1

/

of

6

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

JB/T 6688-1993 English PDF (JB/T6688-1993)

JB/T 6688-1993 English PDF (JB/T6688-1993)

Regular price

$70.00 USD

Regular price

Sale price

$70.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get Quotation: Click JB/T 6688-1993 (Self-service in 1-minute)

Historical versions (Master-website): JB/T 6688-1993

Preview True-PDF (Reload/Scroll-down if blank)

JB/T 6688-1993: Specification for 12-spline Flange Nut and 12 point Flange Nut

JB/T 6688-1993

JB

INDUSTRY STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

J 13

Specification for 12-spline Flange Nut and 12

point Flange Nut

ISSUED ON. JUNE 01, 1993

IMPLEMENTED ON. JANUARY 01, 1994

Issued by. Ministry of Machinery Industry of PRC

Table of Contents

1 Scope ... 3

2 Normative references ... 3

3 Technical conditions ... 3

4 Inspection rules ... 8

5 Acceptance inspection, marking and packaging ... 9

Additional Information... 9

Specification for 12-spline Flange Nut and 12 point

Flange Nut

1 Scope

This Standard applies to the manufacture and acceptance of 12-spline flange nut and

12 point flange nut (hereinafter referred to as bolt and nut respectively) that are used for

gas turbine power plant.

2 Normative references

GB 3 Run-outs, undercuts and chamfers for general purpose metric screw

threads

GB 196 General purpose screw threads - Basic dimensions for diameter from 1

to 600mm

GB 197 General purpose screw threads - Tolerances and fits for diameter from 1

to 355mm

GB 228 Tensile testing of metallic materials

GB 3077 Technical requirements for alloy structure steels

GB 3098.1~3098.4 Mechanical properties of fasteners

GB 3099 Bolts, screws, nuts and accessories - terminology and nomenclature

GB 3106 Bolts, screws and studs - Nominal lengths and thread lengths for

general purpose bolts

GB 5276 Fasteners - Bolts, screws, studs and nuts - Symbols and designations

of dimensions

GBn 177 Hot-rolled and forged heat-resisting super alloy bars for general

force-bearing parts

3 Technical conditions

3.1 Main indicators

3.1.3.1 Tolerance of screw thread

a. Tolerance of outer screw thread is 6g;

b. Tolerance of inner screw thread is 6H.

3.1.3.2 The biggest permissible value of surface roughness parameter for screw

thread side Ra is 3.2µm.

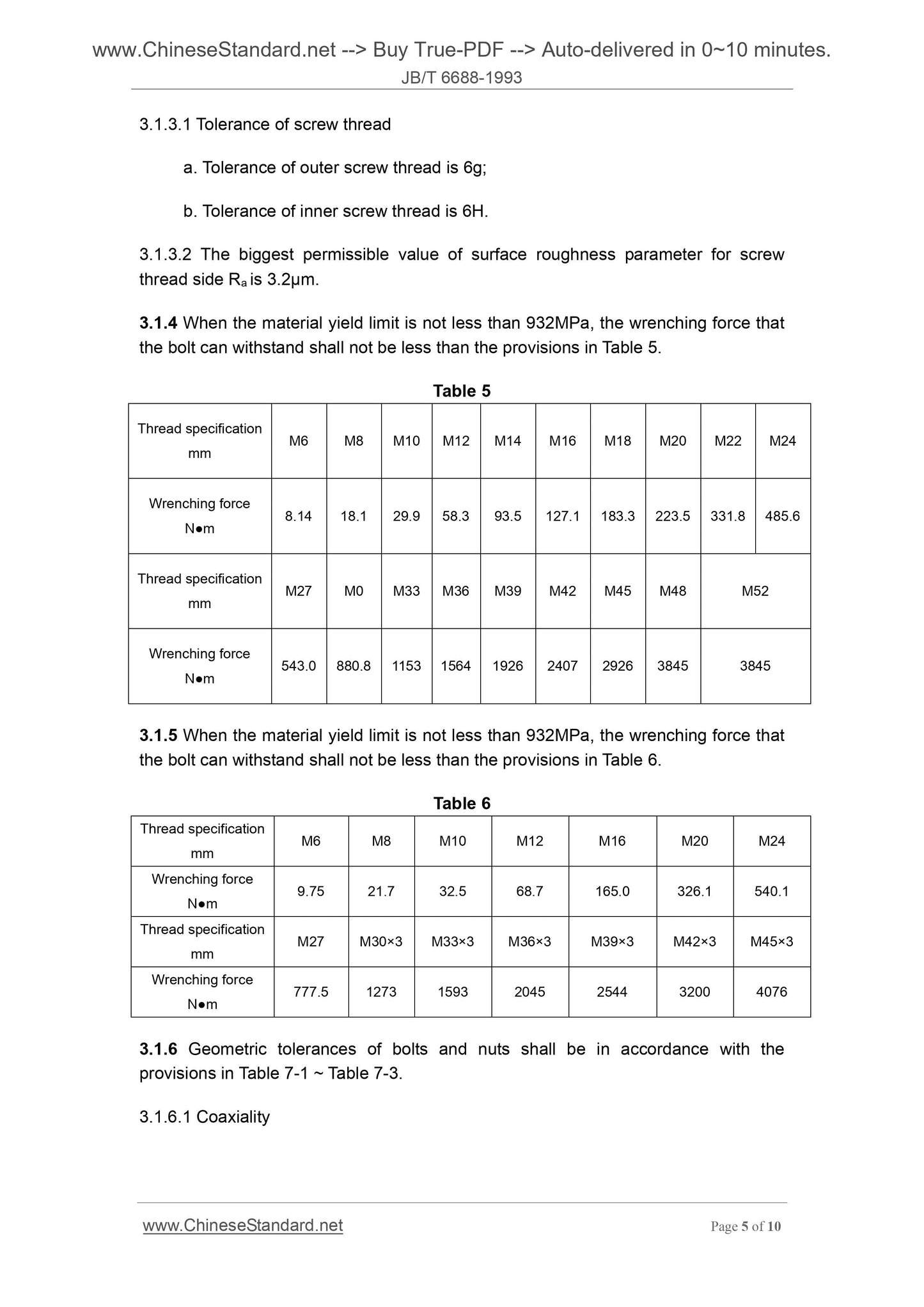

3.1.4 When the material yield limit is not less than 932MPa, the wrenching force that

the bolt can withstand shall not be less than the provisions in Table 5.

Table 5

Thread specification

mm M6 M8 M10 M12 M14 M16 M18 M20 M22 M24

Wrenching force

N●m 8.14 18.1 29.9 58.3 93.5 127.1 183.3 223.5 331.8 485.6

Thread specification

mm M27 M0 M33 M36 M39 M42 M45 M48 M52

Wrenching force

N●m 543.0 880.8 1153 1564 1926 2407 2926 3845 3845

3.1.5 When the material yield limit is not less than 932MPa, the wrenching force that

the bolt can withstand shall not be less than the provisions in Table 6.

Table 6

Thread specification

mm M6 M8 M10 M12 M16 M20 M24

Wrenching force

N●m 9.75 21.7 32.5 68.7 165.0 326.1 540.1

Thread specification

mm M27 M30×3 M33×3 M36×3 M39×3 M42×3 M45×3

Wrenching force

N●m 777.5 1273 1593 2045 2544 3200 4076

3.1.6 Geometric tolerances of bolts and nuts shall be in accordance with the

provisions in Table 7-1 ~ Table 7-3.

3.1.6.1 Coaxiality

4.7 Wrenching torque test of bolts. When torque reaches to the values in Table 5,

12-spline of bolts shall not produce the permanent deformation that influences the

usage and sliding between wrenches. Accuracy of torque measuring device shall not

be less than ±5%.

4.8 Wrenching torque test of nuts. When torque reaches to the values in Table 5, 12

point of nuts shall not produce the permanent deformation that influences the usage

and sliding between wrenches. Accuracy of torque measuring device shall not be less

than ±5%.

5 Acceptance inspection, marking and packaging

5.1 Bolts and nuts shall be submitted for inspection in batch. Each batch shall be

made of materials with same type, same size and same furnace number. It shall

conduct heat treatment according to the same specification.

5.2 Appearance of bolts and nuts shall be subject to 100% inspection.

5.3 As required, bolts and nuts can be subject to magnetic particle inspection or

fluorescence detection.

5.4 Bolts shall be marked at the head-top by braille or concave characters. Nuts shall

be marked at the supporting surface by concave characters. Marking symbol.

30CrMnSi and 40CrNiMoA use symbol “D”; 40Cr2MoV use symbol “Z”; GH2132 use

symbol “G”.

5.5 Other acceptance rules and packaging shall be in accordance with GB 90

“Acceptance inspection, marking and packaging of fasteners”.

Additional Information.

The Standard was proposed by Nanjing Institute of Gas Turbine.

This Standard shall be under the jurisdiction of Nanjing Institute of Gas Turbine.

This standard is drafted by the following organizations. Nanjing Turbine and Electric

Machinery (Group) Co., Ltd., Nanjing Institute of Gas Turbine, Harbin Steam Turbine

Plant, and China Shipbuilding Industry Corporation 703 Research Institute.

JB/T 6688-1993

JB

INDUSTRY STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

J 13

Specification for 12-spline Flange Nut and 12

point Flange Nut

ISSUED ON. JUNE 01, 1993

IMPLEMENTED ON. JANUARY 01, 1994

Issued by. Ministry of Machinery Industry of PRC

Table of Contents

1 Scope ... 3

2 Normative references ... 3

3 Technical conditions ... 3

4 Inspection rules ... 8

5 Acceptance inspection, marking and packaging ... 9

Additional Information... 9

Specification for 12-spline Flange Nut and 12 point

Flange Nut

1 Scope

This Standard applies to the manufacture and acceptance of 12-spline flange nut and

12 point flange nut (hereinafter referred to as bolt and nut respectively) that are used for

gas turbine power plant.

2 Normative references

GB 3 Run-outs, undercuts and chamfers for general purpose metric screw

threads

GB 196 General purpose screw threads - Basic dimensions for diameter from 1

to 600mm

GB 197 General purpose screw threads - Tolerances and fits for diameter from 1

to 355mm

GB 228 Tensile testing of metallic materials

GB 3077 Technical requirements for alloy structure steels

GB 3098.1~3098.4 Mechanical properties of fasteners

GB 3099 Bolts, screws, nuts and accessories - terminology and nomenclature

GB 3106 Bolts, screws and studs - Nominal lengths and thread lengths for

general purpose bolts

GB 5276 Fasteners - Bolts, screws, studs and nuts - Symbols and designations

of dimensions

GBn 177 Hot-rolled and forged heat-resisting super alloy bars for general

force-bearing parts

3 Technical conditions

3.1 Main indicators

3.1.3.1 Tolerance of screw thread

a. Tolerance of outer screw thread is 6g;

b. Tolerance of inner screw thread is 6H.

3.1.3.2 The biggest permissible value of surface roughness parameter for screw

thread side Ra is 3.2µm.

3.1.4 When the material yield limit is not less than 932MPa, the wrenching force that

the bolt can withstand shall not be less than the provisions in Table 5.

Table 5

Thread specification

mm M6 M8 M10 M12 M14 M16 M18 M20 M22 M24

Wrenching force

N●m 8.14 18.1 29.9 58.3 93.5 127.1 183.3 223.5 331.8 485.6

Thread specification

mm M27 M0 M33 M36 M39 M42 M45 M48 M52

Wrenching force

N●m 543.0 880.8 1153 1564 1926 2407 2926 3845 3845

3.1.5 When the material yield limit is not less than 932MPa, the wrenching force that

the bolt can withstand shall not be less than the provisions in Table 6.

Table 6

Thread specification

mm M6 M8 M10 M12 M16 M20 M24

Wrenching force

N●m 9.75 21.7 32.5 68.7 165.0 326.1 540.1

Thread specification

mm M27 M30×3 M33×3 M36×3 M39×3 M42×3 M45×3

Wrenching force

N●m 777.5 1273 1593 2045 2544 3200 4076

3.1.6 Geometric tolerances of bolts and nuts shall be in accordance with the

provisions in Table 7-1 ~ Table 7-3.

3.1.6.1 Coaxiality

4.7 Wrenching torque test of bolts. When torque reaches to the values in Table 5,

12-spline of bolts shall not produce the permanent deformation that influences the

usage and sliding between wrenches. Accuracy of torque measuring device shall not

be less than ±5%.

4.8 Wrenching torque test of nuts. When torque reaches to the values in Table 5, 12

point of nuts shall not produce the permanent deformation that influences the usage

and sliding between wrenches. Accuracy of torque measuring device shall not be less

than ±5%.

5 Acceptance inspection, marking and packaging

5.1 Bolts and nuts shall be submitted for inspection in batch. Each batch shall be

made of materials with same type, same size and same furnace number. It shall

conduct heat treatment according to the same specification.

5.2 Appearance of bolts and nuts shall be subject to 100% inspection.

5.3 As required, bolts and nuts can be subject to magnetic particle inspection or

fluorescence detection.

5.4 Bolts shall be marked at the head-top by braille or concave characters. Nuts shall

be marked at the supporting surface by concave characters. Marking symbol.

30CrMnSi and 40CrNiMoA use symbol “D”; 40Cr2MoV use symbol “Z”; GH2132 use

symbol “G”.

5.5 Other acceptance rules and packaging shall be in accordance with GB 90

“Acceptance inspection, marking and packaging of fasteners”.

Additional Information.

The Standard was proposed by Nanjing Institute of Gas Turbine.

This Standard shall be under the jurisdiction of Nanjing Institute of Gas Turbine.

This standard is drafted by the following organizations. Nanjing Turbine and Electric

Machinery (Group) Co., Ltd., Nanjing Institute of Gas Turbine, Harbin Steam Turbine

Plant, and China Shipbuilding Industry Corporation 703 Research Institute.

Get Quotation: Click JB/T 6688-1993 (Self-service in 1-minute)

Historical versions (Master-website): JB/T 6688-1993

Preview True-PDF (Reload/Scroll-down if blank)

JB/T 6688-1993: Specification for 12-spline Flange Nut and 12 point Flange Nut

JB/T 6688-1993

JB

INDUSTRY STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

J 13

Specification for 12-spline Flange Nut and 12

point Flange Nut

ISSUED ON. JUNE 01, 1993

IMPLEMENTED ON. JANUARY 01, 1994

Issued by. Ministry of Machinery Industry of PRC

Table of Contents

1 Scope ... 3

2 Normative references ... 3

3 Technical conditions ... 3

4 Inspection rules ... 8

5 Acceptance inspection, marking and packaging ... 9

Additional Information... 9

Specification for 12-spline Flange Nut and 12 point

Flange Nut

1 Scope

This Standard applies to the manufacture and acceptance of 12-spline flange nut and

12 point flange nut (hereinafter referred to as bolt and nut respectively) that are used for

gas turbine power plant.

2 Normative references

GB 3 Run-outs, undercuts and chamfers for general purpose metric screw

threads

GB 196 General purpose screw threads - Basic dimensions for diameter from 1

to 600mm

GB 197 General purpose screw threads - Tolerances and fits for diameter from 1

to 355mm

GB 228 Tensile testing of metallic materials

GB 3077 Technical requirements for alloy structure steels

GB 3098.1~3098.4 Mechanical properties of fasteners

GB 3099 Bolts, screws, nuts and accessories - terminology and nomenclature

GB 3106 Bolts, screws and studs - Nominal lengths and thread lengths for

general purpose bolts

GB 5276 Fasteners - Bolts, screws, studs and nuts - Symbols and designations

of dimensions

GBn 177 Hot-rolled and forged heat-resisting super alloy bars for general

force-bearing parts

3 Technical conditions

3.1 Main indicators

3.1.3.1 Tolerance of screw thread

a. Tolerance of outer screw thread is 6g;

b. Tolerance of inner screw thread is 6H.

3.1.3.2 The biggest permissible value of surface roughness parameter for screw

thread side Ra is 3.2µm.

3.1.4 When the material yield limit is not less than 932MPa, the wrenching force that

the bolt can withstand shall not be less than the provisions in Table 5.

Table 5

Thread specification

mm M6 M8 M10 M12 M14 M16 M18 M20 M22 M24

Wrenching force

N●m 8.14 18.1 29.9 58.3 93.5 127.1 183.3 223.5 331.8 485.6

Thread specification

mm M27 M0 M33 M36 M39 M42 M45 M48 M52

Wrenching force

N●m 543.0 880.8 1153 1564 1926 2407 2926 3845 3845

3.1.5 When the material yield limit is not less than 932MPa, the wrenching force that

the bolt can withstand shall not be less than the provisions in Table 6.

Table 6

Thread specification

mm M6 M8 M10 M12 M16 M20 M24

Wrenching force

N●m 9.75 21.7 32.5 68.7 165.0 326.1 540.1

Thread specification

mm M27 M30×3 M33×3 M36×3 M39×3 M42×3 M45×3

Wrenching force

N●m 777.5 1273 1593 2045 2544 3200 4076

3.1.6 Geometric tolerances of bolts and nuts shall be in accordance with the

provisions in Table 7-1 ~ Table 7-3.

3.1.6.1 Coaxiality

4.7 Wrenching torque test of bolts. When torque reaches to the values in Table 5,

12-spline of bolts shall not produce the permanent deformation that influences the

usage and sliding between wrenches. Accuracy of torque measuring device shall not

be less than ±5%.

4.8 Wrenching torque test of nuts. When torque reaches to the values in Table 5, 12

point of nuts shall not produce the permanent deformation that influences the usage

and sliding between wrenches. Accuracy of torque measuring device shall not be less

than ±5%.

5 Acceptance inspection, marking and packaging

5.1 Bolts and nuts shall be submitted for inspection in batch. Each batch shall be

made of materials with same type, same size and same furnace number. It shall

conduct heat treatment according to the same specification.

5.2 Appearance of bolts and nuts shall be subject to 100% inspection.

5.3 As required, bolts and nuts can be subject to magnetic particle inspection or

fluorescence detection.

5.4 Bolts shall be marked at the head-top by braille or concave characters. Nuts shall

be marked at the supporting surface by concave characters. Marking symbol.

30CrMnSi and 40CrNiMoA use symbol “D”; 40Cr2MoV use symbol “Z”; GH2132 use

symbol “G”.

5.5 Other acceptance rules and packaging shall be in accordance with GB 90

“Acceptance inspection, marking and packaging of fasteners”.

Additional Information.

The Standard was proposed by Nanjing Institute of Gas Turbine.

This Standard shall be under the jurisdiction of Nanjing Institute of Gas Turbine.

This standard is drafted by the following organizations. Nanjing Turbine and Electric

Machinery (Group) Co., Ltd., Nanjing Institute of Gas Turbine, Harbin Steam Turbine

Plant, and China Shipbuilding Industry Corporation 703 Research Institute.

JB/T 6688-1993

JB

INDUSTRY STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

J 13

Specification for 12-spline Flange Nut and 12

point Flange Nut

ISSUED ON. JUNE 01, 1993

IMPLEMENTED ON. JANUARY 01, 1994

Issued by. Ministry of Machinery Industry of PRC

Table of Contents

1 Scope ... 3

2 Normative references ... 3

3 Technical conditions ... 3

4 Inspection rules ... 8

5 Acceptance inspection, marking and packaging ... 9

Additional Information... 9

Specification for 12-spline Flange Nut and 12 point

Flange Nut

1 Scope

This Standard applies to the manufacture and acceptance of 12-spline flange nut and

12 point flange nut (hereinafter referred to as bolt and nut respectively) that are used for

gas turbine power plant.

2 Normative references

GB 3 Run-outs, undercuts and chamfers for general purpose metric screw

threads

GB 196 General purpose screw threads - Basic dimensions for diameter from 1

to 600mm

GB 197 General purpose screw threads - Tolerances and fits for diameter from 1

to 355mm

GB 228 Tensile testing of metallic materials

GB 3077 Technical requirements for alloy structure steels

GB 3098.1~3098.4 Mechanical properties of fasteners

GB 3099 Bolts, screws, nuts and accessories - terminology and nomenclature

GB 3106 Bolts, screws and studs - Nominal lengths and thread lengths for

general purpose bolts

GB 5276 Fasteners - Bolts, screws, studs and nuts - Symbols and designations

of dimensions

GBn 177 Hot-rolled and forged heat-resisting super alloy bars for general

force-bearing parts

3 Technical conditions

3.1 Main indicators

3.1.3.1 Tolerance of screw thread

a. Tolerance of outer screw thread is 6g;

b. Tolerance of inner screw thread is 6H.

3.1.3.2 The biggest permissible value of surface roughness parameter for screw

thread side Ra is 3.2µm.

3.1.4 When the material yield limit is not less than 932MPa, the wrenching force that

the bolt can withstand shall not be less than the provisions in Table 5.

Table 5

Thread specification

mm M6 M8 M10 M12 M14 M16 M18 M20 M22 M24

Wrenching force

N●m 8.14 18.1 29.9 58.3 93.5 127.1 183.3 223.5 331.8 485.6

Thread specification

mm M27 M0 M33 M36 M39 M42 M45 M48 M52

Wrenching force

N●m 543.0 880.8 1153 1564 1926 2407 2926 3845 3845

3.1.5 When the material yield limit is not less than 932MPa, the wrenching force that

the bolt can withstand shall not be less than the provisions in Table 6.

Table 6

Thread specification

mm M6 M8 M10 M12 M16 M20 M24

Wrenching force

N●m 9.75 21.7 32.5 68.7 165.0 326.1 540.1

Thread specification

mm M27 M30×3 M33×3 M36×3 M39×3 M42×3 M45×3

Wrenching force

N●m 777.5 1273 1593 2045 2544 3200 4076

3.1.6 Geometric tolerances of bolts and nuts shall be in accordance with the

provisions in Table 7-1 ~ Table 7-3.

3.1.6.1 Coaxiality

4.7 Wrenching torque test of bolts. When torque reaches to the values in Table 5,

12-spline of bolts shall not produce the permanent deformation that influences the

usage and sliding between wrenches. Accuracy of torque measuring device shall not

be less than ±5%.

4.8 Wrenching torque test of nuts. When torque reaches to the values in Table 5, 12

point of nuts shall not produce the permanent deformation that influences the usage

and sliding between wrenches. Accuracy of torque measuring device shall not be less

than ±5%.

5 Acceptance inspection, marking and packaging

5.1 Bolts and nuts shall be submitted for inspection in batch. Each batch shall be

made of materials with same type, same size and same furnace number. It shall

conduct heat treatment according to the same specification.

5.2 Appearance of bolts and nuts shall be subject to 100% inspection.

5.3 As required, bolts and nuts can be subject to magnetic particle inspection or

fluorescence detection.

5.4 Bolts shall be marked at the head-top by braille or concave characters. Nuts shall

be marked at the supporting surface by concave characters. Marking symbol.

30CrMnSi and 40CrNiMoA use symbol “D”; 40Cr2MoV use symbol “Z”; GH2132 use

symbol “G”.

5.5 Other acceptance rules and packaging shall be in accordance with GB 90

“Acceptance inspection, marking and packaging of fasteners”.

Additional Information.

The Standard was proposed by Nanjing Institute of Gas Turbine.

This Standard shall be under the jurisdiction of Nanjing Institute of Gas Turbine.

This standard is drafted by the following organizations. Nanjing Turbine and Electric

Machinery (Group) Co., Ltd., Nanjing Institute of Gas Turbine, Harbin Steam Turbine

Plant, and China Shipbuilding Industry Corporation 703 Research Institute.

Share