1

/

of

7

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

JG 225-2007 English PDF

JG 225-2007 English PDF

Regular price

$120.00 USD

Regular price

Sale price

$120.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click JG 225-2007

Historical versions: JG 225-2007

Preview True-PDF (Reload/Scroll if blank)

JG 225-2007: Corrugated metal dusts for prestressee concrete

JG 225-2007

JG

CONSTRUCTION INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

Replacing JG/T 3013-1994

Corrugated metal ducts for prestressed concrete

ISSUED ON. SEPTEMBER 4, 2007

IMPLEMENTED ON. FEBRUARY 1, 2008

Issued by. Ministry of Construction of the People's Republic of China

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Classification and marking ... 5

4 Requirements ... 6

5 Test methods ... 9

6 Inspection rules ... 13

7 Packaging, marks ... 15

8 Transport, storage ... 15

9 Use ... 16

Annex A (Informative) Quality inspection table of corrugated metal ducts for

prestressed concrete ... 17

Annex B (Informative) Selection table of corrugated metal ducts for prestressed

concrete ... 18

Foreword

4.5 and 4.6 of this Standard are mandatory; the rest are recommendatory.

Since the implementation of this Standard, it replaces JG/T 3013-1994 Metal

spiral sheath for prestressed concrete.

Compared with JG/T 3013-1994, main technical changes in this Standard are

as follows.

1. modified material requirements;

2. corrugated metal ducts are divided into standard type and enhanced type

according to rigidity; standard type and enhanced type are basically

identical; enhanced type is the content added;

3. added a clause about marking of corrugated metal ducts;

4. added the minimum overlap width of the folded seam of corrugated metal

ducts;

5. modified dimensional and tolerance requirements for round ducts and flat

ducts;

6. added minimum ripple height requirements of corrugated metal ducts;

7. added radial rigidity requirements of enhanced-type corrugated metal ducts;

8. modified the concentrated load value and uniform load value of radial

rigidity test of flat ducts;

9. modified radial rigidity test method of corrugated metal ducts;

10. modified resistance to leakage of the length of the specimen and test

method of corrugated metal ducts;

11. deleted the anti-leakage performance test of specimen after bearing

uniform load;

12. modified quality assurance documentation requirements for exit-factory

products;

13. improved product transport and storage requirements; added stack height

limit of corrugated metal ducts;

14. added use requirements;

15. merged and adjusted of relevant provisions;

16. modified an annex. Annex A Quality inspection table of corrugated metal

ducts for prestressed concrete which is informative;

17. added an annex. Annex B Selection table of corrugated metal ducts for

prestressed concrete which is informative.

This Standard was proposed by Institute of Standard Quota of Ministry of

Construction of China.

This Standard shall be under the jurisdiction of China Building Research

Institute (the jurisdiction organization specially for standard in construction

engineering of Ministry of Construction).

Main drafting organization of this Standard. China Building Research Institute.

The drafting organizations of this Standard. Zhejiang Institute of Architectural

Science Design and Research Co., Ltd., Kaifeng Strong Anchoring Technology

Co., Ltd., Henan Hongqiao Prestressed Manufacturing Co., Ltd.

Main drafters of this Standard. Li Dongbin, Dai Weiming, Huo Tingbo, Li Guozhu,

Qiao Yongli.

This Standard was issued on October 1994 for the first time. This is the first

revision.

Corrugated metal ducts for prestressed concrete

1 Scope

This Standard specifies the classification and marking, requirements, test

methods, inspection rules, packaging, marks, transport, storage and use of

corrugated metal ducts for prestressed concrete.

This Standard is applicable to metal ducts of reserved hole which are made by

plated or non-plated low-carbon steel with a screw folded seam and used in

post-tensioned prestressed concrete structural pieces.

2 Normative references

The following standards contain the provisions which, through reference in this

Standard, constitute the provisions of this Standard. For dated references,

subsequent amendments (excluding corrections) or revisions do not apply to

this Standard. However, the parties who enter into agreement based on this

Standard are encouraged to investigate whether the latest versions of these

documents are applicable. For undated reference documents, the latest

versions apply to this Standard.

GB 716 Cold-rolled carbon structural steel strips

GB/T 2518 Continuously hot-dip zinc-coated steel sheet and strip

3 Classification and marking

3.1 Classification

Corrugated metal ducts for prestressed concrete are divided into standard type

and enhanced type according to radial rigidity, round and flat according to

sectional shape, dual-wave and multi-wave according to the number of raised

corrugations between each two adjacent folded bites.

3.2 Marking

The mark of corrugated metal ducts for prestressed concrete consists of three

parts. code, diameter size and radial rigidity category.

4 Anti-leakage after concentrated load 3 5.4 4.6

5 Anti-leakage after bending 3 5.4 4.6

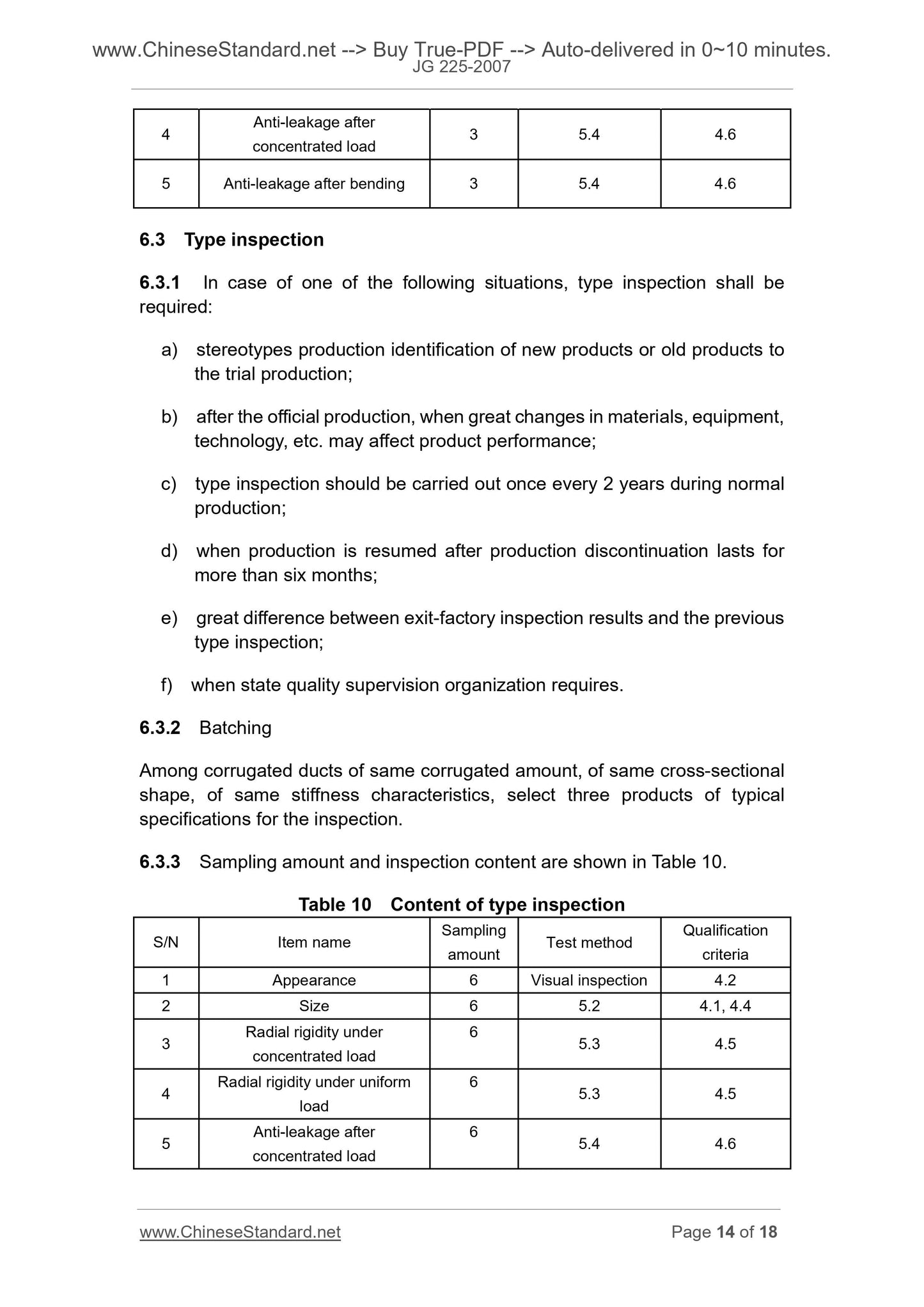

6.3 Type inspection

6.3.1 In case of one of the following situations, type inspection shall be

required.

a) stereotypes production identification of new products or old products to

the trial production;

b) after the official production, when great changes in materials, equipment,

technology, etc. may affect product performance;

c) type inspection should be carried out once every 2 years during normal

production;

d) when production is resumed after production discontinuation lasts for

more than six months;

e) great difference between exit-factory inspection results and the previous

type inspection;

f) when state quality supervision organization requires.

6.3.2 Batching

Among corrugated ducts of same corrugated amount, of same cross-sectional

shape, of same stiffness characteristics, select three products of typical

specifications for the inspection.

6.3.3 Sampling amount and inspection content are shown in Table 10.

Table 10 Content of type inspection

S/N Item name Sampling amount Test method

Qualification

criteria

1 Appearance 6 Visual inspection 4.2

2 Size 6 5.2 4.1, 4.4

3 Radial rigidity under concentrated load

6 5.3 4.5

4 Radial rigidity under uniform load

6 5.3 4.5

5 Anti-leakage after concentrated load

6 5.4 4.6

9 Use

9.1 During cast-in-place prestressing project, it shall use galvanized

corrugated metal ducts. During the production of prefabricated components,

when there is no corrosion of corrugated metal ducts, it shall use un- galvanized

corrugated metal ducts.

9.2 During prestressed concrete project, when it uses pre-beam through

process, it shall select standard type corrugated metal ducts; when it uses post-

beam through process, it shall use enhanced type corrugated metal ducts.

Enhanced type corrugated metal ducts shall also apply pore forming of vertical

and special position in construction project. When used in circular pore forming

of nuclear power plant containment, the thickness of steel strip should be

increased appropriately. The diameter selection of corrugated metal ducts shall

refer to Annex B.

9.3 The diameter of connecting pipe of corrugated metal round duct shall be

one diameter level greater than the connected pipe. Its length is 4 ~ 5 times

inner diameter of connected pipe and not less than 300 mm.

9.4 It shall use grinding wheel saw to cut corrugated metal ducts. Sta...

Get QUOTATION in 1-minute: Click JG 225-2007

Historical versions: JG 225-2007

Preview True-PDF (Reload/Scroll if blank)

JG 225-2007: Corrugated metal dusts for prestressee concrete

JG 225-2007

JG

CONSTRUCTION INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

Replacing JG/T 3013-1994

Corrugated metal ducts for prestressed concrete

ISSUED ON. SEPTEMBER 4, 2007

IMPLEMENTED ON. FEBRUARY 1, 2008

Issued by. Ministry of Construction of the People's Republic of China

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Classification and marking ... 5

4 Requirements ... 6

5 Test methods ... 9

6 Inspection rules ... 13

7 Packaging, marks ... 15

8 Transport, storage ... 15

9 Use ... 16

Annex A (Informative) Quality inspection table of corrugated metal ducts for

prestressed concrete ... 17

Annex B (Informative) Selection table of corrugated metal ducts for prestressed

concrete ... 18

Foreword

4.5 and 4.6 of this Standard are mandatory; the rest are recommendatory.

Since the implementation of this Standard, it replaces JG/T 3013-1994 Metal

spiral sheath for prestressed concrete.

Compared with JG/T 3013-1994, main technical changes in this Standard are

as follows.

1. modified material requirements;

2. corrugated metal ducts are divided into standard type and enhanced type

according to rigidity; standard type and enhanced type are basically

identical; enhanced type is the content added;

3. added a clause about marking of corrugated metal ducts;

4. added the minimum overlap width of the folded seam of corrugated metal

ducts;

5. modified dimensional and tolerance requirements for round ducts and flat

ducts;

6. added minimum ripple height requirements of corrugated metal ducts;

7. added radial rigidity requirements of enhanced-type corrugated metal ducts;

8. modified the concentrated load value and uniform load value of radial

rigidity test of flat ducts;

9. modified radial rigidity test method of corrugated metal ducts;

10. modified resistance to leakage of the length of the specimen and test

method of corrugated metal ducts;

11. deleted the anti-leakage performance test of specimen after bearing

uniform load;

12. modified quality assurance documentation requirements for exit-factory

products;

13. improved product transport and storage requirements; added stack height

limit of corrugated metal ducts;

14. added use requirements;

15. merged and adjusted of relevant provisions;

16. modified an annex. Annex A Quality inspection table of corrugated metal

ducts for prestressed concrete which is informative;

17. added an annex. Annex B Selection table of corrugated metal ducts for

prestressed concrete which is informative.

This Standard was proposed by Institute of Standard Quota of Ministry of

Construction of China.

This Standard shall be under the jurisdiction of China Building Research

Institute (the jurisdiction organization specially for standard in construction

engineering of Ministry of Construction).

Main drafting organization of this Standard. China Building Research Institute.

The drafting organizations of this Standard. Zhejiang Institute of Architectural

Science Design and Research Co., Ltd., Kaifeng Strong Anchoring Technology

Co., Ltd., Henan Hongqiao Prestressed Manufacturing Co., Ltd.

Main drafters of this Standard. Li Dongbin, Dai Weiming, Huo Tingbo, Li Guozhu,

Qiao Yongli.

This Standard was issued on October 1994 for the first time. This is the first

revision.

Corrugated metal ducts for prestressed concrete

1 Scope

This Standard specifies the classification and marking, requirements, test

methods, inspection rules, packaging, marks, transport, storage and use of

corrugated metal ducts for prestressed concrete.

This Standard is applicable to metal ducts of reserved hole which are made by

plated or non-plated low-carbon steel with a screw folded seam and used in

post-tensioned prestressed concrete structural pieces.

2 Normative references

The following standards contain the provisions which, through reference in this

Standard, constitute the provisions of this Standard. For dated references,

subsequent amendments (excluding corrections) or revisions do not apply to

this Standard. However, the parties who enter into agreement based on this

Standard are encouraged to investigate whether the latest versions of these

documents are applicable. For undated reference documents, the latest

versions apply to this Standard.

GB 716 Cold-rolled carbon structural steel strips

GB/T 2518 Continuously hot-dip zinc-coated steel sheet and strip

3 Classification and marking

3.1 Classification

Corrugated metal ducts for prestressed concrete are divided into standard type

and enhanced type according to radial rigidity, round and flat according to

sectional shape, dual-wave and multi-wave according to the number of raised

corrugations between each two adjacent folded bites.

3.2 Marking

The mark of corrugated metal ducts for prestressed concrete consists of three

parts. code, diameter size and radial rigidity category.

4 Anti-leakage after concentrated load 3 5.4 4.6

5 Anti-leakage after bending 3 5.4 4.6

6.3 Type inspection

6.3.1 In case of one of the following situations, type inspection shall be

required.

a) stereotypes production identification of new products or old products to

the trial production;

b) after the official production, when great changes in materials, equipment,

technology, etc. may affect product performance;

c) type inspection should be carried out once every 2 years during normal

production;

d) when production is resumed after production discontinuation lasts for

more than six months;

e) great difference between exit-factory inspection results and the previous

type inspection;

f) when state quality supervision organization requires.

6.3.2 Batching

Among corrugated ducts of same corrugated amount, of same cross-sectional

shape, of same stiffness characteristics, select three products of typical

specifications for the inspection.

6.3.3 Sampling amount and inspection content are shown in Table 10.

Table 10 Content of type inspection

S/N Item name Sampling amount Test method

Qualification

criteria

1 Appearance 6 Visual inspection 4.2

2 Size 6 5.2 4.1, 4.4

3 Radial rigidity under concentrated load

6 5.3 4.5

4 Radial rigidity under uniform load

6 5.3 4.5

5 Anti-leakage after concentrated load

6 5.4 4.6

9 Use

9.1 During cast-in-place prestressing project, it shall use galvanized

corrugated metal ducts. During the production of prefabricated components,

when there is no corrosion of corrugated metal ducts, it shall use un- galvanized

corrugated metal ducts.

9.2 During prestressed concrete project, when it uses pre-beam through

process, it shall select standard type corrugated metal ducts; when it uses post-

beam through process, it shall use enhanced type corrugated metal ducts.

Enhanced type corrugated metal ducts shall also apply pore forming of vertical

and special position in construction project. When used in circular pore forming

of nuclear power plant containment, the thickness of steel strip should be

increased appropriately. The diameter selection of corrugated metal ducts shall

refer to Annex B.

9.3 The diameter of connecting pipe of corrugated metal round duct shall be

one diameter level greater than the connected pipe. Its length is 4 ~ 5 times

inner diameter of connected pipe and not less than 300 mm.

9.4 It shall use grinding wheel saw to cut corrugated metal ducts. Sta...

Share