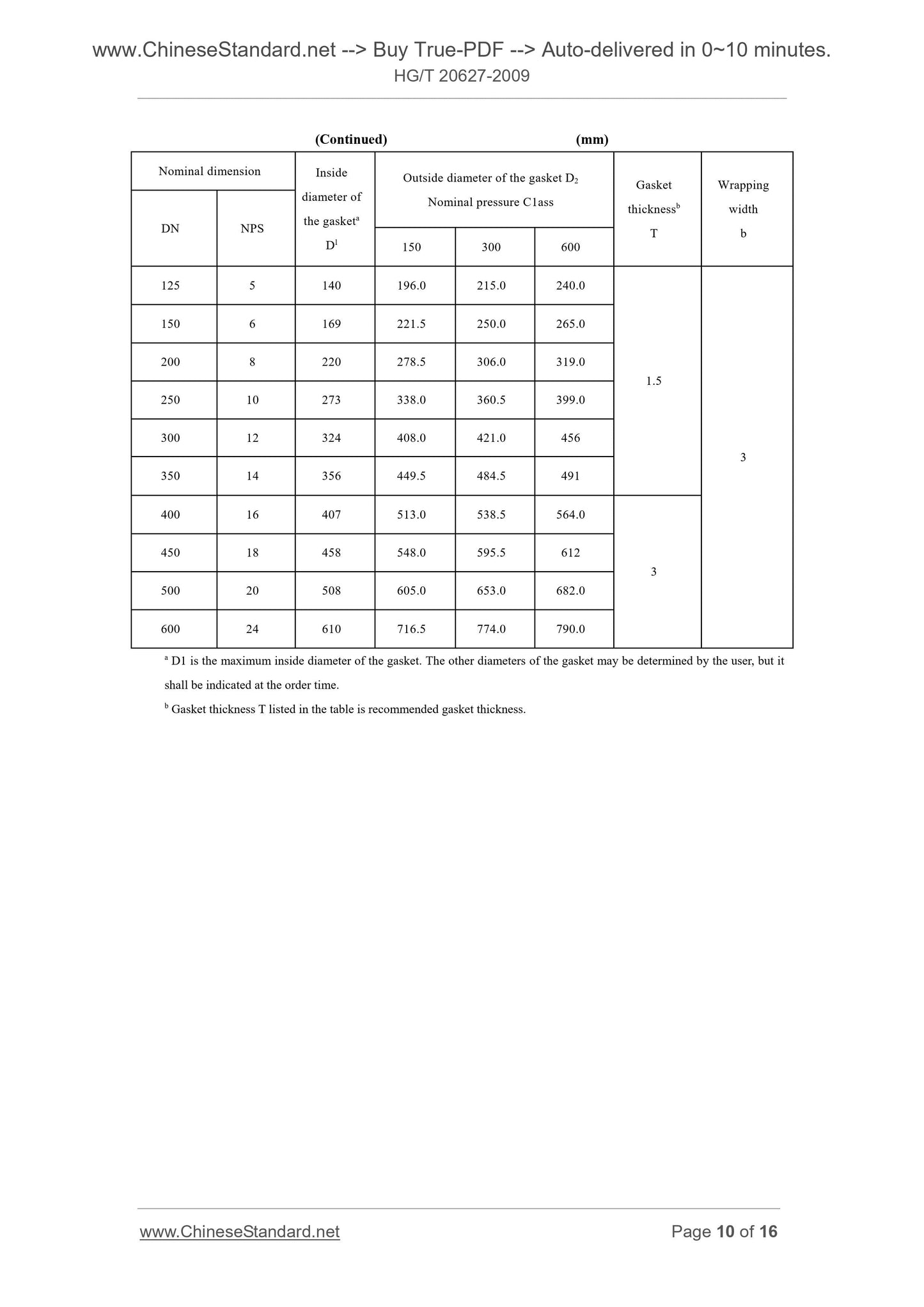

(Continued) (mm)

Nominal dimension Inside

diameter of

the gasketa

Dl

Outside diameter of the gasket D2

Nominal pressure C1ass

Gasket

thicknessb

Wrapping

width

b DN NPS

125 5 140 196.0 215.0 240.0

1.5

150 6 169 221.5 250.0 265.0

200 8 220 278.5 306.0 319.0

250 10 273 338.0 360.5 399.0

300 12 324 408.0 421.0 456

350 14 356 449.5 484.5 491

400 16 407 513.0 538.5 564.0

450 18 458 548.0 595.5 612

500 20 508 605.0 653.0 682.0

600 24 610 716.5 774.0 790.0

a D1 is the maximum inside diameter of the gasket. The other diameters of the gasket may be determined by the user, but it

shall be indicated at the order time.

b Gasket thickness T listed in the table is recommended gasket thickness.

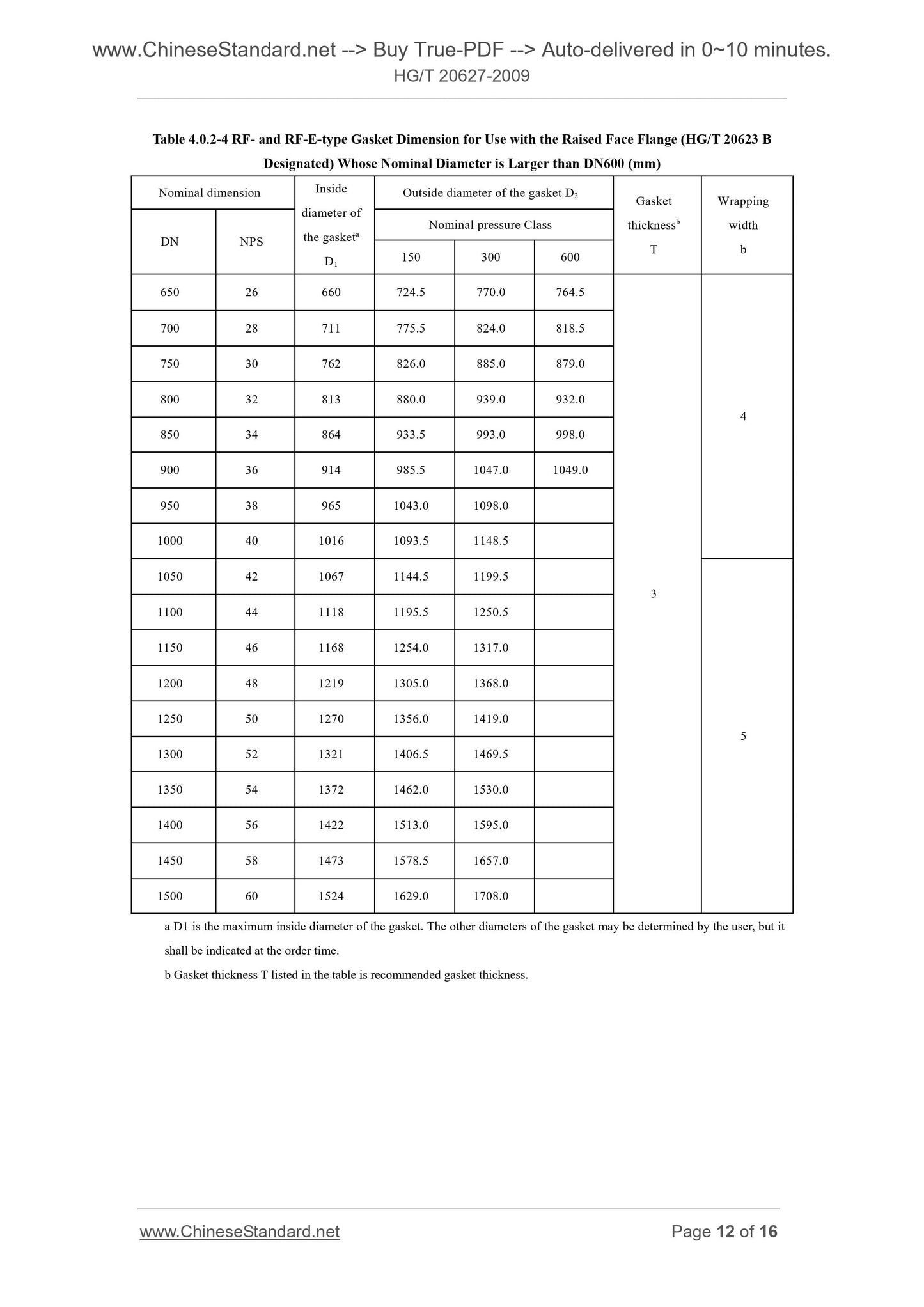

Table 4.0.2-4 RF- and RF-E-type Gasket Dimension for Use with the Raised Face Flange (HG/T 20623 B

Designated) Whose Nominal Diameter is Larger than DN600 (mm)

Nominal dimension Inside

diameter of

the gasketa

D1

Outside diameter of the gasket D2 Gasket

thicknessb

Wrapping

width

b DN NPS

Nominal pressure Class

650 26 660 724.5 770.0 764.5

700 28 711 775.5 824.0 818.5

750 30 762 826.0 885.0 879.0

800 32 813 880.0 939.0 932.0

850 34 864 933.5 993.0 998.0

900 36 914 985.5 1047.0 1049.0

950 38 965 1043.0 1098.0

1000 40 1016 1093.5 1148.5

1050 42 1067 1144.5 1199.5

1100 44 1118 1195.5 1250.5

1150 46 1168 1254.0 1317.0

1200 48 1219 1305.0 1368.0

1250 50 1270 1356.0 1419.0

1300 52 1321 1406.5 1469.5

1350 54 1372 1462.0 1530.0

1400 56 1422 1513.0 1595.0

1450 58 1473 1578.5 1657.0

1500 60 1524 1629.0 1708.0

a D1 is the maximum inside diameter of the g...

Get QUOTATION in 1-minute: Click HG/T 20627-2009

Historical versions: HG/T 20627-2009

Preview True-PDF (Reload/Scroll if blank)

HG/T 20627-2009: Non-metallic flat gaskets for use with steel pipe flanges (Class designated)

HG/T 20627-2009

Chemical Industry Standard

of the People's Republic of China

HG

Replacing HG 20627-1997, HG 20629-1997

Non-metallic Flat Gaskets for Use with Steel Pipe Flanges

(Class Designated)

(Class)系列

ISSUED ON. FEBRUARY 5, 2009

IMPLEMENTED ON. JULY 1, 2009

Issued by. Ministry of Industry and Information Technology of the People’s

Republic of China

Contents

1. Scope ... 3

2. Normative references ... 3

3. Material and working conditions ... 3

4. Gasket type and dimension ... 6

5. Technical requirements ... 14

6. Marking illustration ... 15

1. Scope

This standard specifies the type, dimension and technical requirements of non-metallic

flat gaskets (with insertion or without insertion) for use with steel pipe flanges.

This standard is applicable to the non-metallic flat gaskets for use with steel pipe flanges

whose nominal pressures from C1assl50 (PN20)-C1ass600 (PN110) are specified in HG/T

20615 and HG/T 20623.

Note. As for the use of the gaskets in which contain the material of asbestos, it shall meet the requirements of the relevant

laws and regulations. If the aforesaid gaskets are used, the protective measures shall be adopted to prevent man from damaging.

2. Normative references

The following provisions contained in the following standards are turned into the

provisions of this national standard by being referred in this national standard. For date

reference, the subsequent amendments to (excluding amending error in the text) or revisions

of, any of these publications do not apply. And parties to agreements based on this standard

are encouraged to investigate the possibility of applying the most recent editions of the

standards indicated below. For undated references, its latest edition referred to applies.

GB/T 528 "Rubber, Vulcamized or Thermoplastic--Determination of Tensile Stress-strain

Properties"

GB/T 539 "Oil-resisting compressed asbestos fiber jointing"

GB/T 3280 "Cold rolled stainless steel plate sheet and strip"

GB/T 3985 "Compressed asbestos fiber jointing"

HG/T 20615 "Steel Pipe Flange (Class Designated)"

HG/T 20623 "Major Diameter Steel Pipe Flange (Class Designated)"

HG/T 20635 "Specification for Selection of Steel Pipe Flange, Gaskets and Bolting

(Class designated)"

JB/T 6613 "The classification code and sign of flexible graphite sheets/strip"

JB/T 6628 "Reinforced flexible graphite (sheets) gaskets"

JB/T 7758.2 "Specifications of flexible graphite sheets"

QB/T 3625-1999 "PTFE sheet"

3. Material and working conditions

3.0.1 Material category

The materials of the non-metallic flat gaskets for use with steel pipe flanges contain.

1 Natural rubber, neoprene, styrene-butadiene rubber, chemigum, ethylene propylene

diene copolymer and viton;

manufacturer's brand shall be indicated. The applicable pressure, temperature and maximum

(P×T) value of the gaskets shall be determined according to the working condition.

3.0.3 Working Conditions

Working conditions of the nonmetallic flat gaskets shall meet the requirements of Table

3.0.3.

Table 3.0.3 Working Conditions of Non-metallic Flat Gaskets

Classification Name Standard Code name

Application Range

Maximum

(p×T)

(MPa×℃)

Nominal

pressureC1ass

Working

temperature

(℃)

Rubber

Natural rubber

NR 150 -50-+80 60

Neoprene CR 150 -20-+100 60

Chemigum NBR 150 -20- +110 60

Styrene-butadiene rubber SBR 150 -20-+90 60

Ethylene propylene diene

copolymer EPDM 150 -30-+140 90

Viton FKM 150 -20-+200 90

Asbestos rubber

Paronite GB/T 3985

XB350

150 -40-+300 650 XB450

Oil-resisting paronite GB/T 539 NY400

Non asbestos

fiber rubber

Non asbestos

fiber rubber

pressing-a

Inorganic

fiber

b NAS ≤300

-40-+290-d

Organic

fiber -40-+200

-d

Teflon

PTFE sheet QB/T 3625 PTFE

-50-+100

Expansion PTFE sheet/strip

b.c

ePTFE

-200-+200-d

Stuffing modified PTFE sheet RPTFE ≤300

Flexible graphite

sheets

Reinforced flexible graphite

sheet-e

JB/T 6628

JB/T 7758.2 RSB ≤600

-240-+650(used

in oxidative

medium. -240 -

+450)

High-temperature

mica

High-temperature mica

composite plate ≤600 -196-+900

Note. 1 Reinforced flexible graphite sheet is compounded by stainless steel impacting or punch drying plate and expanded

graphite particle. And stainless steel impacting or punch drying plate plays a role in enhancement.

Table 4.0.2-1 The Dimension Ff-type Gasket for Use with Flat Face Flange Class150 (PN20) (mm)

Nominal dimension Inside

diameter of

the gasketa Dl

Outside

diameter of

the gasket

D2

Number of

bolt hole

n (piece)

Diameter of

bolt hole L

Diameter of

bolt-hole

center circle

Gasket

thicknessb T DN NPS

15 21 22 89 4 16 60.3

1.5c

20 411 27 98 4 16 69.9

25 1 34 108 4 16 79.4

32 411 43 117 4 16 88.9

40 211 49 127 4 16 98.4

50 2 6l 152 4 18 120.7

65 212 77 178 4 18 139.7

80 3 89 191 4 18 152.4

100 4 115 229 8 18 190.5

125 5 141 254 8 22 215.9

150 6 169 279 8 22 241.3

200 8 220 343 8 22 298.5

250 10 273 406 12 26 362.0

300 12 324 483 12 26 431.8

350 14 356 533 12 30 476.3

3d

400 16 407 597 16 30 539.8

450 18 458 635 16 33 577.9

500 20 508 699 20 33 635.0

600 24 610 813 20 36 749.3

a D1 is the maximum inside diameter of the gasket. The other diameters of the internal diameters gasket may be determined

by the user, but it shall be indicated at the order time.

b Gasket thickness T listed in the table is recommended gasket thickness.

c Rubber blanket thickness is larger than or equal to 1.5mm.

d Rubber blanket thickness is larger than or equal to 3mm.

(Continued) (mm)

Nominal dimension Inside

diameter of

the gasketa

Dl

Outside diameter of the gasket D2

Nominal pressure C1ass

Gasket

thicknessb

Wrapping

width

b DN NPS

125 5 140 196.0 215.0 240.0

1.5

150 6 169 221.5 250.0 265.0

200 8 220 278.5 306.0 319.0

250 10 273 338.0 360.5 399.0

300 12 324 408.0 421.0 456

350 14 356 449.5 484.5 491

400 16 407 513.0 538.5 564.0

450 18 458 548.0 595.5 612

500 20 508 605.0 653.0 682.0

600 24 610 716.5 774.0 790.0

a D1 is the maximum inside diameter of the gasket. The other diameters of the gasket may be determined by the user, but it

shall be indicated at the order time.

b Gasket thickness T listed in the table is recommended gasket thickness.

Table 4.0.2-4 RF- and RF-E-type Gasket Dimension for Use with the Raised Face Flange (HG/T 20623 B

Designated) Whose Nominal Diameter is Larger than DN600 (mm)

Nominal dimension Inside

diameter of

the gasketa

D1

Outside diameter of the gasket D2 Gasket

thicknessb

Wrapping

width

b DN NPS

Nominal pressure Class

650 26 660 724.5 770.0 764.5

700 28 711 775.5 824.0 818.5

750 30 762 826.0 885.0 879.0

800 32 813 880.0 939.0 932.0

850 34 864 933.5 993.0 998.0

900 36 914 985.5 1047.0 1049.0

950 38 965 1043.0 1098.0

1000 40 1016 1093.5 1148.5

1050 42 1067 1144.5 1199.5

1100 44 1118 1195.5 1250.5

1150 46 1168 1254.0 1317.0

1200 48 1219 1305.0 1368.0

1250 50 1270 1356.0 1419.0

1300 52 1321 1406.5 1469.5

1350 54 1372 1462.0 1530.0

1400 56 1422 1513.0 1595.0

1450 58 1473 1578.5 1657.0

1500 60 1524 1629.0 1708.0

a D1 is the maximum inside diameter of the g...

Share