1

/

of

10

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

HG/T 5919-2021 English PDF (HGT5919-2021)

HG/T 5919-2021 English PDF (HGT5919-2021)

Regular price

$275.00 USD

Regular price

Sale price

$275.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click HG/T 5919-2021

Historical versions: HG/T 5919-2021

Preview True-PDF (Reload/Scroll if blank)

HG/T 5919-2021: Nickel sulfate for battery materials

HG/T 5919-2021

HG

CHEMICAL INDUSTRY STANDARD OF

THE PEOPLE’S REPUBLIC OF CHINA

ICS 71.060.50

CCS G 12

Nickel sulfate for battery materials

ISSUED ON: DECEMBER 02, 2021

IMPLEMENTED ON: APRIL 01, 2022

Issued by: Ministry of Industry and Information Technology of the People's

Republic of China

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Terms and definitions ... 4

4 Molecular formula and relative molecular mass ... 5

5 Classification ... 5

6 Requirements ... 5

7 Test methods ... 6

8 Inspection rules ... 17

9 Marks, labels ... 18

10 Packaging, transportation, storage ... 18

Nickel sulfate for battery materials

1 Scope

This document specifies the classification, requirements, test methods, inspection rules,

marks, labels, packaging, transportation, storage of nickel sulfate for battery materials.

This document applies to nickel sulfate for battery materials.

2 Normative references

The following referenced documents are indispensable for the application of this

document. For dated references, only the edition cited applies. For undated references,

the latest edition of the referenced document (including any amendments) applies.

GB/T 191, Packaging and storage marks

GB/T 6678, General principles for sampling chemical products

GB/T 6682-2008, Water for analytical laboratory use - Specification and test

methods

GB/T 8170, Rules of rounding off for numerical values and expression and

judgement of limiting values

HG/T 3696.1, Inorganic chemicals for industrial use. Preparations of standard and

reagent solutions for chemical analysis. Part 1: Preparations of standard volumetric

solutions

HG/T 3696.2, Inorganic chemicals for industrial use. Preparations of standard and

reagent solutions for chemical analysis. Part 2: Preparations of standard solutions

for impurity

HG/T 3696.3, Inorganic chemicals for industrial use. Preparations of standard and

reagent solutions for chemical analysis. Part 3: Preparations of reagent solutions

3 Terms and definitions

This document does not have terms and definitions that need to be defined.

4 Molecular formula and relative molecular mass

Molecular formula: NiSO4•6H2O

Relative molecular mass: 262.86 (according to the international relative atomic mass in

2018)

5 Classification

Nickel sulfate for battery materials is divided into two categories: solid type and

solution type.

Solid nickel sulfate for battery materials is divided into Type I and Type II according to

product use:

- Type I is for ternary battery materials;

- Type II is for other battery materials.

6 Requirements

6.1 Appearance: The solid is emerald, green granular crystal. The solution is green

transparent liquid.

6.2 Nickel sulfate for battery materials shall be tested according to the test methods

specified in this document and shall meet the requirements in Table 1.

7.3.1 Weight method (arbitration method)

7.3.1.1 Principle

In the ammonia solution, add tartaric acid to form a soluble complex with impurities

such as iron and aluminum to eliminate interference. Dimethylglyoxalxime nickel

precipitates with red color from dimethylglyoxalxime and nickel. Filter. Wash. Weigh

after drying. Calculate the nickel content.

7.3.1.2 Reagents or materials

7.3.1.2.1 Ethanol solution: 1+4.

7.3.1.2.2 Hydrochloric acid solution: 1+1.

7.3.1.2.3 Ammonia solution: 1+1.

7.3.1.2.4 Ammonium chloride solution: 200 g/L.

7.3.1.2.5 Tartaric acid solution: 200 g/L.

7.3.1.2.6 Ethanol solution of dimethylglyoxalxime: 10 g/L.

7.3.1.3 Instruments and equipment

7.3.1.3.1 Glass sand crucible: filter plate pore size is 5 μm ~ 15 μm.

7.3.1.3.2 Electric constant temperature drying oven: the temperature can be controlled

at 105°C ± 2°C.

7.3.1.4 Test steps

Weigh an appropriate amount of specimen (about 2.0 g for solid product, about 5.0 g

for solution product) (accurate to 0.0002 g). Place in a 250 mL beaker. Add 1 mL of

hydrochloric acid solution and 50 mL of water. The solid specimen is heated until the

sample is dissolved. Cool to room temperature. Transfer completely to a 100 mL

volumetric flask. Use water to dilute to the scale. Shake well.

Use a pipette to pipette 10 mL of the test solution. Place in a 400 mL beaker. Add 150

mL of water, 5 mL of ammonium chloride solution and 5 mL of tartaric acid solution.

Cover with a watch glass. Heat to boiling. When cooling to 70°C~80°C, slowly add 30

mL of dimethylglyoxalxime ethanol solution under continuous stirring. Add dropwise

ammonia solution to adjust the pH of the solution to be 8 ~ 9 (use precision pH test

paper to test). Exceed by 1 mL ~ 2 mL. Incubate at 70°C~80°C for 30 min. Use a glass

sand crucible that has been dried at 105°C ± 2°C to a constant mass to filter. Use ethanol

solution to wash 4~5 times. Dry at 105°C ± 2°C until the mass is constant.

7.3.1.5 Test data processing

0.996 - the coefficient to convert cobalt to nickel.

Take the arithmetic mean of the parallel determination results as the determination

result. The absolute difference between the two parallel determination results is not

more than 0.1%.

7.4 Determination of cobalt, copper, iron, manganese, zinc, calcium, magnesium,

chromium, cadmium and lead content

7.4.1 Principle

In nitric acid medium, use the standard curve method and inductively-coupled plasma

optical emission spectrometer to determine the contents of the analyte elements.

7.4.2 Reagents or materials

7.4.2.1 Nitric acid solution: 1+1.

7.4.2.2 Nickel matrix solution: ρ(Ni)≈20 g/L. The mass fractions of cobalt, copper, iron,

manganese, zinc, calcium, magnesium, chromium, cadmium, lead, and sodium are not

greater than 0.0002%.

Weigh about 20 g of metallic nickel (nickel mass fraction is not less than 99.99%)

(accurate to 0.01 g). Place in a 400 mL beaker. Add a little water to moisten. Slowly

add 150 mL of nitric acid solution. Heat till all is dissolved. Cool to room temperature.

Transfer into a 1000 mL volumetric flask. Use water to dilute to the scale. Shake well.

7.4.2.3 Mixed standard solution: 1 mL contains 0.01 mg each of cobalt, copper, iron,

manganese, zinc, calcium, magnesium, chromium and cadmium, and 0.05 mg of lead.

Respectively pipette 1 mL of cobalt, copper, iron, manganese, zinc, calcium,

magnesium, chromium, cadmium standard solutions prepared according to HG/T

3696.2 and 5 mL of lead standard solution prepared according to HG/T 3696.2. Place

them in the same 100 mL volumetric flask. Use water to dilute to the scale. Shake well.

Prepare this solution when it is needed.

7.4.2.4 Water: grade two water specified in GB/T 6682-2008.

7.4.3 Instruments and equipment

Inductively-coupled plasma optical emission spectrometer.

7.4.4 Test steps

7.4.4.1 Drawing of standard curve

Pipette 0.00 mL, 0.50 mL, 1.00 mL, 2.00 mL, 4.00 mL, 8.00 mL of mixed standard

solutions respectively. Place in six 100 mL volumetric flasks. Add 10 mL of nickel

matrix solution and 2 mL of nitric acid solution respectively. Use water to dilute to the

m - The value of the mass of the test material, in grams (g).

Take the arithmetic mean of the parallel determination results as the determination

result. The absolute difference between two parallel determination results is not more

than 20% of the arithmetic mean.

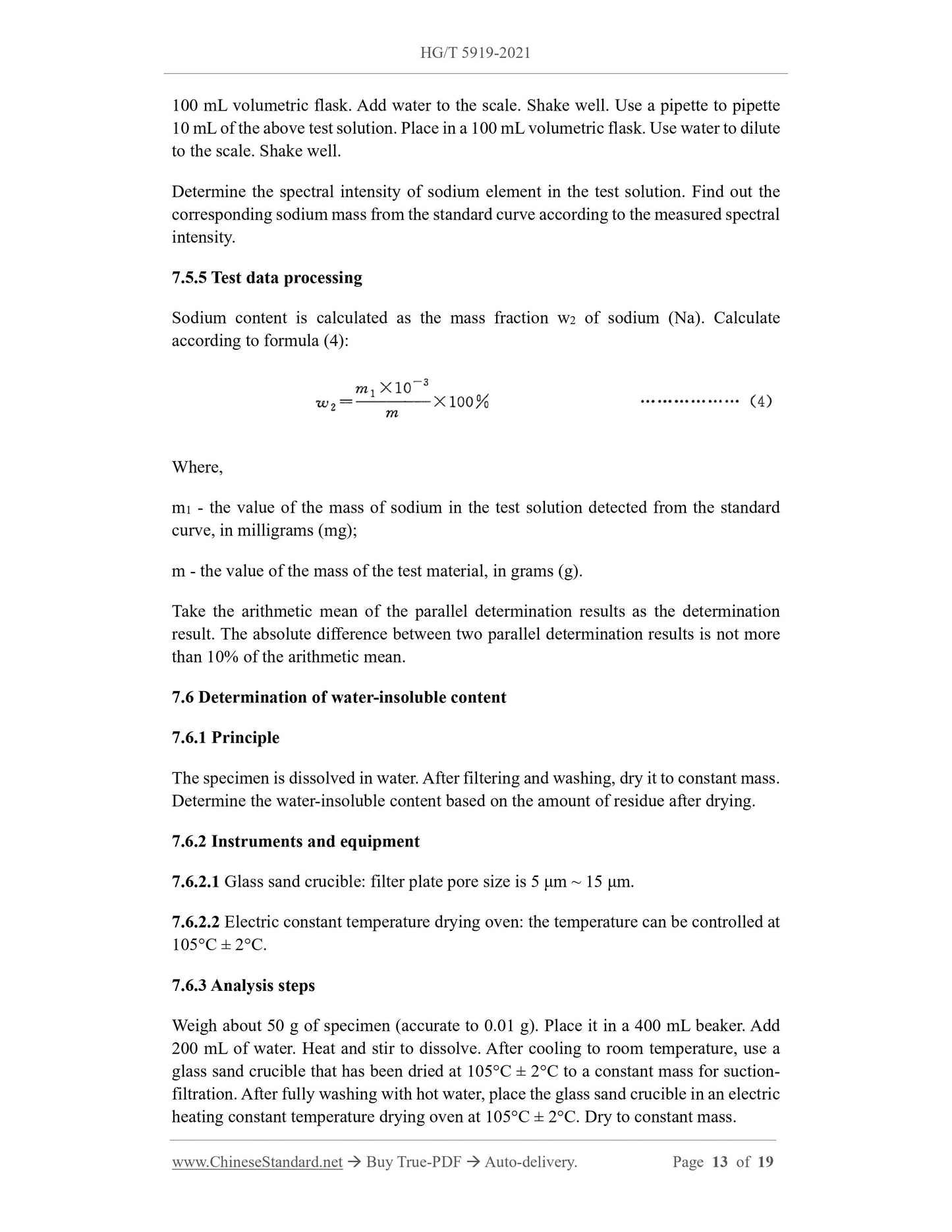

7.5 Determination of sodium content

7.5.1 Principle

In nitric acid medium, use the standard curve method and inductively-coupled plasma <...

Get QUOTATION in 1-minute: Click HG/T 5919-2021

Historical versions: HG/T 5919-2021

Preview True-PDF (Reload/Scroll if blank)

HG/T 5919-2021: Nickel sulfate for battery materials

HG/T 5919-2021

HG

CHEMICAL INDUSTRY STANDARD OF

THE PEOPLE’S REPUBLIC OF CHINA

ICS 71.060.50

CCS G 12

Nickel sulfate for battery materials

ISSUED ON: DECEMBER 02, 2021

IMPLEMENTED ON: APRIL 01, 2022

Issued by: Ministry of Industry and Information Technology of the People's

Republic of China

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Terms and definitions ... 4

4 Molecular formula and relative molecular mass ... 5

5 Classification ... 5

6 Requirements ... 5

7 Test methods ... 6

8 Inspection rules ... 17

9 Marks, labels ... 18

10 Packaging, transportation, storage ... 18

Nickel sulfate for battery materials

1 Scope

This document specifies the classification, requirements, test methods, inspection rules,

marks, labels, packaging, transportation, storage of nickel sulfate for battery materials.

This document applies to nickel sulfate for battery materials.

2 Normative references

The following referenced documents are indispensable for the application of this

document. For dated references, only the edition cited applies. For undated references,

the latest edition of the referenced document (including any amendments) applies.

GB/T 191, Packaging and storage marks

GB/T 6678, General principles for sampling chemical products

GB/T 6682-2008, Water for analytical laboratory use - Specification and test

methods

GB/T 8170, Rules of rounding off for numerical values and expression and

judgement of limiting values

HG/T 3696.1, Inorganic chemicals for industrial use. Preparations of standard and

reagent solutions for chemical analysis. Part 1: Preparations of standard volumetric

solutions

HG/T 3696.2, Inorganic chemicals for industrial use. Preparations of standard and

reagent solutions for chemical analysis. Part 2: Preparations of standard solutions

for impurity

HG/T 3696.3, Inorganic chemicals for industrial use. Preparations of standard and

reagent solutions for chemical analysis. Part 3: Preparations of reagent solutions

3 Terms and definitions

This document does not have terms and definitions that need to be defined.

4 Molecular formula and relative molecular mass

Molecular formula: NiSO4•6H2O

Relative molecular mass: 262.86 (according to the international relative atomic mass in

2018)

5 Classification

Nickel sulfate for battery materials is divided into two categories: solid type and

solution type.

Solid nickel sulfate for battery materials is divided into Type I and Type II according to

product use:

- Type I is for ternary battery materials;

- Type II is for other battery materials.

6 Requirements

6.1 Appearance: The solid is emerald, green granular crystal. The solution is green

transparent liquid.

6.2 Nickel sulfate for battery materials shall be tested according to the test methods

specified in this document and shall meet the requirements in Table 1.

7.3.1 Weight method (arbitration method)

7.3.1.1 Principle

In the ammonia solution, add tartaric acid to form a soluble complex with impurities

such as iron and aluminum to eliminate interference. Dimethylglyoxalxime nickel

precipitates with red color from dimethylglyoxalxime and nickel. Filter. Wash. Weigh

after drying. Calculate the nickel content.

7.3.1.2 Reagents or materials

7.3.1.2.1 Ethanol solution: 1+4.

7.3.1.2.2 Hydrochloric acid solution: 1+1.

7.3.1.2.3 Ammonia solution: 1+1.

7.3.1.2.4 Ammonium chloride solution: 200 g/L.

7.3.1.2.5 Tartaric acid solution: 200 g/L.

7.3.1.2.6 Ethanol solution of dimethylglyoxalxime: 10 g/L.

7.3.1.3 Instruments and equipment

7.3.1.3.1 Glass sand crucible: filter plate pore size is 5 μm ~ 15 μm.

7.3.1.3.2 Electric constant temperature drying oven: the temperature can be controlled

at 105°C ± 2°C.

7.3.1.4 Test steps

Weigh an appropriate amount of specimen (about 2.0 g for solid product, about 5.0 g

for solution product) (accurate to 0.0002 g). Place in a 250 mL beaker. Add 1 mL of

hydrochloric acid solution and 50 mL of water. The solid specimen is heated until the

sample is dissolved. Cool to room temperature. Transfer completely to a 100 mL

volumetric flask. Use water to dilute to the scale. Shake well.

Use a pipette to pipette 10 mL of the test solution. Place in a 400 mL beaker. Add 150

mL of water, 5 mL of ammonium chloride solution and 5 mL of tartaric acid solution.

Cover with a watch glass. Heat to boiling. When cooling to 70°C~80°C, slowly add 30

mL of dimethylglyoxalxime ethanol solution under continuous stirring. Add dropwise

ammonia solution to adjust the pH of the solution to be 8 ~ 9 (use precision pH test

paper to test). Exceed by 1 mL ~ 2 mL. Incubate at 70°C~80°C for 30 min. Use a glass

sand crucible that has been dried at 105°C ± 2°C to a constant mass to filter. Use ethanol

solution to wash 4~5 times. Dry at 105°C ± 2°C until the mass is constant.

7.3.1.5 Test data processing

0.996 - the coefficient to convert cobalt to nickel.

Take the arithmetic mean of the parallel determination results as the determination

result. The absolute difference between the two parallel determination results is not

more than 0.1%.

7.4 Determination of cobalt, copper, iron, manganese, zinc, calcium, magnesium,

chromium, cadmium and lead content

7.4.1 Principle

In nitric acid medium, use the standard curve method and inductively-coupled plasma

optical emission spectrometer to determine the contents of the analyte elements.

7.4.2 Reagents or materials

7.4.2.1 Nitric acid solution: 1+1.

7.4.2.2 Nickel matrix solution: ρ(Ni)≈20 g/L. The mass fractions of cobalt, copper, iron,

manganese, zinc, calcium, magnesium, chromium, cadmium, lead, and sodium are not

greater than 0.0002%.

Weigh about 20 g of metallic nickel (nickel mass fraction is not less than 99.99%)

(accurate to 0.01 g). Place in a 400 mL beaker. Add a little water to moisten. Slowly

add 150 mL of nitric acid solution. Heat till all is dissolved. Cool to room temperature.

Transfer into a 1000 mL volumetric flask. Use water to dilute to the scale. Shake well.

7.4.2.3 Mixed standard solution: 1 mL contains 0.01 mg each of cobalt, copper, iron,

manganese, zinc, calcium, magnesium, chromium and cadmium, and 0.05 mg of lead.

Respectively pipette 1 mL of cobalt, copper, iron, manganese, zinc, calcium,

magnesium, chromium, cadmium standard solutions prepared according to HG/T

3696.2 and 5 mL of lead standard solution prepared according to HG/T 3696.2. Place

them in the same 100 mL volumetric flask. Use water to dilute to the scale. Shake well.

Prepare this solution when it is needed.

7.4.2.4 Water: grade two water specified in GB/T 6682-2008.

7.4.3 Instruments and equipment

Inductively-coupled plasma optical emission spectrometer.

7.4.4 Test steps

7.4.4.1 Drawing of standard curve

Pipette 0.00 mL, 0.50 mL, 1.00 mL, 2.00 mL, 4.00 mL, 8.00 mL of mixed standard

solutions respectively. Place in six 100 mL volumetric flasks. Add 10 mL of nickel

matrix solution and 2 mL of nitric acid solution respectively. Use water to dilute to the

m - The value of the mass of the test material, in grams (g).

Take the arithmetic mean of the parallel determination results as the determination

result. The absolute difference between two parallel determination results is not more

than 20% of the arithmetic mean.

7.5 Determination of sodium content

7.5.1 Principle

In nitric acid medium, use the standard curve method and inductively-coupled plasma <...

Share