1

/

of

5

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

JB/T 5313-2001 English PDF (JB/T5313-2001)

JB/T 5313-2001 English PDF (JB/T5313-2001)

Regular price

$390.00 USD

Regular price

Sale price

$390.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click JB/T 5313-2001

Historical versions: JB/T 5313-2001

Preview True-PDF (Reload/Scroll if blank)

JB/T 5313-2001: Rolling bearing. Measuring methods for vibration(velocity)

JB/T 5313-2001

JB

MECHANICAL INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 21.100.20

J 11

Rolling Bearing - Measuring Methods for Vibration

(Velocity)

ISSUED ON: MAY 23, 2001

IMPLEMENTED ON: OCTOBER 01, 2001

Issued by: China Machinery Industry Federation

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative References ... 4

3 Term and Definitions ... 4

4 Physical Quantity and Unit ... 5

5 Assessment of Bearing Vibration (Velocity) ... 5

6 Test Conditions ... 5

7 Test Method and Procedure ... 11

Rolling Bearing - Measuring Methods for Vibration

(Velocity)

1 Scope

This standard specifies measuring methods for vibration (velocity) of DN 3~120mm

deep groove ball bearings, angular contact ball bearing, tapered roller bearing and

cylindrical roller bearing (Types N, NU, NJ and NF).

This standard is applicable to the inspection of the vibration (velocity) of rolling

bearings above by laboratory, manufacturer and users.

2 Normative References

The following normative documents contain the provisions which, through reference in

this standard, constitute the provisions of this standard. At time of publication, the

editions indicated were valid. All the standards will be revised, all parties who reach an

agreement according to this standard are encouraged to study whether the latest editions

of the following standards are applicable.

GB/T 307.1-1994 Rolling Bearings - Radial Bearings - Tolerances

GB/T 6930-1986 Rolling bearings - Vocabulary

3 Term and Definitions

3.1 Bearing vibration

All movements with periodic variation are called bearing vibration, except some

intrinsic, function-required movements between bearing parts in the rotation.

Bearing vibration measured in this standard refers to: the radial vibration velocity of

bearing outer ring -- where the raceway center section is intersected with the cylindrical

surface (highest point) outside the outer ring, when inner ring end face of bearing abuts

against mandrel shoulder and rotates at some constant rotation speed, and while the

outer ring does not rotate but bears certain radial or axial loads.

3.2 Bearing vibration (velocity) value

Under certain rotation speed and test load, it is tested at three equidistant points at the

direction of the cylindrical surface circumference outside bearing outer ring and the

arithmetic mean of vibration speeds at the high-, medium- and low-frequency band, that

is the vibration (velocity) value of this bearing at the corresponding frequency band. If

the bearing needs to be tested on both sides, the higher value (mean value of three points)

at each frequency band is the vibration (velocity) value of the bearing at this frequency

band.

4 Physical Quantity and Unit

The physical quantity for vibration of measured bearing is the radial vibration velocity

of bearing outer ring, μm/s.

5 Assessment of Bearing Vibration (Velocity)

5.1 Frequency range

Within 50~10000Hz frequency range, the three measuring frequency bands of bearing

vibration (velocity) shall be according to those specified in Table 1.

5.2 Time averaging method

The vibration speed signal at each measuring point shall be measured for not less than

0.5s and not be read until the pointer is still. If the signal is fluctuated, the medium value

of the fluctuation range shall be taken.

6 Test Conditions

6.1 Mechanical device

6.1.1 Basic vibration

Start main drive axle (each frequency band range switch placed at minimum gear), press

transducer measuring point down so that it is at the condition identical to the test mode;

in this case, the indicated values at each frequency band shall be in accordance with

those specified in Table 2.

Figure 2 -- Radial Load Plant Diagram

The applied composite radial load is down vertically, its action line has an included

angle not greater than 2° with the vertical line of main drive axle center, the distance to

the main drive axle center line shall be less than 0.5mm.

6.1.5 Transducer holder

The transducer holder may move along axis direction and vertical direction of main

drive axle separately, and ensure that the action line of the transducer on contact load

of measured bearing outer ring has an included angle not greater than 2° with vertical

line of main drive axle center, the distance off the axial line shall be less than 0.2mm.

6.2 Transducer

What is induced by the transducer is the rate of change in radial vibration displacement

of bearing outer ring.

6.2.1 Within 50~10000Hz frequency range, the transducer and the measured bearing

outer ring shall be free from separation, and the contact load of transducer for the

measured bearing outer ring must be less than 0.7N.

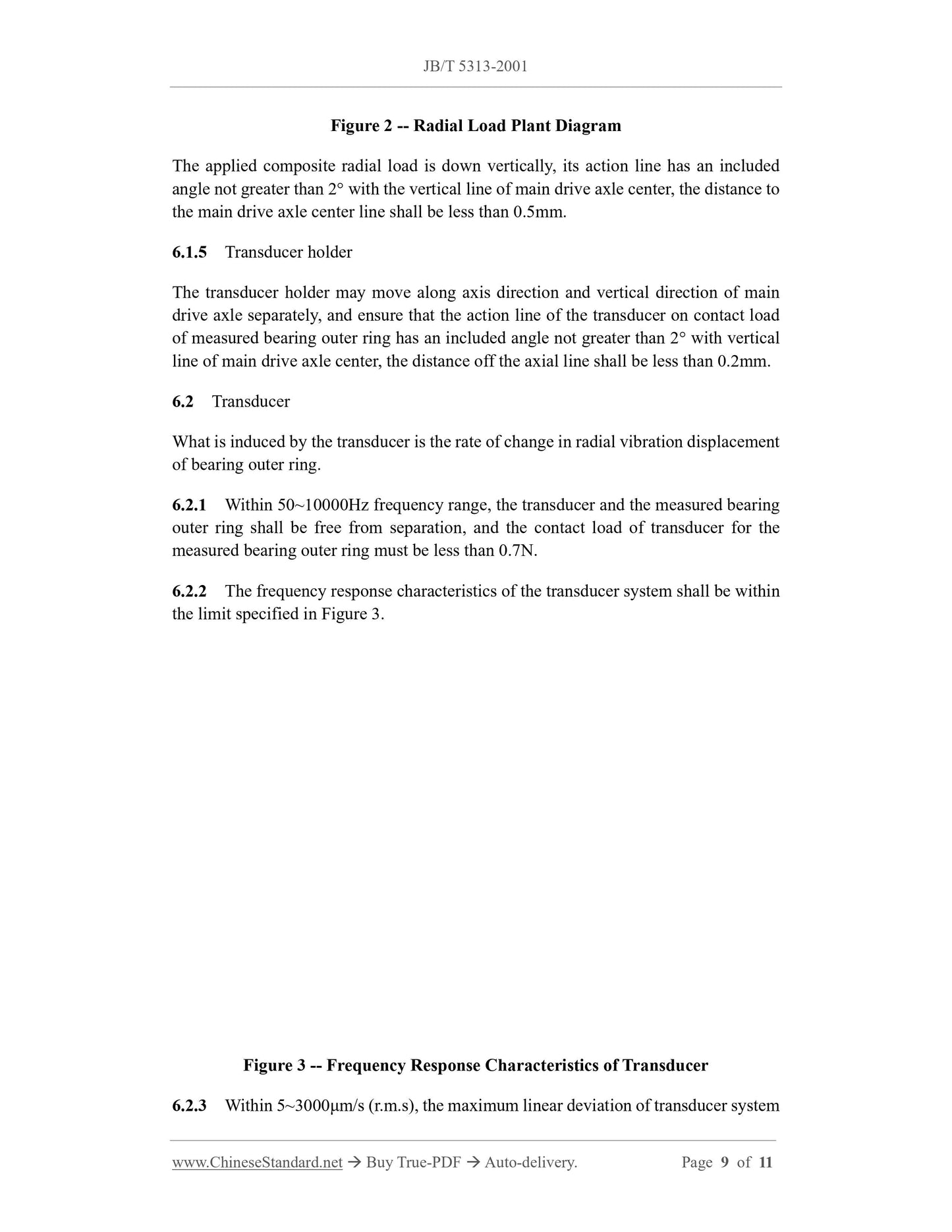

6.2.2 The frequency response characteristics of the transducer system shall be within

the limit specified in Figure 3.

Figure 3 -- Frequency Response Characteristics of Transducer

6.2.3 Within 5~3000μm/s (r.m.s), the maximum linear deviation of transducer system

Get QUOTATION in 1-minute: Click JB/T 5313-2001

Historical versions: JB/T 5313-2001

Preview True-PDF (Reload/Scroll if blank)

JB/T 5313-2001: Rolling bearing. Measuring methods for vibration(velocity)

JB/T 5313-2001

JB

MECHANICAL INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 21.100.20

J 11

Rolling Bearing - Measuring Methods for Vibration

(Velocity)

ISSUED ON: MAY 23, 2001

IMPLEMENTED ON: OCTOBER 01, 2001

Issued by: China Machinery Industry Federation

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative References ... 4

3 Term and Definitions ... 4

4 Physical Quantity and Unit ... 5

5 Assessment of Bearing Vibration (Velocity) ... 5

6 Test Conditions ... 5

7 Test Method and Procedure ... 11

Rolling Bearing - Measuring Methods for Vibration

(Velocity)

1 Scope

This standard specifies measuring methods for vibration (velocity) of DN 3~120mm

deep groove ball bearings, angular contact ball bearing, tapered roller bearing and

cylindrical roller bearing (Types N, NU, NJ and NF).

This standard is applicable to the inspection of the vibration (velocity) of rolling

bearings above by laboratory, manufacturer and users.

2 Normative References

The following normative documents contain the provisions which, through reference in

this standard, constitute the provisions of this standard. At time of publication, the

editions indicated were valid. All the standards will be revised, all parties who reach an

agreement according to this standard are encouraged to study whether the latest editions

of the following standards are applicable.

GB/T 307.1-1994 Rolling Bearings - Radial Bearings - Tolerances

GB/T 6930-1986 Rolling bearings - Vocabulary

3 Term and Definitions

3.1 Bearing vibration

All movements with periodic variation are called bearing vibration, except some

intrinsic, function-required movements between bearing parts in the rotation.

Bearing vibration measured in this standard refers to: the radial vibration velocity of

bearing outer ring -- where the raceway center section is intersected with the cylindrical

surface (highest point) outside the outer ring, when inner ring end face of bearing abuts

against mandrel shoulder and rotates at some constant rotation speed, and while the

outer ring does not rotate but bears certain radial or axial loads.

3.2 Bearing vibration (velocity) value

Under certain rotation speed and test load, it is tested at three equidistant points at the

direction of the cylindrical surface circumference outside bearing outer ring and the

arithmetic mean of vibration speeds at the high-, medium- and low-frequency band, that

is the vibration (velocity) value of this bearing at the corresponding frequency band. If

the bearing needs to be tested on both sides, the higher value (mean value of three points)

at each frequency band is the vibration (velocity) value of the bearing at this frequency

band.

4 Physical Quantity and Unit

The physical quantity for vibration of measured bearing is the radial vibration velocity

of bearing outer ring, μm/s.

5 Assessment of Bearing Vibration (Velocity)

5.1 Frequency range

Within 50~10000Hz frequency range, the three measuring frequency bands of bearing

vibration (velocity) shall be according to those specified in Table 1.

5.2 Time averaging method

The vibration speed signal at each measuring point shall be measured for not less than

0.5s and not be read until the pointer is still. If the signal is fluctuated, the medium value

of the fluctuation range shall be taken.

6 Test Conditions

6.1 Mechanical device

6.1.1 Basic vibration

Start main drive axle (each frequency band range switch placed at minimum gear), press

transducer measuring point down so that it is at the condition identical to the test mode;

in this case, the indicated values at each frequency band shall be in accordance with

those specified in Table 2.

Figure 2 -- Radial Load Plant Diagram

The applied composite radial load is down vertically, its action line has an included

angle not greater than 2° with the vertical line of main drive axle center, the distance to

the main drive axle center line shall be less than 0.5mm.

6.1.5 Transducer holder

The transducer holder may move along axis direction and vertical direction of main

drive axle separately, and ensure that the action line of the transducer on contact load

of measured bearing outer ring has an included angle not greater than 2° with vertical

line of main drive axle center, the distance off the axial line shall be less than 0.2mm.

6.2 Transducer

What is induced by the transducer is the rate of change in radial vibration displacement

of bearing outer ring.

6.2.1 Within 50~10000Hz frequency range, the transducer and the measured bearing

outer ring shall be free from separation, and the contact load of transducer for the

measured bearing outer ring must be less than 0.7N.

6.2.2 The frequency response characteristics of the transducer system shall be within

the limit specified in Figure 3.

Figure 3 -- Frequency Response Characteristics of Transducer

6.2.3 Within 5~3000μm/s (r.m.s), the maximum linear deviation of transducer system

Share