1

/

of

9

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

JJG 245-2005 English PDF

JJG 245-2005 English PDF

Regular price

$620.00 USD

Regular price

Sale price

$620.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click JJG 245-2005

Historical versions: JJG 245-2005

Preview True-PDF (Reload/Scroll if blank)

JJG 245-2005: Verification Regulation of Illuminance Meter

JJG 245-2005

JJG

METROLOGICAL VERIFICATION REGULATION

OF THE PEOPLE’S REPUBLIC OF CHINA

Illuminance meter

光照度计

ISSUED ON: APRIL 28, 2005

IMPLEMENTED ON: OCTOBER 10, 2005

Issued by: General Administration of Quality Supervision, Inspection and

Quarantine of PRC.

Table of Contents

1 Scope ... 4

2 Normative references ... 4

3 Overview ... 4

4 Metering performance requirements ... 4

4.1 Relative indication error ... 4

4.2 V(λ) matching error ... 5

4.3 Cosine characteristic (directional response) error ... 5

4.4 Nonlinear error ... 5

4.5 Shift error ... 5

4.6 Fatigue error ... 6

4.7 Infrared response error ... 6

4.8 UV response error ... 6

4.9 Temperature coefficient ... 6

5 General technical requirements ... 7

5.1 Appearance ... 7

5.2 Identification ... 7

5.3 Instructions ... 7

6 Metering instrument control ... 7

6.1 Verification conditions ... 7

6.2 Verification items ... 8

6.3 Verification method ... 9

6.4 Processing of verification results ... 13

6.5 Verification cycle ... 14

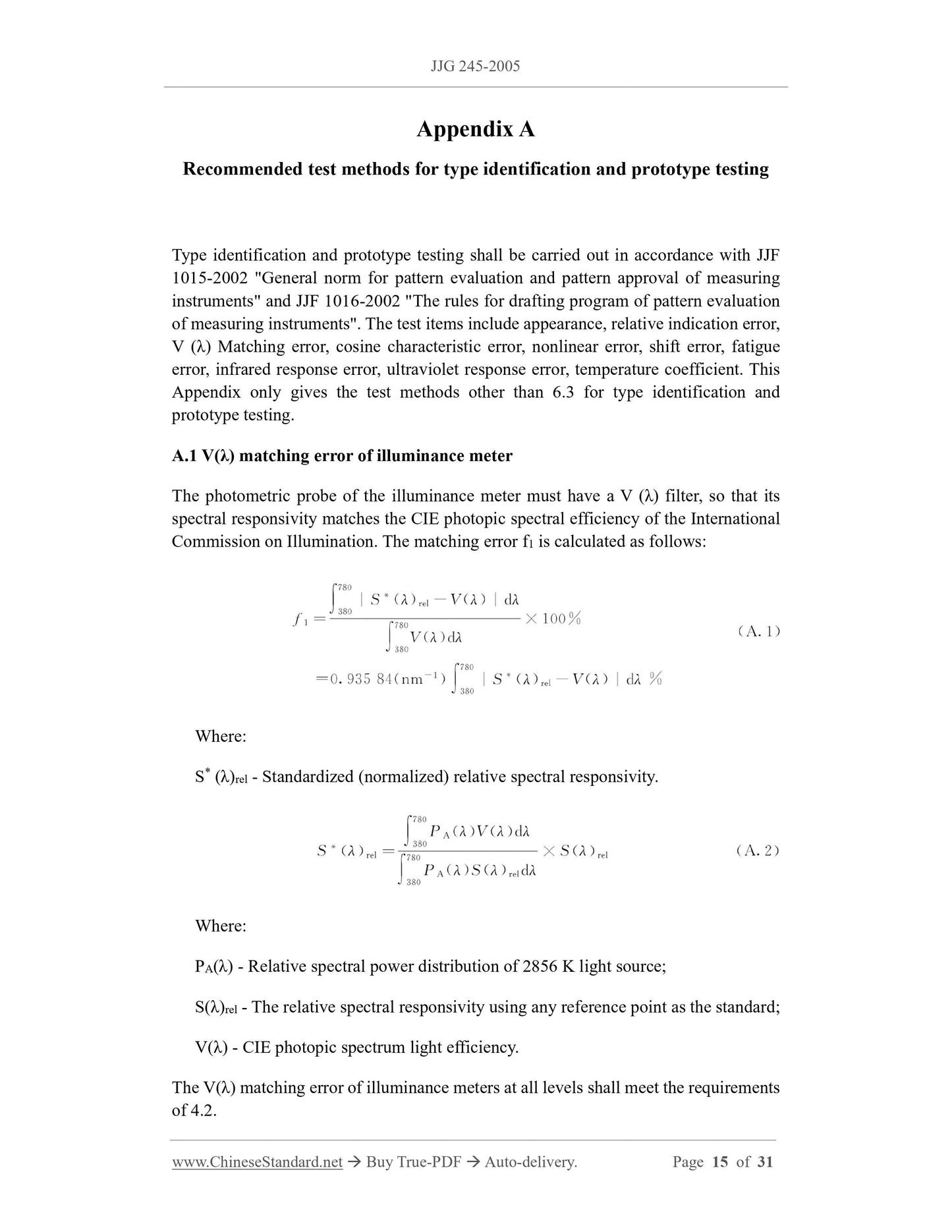

Appendix A Recommended test methods for type identification and prototype testing

... 15

Appendix B Verification of illuminance meter using comparison method ... 20

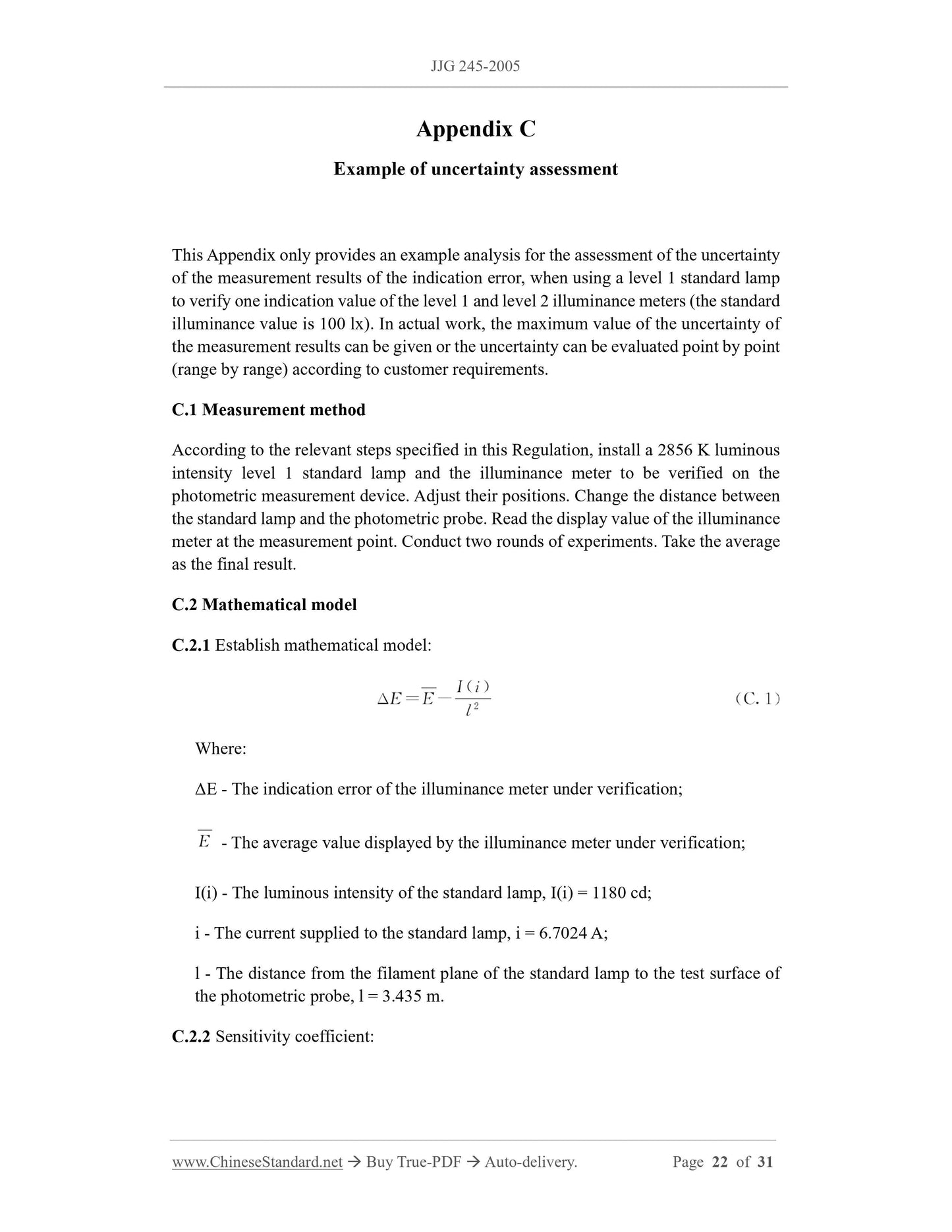

Appendix C Example of uncertainty assessment ... 22

Appendix D The relationship between the two formulas of cosine characteristic error

... 28

Appendix E Format of the inner page of the illuminance meter's verification certificate

and verification result notification ... 30

Verification regulation of illuminance meter

1 Scope

This Regulation applies to the initial verification, subsequent verification, in-use

inspection of illuminance meters (hereinafter referred to as illuminance meters). The

requirements related to measurement performance in type identification and prototype

testing can be implemented with reference to Regulation.

2 Normative references

This Regulation cites the following documents:

"Illuminance Meter" OIML 1988 English version

"Performance Test Methods for Photometers and Luminometers" CIE 1987 English

version

JJF 1059-1999 "Evaluation and Expression of Uncertainty in Measurement"

When using this Regulation, attention shall be paid to using the currently valid versions

of the above cited documents.

3 Overview

An illuminance meter is a measuring instrument for measuring illuminance. It consists

of a photometric probe (including a cosine corrector, a V (λ) correction filter, a

photoelectric receiver) and a display (digital or pointer type). When the photoelectric

receiver receives the optical radiation passing through the cosine corrector and V(λ)

filter, the generated photoelectric signal is processed and the corresponding illumination

value is displayed on the display.

4 Metering performance requirements

4.1 Relative indication error

The relative indication error of the illuminance meter shall not exceed the requirements

of Table 1.

l - The distance from the filament plane of the standard lamp to the test surface of

the photometric probe, m.

During verification, the distance -- between the filament plane of the standard lamp and

the photometric probe must be at least 15 times greater than the maximum linear

dimension of the light-emitting surface or the test surface of the photometric probe (the

diagonal length or diameter of the filament plane and the test surface of the photometric

probe).

The standard illuminance meter shall calibrate at least five equally spaced points, within

the full range of each gear. The level 1 and level 2 illuminance meters shall calibrate at

least three equally spaced points. Each point shall be illuminated for 5 seconds and its

display value shall be read. Each instrument is required to be verified for two rounds.

The relative deviation of the two rounds of values: standard, level 1, level 2 illuminance

meters shall not exceed 0.6%, 1%, 1.5%, respectively. The average value of each point

is taken as the final result. The relative indication errors of illuminance meters at all

levels shall comply with the requirements of 4.1.

Relative indication error = [(Displayed value - standard value) / Standard value] × 100%

(2)

For level 1 and level 2 illuminance meters, the comparison method can also be used for

verification. See Appendix B for the method.

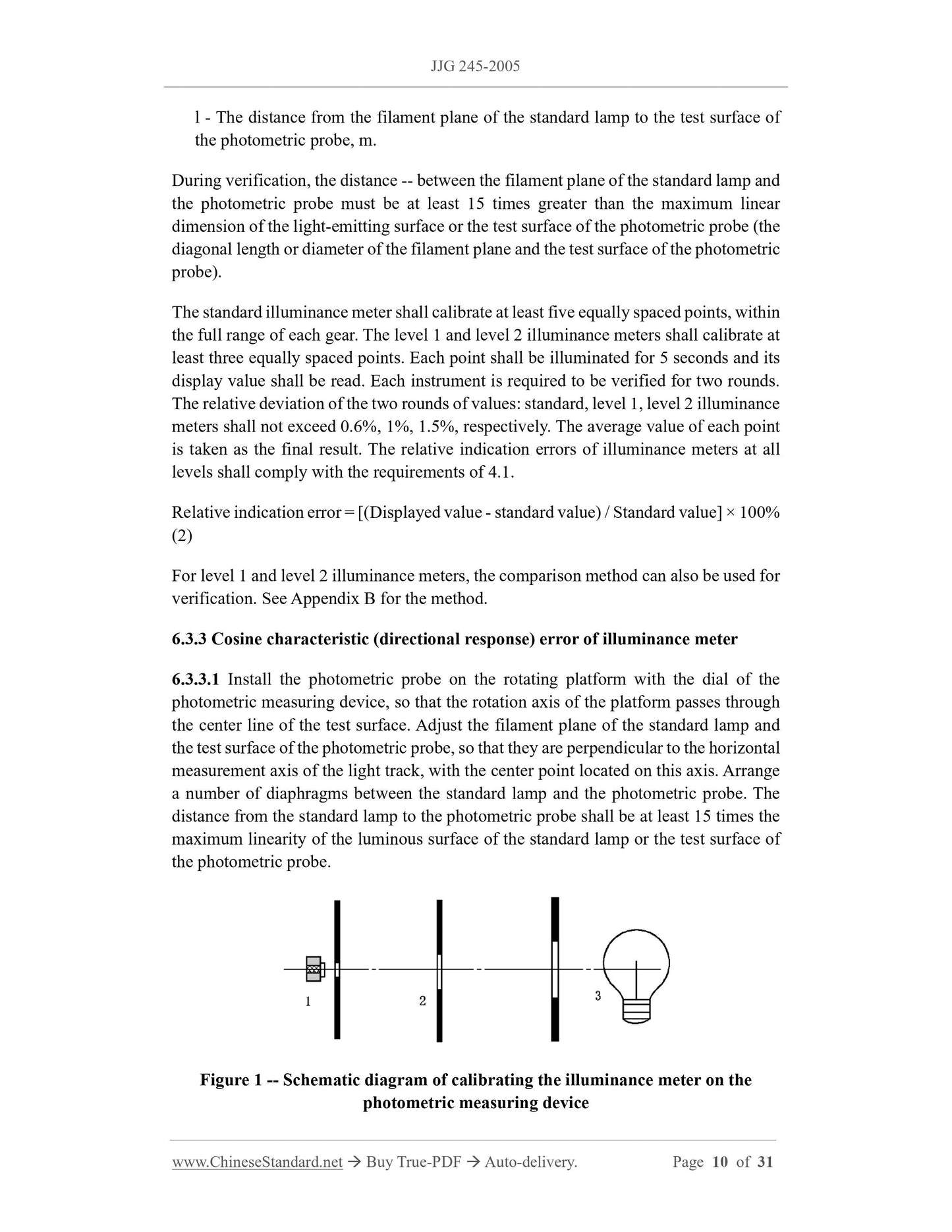

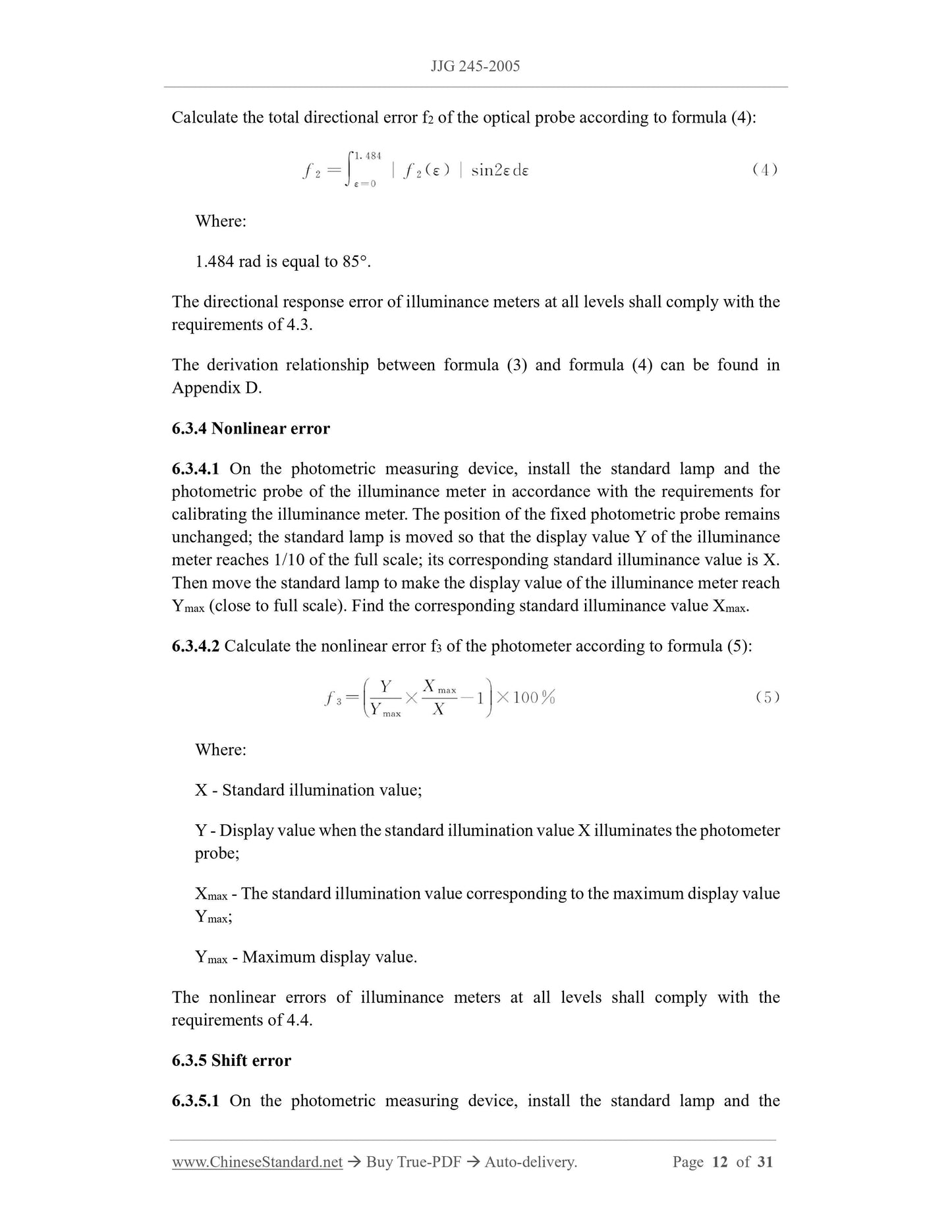

6.3.3 Cosine characteristic (directional response) error of illuminance meter

6.3.3.1 Install the photometric probe on the rotating platform with the dial of the

photometric measuring device, so that the rotation axis of the platform passes through

the center line of the test surface. Adjust the filament plane of the standard lamp and

the test surface of the photometric probe, so that they are perpendicular to the horizontal

measurement axis of the light track, with the center point located on this axis. Arrange

a number of diaphragms between the standard lamp and the photometric probe. The

distance from the standard lamp to the photometric probe shall be at least 15 times the

maximum linearity of the luminous surface of the standard lamp or the test surface of

the photometric probe.

Figure 1 -- Schematic diagram of calibrating the illuminance meter on the

photometric measuring device

Calculate the total directional error f2 of the optical probe according to formula (4):

Where:

1.484 rad is equal to 85°.

The directional response error of illuminance meters at all levels shall comply with the

requirements of 4.3.

The derivation relationship between formula (3) and formula (4) can be found in

Appendix D.

6.3.4 Nonlinear error

6.3.4.1 On the photometric measuring device, install the standard lamp and the

photometric probe of the illuminance meter in accordance with the requirements for

calibrating the illuminance meter. The position of the fixed photometric probe remains

unchanged; the standard lamp is moved so that the display value Y of the illuminance

meter reaches 1/10 of the full scale; its corresponding standard illuminance value is X.

Then move the standard lamp to make the display value of the illuminance meter reach

Ymax (close to full scale). Find the corresponding standard illuminance value Xmax.

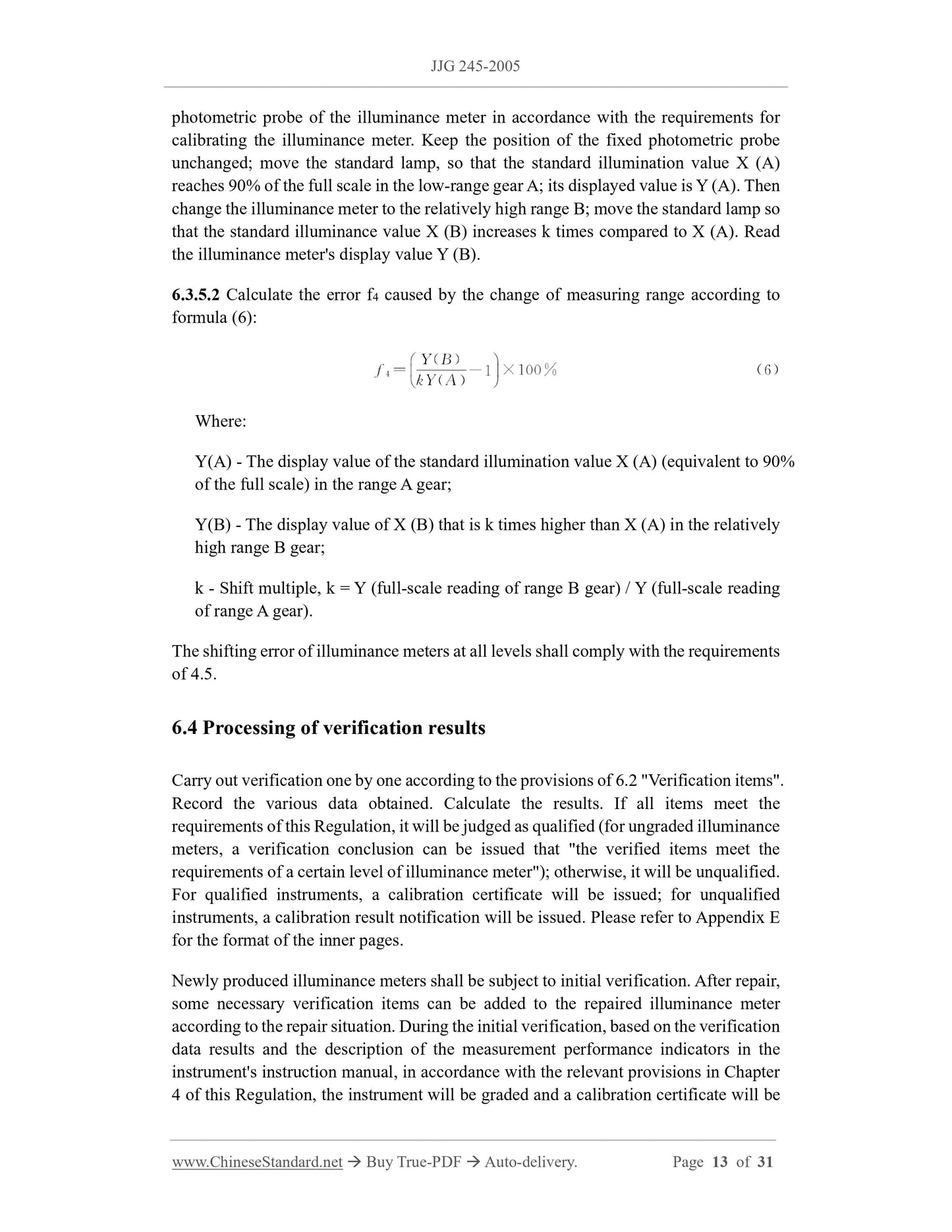

6.3.4.2 Calculate the nonlinear error f3 of the photometer according to formula (5):

Where:

X - Standard illumination value;

Y - Display value when the standard illumination value X illuminates the photometer

probe;

Xmax - The standard illumination value corresponding to the maximum display value

Ymax;

Ymax - Maximum display value.

The nonlinear errors of illuminance meters at all levels shall comply with the

requirements of 4.4.

6.3.5 Shift error

6.3.5.1 On the photometric measuring device, install the standard lamp and the

photometric probe of the illuminance meter in accordance with the requirements for

calibrating the illuminance meter. Keep the position of the fixed photometric probe

unchanged; move the standard lamp, so that the standard illumination value X (A)

reaches 90% of the full scale in the low-range gear A; its displayed value is Y (A). Then

change the illuminance meter to the relatively high range B; move the standard lamp so

that the standard illuminance value X (B) increases k times compared to X (A). Read

the illuminance meter's display value Y (B).

6.3.5.2 Calculate the error f4 caused by the change of measuring range according to

formula (6):

Where:

Y(A) - The display value of the standard illumination value X (A) (equivalent to 90%

of th...

Get QUOTATION in 1-minute: Click JJG 245-2005

Historical versions: JJG 245-2005

Preview True-PDF (Reload/Scroll if blank)

JJG 245-2005: Verification Regulation of Illuminance Meter

JJG 245-2005

JJG

METROLOGICAL VERIFICATION REGULATION

OF THE PEOPLE’S REPUBLIC OF CHINA

Illuminance meter

光照度计

ISSUED ON: APRIL 28, 2005

IMPLEMENTED ON: OCTOBER 10, 2005

Issued by: General Administration of Quality Supervision, Inspection and

Quarantine of PRC.

Table of Contents

1 Scope ... 4

2 Normative references ... 4

3 Overview ... 4

4 Metering performance requirements ... 4

4.1 Relative indication error ... 4

4.2 V(λ) matching error ... 5

4.3 Cosine characteristic (directional response) error ... 5

4.4 Nonlinear error ... 5

4.5 Shift error ... 5

4.6 Fatigue error ... 6

4.7 Infrared response error ... 6

4.8 UV response error ... 6

4.9 Temperature coefficient ... 6

5 General technical requirements ... 7

5.1 Appearance ... 7

5.2 Identification ... 7

5.3 Instructions ... 7

6 Metering instrument control ... 7

6.1 Verification conditions ... 7

6.2 Verification items ... 8

6.3 Verification method ... 9

6.4 Processing of verification results ... 13

6.5 Verification cycle ... 14

Appendix A Recommended test methods for type identification and prototype testing

... 15

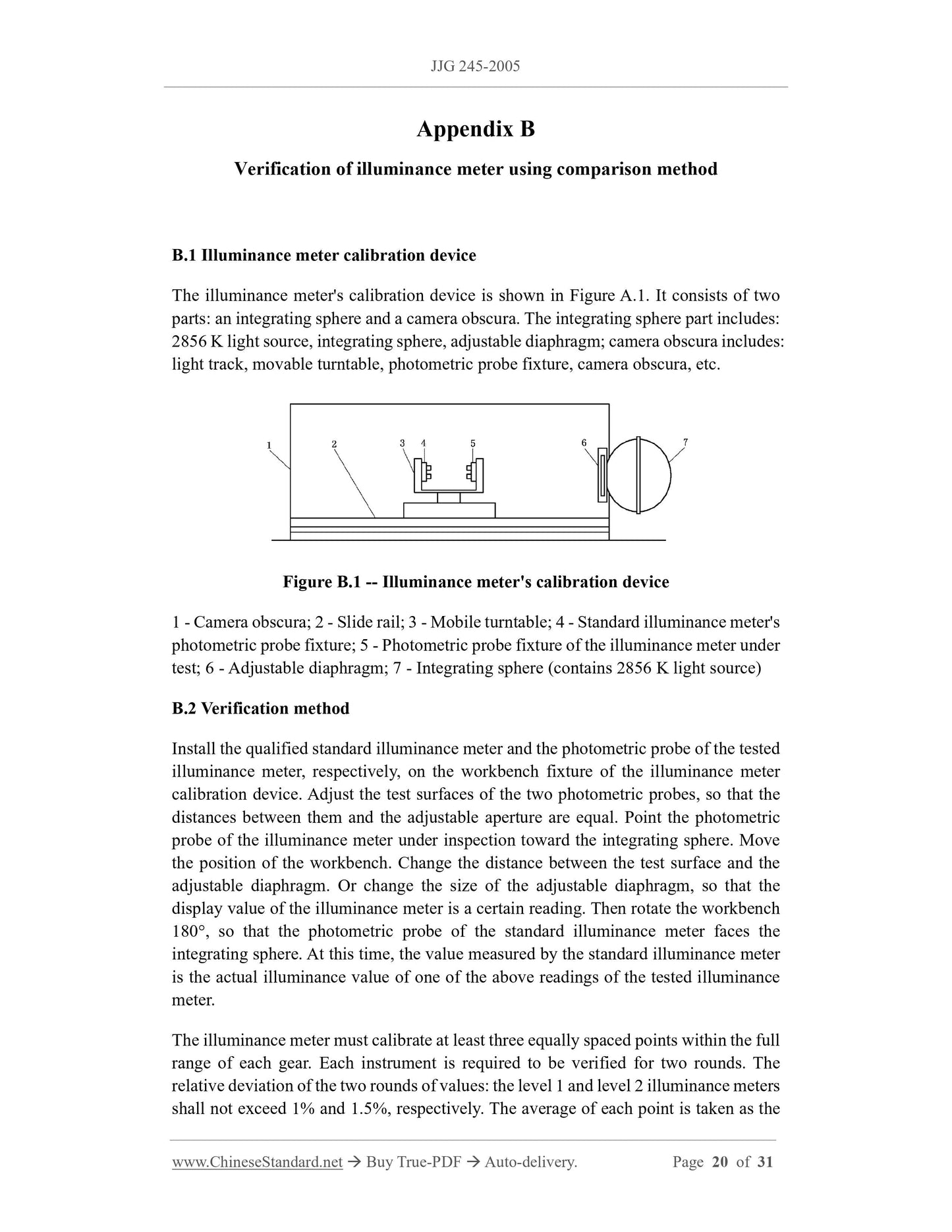

Appendix B Verification of illuminance meter using comparison method ... 20

Appendix C Example of uncertainty assessment ... 22

Appendix D The relationship between the two formulas of cosine characteristic error

... 28

Appendix E Format of the inner page of the illuminance meter's verification certificate

and verification result notification ... 30

Verification regulation of illuminance meter

1 Scope

This Regulation applies to the initial verification, subsequent verification, in-use

inspection of illuminance meters (hereinafter referred to as illuminance meters). The

requirements related to measurement performance in type identification and prototype

testing can be implemented with reference to Regulation.

2 Normative references

This Regulation cites the following documents:

"Illuminance Meter" OIML 1988 English version

"Performance Test Methods for Photometers and Luminometers" CIE 1987 English

version

JJF 1059-1999 "Evaluation and Expression of Uncertainty in Measurement"

When using this Regulation, attention shall be paid to using the currently valid versions

of the above cited documents.

3 Overview

An illuminance meter is a measuring instrument for measuring illuminance. It consists

of a photometric probe (including a cosine corrector, a V (λ) correction filter, a

photoelectric receiver) and a display (digital or pointer type). When the photoelectric

receiver receives the optical radiation passing through the cosine corrector and V(λ)

filter, the generated photoelectric signal is processed and the corresponding illumination

value is displayed on the display.

4 Metering performance requirements

4.1 Relative indication error

The relative indication error of the illuminance meter shall not exceed the requirements

of Table 1.

l - The distance from the filament plane of the standard lamp to the test surface of

the photometric probe, m.

During verification, the distance -- between the filament plane of the standard lamp and

the photometric probe must be at least 15 times greater than the maximum linear

dimension of the light-emitting surface or the test surface of the photometric probe (the

diagonal length or diameter of the filament plane and the test surface of the photometric

probe).

The standard illuminance meter shall calibrate at least five equally spaced points, within

the full range of each gear. The level 1 and level 2 illuminance meters shall calibrate at

least three equally spaced points. Each point shall be illuminated for 5 seconds and its

display value shall be read. Each instrument is required to be verified for two rounds.

The relative deviation of the two rounds of values: standard, level 1, level 2 illuminance

meters shall not exceed 0.6%, 1%, 1.5%, respectively. The average value of each point

is taken as the final result. The relative indication errors of illuminance meters at all

levels shall comply with the requirements of 4.1.

Relative indication error = [(Displayed value - standard value) / Standard value] × 100%

(2)

For level 1 and level 2 illuminance meters, the comparison method can also be used for

verification. See Appendix B for the method.

6.3.3 Cosine characteristic (directional response) error of illuminance meter

6.3.3.1 Install the photometric probe on the rotating platform with the dial of the

photometric measuring device, so that the rotation axis of the platform passes through

the center line of the test surface. Adjust the filament plane of the standard lamp and

the test surface of the photometric probe, so that they are perpendicular to the horizontal

measurement axis of the light track, with the center point located on this axis. Arrange

a number of diaphragms between the standard lamp and the photometric probe. The

distance from the standard lamp to the photometric probe shall be at least 15 times the

maximum linearity of the luminous surface of the standard lamp or the test surface of

the photometric probe.

Figure 1 -- Schematic diagram of calibrating the illuminance meter on the

photometric measuring device

Calculate the total directional error f2 of the optical probe according to formula (4):

Where:

1.484 rad is equal to 85°.

The directional response error of illuminance meters at all levels shall comply with the

requirements of 4.3.

The derivation relationship between formula (3) and formula (4) can be found in

Appendix D.

6.3.4 Nonlinear error

6.3.4.1 On the photometric measuring device, install the standard lamp and the

photometric probe of the illuminance meter in accordance with the requirements for

calibrating the illuminance meter. The position of the fixed photometric probe remains

unchanged; the standard lamp is moved so that the display value Y of the illuminance

meter reaches 1/10 of the full scale; its corresponding standard illuminance value is X.

Then move the standard lamp to make the display value of the illuminance meter reach

Ymax (close to full scale). Find the corresponding standard illuminance value Xmax.

6.3.4.2 Calculate the nonlinear error f3 of the photometer according to formula (5):

Where:

X - Standard illumination value;

Y - Display value when the standard illumination value X illuminates the photometer

probe;

Xmax - The standard illumination value corresponding to the maximum display value

Ymax;

Ymax - Maximum display value.

The nonlinear errors of illuminance meters at all levels shall comply with the

requirements of 4.4.

6.3.5 Shift error

6.3.5.1 On the photometric measuring device, install the standard lamp and the

photometric probe of the illuminance meter in accordance with the requirements for

calibrating the illuminance meter. Keep the position of the fixed photometric probe

unchanged; move the standard lamp, so that the standard illumination value X (A)

reaches 90% of the full scale in the low-range gear A; its displayed value is Y (A). Then

change the illuminance meter to the relatively high range B; move the standard lamp so

that the standard illuminance value X (B) increases k times compared to X (A). Read

the illuminance meter's display value Y (B).

6.3.5.2 Calculate the error f4 caused by the change of measuring range according to

formula (6):

Where:

Y(A) - The display value of the standard illumination value X (A) (equivalent to 90%

of th...

Share