1

/

of

9

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

JB/T 5000.3-2007 English PDF (JB/T5000.3-2007)

JB/T 5000.3-2007 English PDF (JB/T5000.3-2007)

Regular price

$85.00 USD

Regular price

Sale price

$85.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click JB/T 5000.3-2007

Historical versions: JB/T 5000.3-2007

Preview True-PDF (Reload/Scroll if blank)

JB/T 5000.3-2007: Heavy mechanical general techniques - Part 3: And standards welding

JB/T 5000.3-2007

JB

NATIONAL MACHINERY INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 25.160

J 33

Record number. 21697-2007

Replacing JB/T 5000.3-1998

Heavy mechanical general techniques

- Part 3. And standards welding

ISSUED ON. AUGUST 28, 2007

IMPLEMENTED ON. FEBRUARY 1, 2008

Issued by. National Development and Reform Commission, People’s

Republic of China

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 General requirements ... 6

4 Preliminary straightening of steel ... 7

5 Forming bending of steel ... 8

6 Welding assembly ... 11

7 Welding ... 12

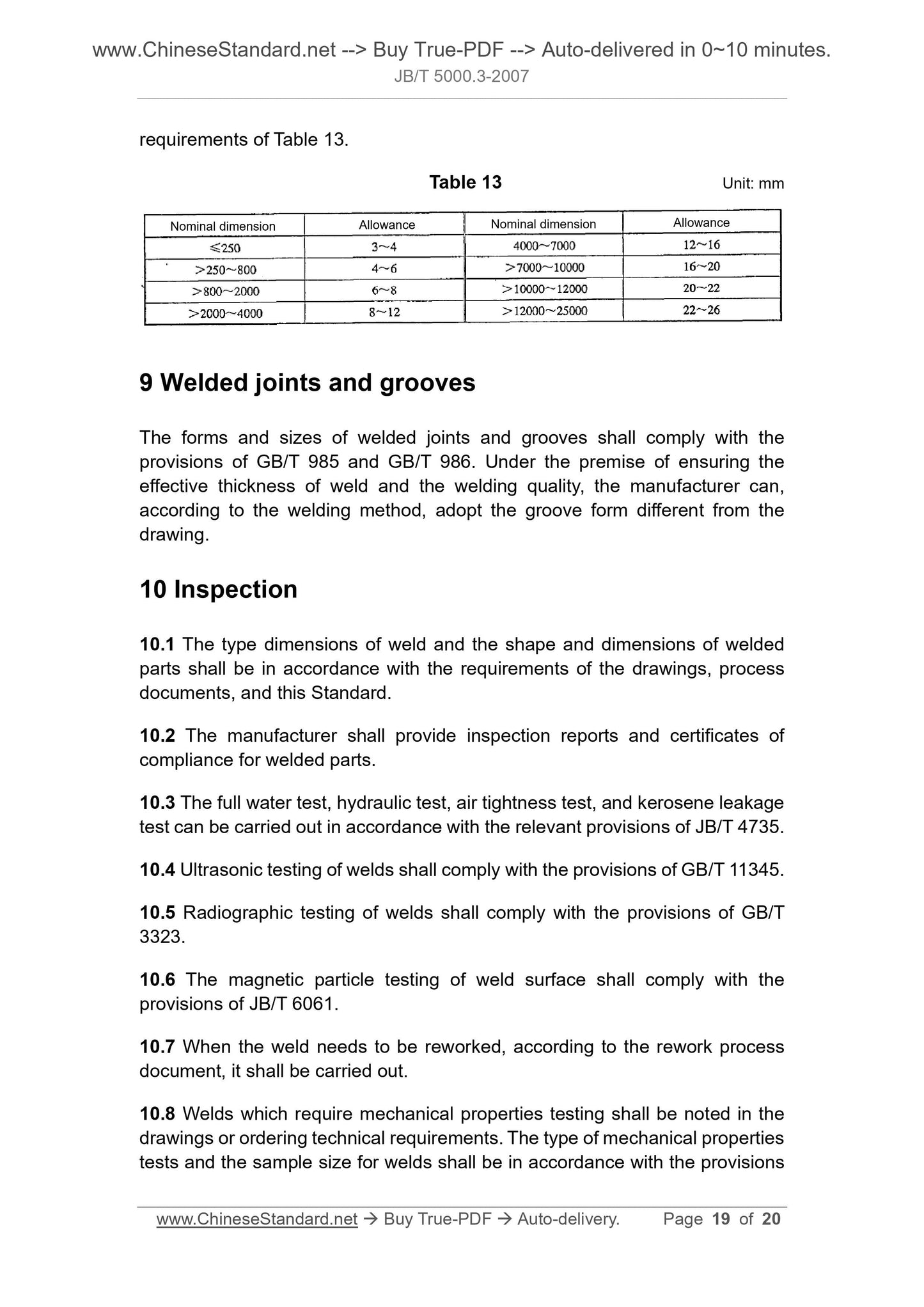

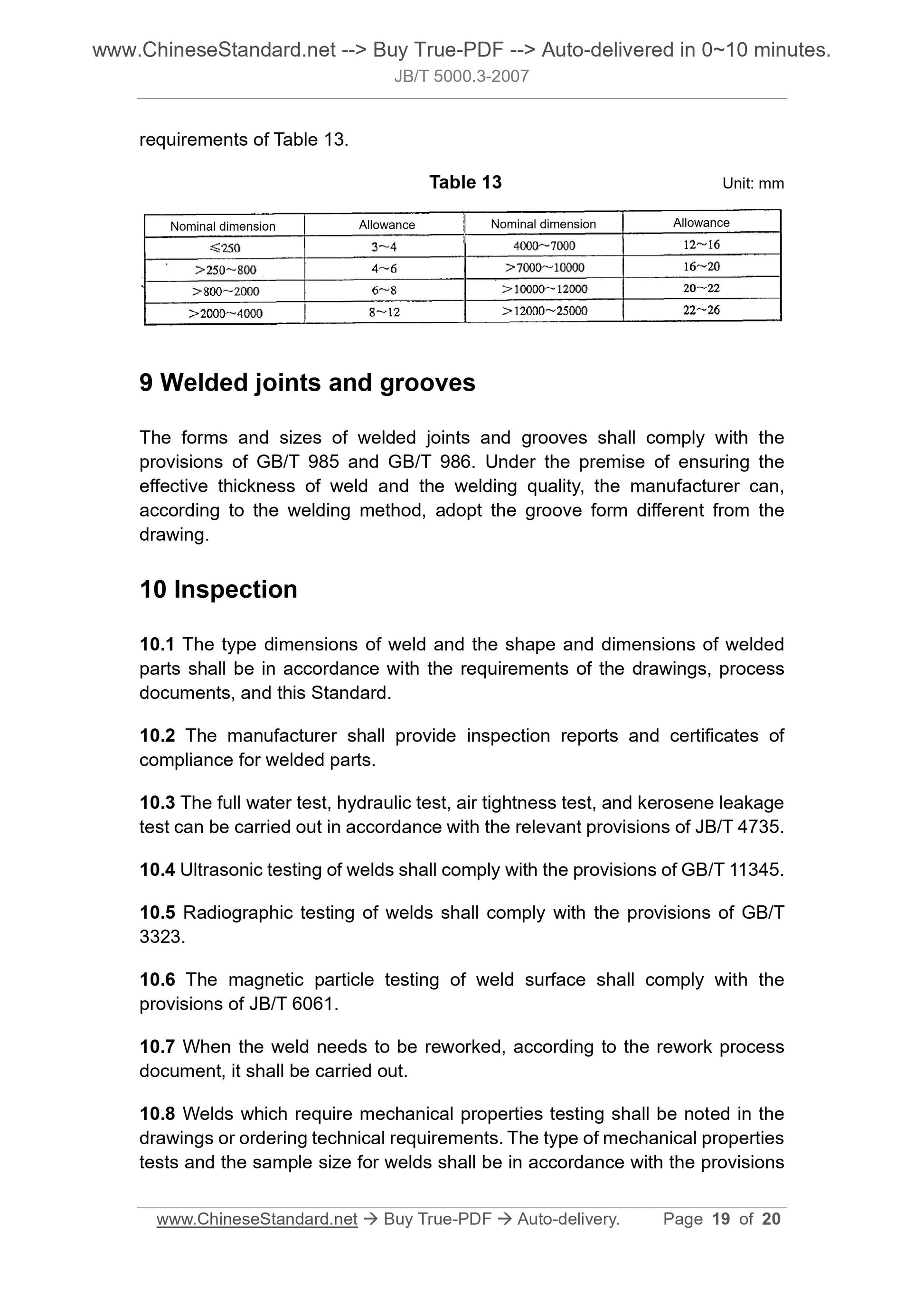

8 Machining allowance of welded structural parts ... 18

9 Welded joints and grooves ... 19

10 Inspection ... 19

11 Drawing indications ... 20

Foreword

JB/T 5000 “Heavy mechanical general techniques and standards” is divided

into 15 parts.

- Part 1. Check of product;

- Part 2. Oxygen cutting workpiece;

- Part 3. And standards welding [Translator note. should be “Welding”];

- Part 4. Iron Casting;

- Part 5. Non-ferrous casting;

- Part 6. Steel Castings;

- Part 7. Repair welding for steel castings;

- Part 8. Forging;

- Part 9. Cutting;

- Part 10. Assembly;

- Part 11. Attached piping;

- Part 12. Paint;

- Part 13. Packing;

- Part 14. Non-destructive inspection of cast steel;

- Part 15. Non-destructive inspection of forged steel.

This Part is Part 3 of JB/T 5000.

This Part replaces JB/T 5000.3-1998 “The heavy mechanical general

techniques and standards - Welding”.

As compared with JB/T 5000.3-1998, the main changes of this Part are as

follows.

- ADD the requirement for chamfering the edges and corners of the bent steel

part when the steel is rolled.

- ADD length, weld angle, and quality requirements for tack weld.

Heavy mechanical general techniques

- Part 3. And standards welding

1 Scope

This Part of JB/T 5000 specifies the technical requirements, inspection methods,

and drawing indications of steel welded parts.

This Part applies to steel welded parts by shielded metal arc welding, gas

shielded welding, and submerged arc welding in heavy machinery and

components.

Where there are no special requirements in product drawings, technical

documents, and ordering technical conditions, the provisions of this Part shall

be complied with.

2 Normative references

The clauses in the following documents, by reference in this Part of JB/T 5000,

constitute the clauses of this Part. For the dated references, the subsequent

amendments (not including errata content) or revisions do not apply to this Part.

However, parties which have reached an agreement according to this Part are

encouraged to study whether the latest edition of these documents can be used.

For the undated references, the latest edition is applicable to this Part.

GB/T 324 Welds - symbolic representation on drawings (GB/T 324-1988, eqv

ISO 2553.1989)

GB/T 985 Basic forms and sizes of weld grooves for gas welding, manual

arc welding and gas-shielded welding

GB/T 986 Basic forms and sizes of weld grooves for submerged arc welding

GB/T 2649 Methods of sampling for mechanical properties tests of welded

joint

GB/T 2650 Impact test methods on welded joints

GB/T 2651 Tensile test method on welded joints

GB/T 2652 Tensile test methods on weld and deposited metal

GB/T 2653 Methods of bend and compression tests for welded joint

GB/T 2654 Methods of hardness tests for welded joint and surfacing metal

GB/T 3323 Radiographic examination of fusion welded joints in metallic

materials (GB/T 3323-2005, EN 135.1997, MOD)

GB/T 11345 Non-destructive testing of welds - Ultrasonic testing -

Techniques, testing levels, and assessment

JB/T 3223 Welding material quality management procedures

JB/T 4735 Steel welded atmospheric pressure vessels

JB/T 5000.2 Heavy mechanical general techniques and standards - Part 2.

Oxygen cutting workpiece

JB/T 5000.11 Heavy mechanical general techniques and standards - Part 11.

Attached piping

JB/T 5000.12 Heavy mechanical general techniques and standards - Part 12.

Paint

JB/T 5926 Vibrating stress relief effect - Evaluation methods

JB/T 6046 Welding assembly for carbon steel and low alloy steel - Post-

welding heat treatment method

JB/T 6061 Non-destructive testing - Magnetic particle testing of welds

JB/T 7949 Weld outer dimensions for steel construction

3 General requirements

3.1 Welded parts shall be manufactured in accordance with the design drawings,

process documents, and this Part.

3.2 The steel grade, specifications, and dimensions of the raw materials (steel

sheets, section steel, and steel pipes, etc.) used to manufacture the welded

parts shall comply with the requirements of design drawings. For material

substitution, substitution sheet shall be handled in accordance with relevant

regulations.

3.3 Raw materials and welding materials (welding rods, welding wire, flux,

shield gas, etc.) used to manufacture welded parts shall, when entering the

factory, based on the certificate of compliance provided by the supplier,

5 Forming bending of steel

5.1 For the rolling bending of steel, when the bending radius (inner radius) is

greater than the following values, cold bending can be carried out (SEE Figure

1). However, regardless of cold bending or hot bending, the edges and corners

of the steel sheet near the bent part shall be chamfered.

5.1.1 Steel sheet. For low alloy steel, R≥25δ;

For low carbon steel, R≥20δ.

R - Bending radius; δ - Thickness of steel sheet.

5.1.2 I-beam. R≥25H or R≥25B (depending on the direction of bending);

H - I-beam’s height; B - I-beam’s width.

5.1.3 Channel steel. R≥45B or R≥25H (depending on the direction of bending);

H - Channel steel’s height; B - Channel steel’s width.

5.1.4 Angle steel. R≥45B;

B - Angle steel’s edge-width (for unequal angle steel,

depending on the direction of bending).

5.2 For the rolling bending of steel, when the bending radius (inner radius) is

less than the values specified in 5.1, according to the specific situation, the

technician shall determine whether to perform annealing heat treatment after

hot bending or cold bending.

5.3 The tolerances for the dimensions of bend formed cylinder shall be in

accordance with Figure 2 and Table 3.

5.4 The unfitness of butt joint e for the butt joint between cylinders or for the

longitudinal joint of cylinder shall not exceed 20% of thickness and no more

than 4mm (SEE Figure 3 and Figure 4).

5.5 For the bend forming of the pipe, during hot bending, the heating

temperature is 900°C~1000°C. During bending, the temperature shall not be

lower than 700°C. Cold bending shall be carried out on a special pipe bender.

5.6 The bending radius R of the pipe (SEE Figure 5) shall comply with the

provisions of JB/T 5000.11.

7.1.1 Welders shall be specially trained and qualified before they can perform

welding work.

7.1.2 If the steel is not pretreated, before welding, the surface dirt of welding

area shall be removed, such as rust scale, oil stain, paint, and other impurities

which affect the quality of weld. The cleaning area is not less than 20mm from

the edge of the weld.

7.1.3 During open-air welding, in case of rain, snow, heavy fog, and strong wind,

if no protective measures are taken, welding shall not be carried out.

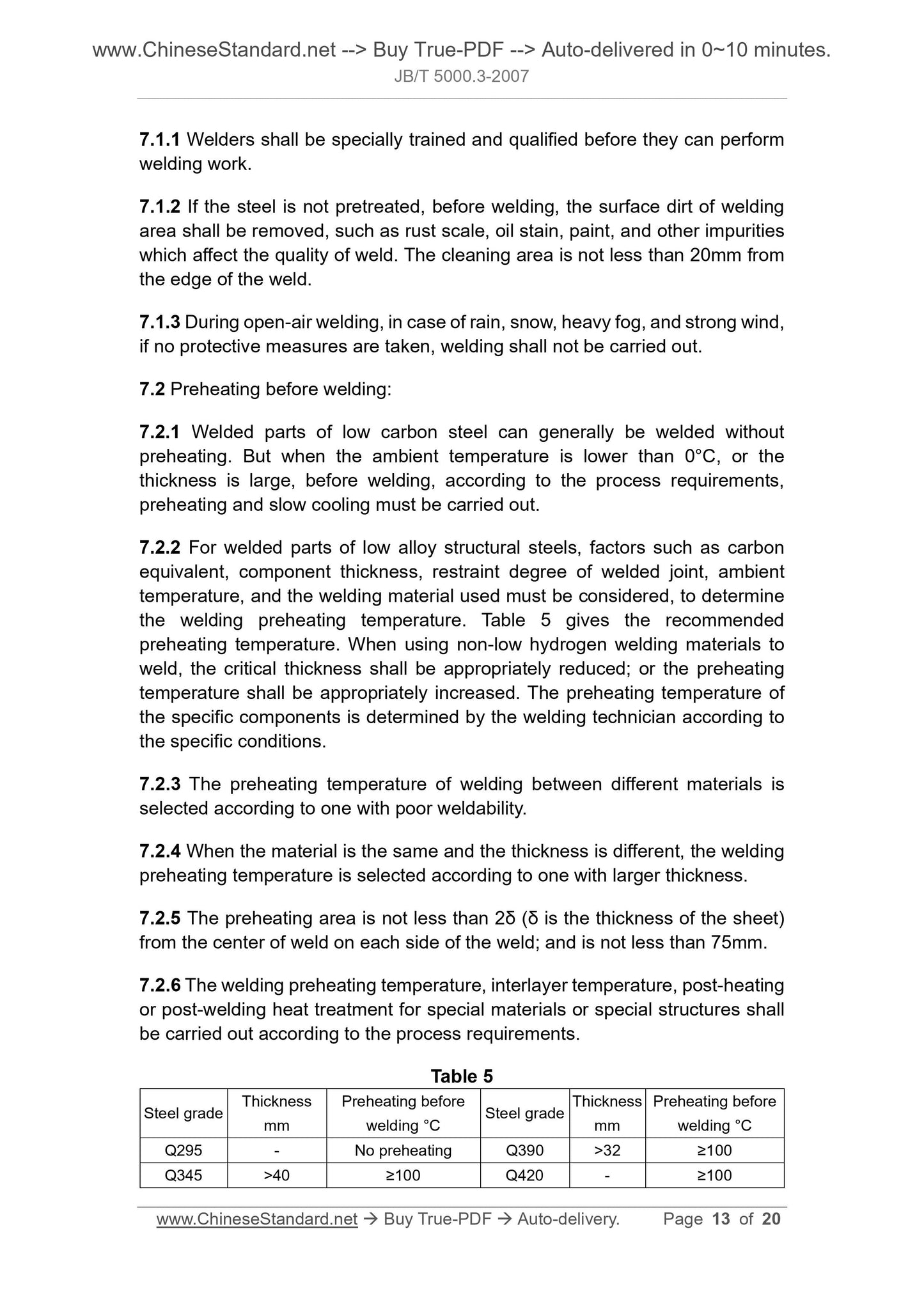

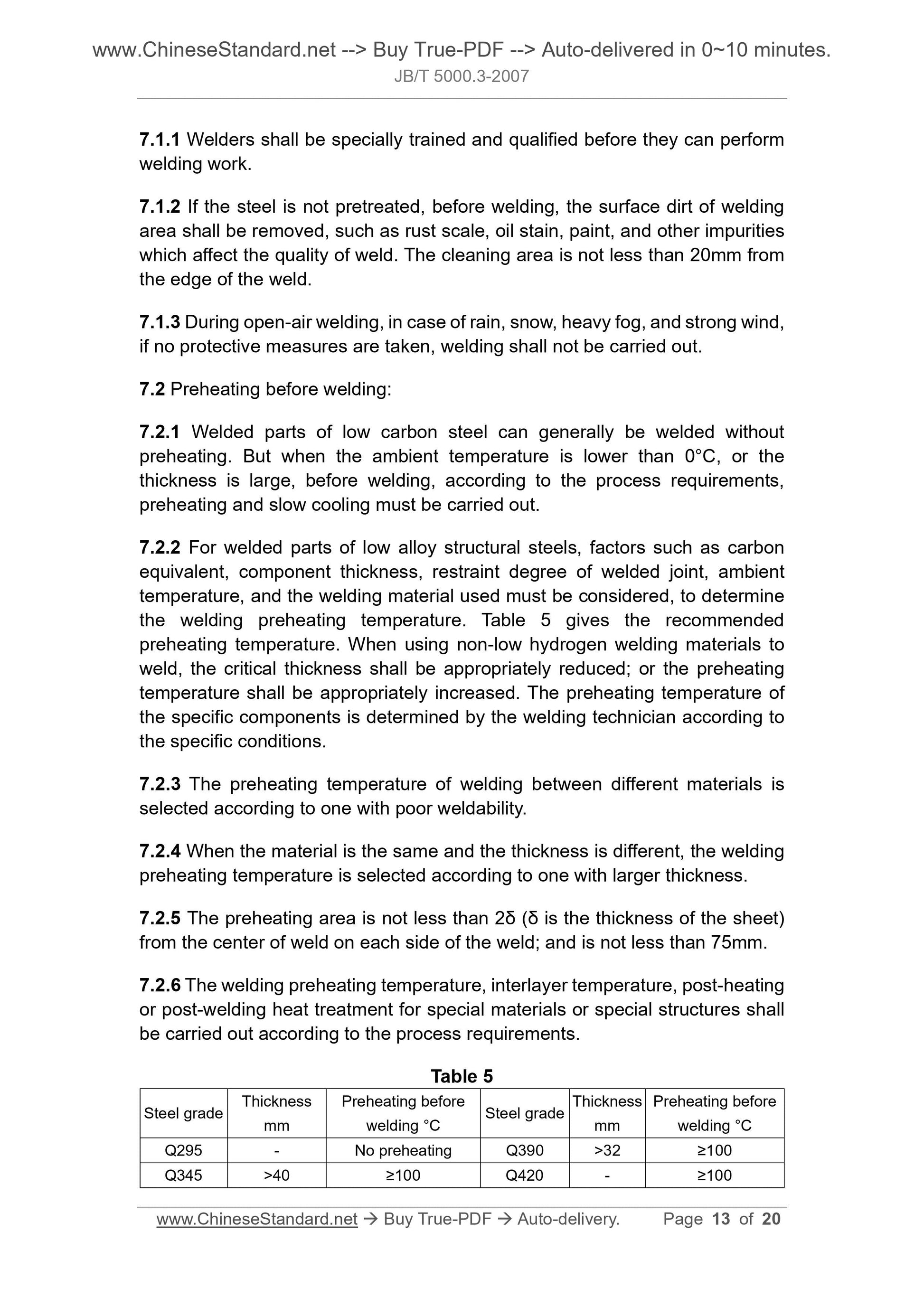

7.2 Preheating before welding.

7.2.1 Welded parts of low carbon stee...

Get QUOTATION in 1-minute: Click JB/T 5000.3-2007

Historical versions: JB/T 5000.3-2007

Preview True-PDF (Reload/Scroll if blank)

JB/T 5000.3-2007: Heavy mechanical general techniques - Part 3: And standards welding

JB/T 5000.3-2007

JB

NATIONAL MACHINERY INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 25.160

J 33

Record number. 21697-2007

Replacing JB/T 5000.3-1998

Heavy mechanical general techniques

- Part 3. And standards welding

ISSUED ON. AUGUST 28, 2007

IMPLEMENTED ON. FEBRUARY 1, 2008

Issued by. National Development and Reform Commission, People’s

Republic of China

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 General requirements ... 6

4 Preliminary straightening of steel ... 7

5 Forming bending of steel ... 8

6 Welding assembly ... 11

7 Welding ... 12

8 Machining allowance of welded structural parts ... 18

9 Welded joints and grooves ... 19

10 Inspection ... 19

11 Drawing indications ... 20

Foreword

JB/T 5000 “Heavy mechanical general techniques and standards” is divided

into 15 parts.

- Part 1. Check of product;

- Part 2. Oxygen cutting workpiece;

- Part 3. And standards welding [Translator note. should be “Welding”];

- Part 4. Iron Casting;

- Part 5. Non-ferrous casting;

- Part 6. Steel Castings;

- Part 7. Repair welding for steel castings;

- Part 8. Forging;

- Part 9. Cutting;

- Part 10. Assembly;

- Part 11. Attached piping;

- Part 12. Paint;

- Part 13. Packing;

- Part 14. Non-destructive inspection of cast steel;

- Part 15. Non-destructive inspection of forged steel.

This Part is Part 3 of JB/T 5000.

This Part replaces JB/T 5000.3-1998 “The heavy mechanical general

techniques and standards - Welding”.

As compared with JB/T 5000.3-1998, the main changes of this Part are as

follows.

- ADD the requirement for chamfering the edges and corners of the bent steel

part when the steel is rolled.

- ADD length, weld angle, and quality requirements for tack weld.

Heavy mechanical general techniques

- Part 3. And standards welding

1 Scope

This Part of JB/T 5000 specifies the technical requirements, inspection methods,

and drawing indications of steel welded parts.

This Part applies to steel welded parts by shielded metal arc welding, gas

shielded welding, and submerged arc welding in heavy machinery and

components.

Where there are no special requirements in product drawings, technical

documents, and ordering technical conditions, the provisions of this Part shall

be complied with.

2 Normative references

The clauses in the following documents, by reference in this Part of JB/T 5000,

constitute the clauses of this Part. For the dated references, the subsequent

amendments (not including errata content) or revisions do not apply to this Part.

However, parties which have reached an agreement according to this Part are

encouraged to study whether the latest edition of these documents can be used.

For the undated references, the latest edition is applicable to this Part.

GB/T 324 Welds - symbolic representation on drawings (GB/T 324-1988, eqv

ISO 2553.1989)

GB/T 985 Basic forms and sizes of weld grooves for gas welding, manual

arc welding and gas-shielded welding

GB/T 986 Basic forms and sizes of weld grooves for submerged arc welding

GB/T 2649 Methods of sampling for mechanical properties tests of welded

joint

GB/T 2650 Impact test methods on welded joints

GB/T 2651 Tensile test method on welded joints

GB/T 2652 Tensile test methods on weld and deposited metal

GB/T 2653 Methods of bend and compression tests for welded joint

GB/T 2654 Methods of hardness tests for welded joint and surfacing metal

GB/T 3323 Radiographic examination of fusion welded joints in metallic

materials (GB/T 3323-2005, EN 135.1997, MOD)

GB/T 11345 Non-destructive testing of welds - Ultrasonic testing -

Techniques, testing levels, and assessment

JB/T 3223 Welding material quality management procedures

JB/T 4735 Steel welded atmospheric pressure vessels

JB/T 5000.2 Heavy mechanical general techniques and standards - Part 2.

Oxygen cutting workpiece

JB/T 5000.11 Heavy mechanical general techniques and standards - Part 11.

Attached piping

JB/T 5000.12 Heavy mechanical general techniques and standards - Part 12.

Paint

JB/T 5926 Vibrating stress relief effect - Evaluation methods

JB/T 6046 Welding assembly for carbon steel and low alloy steel - Post-

welding heat treatment method

JB/T 6061 Non-destructive testing - Magnetic particle testing of welds

JB/T 7949 Weld outer dimensions for steel construction

3 General requirements

3.1 Welded parts shall be manufactured in accordance with the design drawings,

process documents, and this Part.

3.2 The steel grade, specifications, and dimensions of the raw materials (steel

sheets, section steel, and steel pipes, etc.) used to manufacture the welded

parts shall comply with the requirements of design drawings. For material

substitution, substitution sheet shall be handled in accordance with relevant

regulations.

3.3 Raw materials and welding materials (welding rods, welding wire, flux,

shield gas, etc.) used to manufacture welded parts shall, when entering the

factory, based on the certificate of compliance provided by the supplier,

5 Forming bending of steel

5.1 For the rolling bending of steel, when the bending radius (inner radius) is

greater than the following values, cold bending can be carried out (SEE Figure

1). However, regardless of cold bending or hot bending, the edges and corners

of the steel sheet near the bent part shall be chamfered.

5.1.1 Steel sheet. For low alloy steel, R≥25δ;

For low carbon steel, R≥20δ.

R - Bending radius; δ - Thickness of steel sheet.

5.1.2 I-beam. R≥25H or R≥25B (depending on the direction of bending);

H - I-beam’s height; B - I-beam’s width.

5.1.3 Channel steel. R≥45B or R≥25H (depending on the direction of bending);

H - Channel steel’s height; B - Channel steel’s width.

5.1.4 Angle steel. R≥45B;

B - Angle steel’s edge-width (for unequal angle steel,

depending on the direction of bending).

5.2 For the rolling bending of steel, when the bending radius (inner radius) is

less than the values specified in 5.1, according to the specific situation, the

technician shall determine whether to perform annealing heat treatment after

hot bending or cold bending.

5.3 The tolerances for the dimensions of bend formed cylinder shall be in

accordance with Figure 2 and Table 3.

5.4 The unfitness of butt joint e for the butt joint between cylinders or for the

longitudinal joint of cylinder shall not exceed 20% of thickness and no more

than 4mm (SEE Figure 3 and Figure 4).

5.5 For the bend forming of the pipe, during hot bending, the heating

temperature is 900°C~1000°C. During bending, the temperature shall not be

lower than 700°C. Cold bending shall be carried out on a special pipe bender.

5.6 The bending radius R of the pipe (SEE Figure 5) shall comply with the

provisions of JB/T 5000.11.

7.1.1 Welders shall be specially trained and qualified before they can perform

welding work.

7.1.2 If the steel is not pretreated, before welding, the surface dirt of welding

area shall be removed, such as rust scale, oil stain, paint, and other impurities

which affect the quality of weld. The cleaning area is not less than 20mm from

the edge of the weld.

7.1.3 During open-air welding, in case of rain, snow, heavy fog, and strong wind,

if no protective measures are taken, welding shall not be carried out.

7.2 Preheating before welding.

7.2.1 Welded parts of low carbon stee...

Share