1

/

of

8

PayPal, credit cards. Download editable-PDF & invoice in 1 second!

JJF 1561-2016 English PDF (JJF1561-2016)

JJF 1561-2016 English PDF (JJF1561-2016)

Regular price

$160.00 USD

Regular price

Sale price

$160.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click JJF 1561-2016

Historical versions: JJF 1561-2016

Preview True-PDF (Reload/Scroll if blank)

JJF 1561-2016: Calibration Specification for Gear Measuring Centers

JJF 1561-2016

JJF

METROLOGICAL TECHNICAL SPECIFICATION

OF THE PEOPLE’S REPUBLIC OF CHINA

Calibration specification for gear measuring centers

ISSUED ON. JUNE 27, 2016

IMPLEMENTED ON. SEPTEMBER 27, 2016

Issued by. General Administration of Quality Supervision Inspection and

Quarantine of PRC

Table of Contents

Introduction ... 5

1 Scope ... 6

2 Normative references ... 6

3 Overview ... 6

4 Measurement characteristics ... 8

4.1 Oblique circular runout of the tip of the main rotary axis ... 8

4.2 Coaxiality of the upper tip axis and the main rotary axis ... 8

4.3 Parallelism between the lines from the movement of the axial guide to the two

tips ... 8

4.4 Indication error of tooth profile deviation measurement ... 8

4.5 Consistency of tooth profile tilt deviation measurement ... 8

4.6 Repeatability of total tooth profile deviation measurement ... 8

4.7 Indication error of spiral deviation measurement ... 8

4.8 Consistency of spiral tilt deviation measurement ... 8

4.9 Repeatability of total spiral deviation measurement ... 8

4.10 Indication error of total accumulative deviation measurement of pitch ... 8

4.11 Repeatability of single pitch deviation measurement ... 8

4.12 Indication error of gear radial runout measurement ... 8

5 Calibration conditions ... 9

5.1 Environmental conditions ... 9

5.2 Measurement standard tools and other equipment ... 9

6 Calibration items and calibration methods ... 11

6.1 Calibration items... 11

6.2 Calibration method ... 11

7 Calibration result expression ... 16

8 Re-calibration time interval... 17

Appendix A Additional measurement of the gear measurement center ... 18

Appendix B Evaluation of indication error uncertainty of instrument

measurement tooth profile tilt deviation ... 21

Appendix C Evaluation of indication error uncertainty of instrument measuring

total accumulative pitch deviation ... 24

Appendix D Calibration certificate content and inside page format ... 27

Appendix E Recommended value of metering characteristics of gear measuring

center ... 29

Calibration specification for gear measuring centers

1 Scope

This specification is applicable to the calibration of gear measurement centers

that measure gears with a modulus of not less than 0.3 mm and grade 3 and

below.

2 Normative references

This specification makes reference to the following documents.

JJF 1059.1 Evaluation and expression of uncertainty in measurement

JJF 1064-2010 Calibration specification for coordinate measuring machine

JJF 1331-2011 Calibration specification for inductive micrometers

ISO 1328-1.2013 Cylindrical gears - ISO system of flank tolerance

classification - Part 1. Definitions and allowable values of deviations relevant

to flanks of gear teeth

ISO 1328-2.1997 Cylindrical gears - ISO system of accuracy - Part 2.

Definitions and allowable values of deviations relevant to radial composites

deviations and runout information

ISO/TR 10064.5.2005 Cylindrical gears - Code of inspection practice - Part

5. Recommendations relative to evaluation of gear measuring instruments

For dated references, only the dated version applies to this specification; for

undated references, the latest edition (including all amendments) applies to

this specification.

3 Overview

The gear measurement center is an instrument that uses cylindrical or polar

coordinate measurement methods and makes measurement in accordance

with the electronic development method. It generally includes three linear

coordinate axis X, Y, Z and one rotary coordinate axis C. The working principle

is as shown in Figure 1. It consists of mechanical main body, control system,

probe unit and computer software. It can measure multiple parameters of gears

with one loading. In addition, it can be used for the measurement of workpieces

4 Measurement characteristics

4.1 Oblique circular runout of the tip of the main rotary axis

4.2 Coaxiality of the upper tip axis and the main rotary axis

4.3 Parallelism between the lines from the movement of the

axial guide to the two tips

4.4 Indication error of tooth profile deviation measurement

4.5 Consistency of tooth profile tilt deviation measurement

4.6 Repeatability of total tooth profile deviation measurement

4.7 Indication error of spiral deviation measurement

4.8 Consistency of spiral tilt deviation measurement

4.9 Repeatability of total spiral deviation measurement

4.10 Indication error of total accumulative deviation

measurement of pitch

4.11 Repeatability of single pitch deviation measurement

4.12 Indication error of gear radial runout measurement

Note. The indication error of the probe and the indication error of the coordinate

axis positioning are supplementary measurements for the large-scale gear

measurement center. See Appendix A for details.

Appendix A

Additional measurement of the gear measurement center

When the size of the physical gear standard tool cannot reach 50% of the

measurement range of the gear measurement center, it is recommended to

increase the measurement of the probe indication error of the instrument and

the indication error of the coordinate position.

A.1 Indication error of probe

A.1.1 The probe equipped for the gear measuring center are mostly three-

dimensional digital type. For the calibration of the indication error of this type of

probe, it may refer to the requirements of clause 7.1 of JJF 1064-2010. The

probes shall be distributed as evenly as possible along the standard ball (at

least half of the ball is measured), to obtain 25 measurement points, through

determining the spherical distance from the 25 measurement points to the

center of the least squares fit, EVALUATE the three-dimensional probing error

of the probe, which shall not exceed the maximum allowable error provided by

the supplier.

A.1.2 If the gear measuring center is equipped with an inductive probe, the

calibration of the indication error of this type can refer to the requirements of

clause 7.2.6 of JJF 1331-2011. During calibration, USE the measuring block of

the smallest size in not less than 3 equivalent measuring block group to align

the zero position, USE the measuring block of other sizes to measure the

indication error along positive direction; then USE the measuring block of

maximum size to align the zero position, USE the measuring block of other

sizes to measure the indication error along negative direction, the indication

error of each calibration point is obtained by the formula (A.1).

Where.

ri - The indication value read by the probe, μm;

Li - The actual size of the measuring block used for the calibration point, mm;

L0 - The actual size of the measuring block aligned to zero, mm.

In the measuring range, the maximum allowable error of the probe is

calculated in accordance with formula (A.2).

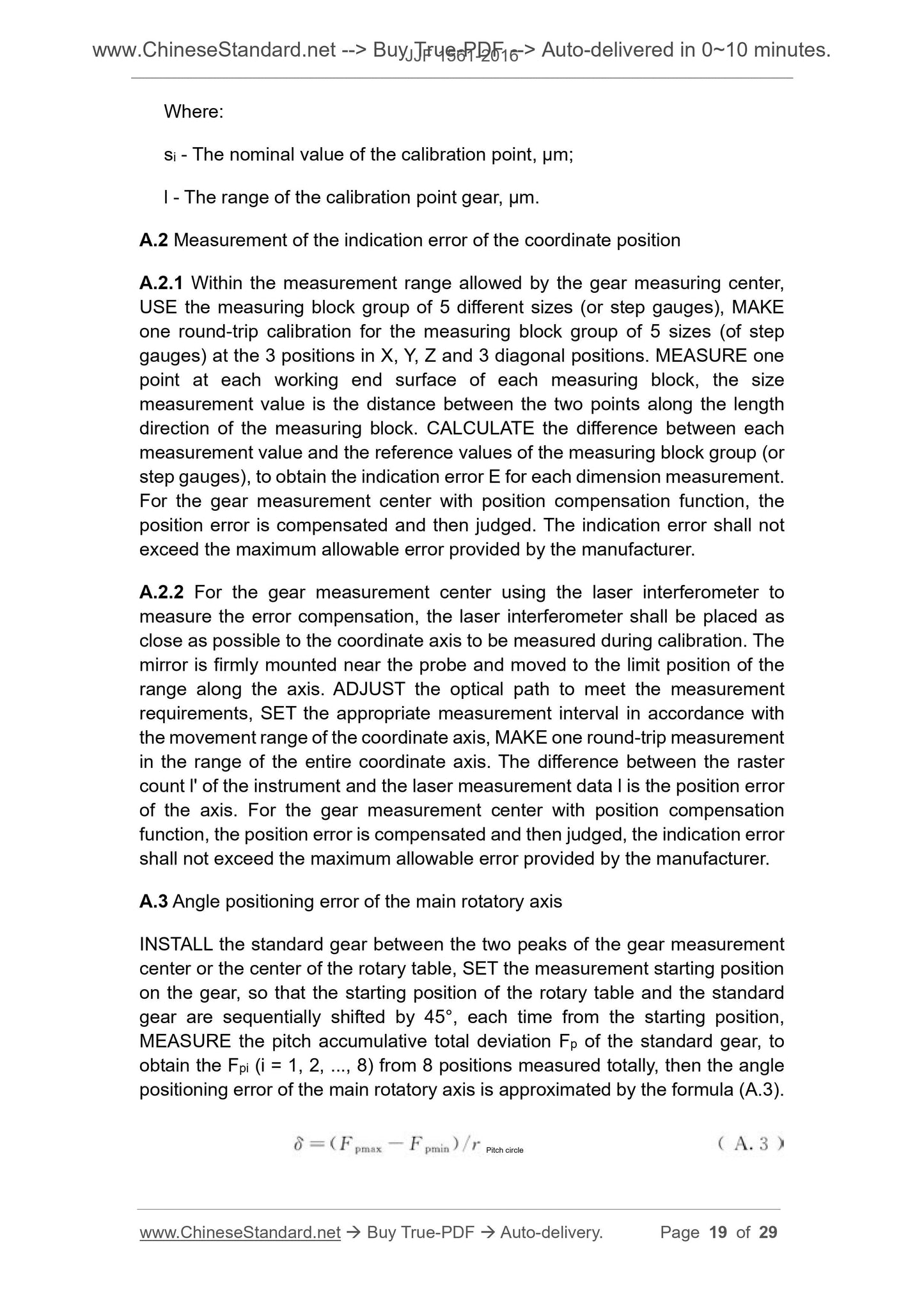

Where.

si - The nominal value of the calibration point, μm;

l - The range of the calibration point gear, μm.

A.2 Measurement of the indication error of the coordinate position

A.2.1 Within the measurement range allowed by the gear measuring center,

USE the measuring block group of 5 different sizes (or step gauges), MAKE

one round-trip calibration for the measuring block group of 5 sizes (of step

gauges) at the 3 positions in X, Y, Z and 3 diagonal positions. MEASURE one

point at each working end surface of each measuring block, the size

measurement value is the distance between th...

Get QUOTATION in 1-minute: Click JJF 1561-2016

Historical versions: JJF 1561-2016

Preview True-PDF (Reload/Scroll if blank)

JJF 1561-2016: Calibration Specification for Gear Measuring Centers

JJF 1561-2016

JJF

METROLOGICAL TECHNICAL SPECIFICATION

OF THE PEOPLE’S REPUBLIC OF CHINA

Calibration specification for gear measuring centers

ISSUED ON. JUNE 27, 2016

IMPLEMENTED ON. SEPTEMBER 27, 2016

Issued by. General Administration of Quality Supervision Inspection and

Quarantine of PRC

Table of Contents

Introduction ... 5

1 Scope ... 6

2 Normative references ... 6

3 Overview ... 6

4 Measurement characteristics ... 8

4.1 Oblique circular runout of the tip of the main rotary axis ... 8

4.2 Coaxiality of the upper tip axis and the main rotary axis ... 8

4.3 Parallelism between the lines from the movement of the axial guide to the two

tips ... 8

4.4 Indication error of tooth profile deviation measurement ... 8

4.5 Consistency of tooth profile tilt deviation measurement ... 8

4.6 Repeatability of total tooth profile deviation measurement ... 8

4.7 Indication error of spiral deviation measurement ... 8

4.8 Consistency of spiral tilt deviation measurement ... 8

4.9 Repeatability of total spiral deviation measurement ... 8

4.10 Indication error of total accumulative deviation measurement of pitch ... 8

4.11 Repeatability of single pitch deviation measurement ... 8

4.12 Indication error of gear radial runout measurement ... 8

5 Calibration conditions ... 9

5.1 Environmental conditions ... 9

5.2 Measurement standard tools and other equipment ... 9

6 Calibration items and calibration methods ... 11

6.1 Calibration items... 11

6.2 Calibration method ... 11

7 Calibration result expression ... 16

8 Re-calibration time interval... 17

Appendix A Additional measurement of the gear measurement center ... 18

Appendix B Evaluation of indication error uncertainty of instrument

measurement tooth profile tilt deviation ... 21

Appendix C Evaluation of indication error uncertainty of instrument measuring

total accumulative pitch deviation ... 24

Appendix D Calibration certificate content and inside page format ... 27

Appendix E Recommended value of metering characteristics of gear measuring

center ... 29

Calibration specification for gear measuring centers

1 Scope

This specification is applicable to the calibration of gear measurement centers

that measure gears with a modulus of not less than 0.3 mm and grade 3 and

below.

2 Normative references

This specification makes reference to the following documents.

JJF 1059.1 Evaluation and expression of uncertainty in measurement

JJF 1064-2010 Calibration specification for coordinate measuring machine

JJF 1331-2011 Calibration specification for inductive micrometers

ISO 1328-1.2013 Cylindrical gears - ISO system of flank tolerance

classification - Part 1. Definitions and allowable values of deviations relevant

to flanks of gear teeth

ISO 1328-2.1997 Cylindrical gears - ISO system of accuracy - Part 2.

Definitions and allowable values of deviations relevant to radial composites

deviations and runout information

ISO/TR 10064.5.2005 Cylindrical gears - Code of inspection practice - Part

5. Recommendations relative to evaluation of gear measuring instruments

For dated references, only the dated version applies to this specification; for

undated references, the latest edition (including all amendments) applies to

this specification.

3 Overview

The gear measurement center is an instrument that uses cylindrical or polar

coordinate measurement methods and makes measurement in accordance

with the electronic development method. It generally includes three linear

coordinate axis X, Y, Z and one rotary coordinate axis C. The working principle

is as shown in Figure 1. It consists of mechanical main body, control system,

probe unit and computer software. It can measure multiple parameters of gears

with one loading. In addition, it can be used for the measurement of workpieces

4 Measurement characteristics

4.1 Oblique circular runout of the tip of the main rotary axis

4.2 Coaxiality of the upper tip axis and the main rotary axis

4.3 Parallelism between the lines from the movement of the

axial guide to the two tips

4.4 Indication error of tooth profile deviation measurement

4.5 Consistency of tooth profile tilt deviation measurement

4.6 Repeatability of total tooth profile deviation measurement

4.7 Indication error of spiral deviation measurement

4.8 Consistency of spiral tilt deviation measurement

4.9 Repeatability of total spiral deviation measurement

4.10 Indication error of total accumulative deviation

measurement of pitch

4.11 Repeatability of single pitch deviation measurement

4.12 Indication error of gear radial runout measurement

Note. The indication error of the probe and the indication error of the coordinate

axis positioning are supplementary measurements for the large-scale gear

measurement center. See Appendix A for details.

Appendix A

Additional measurement of the gear measurement center

When the size of the physical gear standard tool cannot reach 50% of the

measurement range of the gear measurement center, it is recommended to

increase the measurement of the probe indication error of the instrument and

the indication error of the coordinate position.

A.1 Indication error of probe

A.1.1 The probe equipped for the gear measuring center are mostly three-

dimensional digital type. For the calibration of the indication error of this type of

probe, it may refer to the requirements of clause 7.1 of JJF 1064-2010. The

probes shall be distributed as evenly as possible along the standard ball (at

least half of the ball is measured), to obtain 25 measurement points, through

determining the spherical distance from the 25 measurement points to the

center of the least squares fit, EVALUATE the three-dimensional probing error

of the probe, which shall not exceed the maximum allowable error provided by

the supplier.

A.1.2 If the gear measuring center is equipped with an inductive probe, the

calibration of the indication error of this type can refer to the requirements of

clause 7.2.6 of JJF 1331-2011. During calibration, USE the measuring block of

the smallest size in not less than 3 equivalent measuring block group to align

the zero position, USE the measuring block of other sizes to measure the

indication error along positive direction; then USE the measuring block of

maximum size to align the zero position, USE the measuring block of other

sizes to measure the indication error along negative direction, the indication

error of each calibration point is obtained by the formula (A.1).

Where.

ri - The indication value read by the probe, μm;

Li - The actual size of the measuring block used for the calibration point, mm;

L0 - The actual size of the measuring block aligned to zero, mm.

In the measuring range, the maximum allowable error of the probe is

calculated in accordance with formula (A.2).

Where.

si - The nominal value of the calibration point, μm;

l - The range of the calibration point gear, μm.

A.2 Measurement of the indication error of the coordinate position

A.2.1 Within the measurement range allowed by the gear measuring center,

USE the measuring block group of 5 different sizes (or step gauges), MAKE

one round-trip calibration for the measuring block group of 5 sizes (of step

gauges) at the 3 positions in X, Y, Z and 3 diagonal positions. MEASURE one

point at each working end surface of each measuring block, the size

measurement value is the distance between th...

Share