1

/

of

6

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

JB/T 8734.3-2012 English PDF (JB/T8734.3-2012)

JB/T 8734.3-2012 English PDF (JB/T8734.3-2012)

Regular price

$120.00 USD

Regular price

Sale price

$120.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click JB/T 8734.3-2012

Historical versions: JB/T 8734.3-2012

Preview True-PDF (Reload/Scroll if blank)

JB/T 8734.3-2012: Polyvinyl chloride insulated cables and wires and cords of rated voltages up to and including 450/750 V. Part 3: Cords and cables for connecting

JB/T 8734.3-2012

JB

MACHINERY INDUSTRY STANDARD OF

THE PEOPLE’S REPUBLIC OF CHINA

ICS 29.060.20

K 13

Record No. 36478-2012

Replacing JB/T 8734.3-1998

Polyvinyl chloride insulated cables and wires and

cords of rated voltages up to and including 450/750 V

- Part 3. Cords and cables for connecting

ISSUED ON. MAY 24, 2012

IMPLEMENTED ON. NOVEMBER 1, 2012

Issued by. Ministry of Industry and Information Technology of PRC

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Use characteristics ... 6

4 Models ... 6

5 Specifications ... 6

6 Technical requirements ... 7

6.1 General ... 7

6.2 Conductor ... 7

6.3 Insulation ... 7

6.4 Insulated core twisting ... 11

6.5 Sheathing ... 11

6.6 Outer diameter ... 11

7 Inspection ... 12

Foreword

JB/T 8734 Polyvinyl chloride insulated cables and wires and cords of rated

voltages up to and including 450/750 V consists of the following 6 parts.

- Part 1. General requirements;

- Part 2. Insulated cables and wires for fixed wiring;

- Part 3. Cords and cables for connecting;

- Part 4. Insulated wires for internal wiring of equipment;

- Part 5. Screened wires;

- Part 6. Lift cables.

This Part was drafted in accordance with the rules given in GB/T 1.1-2009.

This Part replaces JB/T 8734.3-1998 Polyvinyl chloride insulated cables and

wires and cords of rated voltages up to and including 450/750V - Part 3 . Cords

for connecting. Compared with JB/T 8734.3-1998, the main technical changes

are as follows.

- modified the name from “Cords for connecting” to “Cords and cables for

connecting”;

- added relevant content of rated voltage Uo/U is 300/500 V;

- modified clause name and relevant reference standards in normative

references (see Clause 2 of this edition, Clause 2 of 1998 edition);

- added RVB and RVV cables (see Table 1);

- added general properties of RVB and RVV cables (see Table 4 and Table

5);

- added RVS cable specifications and corresponding technical

requirements (see Table 2 and Table 3);

- added flexing test and insulated core peel-off test (see Clause 7);

- added provisions on flexing test weight of hammer and pulley diameter

(see Table 6).

This Part was proposed by China Machinery Industry Federation.

Polyvinyl chloride insulated cables and wires and

cords of rated voltages up to and including 450/750 V

- Part 3. Cords and cables for connecting

1 Scope

This Part of JB/T 8734 specifies use characteristics, models, specifications,

technical requirements and inspection of cords and cables for connecting.

This Part is only applicable to PVC insulated copper cords and cables for

connecting of electrical appliance, instruments and dynamic lighting of which

the AC rated voltage Uo/U is 300/500 V and less.

2 Normative references

The following referenced documents are indispensable for the application of

this document. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any

amendments) applies.

GB/T 2951.11-2008 Common test methods for insulating and sheathing

materials of electric and optical cables - Part 11. Methods for general

application - Measurement of thickness and overall dimensions

GB/T 2951.12-2008 Common test methods for insulating and sheathing

materials of electric and optical cables - Part 12. Methods for general

application - Thermal ageing methods

GB/T 2951.14-2008 Common test methods for insulating and sheathing

materials of electric and optical cables - Part 14. Methods for general

application - Test at low temperature

GB/T 2951.31-2008 Common test methods for insulating and sheathing

materials of electric and optical cables - Part 31. Methods specific to PVC

compounds - Pressure test at high temperature - Test for resistance to

cracking

GB/T 2951.32-2008 Common test methods for insulating and sheathing

materials of electric and optical cables - Part 32. Methods specific to PVC

compounds - Loss of mass test - Thermal stability test

6 Technical requirements

6.1 General

In addition to the technical requirements specified in this Part, the cords and

cables shall also comply with the provisions of JB/T 8734.1-2012.

6.2 Conductor

The number of cores and structure of conductor shall comply with the provisions

of Table 3 and Table 5.

RVB cord conductor shall use the 6th soft copper conductor specified in GB/T

3956-2008.

RVV cable conductor shall use the 5th soft copper conductor specified in GB/T

3956-2008. The maximum conductor resistance value of copper core conductor

of which the nominal cross-sectional area is 2.0 mm2 at 20°C is 9.79 Ω/km. The

maximum conductor resistance value of tinned copper core conductor of which

the nominal cross-sectional area is 2.0 mm2 at 20°C is 10.2 Ω/km.

6.3 Insulation

The insulation of extrusion on conductor should be PVC blend of which the code

is PVC/D.

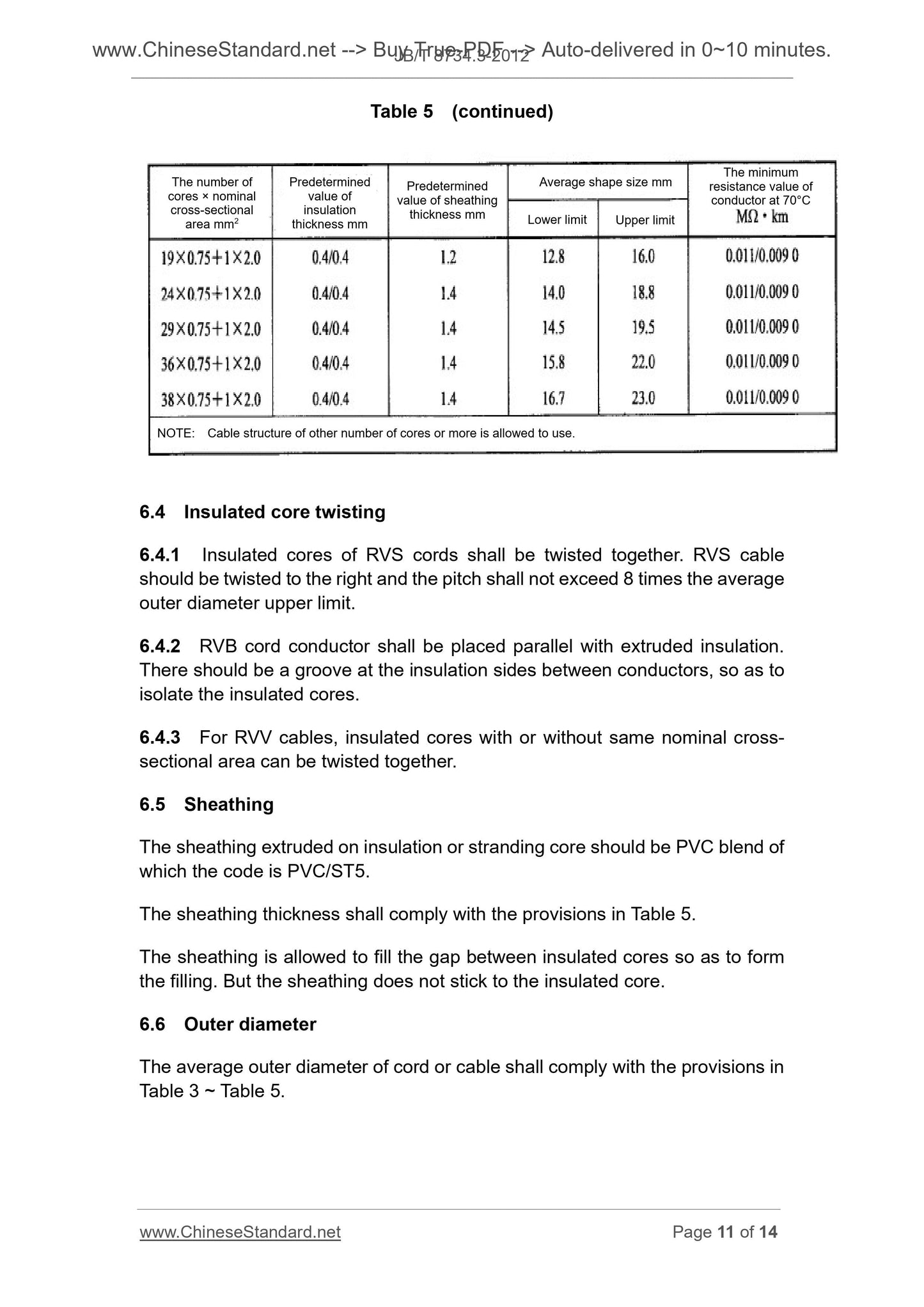

The insulation thickness shall comply with the provisions in Table 3 ~ Table 5.

The insulation resistance shall not be less than the predetermined values in

Table 3 ~ Table 5.

Table 5 (continued)

6.4 Insulated core twisting

6.4.1 Insulated cores of RVS cords shall be twisted together. RVS cable

should be twisted to the right and the pitch shall not exceed 8 times the average

outer diameter upper limit.

6.4.2 RVB cord conductor shall be placed parallel with extruded insulation.

There should be a groove at the insulation sides between conductors, so as to

isolate the insulated cores.

6.4.3 For RVV cables, insulated cores with or without same nominal cross-

sectional area can be twisted together.

6.5 Sheathing

The sheathing extruded on insulation or stranding core should be PVC blend of

which the code is PVC/ST5.

The sheathing thickness shall comply with the provisions in Table 5.

The sheathing is allowed to fill the gap between insulated cores so as to form

the filling. But the sheathing does not stick to the insulated core.

6.6 Outer diameter

The average outer diameter of cord or cable shall comply with the provisions in

Table 3 ~ Table 5.

The number of

cores × nominal

cross-sectional

area mm2

Predetermined

value of

insulation

thickness mm

Predetermined

value of sheathing

thickness mm

Average shape size mm

Lower limit Upper limit

The minimum

resistance value of

conductor at 70°C

NOTE. Cable structure of other number of cores or more is allowed to use.

Get QUOTATION in 1-minute: Click JB/T 8734.3-2012

Historical versions: JB/T 8734.3-2012

Preview True-PDF (Reload/Scroll if blank)

JB/T 8734.3-2012: Polyvinyl chloride insulated cables and wires and cords of rated voltages up to and including 450/750 V. Part 3: Cords and cables for connecting

JB/T 8734.3-2012

JB

MACHINERY INDUSTRY STANDARD OF

THE PEOPLE’S REPUBLIC OF CHINA

ICS 29.060.20

K 13

Record No. 36478-2012

Replacing JB/T 8734.3-1998

Polyvinyl chloride insulated cables and wires and

cords of rated voltages up to and including 450/750 V

- Part 3. Cords and cables for connecting

ISSUED ON. MAY 24, 2012

IMPLEMENTED ON. NOVEMBER 1, 2012

Issued by. Ministry of Industry and Information Technology of PRC

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Use characteristics ... 6

4 Models ... 6

5 Specifications ... 6

6 Technical requirements ... 7

6.1 General ... 7

6.2 Conductor ... 7

6.3 Insulation ... 7

6.4 Insulated core twisting ... 11

6.5 Sheathing ... 11

6.6 Outer diameter ... 11

7 Inspection ... 12

Foreword

JB/T 8734 Polyvinyl chloride insulated cables and wires and cords of rated

voltages up to and including 450/750 V consists of the following 6 parts.

- Part 1. General requirements;

- Part 2. Insulated cables and wires for fixed wiring;

- Part 3. Cords and cables for connecting;

- Part 4. Insulated wires for internal wiring of equipment;

- Part 5. Screened wires;

- Part 6. Lift cables.

This Part was drafted in accordance with the rules given in GB/T 1.1-2009.

This Part replaces JB/T 8734.3-1998 Polyvinyl chloride insulated cables and

wires and cords of rated voltages up to and including 450/750V - Part 3 . Cords

for connecting. Compared with JB/T 8734.3-1998, the main technical changes

are as follows.

- modified the name from “Cords for connecting” to “Cords and cables for

connecting”;

- added relevant content of rated voltage Uo/U is 300/500 V;

- modified clause name and relevant reference standards in normative

references (see Clause 2 of this edition, Clause 2 of 1998 edition);

- added RVB and RVV cables (see Table 1);

- added general properties of RVB and RVV cables (see Table 4 and Table

5);

- added RVS cable specifications and corresponding technical

requirements (see Table 2 and Table 3);

- added flexing test and insulated core peel-off test (see Clause 7);

- added provisions on flexing test weight of hammer and pulley diameter

(see Table 6).

This Part was proposed by China Machinery Industry Federation.

Polyvinyl chloride insulated cables and wires and

cords of rated voltages up to and including 450/750 V

- Part 3. Cords and cables for connecting

1 Scope

This Part of JB/T 8734 specifies use characteristics, models, specifications,

technical requirements and inspection of cords and cables for connecting.

This Part is only applicable to PVC insulated copper cords and cables for

connecting of electrical appliance, instruments and dynamic lighting of which

the AC rated voltage Uo/U is 300/500 V and less.

2 Normative references

The following referenced documents are indispensable for the application of

this document. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any

amendments) applies.

GB/T 2951.11-2008 Common test methods for insulating and sheathing

materials of electric and optical cables - Part 11. Methods for general

application - Measurement of thickness and overall dimensions

GB/T 2951.12-2008 Common test methods for insulating and sheathing

materials of electric and optical cables - Part 12. Methods for general

application - Thermal ageing methods

GB/T 2951.14-2008 Common test methods for insulating and sheathing

materials of electric and optical cables - Part 14. Methods for general

application - Test at low temperature

GB/T 2951.31-2008 Common test methods for insulating and sheathing

materials of electric and optical cables - Part 31. Methods specific to PVC

compounds - Pressure test at high temperature - Test for resistance to

cracking

GB/T 2951.32-2008 Common test methods for insulating and sheathing

materials of electric and optical cables - Part 32. Methods specific to PVC

compounds - Loss of mass test - Thermal stability test

6 Technical requirements

6.1 General

In addition to the technical requirements specified in this Part, the cords and

cables shall also comply with the provisions of JB/T 8734.1-2012.

6.2 Conductor

The number of cores and structure of conductor shall comply with the provisions

of Table 3 and Table 5.

RVB cord conductor shall use the 6th soft copper conductor specified in GB/T

3956-2008.

RVV cable conductor shall use the 5th soft copper conductor specified in GB/T

3956-2008. The maximum conductor resistance value of copper core conductor

of which the nominal cross-sectional area is 2.0 mm2 at 20°C is 9.79 Ω/km. The

maximum conductor resistance value of tinned copper core conductor of which

the nominal cross-sectional area is 2.0 mm2 at 20°C is 10.2 Ω/km.

6.3 Insulation

The insulation of extrusion on conductor should be PVC blend of which the code

is PVC/D.

The insulation thickness shall comply with the provisions in Table 3 ~ Table 5.

The insulation resistance shall not be less than the predetermined values in

Table 3 ~ Table 5.

Table 5 (continued)

6.4 Insulated core twisting

6.4.1 Insulated cores of RVS cords shall be twisted together. RVS cable

should be twisted to the right and the pitch shall not exceed 8 times the average

outer diameter upper limit.

6.4.2 RVB cord conductor shall be placed parallel with extruded insulation.

There should be a groove at the insulation sides between conductors, so as to

isolate the insulated cores.

6.4.3 For RVV cables, insulated cores with or without same nominal cross-

sectional area can be twisted together.

6.5 Sheathing

The sheathing extruded on insulation or stranding core should be PVC blend of

which the code is PVC/ST5.

The sheathing thickness shall comply with the provisions in Table 5.

The sheathing is allowed to fill the gap between insulated cores so as to form

the filling. But the sheathing does not stick to the insulated core.

6.6 Outer diameter

The average outer diameter of cord or cable shall comply with the provisions in

Table 3 ~ Table 5.

The number of

cores × nominal

cross-sectional

area mm2

Predetermined

value of

insulation

thickness mm

Predetermined

value of sheathing

thickness mm

Average shape size mm

Lower limit Upper limit

The minimum

resistance value of

conductor at 70°C

NOTE. Cable structure of other number of cores or more is allowed to use.

Share