1

/

of

12

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

JG/T 234-2008 English PDF (JG/T234-2008)

JG/T 234-2008 English PDF (JG/T234-2008)

Regular price

$150.00 USD

Regular price

Sale price

$150.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click JG/T 234-2008

Historical versions: JG/T 234-2008

Preview True-PDF (Reload/Scroll if blank)

JG/T 234-2008: Porcelain enameling steel panels for building

JG/T 234-2008

JG

BUILDING INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

Porcelain enameling steel panels for building

ISSUED ON. JUNE 03, 2008

IMPLEMENTED ON. NOVEMBER 01, 2008

Issued by. Ministry of Housing and urban-rural development of the

People's Republic of China

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Terms and definitions ... 5

4 Classification and mark ... 7

5 Material... 11

6 Requirements ... 12

7 Test Methods ... 16

8 Inspection rules ... 25

9 Mark, Packing, Transportation and Storage ... 29

Reference ... 30

Foreword

This Standard was proposed by Standard-Quota Institute of Ministry of Housing and

Urban-Rural Development.

This Standard shall be under the jurisdiction of Building Product and Part Standardization

Technical Committee of Ministry of Housing and Urban-Rural Development.

The responsible drafting organizations of this Standard. Zhejiang Kaier Industry Co., Ltd.

AND Shenzhen Xinshan Curtain Wall Technology Consulting Co., Ltd.

The participating drafting organizations of this Standard. Guangzhou Meibiao Yifeng

Enamel Co., Ltd., Baolichang Metal Products (Shenzhen) Co., Ltd., Foshan Weiyi Metal

Products Co., Ltd., Shenzhen Keyuan Building Group Co., Ltd., National Testing Center

For Building Materials, Guangdong Province Academy of Building Science, Building

Curtain-Wall, Door-Window Quality-Inspection Department of National Building

Engineering Quality, Supervision and Test Center, Institute of Vitreous Enamel of

Donghua University, East China Architectural Design and Research Institute Co. Ltd., AND

Hangzhou Zhijiang Silicone Chemicals Co. Ltd.

Main drafters of this Standard. Du Jiyu, Xing Hanxue, Dou Tiebo, Li Zhiqiang, Wang

Jiwen, Zhang Litao, Gu Jinfang, Li Xiuqing, Jiang Quan, Jiang Weizhong, Jiang Ren,

Dang Jie, Tan Shangfei and Liu Ming.

This Standard was issued for first-time.

Porcelain Enameling Steel Panels for Building

1 Scope

This Standard specifies the terms and definitions, classification and mark, material,

requirements, test method, inspection rules and mark, packing, transportation and

storage of porcelain enameling steel panels for building.

This Standard is applicable to porcelain enameling steel panels for interior and exterior

decoration of building.

2 Normative references

The articles contained in the following documents have become part of this document

when they are quoted herein. For the dated documents so quoted, all subsequent

modifications (including all corrections) or revisions made thereafter do not apply to this

Standard. However, the parties who reach an agreement according to this Standard are

encouraged to study whether the latest versions of these documents can be used. For

the undated documents so quoted, the latest versions (including all modification sheets)

apply to this document.

GB/T 191 Packaging - Pictorial marking for handling of goods

GB/T2518 Continuously hot-dip zinc-coated steel sheet and strip

GB/T 3880 Aluminium and aluminium alloy rolled sheet

GB 6566 Limits of radionuclides in building materials

GB 8624-2006 Classification for burning behavior of building materials and products

GB/T 9174 General specification for transport packages of general cargo

GB/T 9978-1999 Fire-resistance tests - Elements of building construction

GB/T 9989-2005 Vitreous and porcelain enamels - Determination of resistance to citric

acid at room temperature

GB/T 12467.2-1998 Quality requirements for welding - Fusion welding of metallic

materials - Part 2. Comprehensive quality requirements

GB/T 13790 Cold rolled sheets and strips for civil enameling

GB/T 15227-2007 Test method of air permeability, watertightness, wind load resistance

performance for curtain walls

JC/T 564 Fiber reinforced calcium silicate sheet

JC/T 884 Building sealants for coloured coat steel plates

QB/T 1855-1993 Enamelled ware in non-contact with food

YB/T5131 Single hot-dip zinc-coated carbon steel sheets

3 Terms and definitions

For the purpose of this Standard, the following terms and definitions are applicable to this

Standard.

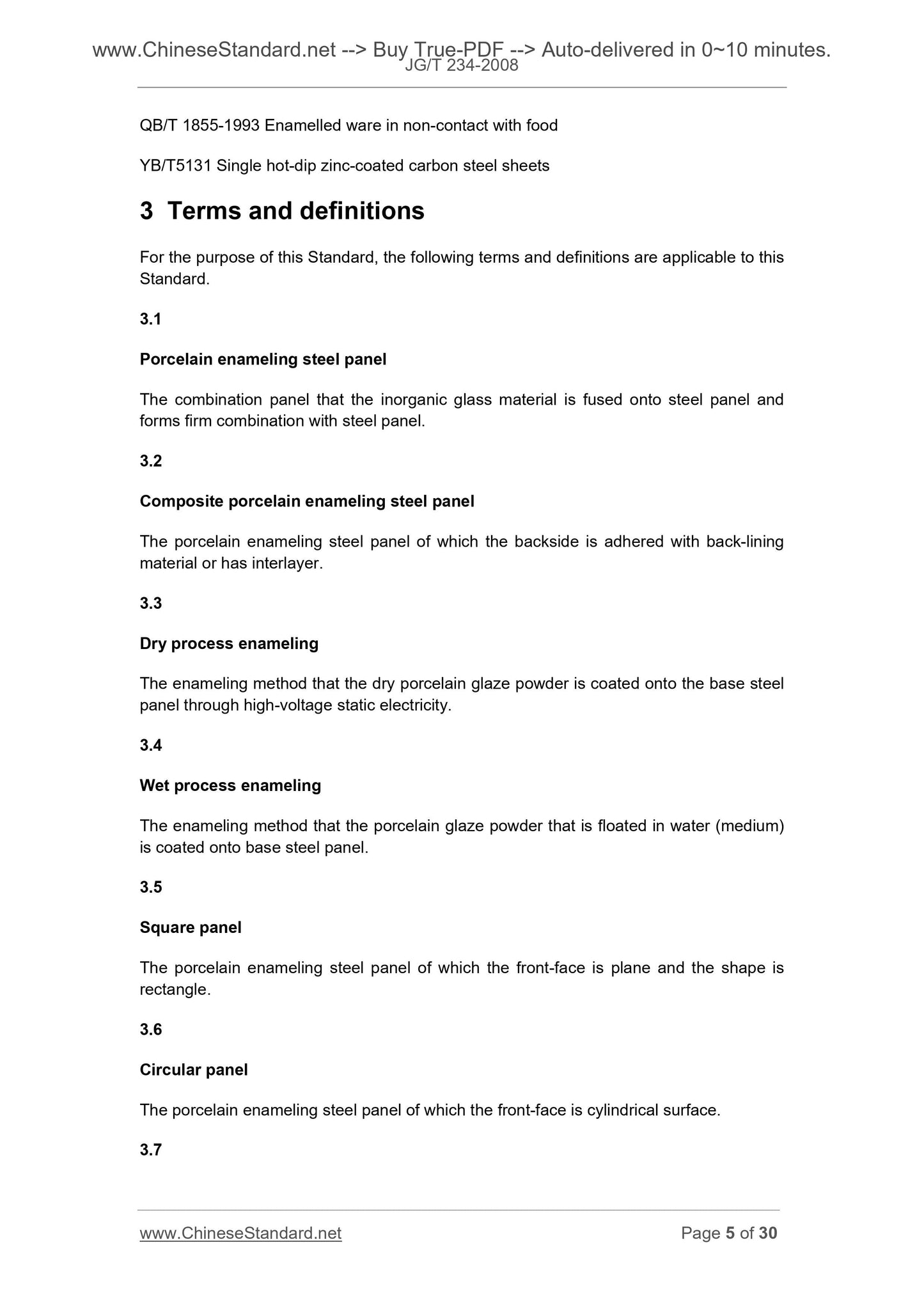

3.1

Porcelain enameling steel panel

The combination panel that the inorganic glass material is fused onto steel panel and

forms firm combination with steel panel.

3.2

Composite porcelain enameling steel panel

The porcelain enameling steel panel of which the backside is adhered with back-lining

material or has interlayer.

3.3

Dry process enameling

The enameling method that the dry porcelain glaze powder is coated onto the base steel

panel through high-voltage static electricity.

3.4

Wet process enameling

The enameling method that the porcelain glaze powder that is floated in water (medium)

is coated onto base steel panel.

3.5

Square panel

The porcelain enameling steel panel of which the front-face is plane and the shape is

rectangle.

3.6

Circular panel

The porcelain enameling steel panel of which the front-face is cylindrical surface.

3.7

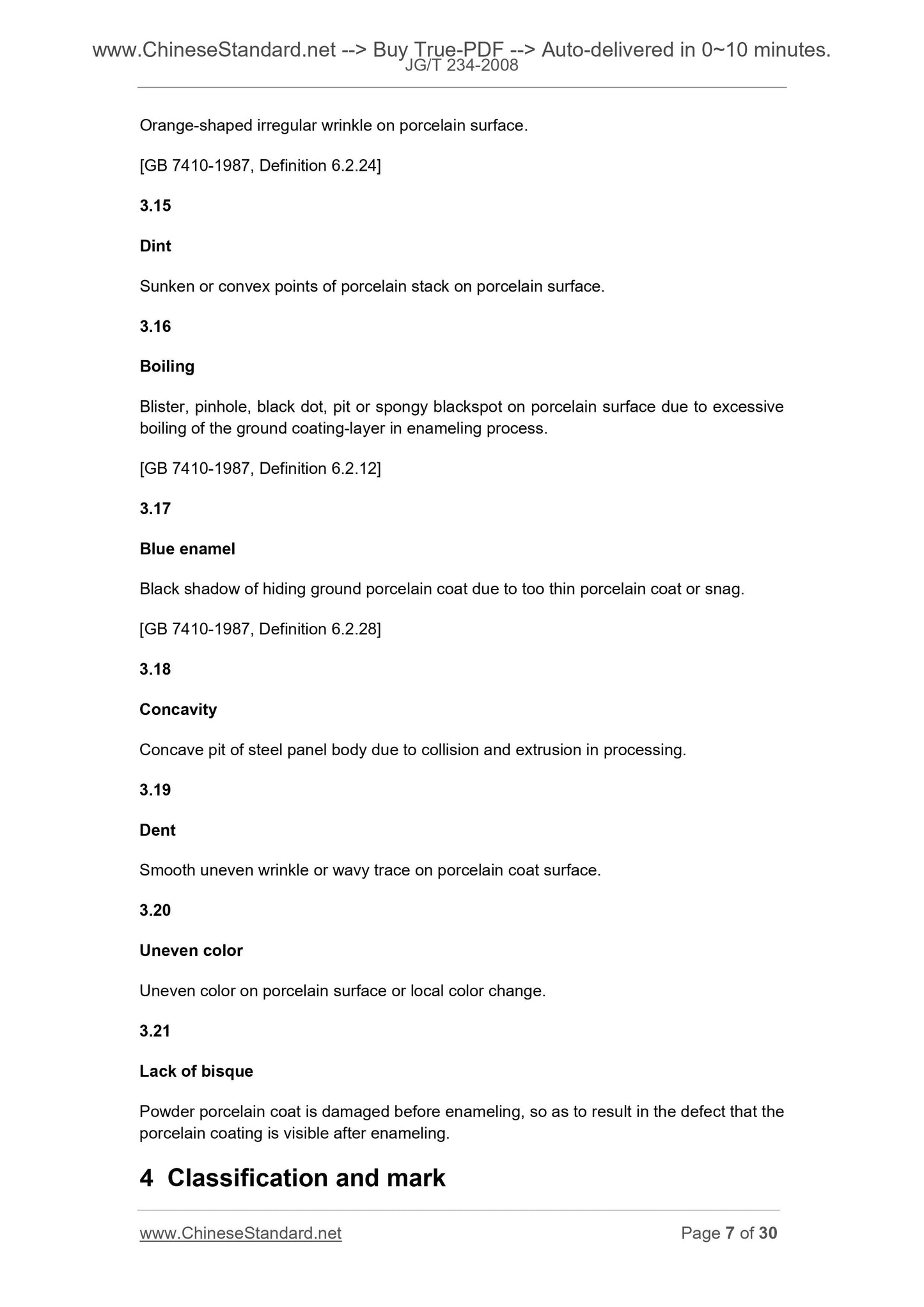

Orange-shaped irregular wrinkle on porcelain surface.

[GB 7410-1987, Definition 6.2.24]

3.15

Dint

Sunken or convex points of porcelain stack on porcelain surface.

3.16

Boiling

Blister, pinhole, black dot, pit or spongy blackspot on porcelain surface due to excessive

boiling of the ground coating-layer in enameling process.

[GB 7410-1987, Definition 6.2.12]

3.17

Blue enamel

Black shadow of hiding ground porcelain coat due to too thin porcelain coat or snag.

[GB 7410-1987, Definition 6.2.28]

3.18

Concavity

Concave pit of steel panel body due to collision and extrusion in processing.

3.19

Dent

Smooth uneven wrinkle or wavy trace on porcelain coat surface.

3.20

Uneven color

Uneven color on porcelain surface or local color change.

3.21

Lack of bisque

Powder porcelain coat is damaged before enameling, so as to result in the defect that the

porcelain coating is visible after enameling.

4 Classification and mark

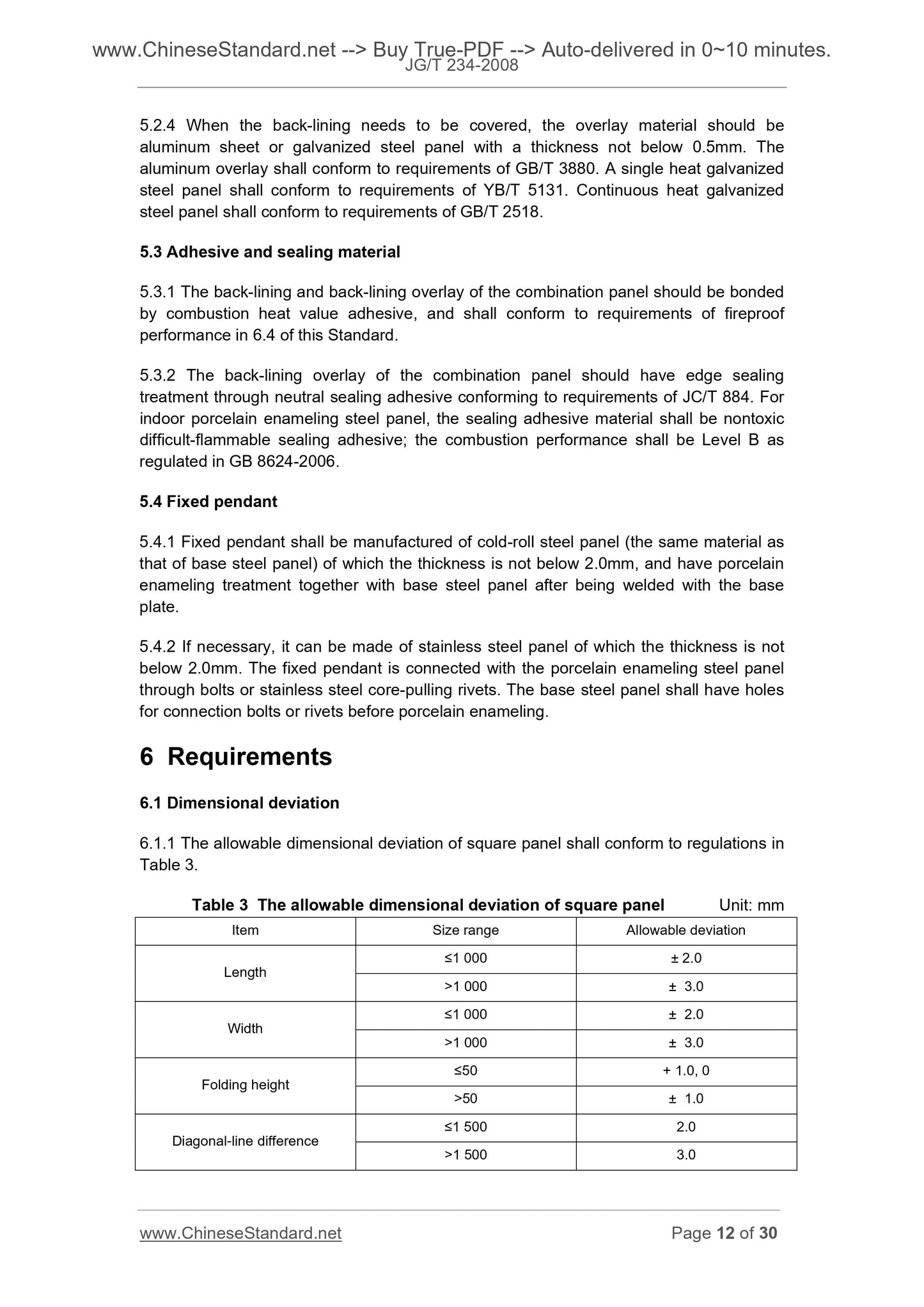

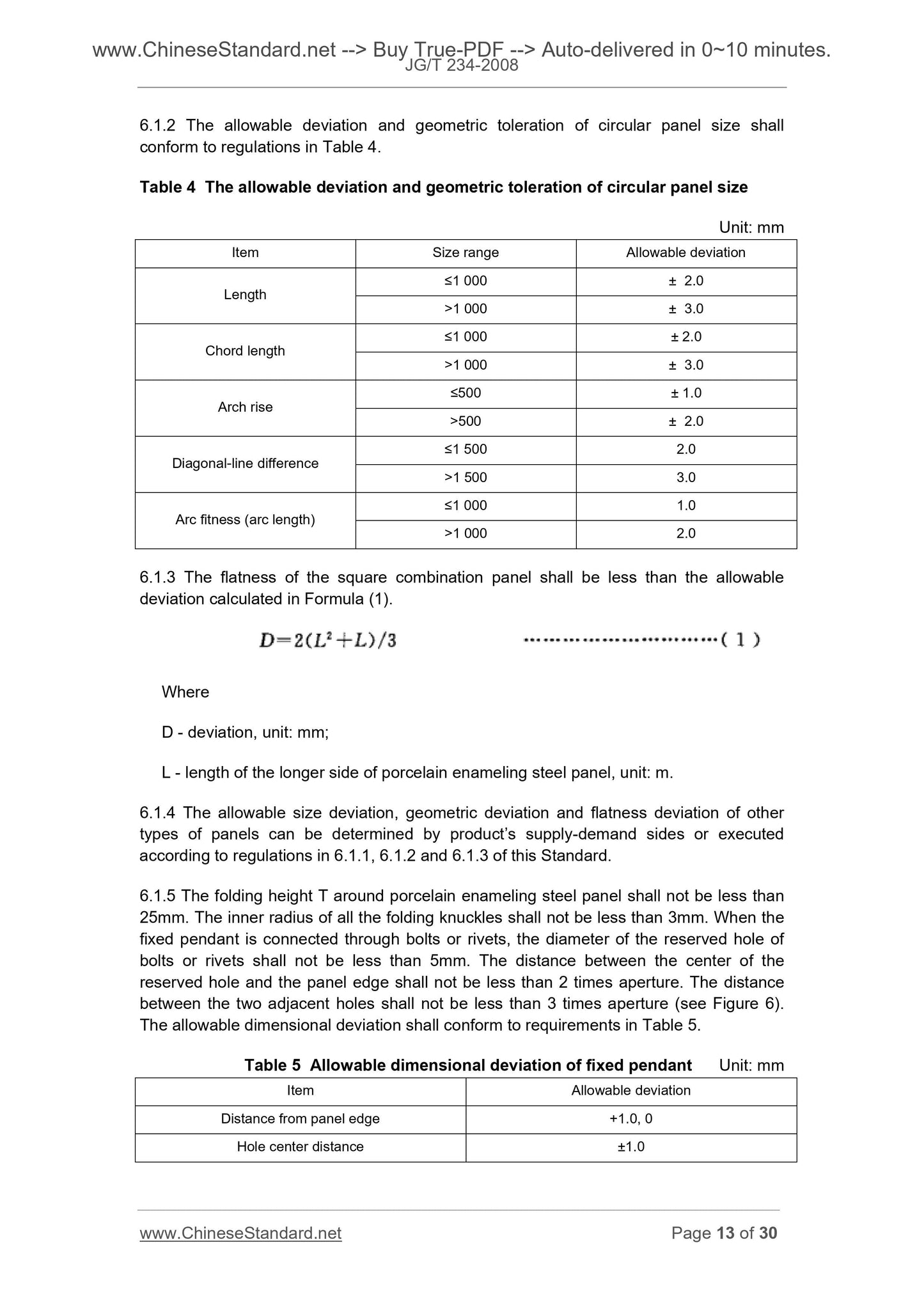

5.2.4 When the back-lining needs to be covered, the overlay material should be

aluminum sheet or galvanized steel panel with a thickness not below 0.5mm. The

aluminum overlay shall conform to requirements of GB/T 3880. A single heat galvanized

steel panel shall conform to requirements of YB/T 5131. Continuous heat galvanized

steel panel shall conform to requirements of GB/T 2518.

5.3 Adhesive and sealing material

5.3.1 The back-lining and back-lining overlay of the combination panel should be bonded

by combustion heat value adhesive, and shall conform to requirements of fireproof

performance in 6.4 of this Standard.

5.3.2 The back-lining overlay of the combination panel should have edge sealing

treatment through neutral sealing adhesive conforming to requirements of JC/T 884. For

indoor porcelain enameling steel panel, the sealing adhesive material shall be nontoxic

difficult-flammable sealing adhesive; the combustion performance shall be Level B as

regulated in GB 8624-2006.

5.4 Fixed pendant

5.4.1 Fixed pendant shall be manufactured of cold-roll steel panel (the same material as

that of base steel panel) of which the thickness is not below 2.0mm, and have porcelain

enameling treatment together with base steel panel after being welded with the base

plate.

5.4.2 If necessary, it can be made of stainless steel panel of which the thickness is not

below 2.0mm. The fixed pendant is connected with the p...

Get QUOTATION in 1-minute: Click JG/T 234-2008

Historical versions: JG/T 234-2008

Preview True-PDF (Reload/Scroll if blank)

JG/T 234-2008: Porcelain enameling steel panels for building

JG/T 234-2008

JG

BUILDING INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

Porcelain enameling steel panels for building

ISSUED ON. JUNE 03, 2008

IMPLEMENTED ON. NOVEMBER 01, 2008

Issued by. Ministry of Housing and urban-rural development of the

People's Republic of China

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Terms and definitions ... 5

4 Classification and mark ... 7

5 Material... 11

6 Requirements ... 12

7 Test Methods ... 16

8 Inspection rules ... 25

9 Mark, Packing, Transportation and Storage ... 29

Reference ... 30

Foreword

This Standard was proposed by Standard-Quota Institute of Ministry of Housing and

Urban-Rural Development.

This Standard shall be under the jurisdiction of Building Product and Part Standardization

Technical Committee of Ministry of Housing and Urban-Rural Development.

The responsible drafting organizations of this Standard. Zhejiang Kaier Industry Co., Ltd.

AND Shenzhen Xinshan Curtain Wall Technology Consulting Co., Ltd.

The participating drafting organizations of this Standard. Guangzhou Meibiao Yifeng

Enamel Co., Ltd., Baolichang Metal Products (Shenzhen) Co., Ltd., Foshan Weiyi Metal

Products Co., Ltd., Shenzhen Keyuan Building Group Co., Ltd., National Testing Center

For Building Materials, Guangdong Province Academy of Building Science, Building

Curtain-Wall, Door-Window Quality-Inspection Department of National Building

Engineering Quality, Supervision and Test Center, Institute of Vitreous Enamel of

Donghua University, East China Architectural Design and Research Institute Co. Ltd., AND

Hangzhou Zhijiang Silicone Chemicals Co. Ltd.

Main drafters of this Standard. Du Jiyu, Xing Hanxue, Dou Tiebo, Li Zhiqiang, Wang

Jiwen, Zhang Litao, Gu Jinfang, Li Xiuqing, Jiang Quan, Jiang Weizhong, Jiang Ren,

Dang Jie, Tan Shangfei and Liu Ming.

This Standard was issued for first-time.

Porcelain Enameling Steel Panels for Building

1 Scope

This Standard specifies the terms and definitions, classification and mark, material,

requirements, test method, inspection rules and mark, packing, transportation and

storage of porcelain enameling steel panels for building.

This Standard is applicable to porcelain enameling steel panels for interior and exterior

decoration of building.

2 Normative references

The articles contained in the following documents have become part of this document

when they are quoted herein. For the dated documents so quoted, all subsequent

modifications (including all corrections) or revisions made thereafter do not apply to this

Standard. However, the parties who reach an agreement according to this Standard are

encouraged to study whether the latest versions of these documents can be used. For

the undated documents so quoted, the latest versions (including all modification sheets)

apply to this document.

GB/T 191 Packaging - Pictorial marking for handling of goods

GB/T2518 Continuously hot-dip zinc-coated steel sheet and strip

GB/T 3880 Aluminium and aluminium alloy rolled sheet

GB 6566 Limits of radionuclides in building materials

GB 8624-2006 Classification for burning behavior of building materials and products

GB/T 9174 General specification for transport packages of general cargo

GB/T 9978-1999 Fire-resistance tests - Elements of building construction

GB/T 9989-2005 Vitreous and porcelain enamels - Determination of resistance to citric

acid at room temperature

GB/T 12467.2-1998 Quality requirements for welding - Fusion welding of metallic

materials - Part 2. Comprehensive quality requirements

GB/T 13790 Cold rolled sheets and strips for civil enameling

GB/T 15227-2007 Test method of air permeability, watertightness, wind load resistance

performance for curtain walls

JC/T 564 Fiber reinforced calcium silicate sheet

JC/T 884 Building sealants for coloured coat steel plates

QB/T 1855-1993 Enamelled ware in non-contact with food

YB/T5131 Single hot-dip zinc-coated carbon steel sheets

3 Terms and definitions

For the purpose of this Standard, the following terms and definitions are applicable to this

Standard.

3.1

Porcelain enameling steel panel

The combination panel that the inorganic glass material is fused onto steel panel and

forms firm combination with steel panel.

3.2

Composite porcelain enameling steel panel

The porcelain enameling steel panel of which the backside is adhered with back-lining

material or has interlayer.

3.3

Dry process enameling

The enameling method that the dry porcelain glaze powder is coated onto the base steel

panel through high-voltage static electricity.

3.4

Wet process enameling

The enameling method that the porcelain glaze powder that is floated in water (medium)

is coated onto base steel panel.

3.5

Square panel

The porcelain enameling steel panel of which the front-face is plane and the shape is

rectangle.

3.6

Circular panel

The porcelain enameling steel panel of which the front-face is cylindrical surface.

3.7

Orange-shaped irregular wrinkle on porcelain surface.

[GB 7410-1987, Definition 6.2.24]

3.15

Dint

Sunken or convex points of porcelain stack on porcelain surface.

3.16

Boiling

Blister, pinhole, black dot, pit or spongy blackspot on porcelain surface due to excessive

boiling of the ground coating-layer in enameling process.

[GB 7410-1987, Definition 6.2.12]

3.17

Blue enamel

Black shadow of hiding ground porcelain coat due to too thin porcelain coat or snag.

[GB 7410-1987, Definition 6.2.28]

3.18

Concavity

Concave pit of steel panel body due to collision and extrusion in processing.

3.19

Dent

Smooth uneven wrinkle or wavy trace on porcelain coat surface.

3.20

Uneven color

Uneven color on porcelain surface or local color change.

3.21

Lack of bisque

Powder porcelain coat is damaged before enameling, so as to result in the defect that the

porcelain coating is visible after enameling.

4 Classification and mark

5.2.4 When the back-lining needs to be covered, the overlay material should be

aluminum sheet or galvanized steel panel with a thickness not below 0.5mm. The

aluminum overlay shall conform to requirements of GB/T 3880. A single heat galvanized

steel panel shall conform to requirements of YB/T 5131. Continuous heat galvanized

steel panel shall conform to requirements of GB/T 2518.

5.3 Adhesive and sealing material

5.3.1 The back-lining and back-lining overlay of the combination panel should be bonded

by combustion heat value adhesive, and shall conform to requirements of fireproof

performance in 6.4 of this Standard.

5.3.2 The back-lining overlay of the combination panel should have edge sealing

treatment through neutral sealing adhesive conforming to requirements of JC/T 884. For

indoor porcelain enameling steel panel, the sealing adhesive material shall be nontoxic

difficult-flammable sealing adhesive; the combustion performance shall be Level B as

regulated in GB 8624-2006.

5.4 Fixed pendant

5.4.1 Fixed pendant shall be manufactured of cold-roll steel panel (the same material as

that of base steel panel) of which the thickness is not below 2.0mm, and have porcelain

enameling treatment together with base steel panel after being welded with the base

plate.

5.4.2 If necessary, it can be made of stainless steel panel of which the thickness is not

below 2.0mm. The fixed pendant is connected with the p...

Share