1

/

of

7

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

JJG 818-2018 English PDF

JJG 818-2018 English PDF

Regular price

$210.00

Regular price

Sale price

$210.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

JJG 818-2018: Magnetic and Eddy Current Measuring Instrument for Coating Thickness

Delivery: 9 seconds. Download (& Email) true-PDF + Invoice.

Get Quotation: Click JJG 818-2018 (Self-service in 1-minute)

Historical versions (Master-website): JJG 818-2018

Preview True-PDF (Reload/Scroll-down if blank)

JJG 818-2018

NATIONAL METROLOGICAL VERIFICATION REGULATIONS

OF THE PEOPLE’S REPUBLIC OF CHINA

Replacing JJG 818-2005

Magnetic and Eddy Current Measuring Instrument for

Coating Thickness

ISSUED ON: DECEMBER 25, 2018

IMPLEMENTED ON: JUNE 25, 2019

Issued by: State Administration for Market Regulation

Table of Contents

Introduction ... 5

1 Scope ... 7

2 Normative references ... 7

3 Overview ... 7

4 Metrological performance requirements ... 10

4.1 Measuring force and its variability ... 10

4.2 Measurement repeatability ... 10

4.3 Indicated value error ... 10

4.4 Stability of indicated value ... 10

4.5 Influence of power supply voltage change on the instrument's indicated value

... 10

4.6 Thickness sheet ... 10

5 General technical requirements ... 11

5.1 Appearance ... 11

5.2 Interaction of each part ... 11

6 Control of measuring tools ... 12

6.1 Verification conditions ... 12

6.2 Verification items and main verification apparatus ... 12

6.3 Verification methods ... 13

7 Processing of verification results ... 17

8 Verification cycle ... 17

Annex A Evaluation of uncertainty in measurement error of thickness measuring

instrument ... 18

Annex B Inner page format of verification certificate and notification of

verification results ... 25

Verification Regulation of Magnetic and Eddy Current

Measuring Instrument for Coating Thickness

1 Scope

This Regulation specifies the first inspection, subsequent inspection, and in-

service inspection of magnetic (magneto-resistive and magnetic-driven) and

eddy current measuring instrument for coating thickness (hereinafter referred

to as thickness measuring instrument).

2 Normative references

This Regulation referred to the following referenced documents.

GB/T 4956-2003, On-magnetic coatings on magnetic substrates -

Measurement of coating thickness - Magnetic method

GB/T 4957-2003, Non-conductive coatings on non-magnetic basis metals -

Measurement of coating thickness - Eddy current

For dated references, only the edition cited applies. For undated references,

the latest edition of the referenced document (including any amendments)

applies.

3 Overview

The magnetic measuring instrument for coating thickness in the thickness

measuring instrument is usually used to measure the thickness of non-magnetic

coating on magnetic metal substrate. The eddy current measuring instrument

for coating thickness is usually used to measure the thickness of non-magnetic

coating on non-magnetic metal substrate.

The thickness measuring instrument, according to the numerical display

method, can be divided into two types: digital type and pointer type. The

measuring range is generally (0~1250) μm. The maximum measuring range is

30mm. The maximum resolution is 0.1μm. According to the maximum allowable

error of the indicated value, it is divided into four accuracy levels: A~D. The

outline structure of the thickness measuring instrument is shown in Figure 1.

The magnetic measuring instrument for coating thickness, according to the

6.3.4 Measurement repeatability

Select the minimum range stop of the thickness measuring instrument. Near

the center of the base work surface, place a thickness sheet with a value greater

than 2/3 range (the thickness measuring instrument without range stop selects

2/3 or more range of minimum resolution). Continuously measure 9 times at the

same location. Take 1/3 of the difference between the maximum value and the

minimum value in 9 times as the measurement repeatability.

6.3.5 Indicated value error

Conduct the zero-point adjustment of thickness measuring instrument

according to the instructions of use. Approximately three to five points are

distributed as the inspection points in each range of the thickness measuring

instrument (including the points closest to the upper and lower limits of the

range). Select thickness sheets of corresponding thickness and accuracy level

(use thickness plate for magnetic-driven measuring instrument for coating

thickness) to measure in sequence. When measuring, make the probe of

thickness measuring instrument as vertical as possible to the middle position of

the thickness measuring instrument (for magnetic-driven measuring instrument

for coating thickness, it needs to be placed on a thickness plate to make the

measuring magnetic steel automatically attached to the middle position of

thickness plate). Continuously measure each inspection point 5 times. Take the

average value as the value of the thickness measuring instrument at that point.

Its indicated value error is calculated according to formula (1):

Where,

- Indicated value error of thickness measuring instrument;

- Average indicated value of thickness measuring instrument;

H- Actual value of thickness sheet.

6.3.6 Indicated value stability

Select the minimum range stop of the thickness measuring instrument for the

AC-powered thickness measuring instrument. Place a thickness sheet with a

value greater than 1/2 of the range near the center of the working surface of the

substrate. Mount the probe on the verification table and press it vertically

towards the thickness sheet and make it fixed. Record the first reading. Take a

reading every 15min later. Continuously record for 1h. Take the difference

between the maximum and minimum values in 5 readings as the measurement

result.

6.3.7 Influence of power supply voltage change on the instrument's

indicated value

For AC-powered thickness measuring instrument, select the minimum range

stop of thickness measuring instrument. Place a thickness sheet with a value

greater than 1/2 of the range near the center of the working surface of the

substrate (single-range thickness gauge is selected in a range of 2/3 or more

of the minimum resolution). Connect an adjustable DC stabilized power supply

or an adjustable AC transformer in series to the power terminal of the thickness

measuring instrument. Use a voltmeter to monitor. Adjust the power supply

voltage to -10% of the rated voltage permitted by the thickness measuring

instrument according to the thickness measuring instrument requirements.

Measure the thickness sheet 5 times. Take the average value as the value of

the point at the voltage. Then adjust the power supply voltage to +10% of the

rated working voltage of the thickness measuring instrument and the rated

voltage of the thickness measuring instrument. Measure the thickness sheet 5

times, respectively. Take the average value as the value of the point at the

voltage. Process the indicated value of each point according to formula (1).

6.3.8 Thickness sheet

Use digital inductive micrometers (select a 1N force probe; for a thickness sheet

not thicker than 50μm, use a flat probe) and tri-equivalent measuring block or

grating micrometer. On the flat workbench, use comparison method to measure

or direct method to measure.

Direct method measurement: First set the digital display inductive micrometer

or grating micrometer to zero. Then place the thickness sheet to be measured

on the flat work bench. There are 5 points evenly distributed in the

measurement area 5mm from the edge (see Figure 3). Take the average value

of the 5 times of the center point as the actual value of the thickness sheet. Its

thickness value H is calculated according to formula (2). Take the maximum

difference between the indicated value and the actual value at each point as

the thickness uniformity. The indicated value ΔHi is calculated according to

formula (3).

Where,

H - Actual value of thickness sheet;

Hi - Indicated value of thickness sheet.

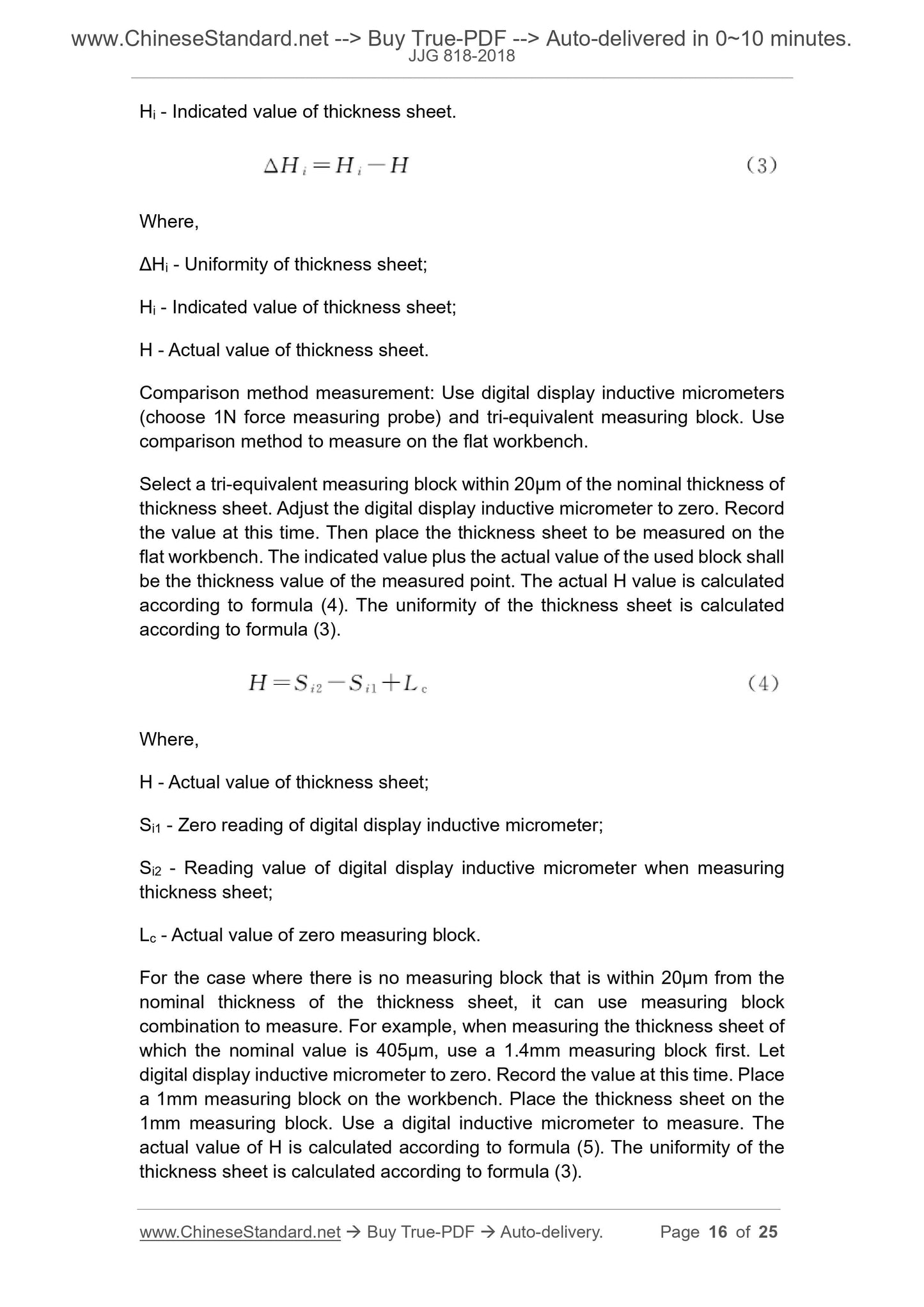

Where,

ΔHi - Uniformity of thickness sheet;

Hi - Indicated value of thickness sheet;

H - Actual value of thickness sheet.

Comparison method measurement: Use digital display inductive micrometers

(choose 1N force measuring probe) and tri-equivalent measuring block. Use

comparison method to measure on the flat workbench.

Select a tri-equivalent measuring block within 20μm of the nominal thickness of

thickness sheet. Adjust the digital display inductive micrometer to zero. Record

the value at this time. Then place the thickness sheet to be measured on the

flat workbench. The indicated value plus the actual value of the used block shall

be the thickness value of the measured point. The actual H value is calculated

according to formula (4). The uniformity of the thickness sheet is calculated

according to formula (3).

Where,

H - Actual value of thickness sheet;

Si1 - Zero reading of digital display inductive micrometer;

Si2 - Reading value of digital display inductive micrometer when measuring

thickness sheet;

Lc - Actual value of zero measuring block.

For the case where there is no measuring block that is within 20μm from the

nominal thickness of the thickness sheet, it can use measuring block

combination to measure. For example, when measuring the thickness sheet of

which the nominal value is 405μm, use a 1.4mm measuring block first. Let

digital display inductive micrometer to zero. Record the value at this time. Place

a 1mm measuring block on the workbench. Place the thickness sheet on the

1mm measuring block. Use a digital inductive micrometer to measure. The

actual value of H is calculated according to formula (5). The uniformity of the

thickness sheet is calculated according to formula (3).

Annex A

Evaluation of uncertainty in measurement error of thickness measuring

instrument

A.1 Measurement method

First, according to the instructions of use, make zero adjustment of thickness

measuring instrument. Then use the thickness measuring instrument to

measure each thickness sheet 5 times. The difference between the average

value of the thickness measuring instrument and the actual value H of the

thickness measuring instrument shall be the indicated value error δH. This

document takes 10μm, 50μm, 100μm, 500μm, 1000μm, 5000μm, and

10000μm measurement points as examples to evaluate the uncertainty of

indicated value error measurement of level-A thickness measuring instrument.

A.2 Measurement model

Calculation formula for indicated value error:

Where,

δH - Indicated value error of thickness measuring instrument at this point;

- Average indicated value of thickness measuring instrument at this point;

H - Actual value of thickness sheet.

A.3 Evaluation of standard uncertainty

A.3.1 Uncertainty component u1 introduced by thickness measuring

instrument

The uncertainty of the thickness measurement results of the thickness sheet is

shown in Table 1, where k=2. According to , then

10μm thickness sheet:

JJG 818-2018

NATIONAL METROLOGICAL VERIFICATION REGULATIONS

OF THE PEOPLE’S REPUBLIC OF CHINA

Replacing JJG 818-2005

Magnetic and Eddy Current Measuring Instrument for

Coating Thickness

ISSUED ON: DECEMBER 25, 2018

IMPLEMENTED ON: JUNE 25, 2019

Issued by: State Administration for Market Regulation

Table of Contents

Introduction ... 5

1 Scope ... 7

2 Normative references ... 7

3 Overview ... 7

4 Metrological performance requirements ... 10

4.1 Measuring force and its variability ... 10

4.2 Measurement repeatability ... 10

4.3 Indicated value error ... 10

4.4 Stability of indicated value ... 10

4.5 Influence of power supply voltage change on the instrument's indicated value

... 10

4.6 Thickness sheet ... 10

5 General technical requirements ... 11

5.1 Appearance ... 11

5.2 Interaction of each part ... 11

6 Control of measuring tools ... 12

6.1 Verification conditions ... 12

6.2 Verification items and main verification apparatus ... 12

6.3 Verification methods ... 13

7 Processing of verification results ... 17

8 Verification cycle ... 17

Annex A Evaluation of uncertainty in measurement error of thickness measuring

instrument ... 18

Annex B Inner page format of verification certificate and notification of

verification results ... 25

Verification Regulation of Magnetic and Eddy Current

Measuring Instrument for Coating Thickness

1 Scope

This Regulation specifies the first inspection, subsequent inspection, and in-

service inspection of magnetic (magneto-resistive and magnetic-driven) and

eddy current measuring instrument for coating thickness (hereinafter referred

to as thickness measuring instrument).

2 Normative references

This Regulation referred to the following referenced documents.

GB/T 4956-2003, On-magnetic coatings on magnetic substrates -

Measurement of coating thickness - Magnetic method

GB/T 4957-2003, Non-conductive coatings on non-magnetic basis metals -

Measurement of coating thickness - Eddy current

For dated references, only the edition cited applies. For undated references,

the latest edition of the referenced document (including any amendments)

applies.

3 Overview

The magnetic measuring instrument for coating thickness in the thickness

measuring instrument is usually used to measure the thickness of non-magnetic

coating on magnetic metal substrate. The eddy current measuring instrument

for coating thickness is usually used to measure the thickness of non-magnetic

coating on non-magnetic metal substrate.

The thickness measuring instrument, according to the numerical display

method, can be divided into two types: digital type and pointer type. The

measuring range is generally (0~1250) μm. The maximum measuring range is

30mm. The maximum resolution is 0.1μm. According to the maximum allowable

error of the indicated value, it is divided into four accuracy levels: A~D. The

outline structure of the thickness measuring instrument is shown in Figure 1.

The magnetic measuring instrument for coating thickness, according to the

6.3.4 Measurement repeatability

Select the minimum range stop of the thickness measuring instrument. Near

the center of the base work surface, place a thickness sheet with a value greater

than 2/3 range (the thickness measuring instrument without range stop selec...

Delivery: 9 seconds. Download (& Email) true-PDF + Invoice.

Get Quotation: Click JJG 818-2018 (Self-service in 1-minute)

Historical versions (Master-website): JJG 818-2018

Preview True-PDF (Reload/Scroll-down if blank)

JJG 818-2018

NATIONAL METROLOGICAL VERIFICATION REGULATIONS

OF THE PEOPLE’S REPUBLIC OF CHINA

Replacing JJG 818-2005

Magnetic and Eddy Current Measuring Instrument for

Coating Thickness

ISSUED ON: DECEMBER 25, 2018

IMPLEMENTED ON: JUNE 25, 2019

Issued by: State Administration for Market Regulation

Table of Contents

Introduction ... 5

1 Scope ... 7

2 Normative references ... 7

3 Overview ... 7

4 Metrological performance requirements ... 10

4.1 Measuring force and its variability ... 10

4.2 Measurement repeatability ... 10

4.3 Indicated value error ... 10

4.4 Stability of indicated value ... 10

4.5 Influence of power supply voltage change on the instrument's indicated value

... 10

4.6 Thickness sheet ... 10

5 General technical requirements ... 11

5.1 Appearance ... 11

5.2 Interaction of each part ... 11

6 Control of measuring tools ... 12

6.1 Verification conditions ... 12

6.2 Verification items and main verification apparatus ... 12

6.3 Verification methods ... 13

7 Processing of verification results ... 17

8 Verification cycle ... 17

Annex A Evaluation of uncertainty in measurement error of thickness measuring

instrument ... 18

Annex B Inner page format of verification certificate and notification of

verification results ... 25

Verification Regulation of Magnetic and Eddy Current

Measuring Instrument for Coating Thickness

1 Scope

This Regulation specifies the first inspection, subsequent inspection, and in-

service inspection of magnetic (magneto-resistive and magnetic-driven) and

eddy current measuring instrument for coating thickness (hereinafter referred

to as thickness measuring instrument).

2 Normative references

This Regulation referred to the following referenced documents.

GB/T 4956-2003, On-magnetic coatings on magnetic substrates -

Measurement of coating thickness - Magnetic method

GB/T 4957-2003, Non-conductive coatings on non-magnetic basis metals -

Measurement of coating thickness - Eddy current

For dated references, only the edition cited applies. For undated references,

the latest edition of the referenced document (including any amendments)

applies.

3 Overview

The magnetic measuring instrument for coating thickness in the thickness

measuring instrument is usually used to measure the thickness of non-magnetic

coating on magnetic metal substrate. The eddy current measuring instrument

for coating thickness is usually used to measure the thickness of non-magnetic

coating on non-magnetic metal substrate.

The thickness measuring instrument, according to the numerical display

method, can be divided into two types: digital type and pointer type. The

measuring range is generally (0~1250) μm. The maximum measuring range is

30mm. The maximum resolution is 0.1μm. According to the maximum allowable

error of the indicated value, it is divided into four accuracy levels: A~D. The

outline structure of the thickness measuring instrument is shown in Figure 1.

The magnetic measuring instrument for coating thickness, according to the

6.3.4 Measurement repeatability

Select the minimum range stop of the thickness measuring instrument. Near

the center of the base work surface, place a thickness sheet with a value greater

than 2/3 range (the thickness measuring instrument without range stop selects

2/3 or more range of minimum resolution). Continuously measure 9 times at the

same location. Take 1/3 of the difference between the maximum value and the

minimum value in 9 times as the measurement repeatability.

6.3.5 Indicated value error

Conduct the zero-point adjustment of thickness measuring instrument

according to the instructions of use. Approximately three to five points are

distributed as the inspection points in each range of the thickness measuring

instrument (including the points closest to the upper and lower limits of the

range). Select thickness sheets of corresponding thickness and accuracy level

(use thickness plate for magnetic-driven measuring instrument for coating

thickness) to measure in sequence. When measuring, make the probe of

thickness measuring instrument as vertical as possible to the middle position of

the thickness measuring instrument (for magnetic-driven measuring instrument

for coating thickness, it needs to be placed on a thickness plate to make the

measuring magnetic steel automatically attached to the middle position of

thickness plate). Continuously measure each inspection point 5 times. Take the

average value as the value of the thickness measuring instrument at that point.

Its indicated value error is calculated according to formula (1):

Where,

- Indicated value error of thickness measuring instrument;

- Average indicated value of thickness measuring instrument;

H- Actual value of thickness sheet.

6.3.6 Indicated value stability

Select the minimum range stop of the thickness measuring instrument for the

AC-powered thickness measuring instrument. Place a thickness sheet with a

value greater than 1/2 of the range near the center of the working surface of the

substrate. Mount the probe on the verification table and press it vertically

towards the thickness sheet and make it fixed. Record the first reading. Take a

reading every 15min later. Continuously record for 1h. Take the difference

between the maximum and minimum values in 5 readings as the measurement

result.

6.3.7 Influence of power supply voltage change on the instrument's

indicated value

For AC-powered thickness measuring instrument, select the minimum range

stop of thickness measuring instrument. Place a thickness sheet with a value

greater than 1/2 of the range near the center of the working surface of the

substrate (single-range thickness gauge is selected in a range of 2/3 or more

of the minimum resolution). Connect an adjustable DC stabilized power supply

or an adjustable AC transformer in series to the power terminal of the thickness

measuring instrument. Use a voltmeter to monitor. Adjust the power supply

voltage to -10% of the rated voltage permitted by the thickness measuring

instrument according to the thickness measuring instrument requirements.

Measure the thickness sheet 5 times. Take the average value as the value of

the point at the voltage. Then adjust the power supply voltage to +10% of the

rated working voltage of the thickness measuring instrument and the rated

voltage of the thickness measuring instrument. Measure the thickness sheet 5

times, respectively. Take the average value as the value of the point at the

voltage. Process the indicated value of each point according to formula (1).

6.3.8 Thickness sheet

Use digital inductive micrometers (select a 1N force probe; for a thickness sheet

not thicker than 50μm, use a flat probe) and tri-equivalent measuring block or

grating micrometer. On the flat workbench, use comparison method to measure

or direct method to measure.

Direct method measurement: First set the digital display inductive micrometer

or grating micrometer to zero. Then place the thickness sheet to be measured

on the flat work bench. There are 5 points evenly distributed in the

measurement area 5mm from the edge (see Figure 3). Take the average value

of the 5 times of the center point as the actual value of the thickness sheet. Its

thickness value H is calculated according to formula (2). Take the maximum

difference between the indicated value and the actual value at each point as

the thickness uniformity. The indicated value ΔHi is calculated according to

formula (3).

Where,

H - Actual value of thickness sheet;

Hi - Indicated value of thickness sheet.

Where,

ΔHi - Uniformity of thickness sheet;

Hi - Indicated value of thickness sheet;

H - Actual value of thickness sheet.

Comparison method measurement: Use digital display inductive micrometers

(choose 1N force measuring probe) and tri-equivalent measuring block. Use

comparison method to measure on the flat workbench.

Select a tri-equivalent measuring block within 20μm of the nominal thickness of

thickness sheet. Adjust the digital display inductive micrometer to zero. Record

the value at this time. Then place the thickness sheet to be measured on the

flat workbench. The indicated value plus the actual value of the used block shall

be the thickness value of the measured point. The actual H value is calculated

according to formula (4). The uniformity of the thickness sheet is calculated

according to formula (3).

Where,

H - Actual value of thickness sheet;

Si1 - Zero reading of digital display inductive micrometer;

Si2 - Reading value of digital display inductive micrometer when measuring

thickness sheet;

Lc - Actual value of zero measuring block.

For the case where there is no measuring block that is within 20μm from the

nominal thickness of the thickness sheet, it can use measuring block

combination to measure. For example, when measuring the thickness sheet of

which the nominal value is 405μm, use a 1.4mm measuring block first. Let

digital display inductive micrometer to zero. Record the value at this time. Place

a 1mm measuring block on the workbench. Place the thickness sheet on the

1mm measuring block. Use a digital inductive micrometer to measure. The

actual value of H is calculated according to formula (5). The uniformity of the

thickness sheet is calculated according to formula (3).

Annex A

Evaluation of uncertainty in measurement error of thickness measuring

instrument

A.1 Measurement method

First, according to the instructions of use, make zero adjustment of thickness

measuring instrument. Then use the thickness measuring instrument to

measure each thickness sheet 5 times. The difference between the average

value of the thickness measuring instrument and the actual value H of the

thickness measuring instrument shall be the indicated value error δH. This

document takes 10μm, 50μm, 100μm, 500μm, 1000μm, 5000μm, and

10000μm measurement points as examples to evaluate the uncertainty of

indicated value error measurement of level-A thickness measuring instrument.

A.2 Measurement model

Calculation formula for indicated value error:

Where,

δH - Indicated value error of thickness measuring instrument at this point;

- Average indicated value of thickness measuring instrument at this point;

H - Actual value of thickness sheet.

A.3 Evaluation of standard uncertainty

A.3.1 Uncertainty component u1 introduced by thickness measuring

instrument

The uncertainty of the thickness measurement results of the thickness sheet is

shown in Table 1, where k=2. According to , then

10μm thickness sheet:

JJG 818-2018

NATIONAL METROLOGICAL VERIFICATION REGULATIONS

OF THE PEOPLE’S REPUBLIC OF CHINA

Replacing JJG 818-2005

Magnetic and Eddy Current Measuring Instrument for

Coating Thickness

ISSUED ON: DECEMBER 25, 2018

IMPLEMENTED ON: JUNE 25, 2019

Issued by: State Administration for Market Regulation

Table of Contents

Introduction ... 5

1 Scope ... 7

2 Normative references ... 7

3 Overview ... 7

4 Metrological performance requirements ... 10

4.1 Measuring force and its variability ... 10

4.2 Measurement repeatability ... 10

4.3 Indicated value error ... 10

4.4 Stability of indicated value ... 10

4.5 Influence of power supply voltage change on the instrument's indicated value

... 10

4.6 Thickness sheet ... 10

5 General technical requirements ... 11

5.1 Appearance ... 11

5.2 Interaction of each part ... 11

6 Control of measuring tools ... 12

6.1 Verification conditions ... 12

6.2 Verification items and main verification apparatus ... 12

6.3 Verification methods ... 13

7 Processing of verification results ... 17

8 Verification cycle ... 17

Annex A Evaluation of uncertainty in measurement error of thickness measuring

instrument ... 18

Annex B Inner page format of verification certificate and notification of

verification results ... 25

Verification Regulation of Magnetic and Eddy Current

Measuring Instrument for Coating Thickness

1 Scope

This Regulation specifies the first inspection, subsequent inspection, and in-

service inspection of magnetic (magneto-resistive and magnetic-driven) and

eddy current measuring instrument for coating thickness (hereinafter referred

to as thickness measuring instrument).

2 Normative references

This Regulation referred to the following referenced documents.

GB/T 4956-2003, On-magnetic coatings on magnetic substrates -

Measurement of coating thickness - Magnetic method

GB/T 4957-2003, Non-conductive coatings on non-magnetic basis metals -

Measurement of coating thickness - Eddy current

For dated references, only the edition cited applies. For undated references,

the latest edition of the referenced document (including any amendments)

applies.

3 Overview

The magnetic measuring instrument for coating thickness in the thickness

measuring instrument is usually used to measure the thickness of non-magnetic

coating on magnetic metal substrate. The eddy current measuring instrument

for coating thickness is usually used to measure the thickness of non-magnetic

coating on non-magnetic metal substrate.

The thickness measuring instrument, according to the numerical display

method, can be divided into two types: digital type and pointer type. The

measuring range is generally (0~1250) μm. The maximum measuring range is

30mm. The maximum resolution is 0.1μm. According to the maximum allowable

error of the indicated value, it is divided into four accuracy levels: A~D. The

outline structure of the thickness measuring instrument is shown in Figure 1.

The magnetic measuring instrument for coating thickness, according to the

6.3.4 Measurement repeatability

Select the minimum range stop of the thickness measuring instrument. Near

the center of the base work surface, place a thickness sheet with a value greater

than 2/3 range (the thickness measuring instrument without range stop selec...

Share