1

/

of

11

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

JJG 1114-2015 English PDF

JJG 1114-2015 English PDF

Regular price

$320.00 USD

Regular price

Sale price

$320.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click JJG 1114-2015

Historical versions: JJG 1114-2015

Preview True-PDF (Reload/Scroll if blank)

JJG 1114-2015: Liquefied Natural Gas Dispensers

JJG 1114-2015

JJG

NATIONAL METROLOGICAL VERIFICATION REGULATION

OF THE PEOPLE’S REPUBLIC OF CHINA

Liquefied Natural Gas Dispensers

ISSUED ON: JUNE 15, 2015

IMPLEMENTED ON: SEPTEMBER 15, 2015

Issued by: General Administration of Quality Supervision, Inspection and

Quarantine of the People's Republic of China

Table of Contents

Introduction ... 5

1 Scope ... 6

2 Normative references ... 6

3 Terms and units of measurement ... 6

3.1 Terms ... 6

3.2 Units of measurement ... 8

4 General ... 9

4.1 Construction ... 9

4.2 Principle ... 9

5 Metrological performance requirements ... 10

5.1 Maximum allowable error ... 10

5.2 Repeatability ... 10

5.3 Flow range ... 10

5.4 Minimum quality variable ... 10

5.5 Payment amount error ... 10

6 General technical requirements ... 10

6.1 Appearance and accompanying documents ... 10

6.2 Error adjustment ... 11

6.3 Seal settings ... 11

6.4 Safety functions ... 12

7 Control of measuring instruments ... 12

7.1 Verification conditions ... 12

7.2 Verification items and methods ... 13

7.3 Processing of verification results ... 21

7.4 Verification cycle ... 21

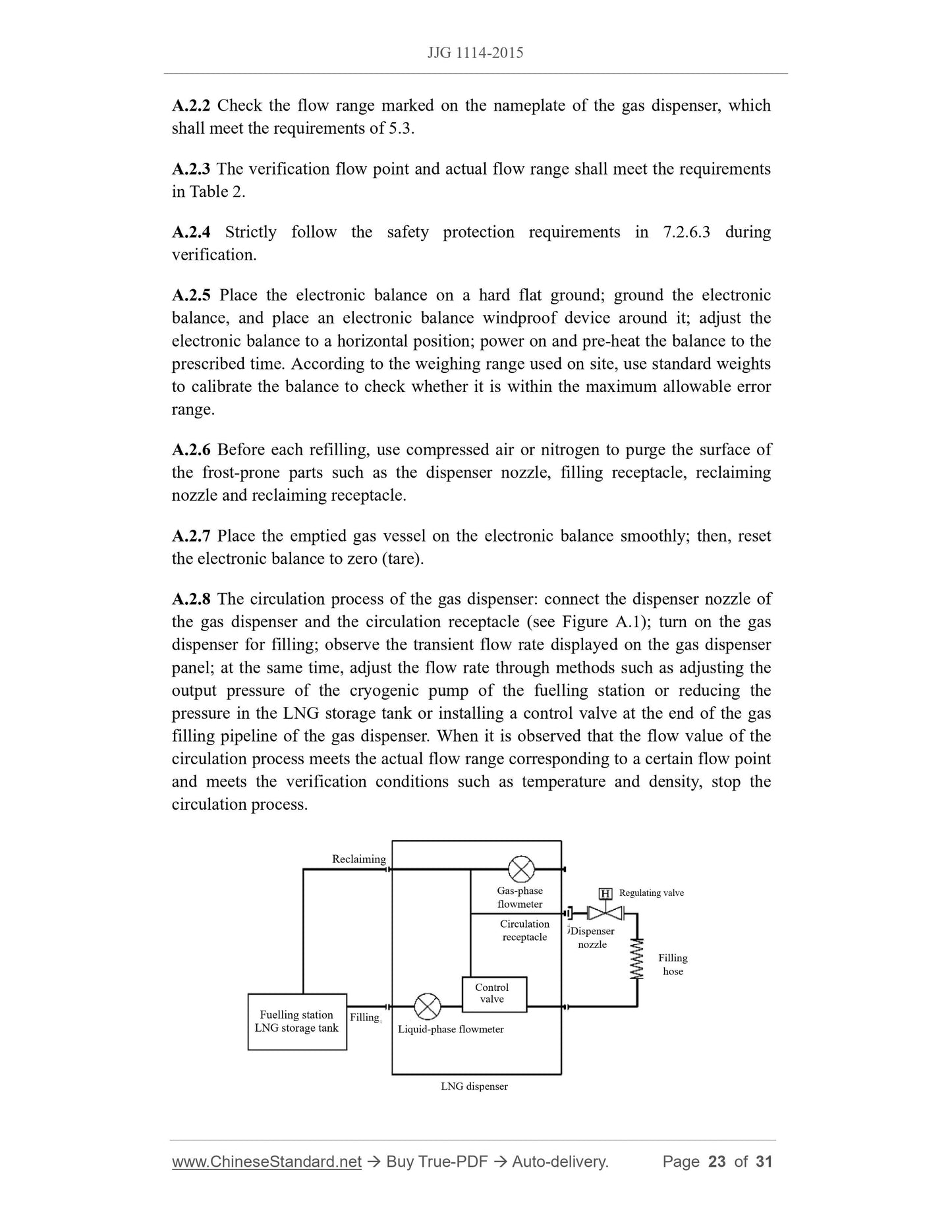

Appendix A Cryogenic liquids flow standard facilities by weighing method ... 22

Appendix B Information format of verification certificate/verification result

notification and original record ... 28

Verification Regulation of Liquefied Natural Gas

Dispensers

1 Scope

This Regulation applies to the initial verification, subsequent verification and

in-service inspection of liquefied natural gas (LNG) dispensers (hereinafter referred

to as dispensers).

2 Normative references

GB/T18442.1, Static vacuum insulated cryogenic pressure vessels - Part 1: General

requirements

GB/T 19204, General characteristics of liquefied natural gas

GB/T 20368, Production, storage and handling of liquefied natural gas (LNG)

GB/T 25986, Filling device of natural gas vehicles

GB 50156, Technical standard of fuelling station

OIML R81:2006(E), Dynamic measuring devices and systems for cryogenic liquids

For dated references, only the dated version applies to this Regulation; for undated

references, the latest edition (including all amendments) applies to this Regulation.

3 Terms and units of measurement

3.1 Terms

3.1.1 Liquefied natural gas (LNG) dispensers

A complete measuring system of LNG semi-invariant – providing LNG filling

service – which generally consists of cryogenic flowmeter, control valve, dispenser

nozzle, reclaiming nozzle, filling hose, reclaiming hose, as well as electronic

computer and ancillary devices.

3.1.2 LNG gas vessel

A vacuum insulated cryogenic pressure vessel used for storing and supplying LNG

fuel, of which the technical indicators shall meet the requirements of GB/T 18442.1.

3.1.3 Filling receptacle

A connecting part, after being connected with the dispenser nozzle, for filling LNG

fuel to the LNG gas vessel.

3.1.4 Reclaiming receptacle

A connecting part, after being connected with the reclaiming nozzle, used to reclaim

the residual gas in the LNG gas vessel.

3.1.5 Circulation receptacle

A connecting part on the gas dispenser used, after being connected with the

dispenser nozzle, for the pre-cooling circulation.

3.1.6 Dispenser nozzle

A special tool for manual operation on the gas dispenser for connecting the filling

receptacle or the circulation receptacle, which shall meet the requirements of GB/T

25986.

3.1.7 Reclaiming nozzle

A special tool for manual operation on the gas dispenser for connecting the

reclaiming receptacle, which shall meet the requirements of GB/T 25986.

3.1.8 Breakaway coupling valve

A special protection device on the gas dispenser, which is installed on the filling

hose and the reclaiming hose of the gas dispenser, and can be broken into two

sections under the action of the rated pull-out force.

3.1.9 Emergency shutdown device

A special protection device on the gas dispenser, which, after being manually

triggered in an emergency, can execute the corresponding shutdown logic, cut off or

isolate the LNG fuel source, and shut down the equipment that will aggravate and

expand the accident due to continued operation. It is generally located at an obvious

location of the gas dispenser.

3.1.10 Electronic computer

A calculation and control device of the gas dispenser, which can receive the flow

electric signal transmitted by the flow meter and the pressure electric signal

transmitted by the pressure sensor, etc., and calculate according to the set parameters;

can carry out data transmission and display operations, and automatically judge and

control the flow of the fluid; has the functions of returning to zero, indicating the

payment amount, etc., and can also realize the adjustment of the measurement error.

refilling. The electronic computer of the gas dispenser automatically controls the gas

filling process, and calculates according to the flow signal output by the flowmeter.

The mass of LNG filled into the gas vessel is the difference between the

measurement value of the liquid-phase flowmeter and the measurement value of the

gas-phase flowmeter (when the gas dispenser is not connected to the reclaiming

pipeline, the measurement value of the gas-phase flowmeter is zero), and the panel

of the gas dispenser displays the final measurement value.

For the gas dispenser used for trade settlement, a gas-phase flow meter must be

installed in the reclaiming pipeline to measure the residual gas in the gas vessel

recycled.

5 Metrological performance requirements

5.1 Maximum allowable error

The maximum allowable error of the gas dispenser is ±1.5%.

5.2 Repeatability

The measurement repeatability of the gas dispenser does not exceed 0.5%.

5.3 Flow range

The mass flow rate of the gas dispenser is less than or equal to 80 kg/min, and the

range ratio is not less than 4:1.

5.4 Minimum quality variable

The minimum quality variable of the gas dispenser shall not be greater than 0.01 kg.

5.5 Payment amount error

The payment amount displayed on the gas dispenser panel shall not be greater than

the calculated payment amount (the product of the unit price and the displayed

value).

6 General technical requirements

6.1 Appearance and accompanying documents

6.1.1 Appearance

6.1.1.1 The nameplate and markings of the gas dispenser shall be clear and reliable.

6.1.1.2 The connectors of the gas dispenser must be firm and reliable, and shall not

loosen or fall off due to vibration.

6.1.2 Accompanying documents

The gas dispenser shall be provided with the factory inspection certificate and the

instruction manual, which shall give the technical requirements, installation

conditions, usage methods, safety protection measures and the like.

6.1.3 Markings and nameplate

6.1.3.1 There shall be obvious safety and operation markings on the dispenser.

6.1.3.2 The nameplate of the gas dispenser generally indicates the following

contents:

1) Manufacturer’s name (trademark), product name and model specifications;

2) Date of manufacture and serial number;

3) Marking and number of the license for manufacturing measuring instruments;

4) Applicable medium, flow range, accuracy grade or maximum allowable error;

5) Applicable ambient temperature range, maximum working pressure, power

supply voltage;

6) Explosion-proof grade, explosion-proof identification and explosion-proof

certifica...

Get QUOTATION in 1-minute: Click JJG 1114-2015

Historical versions: JJG 1114-2015

Preview True-PDF (Reload/Scroll if blank)

JJG 1114-2015: Liquefied Natural Gas Dispensers

JJG 1114-2015

JJG

NATIONAL METROLOGICAL VERIFICATION REGULATION

OF THE PEOPLE’S REPUBLIC OF CHINA

Liquefied Natural Gas Dispensers

ISSUED ON: JUNE 15, 2015

IMPLEMENTED ON: SEPTEMBER 15, 2015

Issued by: General Administration of Quality Supervision, Inspection and

Quarantine of the People's Republic of China

Table of Contents

Introduction ... 5

1 Scope ... 6

2 Normative references ... 6

3 Terms and units of measurement ... 6

3.1 Terms ... 6

3.2 Units of measurement ... 8

4 General ... 9

4.1 Construction ... 9

4.2 Principle ... 9

5 Metrological performance requirements ... 10

5.1 Maximum allowable error ... 10

5.2 Repeatability ... 10

5.3 Flow range ... 10

5.4 Minimum quality variable ... 10

5.5 Payment amount error ... 10

6 General technical requirements ... 10

6.1 Appearance and accompanying documents ... 10

6.2 Error adjustment ... 11

6.3 Seal settings ... 11

6.4 Safety functions ... 12

7 Control of measuring instruments ... 12

7.1 Verification conditions ... 12

7.2 Verification items and methods ... 13

7.3 Processing of verification results ... 21

7.4 Verification cycle ... 21

Appendix A Cryogenic liquids flow standard facilities by weighing method ... 22

Appendix B Information format of verification certificate/verification result

notification and original record ... 28

Verification Regulation of Liquefied Natural Gas

Dispensers

1 Scope

This Regulation applies to the initial verification, subsequent verification and

in-service inspection of liquefied natural gas (LNG) dispensers (hereinafter referred

to as dispensers).

2 Normative references

GB/T18442.1, Static vacuum insulated cryogenic pressure vessels - Part 1: General

requirements

GB/T 19204, General characteristics of liquefied natural gas

GB/T 20368, Production, storage and handling of liquefied natural gas (LNG)

GB/T 25986, Filling device of natural gas vehicles

GB 50156, Technical standard of fuelling station

OIML R81:2006(E), Dynamic measuring devices and systems for cryogenic liquids

For dated references, only the dated version applies to this Regulation; for undated

references, the latest edition (including all amendments) applies to this Regulation.

3 Terms and units of measurement

3.1 Terms

3.1.1 Liquefied natural gas (LNG) dispensers

A complete measuring system of LNG semi-invariant – providing LNG filling

service – which generally consists of cryogenic flowmeter, control valve, dispenser

nozzle, reclaiming nozzle, filling hose, reclaiming hose, as well as electronic

computer and ancillary devices.

3.1.2 LNG gas vessel

A vacuum insulated cryogenic pressure vessel used for storing and supplying LNG

fuel, of which the technical indicators shall meet the requirements of GB/T 18442.1.

3.1.3 Filling receptacle

A connecting part, after being connected with the dispenser nozzle, for filling LNG

fuel to the LNG gas vessel.

3.1.4 Reclaiming receptacle

A connecting part, after being connected with the reclaiming nozzle, used to reclaim

the residual gas in the LNG gas vessel.

3.1.5 Circulation receptacle

A connecting part on the gas dispenser used, after being connected with the

dispenser nozzle, for the pre-cooling circulation.

3.1.6 Dispenser nozzle

A special tool for manual operation on the gas dispenser for connecting the filling

receptacle or the circulation receptacle, which shall meet the requirements of GB/T

25986.

3.1.7 Reclaiming nozzle

A special tool for manual operation on the gas dispenser for connecting the

reclaiming receptacle, which shall meet the requirements of GB/T 25986.

3.1.8 Breakaway coupling valve

A special protection device on the gas dispenser, which is installed on the filling

hose and the reclaiming hose of the gas dispenser, and can be broken into two

sections under the action of the rated pull-out force.

3.1.9 Emergency shutdown device

A special protection device on the gas dispenser, which, after being manually

triggered in an emergency, can execute the corresponding shutdown logic, cut off or

isolate the LNG fuel source, and shut down the equipment that will aggravate and

expand the accident due to continued operation. It is generally located at an obvious

location of the gas dispenser.

3.1.10 Electronic computer

A calculation and control device of the gas dispenser, which can receive the flow

electric signal transmitted by the flow meter and the pressure electric signal

transmitted by the pressure sensor, etc., and calculate according to the set parameters;

can carry out data transmission and display operations, and automatically judge and

control the flow of the fluid; has the functions of returning to zero, indicating the

payment amount, etc., and can also realize the adjustment of the measurement error.

refilling. The electronic computer of the gas dispenser automatically controls the gas

filling process, and calculates according to the flow signal output by the flowmeter.

The mass of LNG filled into the gas vessel is the difference between the

measurement value of the liquid-phase flowmeter and the measurement value of the

gas-phase flowmeter (when the gas dispenser is not connected to the reclaiming

pipeline, the measurement value of the gas-phase flowmeter is zero), and the panel

of the gas dispenser displays the final measurement value.

For the gas dispenser used for trade settlement, a gas-phase flow meter must be

installed in the reclaiming pipeline to measure the residual gas in the gas vessel

recycled.

5 Metrological performance requirements

5.1 Maximum allowable error

The maximum allowable error of the gas dispenser is ±1.5%.

5.2 Repeatability

The measurement repeatability of the gas dispenser does not exceed 0.5%.

5.3 Flow range

The mass flow rate of the gas dispenser is less than or equal to 80 kg/min, and the

range ratio is not less than 4:1.

5.4 Minimum quality variable

The minimum quality variable of the gas dispenser shall not be greater than 0.01 kg.

5.5 Payment amount error

The payment amount displayed on the gas dispenser panel shall not be greater than

the calculated payment amount (the product of the unit price and the displayed

value).

6 General technical requirements

6.1 Appearance and accompanying documents

6.1.1 Appearance

6.1.1.1 The nameplate and markings of the gas dispenser shall be clear and reliable.

6.1.1.2 The connectors of the gas dispenser must be firm and reliable, and shall not

loosen or fall off due to vibration.

6.1.2 Accompanying documents

The gas dispenser shall be provided with the factory inspection certificate and the

instruction manual, which shall give the technical requirements, installation

conditions, usage methods, safety protection measures and the like.

6.1.3 Markings and nameplate

6.1.3.1 There shall be obvious safety and operation markings on the dispenser.

6.1.3.2 The nameplate of the gas dispenser generally indicates the following

contents:

1) Manufacturer’s name (trademark), product name and model specifications;

2) Date of manufacture and serial number;

3) Marking and number of the license for manufacturing measuring instruments;

4) Applicable medium, flow range, accuracy grade or maximum allowable error;

5) Applicable ambient temperature range, maximum working pressure, power

supply voltage;

6) Explosion-proof grade, explosion-proof identification and explosion-proof

certifica...

Share