1

/

of

7

PayPal, credit cards. Download editable-PDF & invoice in 1 second!

JB/T 8583-2008 English PDF (JB/T8583-2008)

JB/T 8583-2008 English PDF (JB/T8583-2008)

Regular price

$160.00 USD

Regular price

Sale price

$160.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click JB/T 8583-2008

Historical versions: JB/T 8583-2008

Preview True-PDF (Reload/Scroll if blank)

JB/T 8583-2008: Resin coated sand for foundry

JB/T 8583-2008

JB

MACHINERY INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 91.100.15

J 31

File No.: 23276-2008

Replacing JB/T 8583-1997

Resin coated sand for foundry

ISSUED ON: MARCH 12, 2008

IMPLEMENTED ON: SEPTEMBER 01, 2008

Issued by: National Development and Reform Commission

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Terms and definitions ... 4

4 Grading and designation ... 5

5 Technical requirements ... 6

6 Test methods ... 6

7 Inspection rules ... 6

8 Labeling, packaging and storage ... 7

Appendix A (normative) Test methods for required performance indicators of resin

coated sand for foundry ... 9

Appendix B (informative) Test methods for other performance indicators of resin

coated sand for foundry ... 12

Resin coated sand for foundry

1 Scope

This Standard specifies the terms and definitions, classification, grading and

designation, technical requirements, test methods, inspection rules, labeling and

packaging of resin coated sand for foundry.

This Standard applies to mold (core) resin coated sand produced with raw sand

(regenerated sand) for foundry and phenolic resin for shell mold (core) as the main raw

materials.

2 Normative references

The following documents contain the provisions which, through reference in this

Standard, become the provisions of this Standard. For dated references, their

subsequent amendments (excluding corrigendum) or revisions do not apply to this

Standard. However, the parties who enter into agreement based on this Standard are

encouraged to investigate whether the latest versions of these documents are applicable.

For undated reference documents, the latest versions apply to this Standard.

GB/T 2684 Test methods for foundry sands and molding mixtures

GB/T 5611 Foundry terminology

GB/T 9442 Foundry silica sand

JB/T 8834 Phenolic resin of mould (core) for foundry

3 Terms and definitions

For the purpose of this Standard, the terms and definitions established in GB/T 5611

and the following apply.

3.1

hot bending strength

The sample is heated to 232 °C ± 5 °C, and the bending strength is measured within 10

s after taken out from the mold.

3.2

5 Technical requirements

5.1 Required performance indicators

The performance indicators that must be tested for resin coated sand for foundry include

room temperature bending strength, hot bending strength, loss on ignition, average

fineness and melting point.

5.1.1 The room temperature bending strength shall comply with the provisions of Table

1.

5.1.2 The loss on ignition shall comply with the provisions of Table 2.

5.1.3 The melting point is 85 °C ~ 110 °C.

5.1.4 The hot bending strength is 1.5 MPa ~ 5.0 MPa.

5.1.5 The determination and calculation method of the average fineness shall be carried

out according to the provisions of GB/T 9442.

5.2 Optional performance indicators

5.2.1 The optional performance indicators of resin coated sand for foundry include

room temperature tensile strength, hot tensile strength, gas evolution volume, fluidity

and hardening rate.

5.2.2 If the buyer has special requirements for the performance indicators in 5.2.1 and

other performance indicators, both the supplier and the buyer shall specify in the order

agreement.

6 Test methods

6.1 See Appendix A for the test methods for room temperature bending strength, hot

bending strength, loss on ignition, average fineness and melting point of resin coated

sand for casting.

6.2 See Appendix B for the test methods for room temperature bending strength, hot

tensile strength, gas evolution volume, fluidity and hardening rate of resin coated sand

for foundry.

7 Inspection rules

7.1 Sampling

7.1.1 Division of batches

It is divided by tonnage; each continuous production of 10 t is a batch.

7.1.2 Sampling method

When sampling the resin coated sand in each batch, it can select the average sample

from the same batch of well-packaged resin coated sand. The average sample of the

bagged resin coated sand is selected from 1 % of the same batch, but it shall not less

than 3 bags at least and shall not be less than 5 kg in weight. The sample required for

the inspection are selected from the total sample using the “quarter method” or riffle

sampler. If there is any doubt about the quality of a certain part of the resin coated sand,

it shall be sampled and inspected separately.

7.2 Inspection

The inspection method for resin coated sand shall be carried out according to the

provisions of Clause 6. The optional performance indicators or other special

performance requirements specified in this Standard shall be determined through

negotiation between the supplier and the buyer. Each batch of resin coated sand from

the supplier shall be inspected according to the required performance indicators

specified in this Standard, and the inspection results and designation shall be written

into the quality report and delivered to the buyer with the product. The buyer may carry

out the acceptance inspection according to the technical requirements of this Standard

or the provisions of the agreement.

7.3 Re-inspection

If one of the indicators fails in the inspection result, the sample shall be doubled for re-

inspection, and the re-inspection result is the final result. If the re-inspection results still

do not meet the indicators specified in this Standard, the batch of products is determined

to be unqualified.

7.4 Arbitration test

In the event of a dispute over quality between the supplier and the buyer, they may

negotiate or entrust a third party selected by both parties to conduct arbitration.

8 Labeling, packaging and storage

8.1 The packaging bag of resin coated sand for foundry shall be moisture-proof and

easy to transport.

8.2 The packaging bag shall be marked with:

a) The words “resin coated sand”;

b) Designation;

The determination of the room temperature bending strength value of the sample is

carried out according to the provisions of GB/T 2684. The bending strength value is 16

times the tensile scale value in the pressure gauge.

NOTE: See Appendix B for another test method for room temperature bending strength of resin coated

sand for foundry.

A.2 Hot bending strength

The preparation of the sample for hot bending strength shall be carried out according to

the provisions of A.1.

For the determination of hot bending strength, the sample is prepared according to the

provisions of A.1.After the sample is taken out, it is placed on the testing machine

immediately; gradually load until the sample breaks. It is required that the test is

completed within 10 s after the sample is taken out. The bending strength value is 16

times the tensile scale value in the pressure gauge.

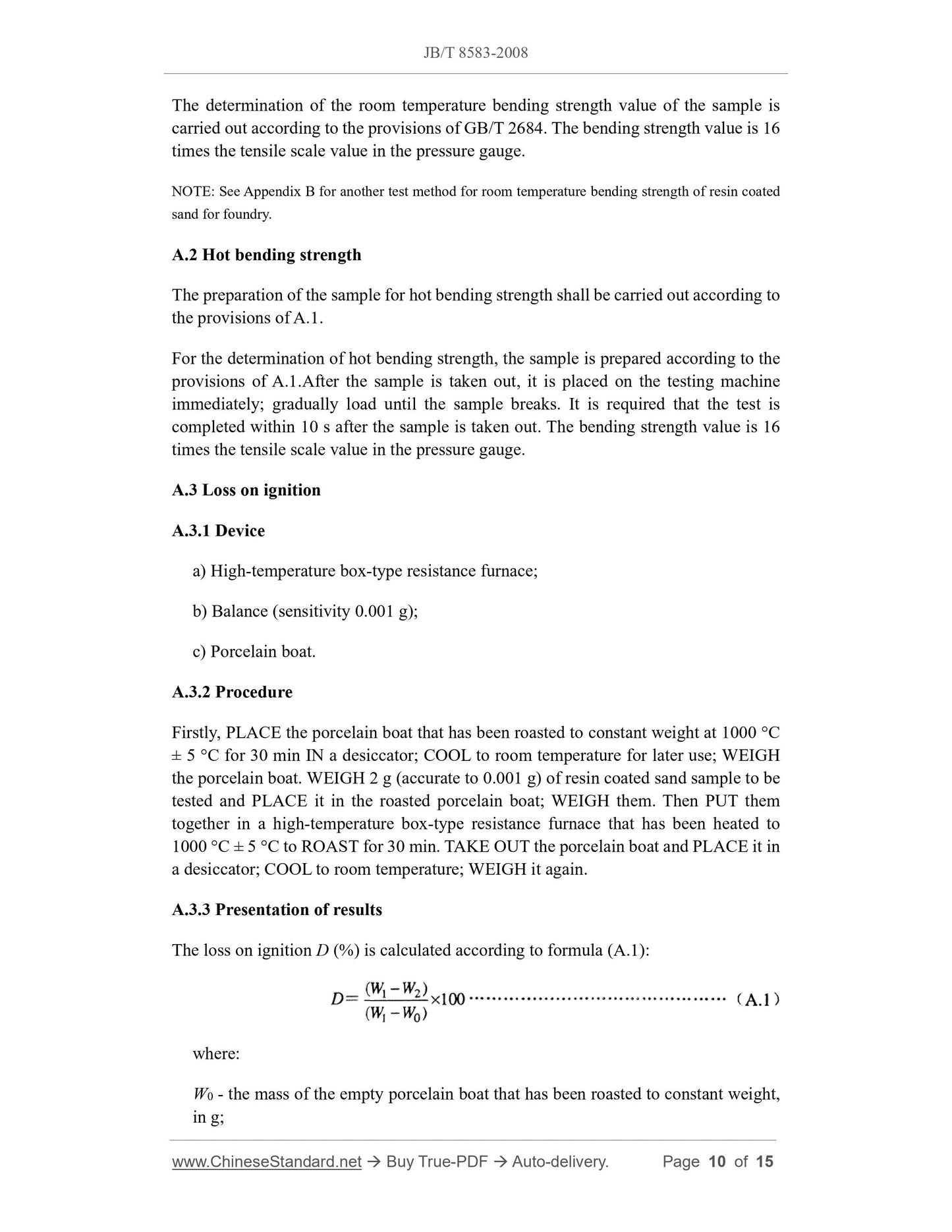

A.3 Loss on ignition

A.3.1 Device

a) High-temperature box-type resistance furnace;

b) Balance (sensitivity 0.001 g);

c) Porcelain boat.

A.3.2 Procedure

Firstly, PLACE the porcelain boat that has been roasted to constant weight at 1000 °C

± 5 °C for 30 min IN a desiccator; COOL to room temperature for later use; WEIGH

the porcelain boat. WEIGH 2 g (accurate to 0.001 g) of resin coated sand sample to be

tested and PLACE it in the roasted porcelain boat; WEIGH them. Then PUT them

together in a high-temperature box-type resistance furnace that has been heated to

1000 °C ± 5 °C to ROAST for 30 min. TAKE OUT the porcelain boat and PLA...

Get QUOTATION in 1-minute: Click JB/T 8583-2008

Historical versions: JB/T 8583-2008

Preview True-PDF (Reload/Scroll if blank)

JB/T 8583-2008: Resin coated sand for foundry

JB/T 8583-2008

JB

MACHINERY INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 91.100.15

J 31

File No.: 23276-2008

Replacing JB/T 8583-1997

Resin coated sand for foundry

ISSUED ON: MARCH 12, 2008

IMPLEMENTED ON: SEPTEMBER 01, 2008

Issued by: National Development and Reform Commission

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Terms and definitions ... 4

4 Grading and designation ... 5

5 Technical requirements ... 6

6 Test methods ... 6

7 Inspection rules ... 6

8 Labeling, packaging and storage ... 7

Appendix A (normative) Test methods for required performance indicators of resin

coated sand for foundry ... 9

Appendix B (informative) Test methods for other performance indicators of resin

coated sand for foundry ... 12

Resin coated sand for foundry

1 Scope

This Standard specifies the terms and definitions, classification, grading and

designation, technical requirements, test methods, inspection rules, labeling and

packaging of resin coated sand for foundry.

This Standard applies to mold (core) resin coated sand produced with raw sand

(regenerated sand) for foundry and phenolic resin for shell mold (core) as the main raw

materials.

2 Normative references

The following documents contain the provisions which, through reference in this

Standard, become the provisions of this Standard. For dated references, their

subsequent amendments (excluding corrigendum) or revisions do not apply to this

Standard. However, the parties who enter into agreement based on this Standard are

encouraged to investigate whether the latest versions of these documents are applicable.

For undated reference documents, the latest versions apply to this Standard.

GB/T 2684 Test methods for foundry sands and molding mixtures

GB/T 5611 Foundry terminology

GB/T 9442 Foundry silica sand

JB/T 8834 Phenolic resin of mould (core) for foundry

3 Terms and definitions

For the purpose of this Standard, the terms and definitions established in GB/T 5611

and the following apply.

3.1

hot bending strength

The sample is heated to 232 °C ± 5 °C, and the bending strength is measured within 10

s after taken out from the mold.

3.2

5 Technical requirements

5.1 Required performance indicators

The performance indicators that must be tested for resin coated sand for foundry include

room temperature bending strength, hot bending strength, loss on ignition, average

fineness and melting point.

5.1.1 The room temperature bending strength shall comply with the provisions of Table

1.

5.1.2 The loss on ignition shall comply with the provisions of Table 2.

5.1.3 The melting point is 85 °C ~ 110 °C.

5.1.4 The hot bending strength is 1.5 MPa ~ 5.0 MPa.

5.1.5 The determination and calculation method of the average fineness shall be carried

out according to the provisions of GB/T 9442.

5.2 Optional performance indicators

5.2.1 The optional performance indicators of resin coated sand for foundry include

room temperature tensile strength, hot tensile strength, gas evolution volume, fluidity

and hardening rate.

5.2.2 If the buyer has special requirements for the performance indicators in 5.2.1 and

other performance indicators, both the supplier and the buyer shall specify in the order

agreement.

6 Test methods

6.1 See Appendix A for the test methods for room temperature bending strength, hot

bending strength, loss on ignition, average fineness and melting point of resin coated

sand for casting.

6.2 See Appendix B for the test methods for room temperature bending strength, hot

tensile strength, gas evolution volume, fluidity and hardening rate of resin coated sand

for foundry.

7 Inspection rules

7.1 Sampling

7.1.1 Division of batches

It is divided by tonnage; each continuous production of 10 t is a batch.

7.1.2 Sampling method

When sampling the resin coated sand in each batch, it can select the average sample

from the same batch of well-packaged resin coated sand. The average sample of the

bagged resin coated sand is selected from 1 % of the same batch, but it shall not less

than 3 bags at least and shall not be less than 5 kg in weight. The sample required for

the inspection are selected from the total sample using the “quarter method” or riffle

sampler. If there is any doubt about the quality of a certain part of the resin coated sand,

it shall be sampled and inspected separately.

7.2 Inspection

The inspection method for resin coated sand shall be carried out according to the

provisions of Clause 6. The optional performance indicators or other special

performance requirements specified in this Standard shall be determined through

negotiation between the supplier and the buyer. Each batch of resin coated sand from

the supplier shall be inspected according to the required performance indicators

specified in this Standard, and the inspection results and designation shall be written

into the quality report and delivered to the buyer with the product. The buyer may carry

out the acceptance inspection according to the technical requirements of this Standard

or the provisions of the agreement.

7.3 Re-inspection

If one of the indicators fails in the inspection result, the sample shall be doubled for re-

inspection, and the re-inspection result is the final result. If the re-inspection results still

do not meet the indicators specified in this Standard, the batch of products is determined

to be unqualified.

7.4 Arbitration test

In the event of a dispute over quality between the supplier and the buyer, they may

negotiate or entrust a third party selected by both parties to conduct arbitration.

8 Labeling, packaging and storage

8.1 The packaging bag of resin coated sand for foundry shall be moisture-proof and

easy to transport.

8.2 The packaging bag shall be marked with:

a) The words “resin coated sand”;

b) Designation;

The determination of the room temperature bending strength value of the sample is

carried out according to the provisions of GB/T 2684. The bending strength value is 16

times the tensile scale value in the pressure gauge.

NOTE: See Appendix B for another test method for room temperature bending strength of resin coated

sand for foundry.

A.2 Hot bending strength

The preparation of the sample for hot bending strength shall be carried out according to

the provisions of A.1.

For the determination of hot bending strength, the sample is prepared according to the

provisions of A.1.After the sample is taken out, it is placed on the testing machine

immediately; gradually load until the sample breaks. It is required that the test is

completed within 10 s after the sample is taken out. The bending strength value is 16

times the tensile scale value in the pressure gauge.

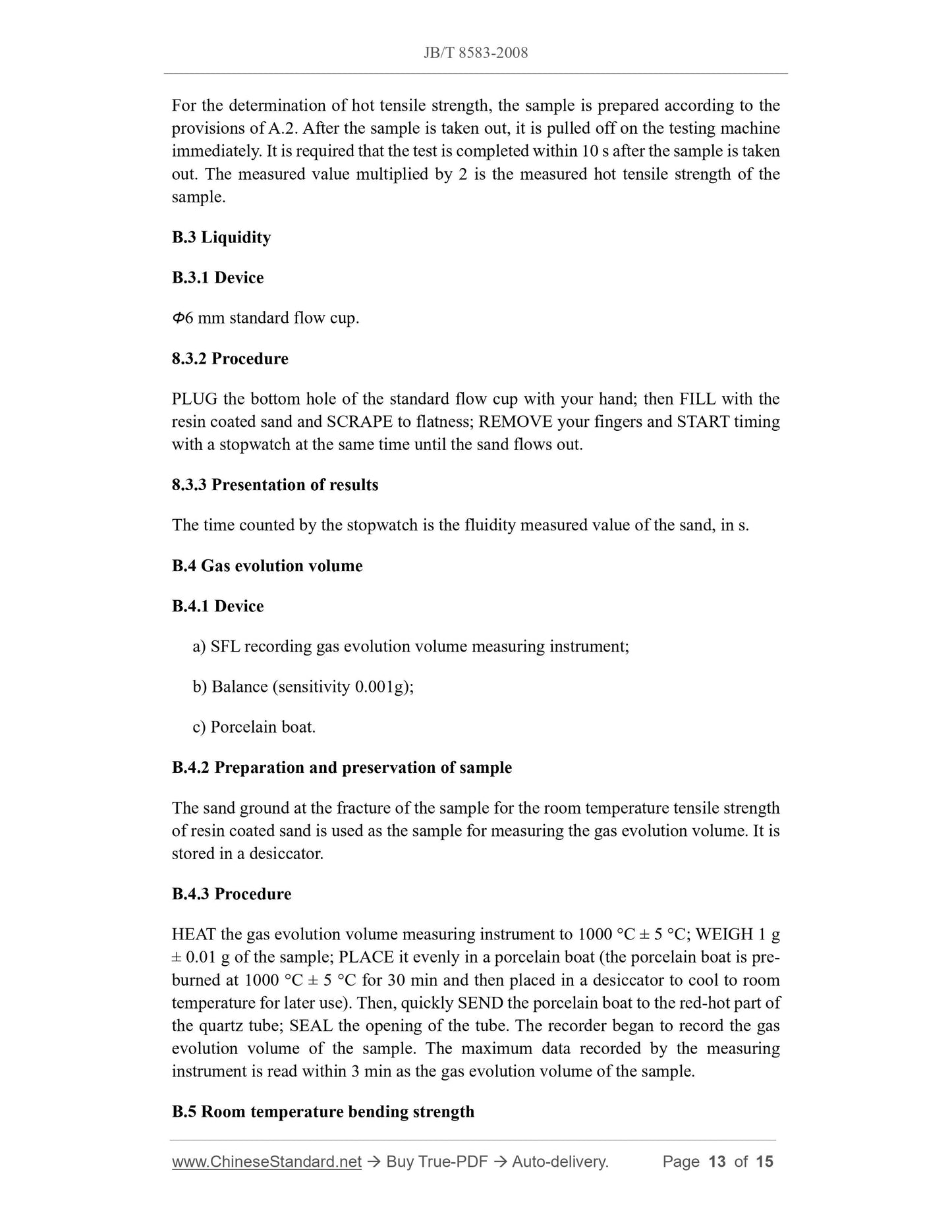

A.3 Loss on ignition

A.3.1 Device

a) High-temperature box-type resistance furnace;

b) Balance (sensitivity 0.001 g);

c) Porcelain boat.

A.3.2 Procedure

Firstly, PLACE the porcelain boat that has been roasted to constant weight at 1000 °C

± 5 °C for 30 min IN a desiccator; COOL to room temperature for later use; WEIGH

the porcelain boat. WEIGH 2 g (accurate to 0.001 g) of resin coated sand sample to be

tested and PLACE it in the roasted porcelain boat; WEIGH them. Then PUT them

together in a high-temperature box-type resistance furnace that has been heated to

1000 °C ± 5 °C to ROAST for 30 min. TAKE OUT the porcelain boat and PLA...

Share