1

/

of

9

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

HJ 101-2019 English PDF (HJ101-2019)

HJ 101-2019 English PDF (HJ101-2019)

Regular price

$225.00 USD

Regular price

Sale price

$225.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click HJ 101-2019

Historical versions: HJ 101-2019

Preview True-PDF (Reload/Scroll if blank)

HJ 101-2019: Technical specifications and test procedures for water quality on-line automatic monitoring equipment of ammonia

HJ/T 101-2019

NATIONAL ENVIRONMENTAL PROTECTION STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

Replacing HJ/T 101-2003

Technical specifications and test procedures for water

quality on-line automatic monitoring equipment of

ammonia

ISSUED ON: DECEMBER 24, 2019

IMPLEMENTED ON: MARCH 24, 2020

Issued by: Ministry of Ecology and Environment

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Terms and definitions ... 6

4 Technical specifications ... 9

5 Performance indexes and test methods ... 13

6 Operating manual ... 22

Technical specifications and test procedures for water

quality on-line automatic monitoring equipment of

ammonia

1 Scope

This Standard specifies the technical specifications, performance indexes and test

methods for water quality on-line automatic monitoring equipment of ammonia.

This Standard applies to guiding production and design, guiding to application type-

selection and implementing performance test.

The measuring range of water quality on-line automatic monitoring equipment of

ammonia shall include 0.1 mg/L ~ 150 mg/L, which can satisfy the monitoring

requirements for underground water, surface water, domestic wastewater and

industrial wastewater.

2 Normative references

This Standard referenced the following documents or clauses therein. For undated

references, the latest edition of the referenced documents (including all amendments)

applies to this document.

GB/T 9969, General principles for preparation of instructions for use of industrial

products

GB/T 13306, Plate

HJ 212, Data transmission standard for online monitoring systems of pollutant

HJ 535, Water quality – Determination of ammonia nitrogen – Nessler reagent

spectrophotometry

HJ 536, Water quality-Determination of ammonia nitrogen – Salicylic acid

spectrophotometry

expressed as relative standard deviation, provided that no unplanned artificial

maintenance and correction is carried out for instruments.

3.7

low level drift in 24 h

The mean value of the deviation absolute value between measured value and initial

value of instruments for the continuous measurement (0 ~ 20%) of upper limit of the

test range of a low concentration reference solution at specified periods, provided that

no unplanned artificial maintenance and correction is carried out for instruments.

3.8

high level drift in 24 h

The percentage of the mean value, in relation to the upper limit of the test range (80%

~ 100%), of the deviation absolute value between measured value and initial value of

instruments for the continuous measurement (0 ~ 20%) of upper limit of the test range

of a high concentration reference solution at specified periods, provided that no

unplanned artificial maintenance and correction is carried out for instruments.

3.9

memory effect

The degree of interference of the residues in the tubes of instruments on the next result

of measurement after the measurement of some reference solution or sample using

instruments.

3.10

interference of voltage

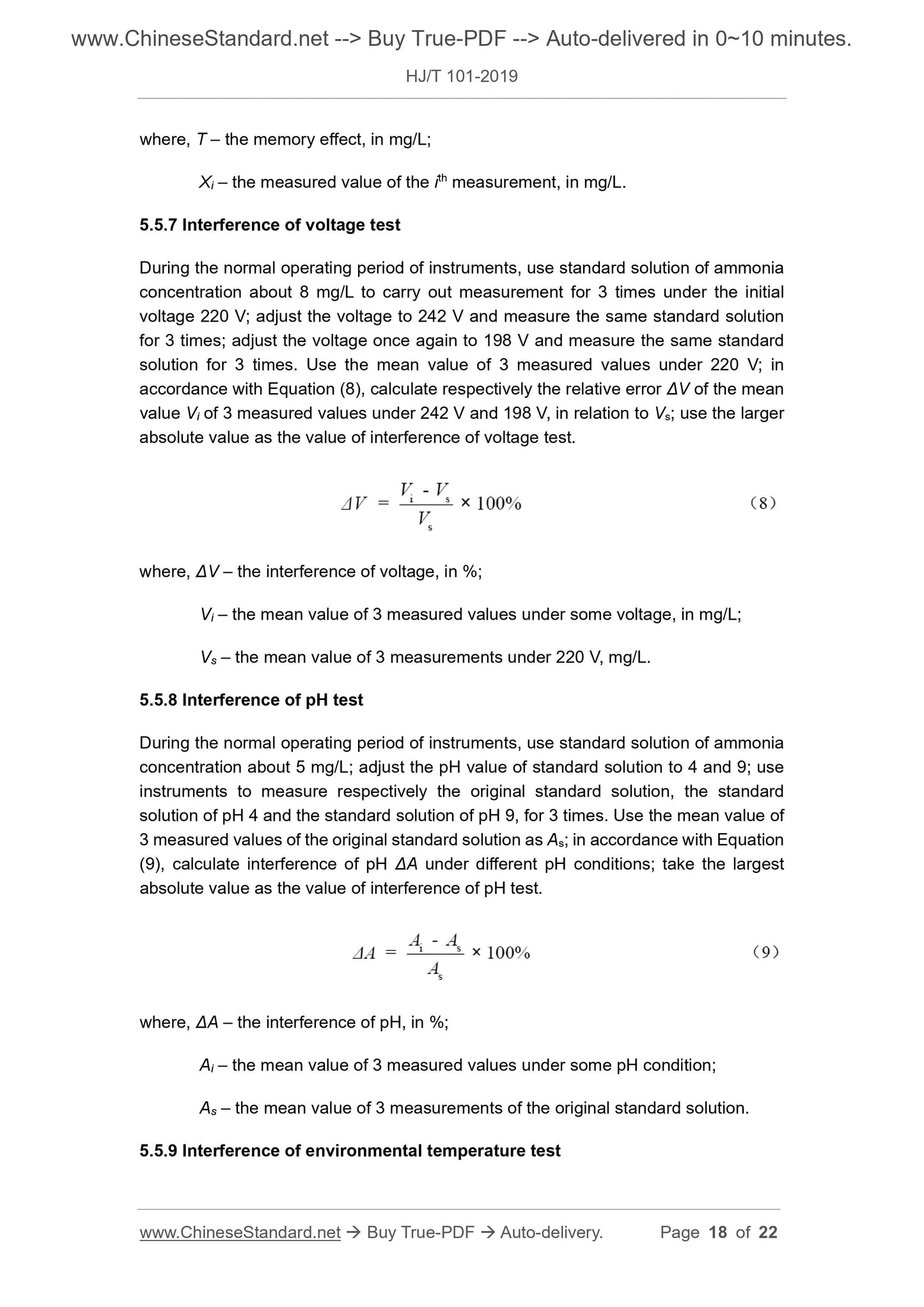

The deviations of measured values, which are obtained in the measurement of the

same reference solution using instruments under different supply voltages, from

measured value under reference voltage (220 V).

3.11

interference of pH

The deviation of measured values, which are obtained from the measurement of a

reference solution using instruments under different pH values, from measured value

from the measurement of a neutral reference solution (pH = 7).

3.12

management, data and running log query and output, and so on; meanwhile, they have

such functions as sample reservation triggering sampling. Control units are capable of

providing corresponding communication protocols when performing the above-

mentioned functions, and such communication protocols satisfy the requirements of

HJ 212.

4.2 Environmental conditions for service

Environmental temperature: 5°C ~ 40°C;

Relative humidity: 65% ± 20%;

Supply voltage: alternating voltage 220 V ± 22V;

Supply frequency: 50 Hz ± 0.5 Hz;

Water sample temperature: 0°C ~ 50°C.

4.3 Appearance requirements

4.3.1 The marking of instruments shall be as specified in GB/T 13306. Plates shall be

affixed to an appropriate, visible position. Plates shall include the following content:

a) category of power supply;

b) name and address of manufacturer;

c) name and specifications of instruments;

d) factory number;

e) manufacturing date;

f) test range and limit of quantitation;

g) limit of quantitation;

h) environmental conditions for service.

4.3.2 The monitor shall be free from stains and damages. All display interfaces shall

be in Chinese and the characters uniform and clear; the screen shall be free from dark

corners, black spots, rainbows, bubbles, flickers, etc.; it is capable of finishing all

operations according to the instructions of the monitor.

4.3.3 The enclosure shall be made of corrosion resistant materials; the surface shall

be free from crack, deformation, contamination, burr, etc.; the coating of the surface

shall be uniform, without corrosion, rust, shedding or abrasion.

4.4.4.2 The output signals of test modules shall be stable.

4.4.4.3 Signal converters shall have the function to convert measured values into a

corresponding quantity of electric signals (4 mA ~ 20 mA DC or RS232/RS485

interfaces).

4.4.4.4 The test period shall not be greater than 60 min.

4.4.5 Control units

4.4.5.1 They shall have the timed test function.

4.4.5.2 They shall have the manual and automatic cleaning function for the units

including sample introduction/measurement, physical/chemical pretreatment and

analysis and test.

4.4.5.3 They shall have the manual and automatic correction function; they are capable

of setting automatic correction period.

4.4.5.4 They shall have the automatic reference sample inspection function.

4.4.5.5 If they have multiple measuring ranges, they shall have the automatic

measuring range switching function; instruments display the final results of

measurement.

4.4.5.6 They shall be capable of automatic acquisition, storage, processing, query,

display, output, etc. of all data, instruments’ parameters and running logs.

4.4.5.7 They shall store initial data and running logs for at least 12 months.

4.4.5.8 They shall have the function to add marks for different test data; the specific

marks shall be as specified in HJ 212.

4.4.5.9 The unit of measured results of instruments shall be mg/L, which shall be

rounded off to the second decimal place.

4.4.5.10 They shall have the digital quantity communication interfaces; output

instructions, relevant data and running logs through the digital quantity communication

interfaces; can receive the remote control instructions of the platform, at least including

remote start, remote time setting function.

4.4.5.11 Data transmission shall be accompanied by communication protocols, as

specified in HJ 212.

4.4.5.12 They shall realize the serial port output and internet access output of

monitored data.

of ammonia standard stock solution.

5.3.3 Other reagents: to be provided by the manufacturer of instruments.

5.4 Test preparation and correction

5.4.1 Check all parts of instruments; adjust instruments to the normal working condition.

5.4.2 Check all reagents of instruments; ensure they are sufficient and that their quality

is as specified.

5.4.3 After switching on, prehea...

Get QUOTATION in 1-minute: Click HJ 101-2019

Historical versions: HJ 101-2019

Preview True-PDF (Reload/Scroll if blank)

HJ 101-2019: Technical specifications and test procedures for water quality on-line automatic monitoring equipment of ammonia

HJ/T 101-2019

NATIONAL ENVIRONMENTAL PROTECTION STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

Replacing HJ/T 101-2003

Technical specifications and test procedures for water

quality on-line automatic monitoring equipment of

ammonia

ISSUED ON: DECEMBER 24, 2019

IMPLEMENTED ON: MARCH 24, 2020

Issued by: Ministry of Ecology and Environment

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Terms and definitions ... 6

4 Technical specifications ... 9

5 Performance indexes and test methods ... 13

6 Operating manual ... 22

Technical specifications and test procedures for water

quality on-line automatic monitoring equipment of

ammonia

1 Scope

This Standard specifies the technical specifications, performance indexes and test

methods for water quality on-line automatic monitoring equipment of ammonia.

This Standard applies to guiding production and design, guiding to application type-

selection and implementing performance test.

The measuring range of water quality on-line automatic monitoring equipment of

ammonia shall include 0.1 mg/L ~ 150 mg/L, which can satisfy the monitoring

requirements for underground water, surface water, domestic wastewater and

industrial wastewater.

2 Normative references

This Standard referenced the following documents or clauses therein. For undated

references, the latest edition of the referenced documents (including all amendments)

applies to this document.

GB/T 9969, General principles for preparation of instructions for use of industrial

products

GB/T 13306, Plate

HJ 212, Data transmission standard for online monitoring systems of pollutant

HJ 535, Water quality – Determination of ammonia nitrogen – Nessler reagent

spectrophotometry

HJ 536, Water quality-Determination of ammonia nitrogen – Salicylic acid

spectrophotometry

expressed as relative standard deviation, provided that no unplanned artificial

maintenance and correction is carried out for instruments.

3.7

low level drift in 24 h

The mean value of the deviation absolute value between measured value and initial

value of instruments for the continuous measurement (0 ~ 20%) of upper limit of the

test range of a low concentration reference solution at specified periods, provided that

no unplanned artificial maintenance and correction is carried out for instruments.

3.8

high level drift in 24 h

The percentage of the mean value, in relation to the upper limit of the test range (80%

~ 100%), of the deviation absolute value between measured value and initial value of

instruments for the continuous measurement (0 ~ 20%) of upper limit of the test range

of a high concentration reference solution at specified periods, provided that no

unplanned artificial maintenance and correction is carried out for instruments.

3.9

memory effect

The degree of interference of the residues in the tubes of instruments on the next result

of measurement after the measurement of some reference solution or sample using

instruments.

3.10

interference of voltage

The deviations of measured values, which are obtained in the measurement of the

same reference solution using instruments under different supply voltages, from

measured value under reference voltage (220 V).

3.11

interference of pH

The deviation of measured values, which are obtained from the measurement of a

reference solution using instruments under different pH values, from measured value

from the measurement of a neutral reference solution (pH = 7).

3.12

management, data and running log query and output, and so on; meanwhile, they have

such functions as sample reservation triggering sampling. Control units are capable of

providing corresponding communication protocols when performing the above-

mentioned functions, and such communication protocols satisfy the requirements of

HJ 212.

4.2 Environmental conditions for service

Environmental temperature: 5°C ~ 40°C;

Relative humidity: 65% ± 20%;

Supply voltage: alternating voltage 220 V ± 22V;

Supply frequency: 50 Hz ± 0.5 Hz;

Water sample temperature: 0°C ~ 50°C.

4.3 Appearance requirements

4.3.1 The marking of instruments shall be as specified in GB/T 13306. Plates shall be

affixed to an appropriate, visible position. Plates shall include the following content:

a) category of power supply;

b) name and address of manufacturer;

c) name and specifications of instruments;

d) factory number;

e) manufacturing date;

f) test range and limit of quantitation;

g) limit of quantitation;

h) environmental conditions for service.

4.3.2 The monitor shall be free from stains and damages. All display interfaces shall

be in Chinese and the characters uniform and clear; the screen shall be free from dark

corners, black spots, rainbows, bubbles, flickers, etc.; it is capable of finishing all

operations according to the instructions of the monitor.

4.3.3 The enclosure shall be made of corrosion resistant materials; the surface shall

be free from crack, deformation, contamination, burr, etc.; the coating of the surface

shall be uniform, without corrosion, rust, shedding or abrasion.

4.4.4.2 The output signals of test modules shall be stable.

4.4.4.3 Signal converters shall have the function to convert measured values into a

corresponding quantity of electric signals (4 mA ~ 20 mA DC or RS232/RS485

interfaces).

4.4.4.4 The test period shall not be greater than 60 min.

4.4.5 Control units

4.4.5.1 They shall have the timed test function.

4.4.5.2 They shall have the manual and automatic cleaning function for the units

including sample introduction/measurement, physical/chemical pretreatment and

analysis and test.

4.4.5.3 They shall have the manual and automatic correction function; they are capable

of setting automatic correction period.

4.4.5.4 They shall have the automatic reference sample inspection function.

4.4.5.5 If they have multiple measuring ranges, they shall have the automatic

measuring range switching function; instruments display the final results of

measurement.

4.4.5.6 They shall be capable of automatic acquisition, storage, processing, query,

display, output, etc. of all data, instruments’ parameters and running logs.

4.4.5.7 They shall store initial data and running logs for at least 12 months.

4.4.5.8 They shall have the function to add marks for different test data; the specific

marks shall be as specified in HJ 212.

4.4.5.9 The unit of measured results of instruments shall be mg/L, which shall be

rounded off to the second decimal place.

4.4.5.10 They shall have the digital quantity communication interfaces; output

instructions, relevant data and running logs through the digital quantity communication

interfaces; can receive the remote control instructions of the platform, at least including

remote start, remote time setting function.

4.4.5.11 Data transmission shall be accompanied by communication protocols, as

specified in HJ 212.

4.4.5.12 They shall realize the serial port output and internet access output of

monitored data.

of ammonia standard stock solution.

5.3.3 Other reagents: to be provided by the manufacturer of instruments.

5.4 Test preparation and correction

5.4.1 Check all parts of instruments; adjust instruments to the normal working condition.

5.4.2 Check all reagents of instruments; ensure they are sufficient and that their quality

is as specified.

5.4.3 After switching on, prehea...

Share