1

/

of

12

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

NB/T 47013.11-2023 English PDF (NB/T47013.11-2023)

NB/T 47013.11-2023 English PDF (NB/T47013.11-2023)

Regular price

$605.00

Regular price

Sale price

$605.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

NB/T 47013.11-2023: Nondestructive testing of pressure equipment - Part 11: X-ray computed radiographic testing

Delivery: 9 seconds. Download (& Email) true-PDF + Invoice.

Get Quotation: Click NB/T 47013.11-2023 (Self-service in 1-minute)

Historical versions (Master-website): NB/T 47013.11-2023

Preview True-PDF (Reload/Scroll-down if blank)

NB/T 47013.11-2023

NB

ENERGY INDUSTRY STANDARD OF

THE PEOPLE’S REPUBLIC OF CHINA

ICS 77.040.20

CCS H 26

Replacing NB/T 47013.11-2015

Nondestructive testing of pressure equipments - Part 11:

Digital radiographic testing

ISSUED ON: OCTOBER 11, 2023

IMPLEMENTED ON: APRIL 11, 2024

Issued by: National Energy Administration

Table of Contents

Foreword ... 4

Introduction ... 7

1 Scope ... 8

2 Normative references ... 8

3 Terms and definitions ... 9

4 General requirements ... 14

5 Testing method ... 20

6 Image quality and evaluation ... 26

7 Defect identification and measurement ... 35

8 Result evaluation and quality grading ... 36

9 Image preservation and storage ... 36

10 Testing records and reports ... 37

Appendix A (Normative) Verification method of system resolution ... 39

Appendix B (Informative) Typical penetration method ... 41

Appendix C (Normative) Calculation of b value ... 44

Appendix D (Informative) Calculation of minimum number of penetrations of girth

welds ... 47

Appendix E (Normative) Identification of double-linear image quality meter ... 51

Appendix F (Normative) Test method of normalized signal-to-noise ratio ... 53

References ... 54

Nondestructive testing of pressure equipments - Part 11:

Digital radiographic testing

1 Scope

1.1 This document specifies the digital radiographic testing technology and quality

grading requirements for the fusion welding joints of pressure-bearing metallic pressure

components of pressure-bearing equipment. The metal materials used to make welding

joints include steel, copper and copper alloys, aluminum and aluminum alloys, titanium

and titanium alloys, nickel and nickel alloys.

1.2 This document is applicable to the digital radiographic testing of butt joints and butt

welds (hereinafter referred to as "butt welds") of plates and tubes, in the manufacture,

installation, in-service testing of pressure-bearing components of pressure-bearing

equipment.

1.3 The imaging device applicable to this document is a digital detector.

1.4 The radiation sources applicable to this document are X-ray sources and Ir192 and

Se75 γ-ray sources, where the maximum tube voltage of the X-ray machine does not

exceed 600 kV.

1.5 The digital radiographic testing of welded joints of pressure-bearing equipment

supports and structural parts, as well as butt welds of inserted and placed pipe corner

joints (hereinafter referred to as "pipe seat corner welds") can make reference to this

document.

2 Normative references

The contents of the following documents constitute the essential provisions of this

document through normative references in the text. Among them, for dated references,

only the version corresponding to that date applies to this document; for undated

references, the latest version (including all amendments) applies to this document.

GB/T 14058 Apparatus for gamma radiography

GB/T 23901.1 Non-destructive testing - Image quality of radiographs - Part 1:

Determination of the image quality value using wire-type image quality indicators

GB/T 23901.5 Non-destructive testing - Image quality of radiographs - Part 5:

Determination of the image unsharpness and basic spatial resolution value using

4.2.3.6 The DR system supplier shall provide an effective detector correction method.

4.2.3.7 The test conditions and methods for DR system performance indicators, such as

bad pixels, sensitivity, resolution ratio, linear range, signal-to-noise ratio, thickness

tolerance, image sticking, etc., shall be implemented in accordance with the relevant

national or industry standards; the requirements for working temperature and humidity

shall be given.

4.2.3.8 The DR system quality certification document shall at least provide the detector

type, scintillator screen parameters (if any), pixel size, imaging area, applicable range

of radiation energy, quantum conversion efficiency, acquisition frame rate and other

technical parameters.

4.2.4 Computer system

The basic configuration of the computer system is determined according to the

performance and acquisition frame rate requirements of the adopted detector system. It

should be equipped with a memory capacity of not less than 512 MB, a hard disk of not

less than 40 GB, a high-brightness and high-resolution display, a burner, a network card,

etc.

The display shall meet the following minimum requirements:

a) Brightness not less than 250 cd/m2;

b) Gray level not less than 8 bit;

c) Image display resolution not less than 1024 × 768;

d) Display pixel pitch less than 0.3 mm.

4.2.5 System software requirements

4.2.5.1 The system software is the core unit of the digital imaging detection system for

radiographic detection, which has the functions such as image acquisition, image

processing, defect geometry measurement, defect marking, image storage, auxiliary

evaluation.

4.2.5.2 It shall include basic digital image processing functions, such as superposition

noise reduction, contrast and brightness adjustment.

4.2.5.3 It shall include signal-to-noise ratio measurement, resolution ratio measurement,

defect marking, size measurement, size calibration functions.

4.2.5.4 It shall have an image magnification function of not less than 4 times.

4.2.5.5 It shall have the browsing and search functions for the collected image-related

information.

4.2.5.6 It should have the function of converting multiple image formats.

4.2.5.7 The test report can be automatically generated.

4.2.5.8 The raw image shall be saved.

4.2.6 Test fixture

4.2.6.1 It shall be designed according to the workpiece to be inspected and meet the

inspection requirements.

4.2.6.2 It should have functions such as translation, rotation, continuously adjustable

speed; ensure high operating accuracy and stability.

4.2.6.3 The stepping motion of the test fixture shall match the data acquisition of the

detector.

4.2.6.4 For the testing of in-service equipment, the testing instruments and equipment

shall be reasonably fixed, according to the on-site environment and testing conditions.

4.2.7 Image quality meter

4.2.7.1 The image quality meters used in this document include linear image quality

meters and dual-linear image quality meters. The image quality meter supplier shall

provide corresponding quality certification documents.

4.2.7.2 The model and specifications of the linear image quality meter shall comply

with the provisions of GB/T 23901.1 and JB/T 7902. The model and specifications of

the dual-linear image quality meter shall comply with the provisions of GB/T 23901.5.

4.2.8 Use performance of testing system

The appropriate testing equipment and instruments shall be selected, according to the

performance indicators of each part of the testing system, in combination with the

inspected workpiece and the requirements of this document; test certification

documents that meet the performance indicators of the above equipment and instrument

and the system software functions shall be provided. The use performance of the testing

system shall meet the image quality requirements specified in this document.

4.2.9 Calibration or operation verification

4.2.9.1 The linear range, signal-to-noise ratio, thickness tolerance, image afterimage,

etc. of the detector system performance shall be checked and recorded at least once a

year.

4.2.9.2 The exposure curve in use shall be checked at least once a year. When the

important parts of the X-ray machine and the detector are replaced or repaired, the

exposure curve shall be re-made.

The width of the testing area shall meet the requirements of relevant laws, regulations,

standards and design technical documents, and other technical requirements agreed

upon by both parties to the contract. The testing area includes the weld and the adjacent

parent material area, at least 5 mm relative to the weld edge.

5.3 Penetration method

5.3.1 The appropriate penetration method shall be selected according to the structural

characteristics and technical requirements of the workpiece to be tested. Except for the

special case where double-wall penetration is allowed for small-diameter tubes or the

parties to the contract agree to select double-wall penetration method, single-wall

penetration method shall be selected when single-wall penetration conditions are

available. For typical penetration methods of welded joints, see Appendix B.

5.3.2 When using the stepping imaging method to collect images, the movement speed

of the tested workpiece shall be matched with the image acquisition frame rate; the

main X-ray beam shall be vertically penetrated (or aligned after the γ source is

collimated) the tested workpiece and reach the effective imaging area of the detector.

5.3.3 The length of the overlapping area of image acquisition shall be no less than 10

mm.

5.3.4 The double-wall double-image penetration method is used for the girth welded

joints of small-diameter tubes. When the following conditions are met at the same time,

inclined penetration elliptical imaging shall be used:

a) T (wall thickness) ≤ 8 mm;

b) g (weld width) ≤ Do/4.

Where Do - Outer diameter of the tube.

The opening width of the image (maximum spacing between the upper and lower weld

projections) shall be controlled to be about 1 times the weld width. When the above

conditions are not met or elliptical imaging is difficult, vertical penetration overlapping

imaging can be used.

5.4 Selection of penetration geometric parameters

5.4.1 See Appendix B for penetration geometric parameters.

5.4.2 The distance f -- between the selected radiation source and the surface of the

workpiece to be inspected -- shall meet the following requirements:

a) Class A digital imaging detection technology: f ≥ 7.5d • bT -1/3;

b) Class AB digital imaging detection technology: f ≥ 10d • bT -1/3;

c) Class B digital imaging detection technology: f ≥ 15d • bT -1/3.

Where: d - Focus (or source) size.

Note 1: When b ≤ 1.2 T, substitute b = T for calculation. For small diameter tubes,

substitute Do = T for calculation.

Note 2: For asymmetric focus, take the larger value of d for calculation.

5.4.3 The maximum distance b value -- between the surface of the workpiece to be

tested (radiation source side) and the detector -- is calculated in Appendix C.

5.4.4 When using the central penetration method where the radiation source is inside,

if the image quality meets the requirements of 6.2.5 and 6.2.6, the f value can be reduced,

but the reduction value shall not exceed 50% of the specified value.

5.4.5 When using the eccentric penetration method where the radiation source is inside,

the image quality meets the requirements of 6.2.5 and 6.2.6, the f value can be reduced,

but the reduction value shall not exceed 20% of the specified value.

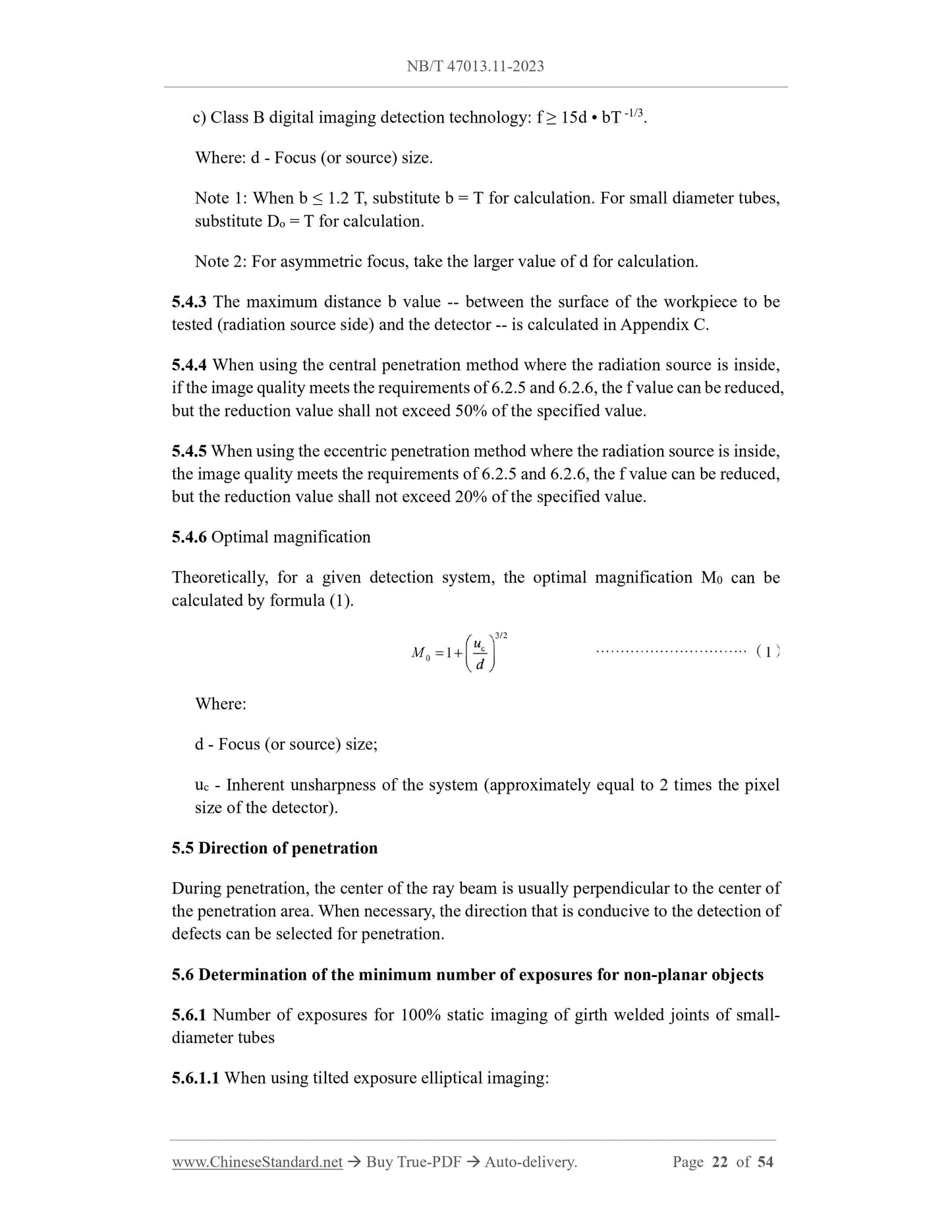

5.4.6 Optimal magnification

Theoretically, for a given detection system, the optimal magnification M0 can be

calculated by formula (1).

Where:

d - Focus (or source) size;

uc - Inherent unsharpness of the system (approximately equal to 2 times the pixel

size of the detector).

5.5 Direction of penetration

During penetration, the center of the ray beam is usually perpendicular to the center of

the penetration area. When necessary, the direction that is conducive to the detection of

defects can be selected for penetration.

5.6 Determination of the minimum number of exposures for non-planar objects

5.6.1 Number of exposures for 100% static imaging of girth welded joints of small-

diameter tubes

5.6.1.1 When using tilted exposure elliptical imaging:

number, part number, penetration date. The penetration after repair shall also have a

repair mark. The penetration with an expanded detection ratio shall have an expanded

detection mark. The identification mark can be written by a computer.

5.8.3 The positioning mark generally includes the center mark " " and the overlap mark

" ". The center mark indicates the center position of the penetration part segment and

the direction of the segment number. The overlap mark is a penetration segment mark,

which is generally composed of appropriate size lead or other suitable heavy metal

numbers, pinyin letters, symbols. When the lead overlap mark is represented by

numbers or letters, the center mark can be omitted.

5.8.4 For the continuous testing of a weld joint, make a positioning mark " " at the

starting position of the testing, where "➔" points to the testing direction. Numbers or

letters can be used to indicate segment marks. Girth weld joint testing can be marked

with a marker in a clockwise direction; longitudinal weld joint testing can be marked

from left to right, meanwhile it shall match the image mark.

5.8.5 The mark shall comply with the relevant provisions of NB/T 47013.2 and shall be

placed outside the testing area. The images of all marks shall not overlap and shall not

be imaged within the effective evaluation range.

5.9 Standard sample

5.9.1 The standard sample is used as a dimension calibration sample when measuring

features in the image. The detailed steps of dimension calibration are as shown in 7.2.1.

5.9.2 The standard sample shall be placed on the workpiece surface on the detector side,

imaged within the effective evaluation range, not interfere with the image within the

effective evaluation range.

5.9.3 The length of the standard sample shall not be less than 15 mm.

5.10 Shielding of useless rays and scattered rays

Appropriate measures such as filter plates, collimators (aperture), lead foils, lead plates,

etc. shall be adopted, to reduce scattered rays and useless rays.

6 Image quality and evaluation

6.1 Image quality

6.1.1 General requirements

6.1.1.1 The requirements of grayscale, image sensitivity, image resolution, normalized

signal-to-noise ratio shall be guaranteed at the same time.

6.1.1.2 Image quality meters for measuring image quality are divided into linear image

6.1.2.2.4 In principle, there shall be an image of the linear image quality meter on each

image. When the penetration parame...

Delivery: 9 seconds. Download (& Email) true-PDF + Invoice.

Get Quotation: Click NB/T 47013.11-2023 (Self-service in 1-minute)

Historical versions (Master-website): NB/T 47013.11-2023

Preview True-PDF (Reload/Scroll-down if blank)

NB/T 47013.11-2023

NB

ENERGY INDUSTRY STANDARD OF

THE PEOPLE’S REPUBLIC OF CHINA

ICS 77.040.20

CCS H 26

Replacing NB/T 47013.11-2015

Nondestructive testing of pressure equipments - Part 11:

Digital radiographic testing

ISSUED ON: OCTOBER 11, 2023

IMPLEMENTED ON: APRIL 11, 2024

Issued by: National Energy Administration

Table of Contents

Foreword ... 4

Introduction ... 7

1 Scope ... 8

2 Normative references ... 8

3 Terms and definitions ... 9

4 General requirements ... 14

5 Testing method ... 20

6 Image quality and evaluation ... 26

7 Defect identification and measurement ... 35

8 Result evaluation and quality grading ... 36

9 Image preservation and storage ... 36

10 Testing records and reports ... 37

Appendix A (Normative) Verification method of system resolution ... 39

Appendix B (Informative) Typical penetration method ... 41

Appendix C (Normative) Calculation of b value ... 44

Appendix D (Informative) Calculation of minimum number of penetrations of girth

welds ... 47

Appendix E (Normative) Identification of double-linear image quality meter ... 51

Appendix F (Normative) Test method of normalized signal-to-noise ratio ... 53

References ... 54

Nondestructive testing of pressure equipments - Part 11:

Digital radiographic testing

1 Scope

1.1 This document specifies the digital radiographic testing technology and quality

grading requirements for the fusion welding joints of pressure-bearing metallic pressure

components of pressure-bearing equipment. The metal materials used to make welding

joints include steel, copper and copper alloys, aluminum and aluminum alloys, titanium

and titanium alloys, nickel and nickel alloys.

1.2 This document is applicable to the digital radiographic testing of butt joints and butt

welds (hereinafter referred to as "butt welds") of plates and tubes, in the manufacture,

installation, in-service testing of pressure-bearing components of pressure-bearing

equipment.

1.3 The imaging device applicable to this document is a digital detector.

1.4 The radiation sources applicable to this document are X-ray sources and Ir192 and

Se75 γ-ray sources, where the maximum tube voltage of the X-ray machine does not

exceed 600 kV.

1.5 The digital radiographic testing of welded joints of pressure-bearing equipment

supports and structural parts, as well as butt welds of inserted and placed pipe corner

joints (hereinafter referred to as "pipe seat corner welds") can make reference to this

document.

2 Normative references

The contents of the following documents constitute the essential provisions of this

document through normative references in the text. Among them, for dated references,

only the version corresponding to that date applies to this document; for undated

references, the latest version (including all amendments) applies to this document.

GB/T 14058 Apparatus for gamma radiography

GB/T 23901.1 Non-destructive testing - Image quality of radiographs - Part 1:

Determination of the image quality value using wire-type image quality indicators

GB/T 23901.5 Non-destructive testing - Image quality of radiographs - Part 5:

Determination of the image unsharpness and basic spatial resolution value using

4.2.3.6 The DR system supplier shall provide an effective detector correction method.

4.2.3.7 The test conditions and methods for DR system performance indicators, such as

bad pixels, sensitivity, resolution ratio, linear range, signal-to-noise ratio, thickness

tolerance, image sticking, etc., shall be implemented in accordance with the relevant

national or industry standards; the requirements for working temperature and humidity

shall be given.

4.2.3.8 The DR system quality certification document shall at least provide the detector

type, scintillator screen parameters (if any), pixel size, imaging area, applicable range

of radiation energy, quantum conversion efficiency, acquisition frame rate and other

technical parameters.

4.2.4 Computer system

The basic configuration of the computer system is determined according to the

performance and acquisition frame rate requirements of the adopted detector system. It

should be equipped with a memory capacity of not less than 512 MB, a hard disk of not

less than 40 GB, a high-brightness and high-resolution display, a burner, a network card,

etc.

The display shall meet the following minimum requirements:

a) Brightness not less than 250 cd/m2;

b) Gray level not less than 8 bit;

c) Image display resolution not less than 1024 × 768;

d) Display pixel pitch less than 0.3 mm.

4.2.5 System software requirements

4.2.5.1 The system software is the core unit of the digital imaging detection system for

radiographic detection, which has the functions such as image acquisition, image

processing, defect geometry measurement, defect marking, image storage, auxiliary

evaluation.

4.2.5.2 It shall include basic digital image processing functions, such as superposition

noise reduction, contrast and brightness adjustment.

4.2.5.3 It shall include signal-to-noise ratio measurement, resolution ratio measurement,

defect marking, size measurement, size calibration functions.

4.2.5.4 It shall have an image magnification function of not less than 4 times.

4.2.5.5 It shall have the browsing and search functions for the collected image-related

information.

4.2.5.6 It should have the function of converting multiple image formats.

4.2.5.7 The test report can be automatically generated.

4.2.5.8 The raw image shall be saved.

4.2.6 Test fixture

4.2.6.1 It shall be designed according to the workpiece to be inspected and meet the

inspection requirements.

4.2.6.2 It should have functions such as translation, rotation, continuously adjustable

speed; ensure high operating accuracy and stability.

4.2.6.3 The stepping motion of the test fixture shall match the data acquisition of the

detector.

4.2.6.4 For the testing of in-service equipment, the testing instruments and equipment

shall be reasonably fixed, according to the on-site environment and testing conditions.

4.2.7 Image quality meter

4.2.7.1 The image quality meters used in this document include linear image quality

meters and dual-linear image quality meters. The image quality meter supplier shall

provide corresponding quality certification documents.

4.2.7.2 The model and specifications of the linear image quality meter shall comply

with the provisions of GB/T 23901.1 and JB/T 7902. The model and specifications of

the dual-linear image quality meter shall comply with the provisions of GB/T 23901.5.

4.2.8 Use performance of testing system

The appropriate testing equipment and instruments shall be selected, according to the

performance indicators of each part of the testing system, in combination with the

inspected workpiece and the requirements of this document; test certification

documents that meet the performance indicators of the above equipment and instrument

and the system software functions shall be provided. The use performance of the testing

system shall meet the image quality requirements specified in this document.

4.2.9 Calibration or operation verification

4.2.9.1 The linear range, signal-to-noise ratio, thickness tolerance, image afterimage,

etc. of the detector system performance shall be checked and recorded at least once a

year.

4.2.9.2 The exposure curve in use shall be checked at least once a year. When the

important parts of the X-ray machine and the detector are replaced or repaired, the

exposure curve shall be re-made.

The width of the testing area shall meet the requirements of relevant laws, regulations,

standards and design technical documents, and other technical requirements agreed

upon by both parties to the contract. The testing area includes the weld and the adjacent

parent material area, at least 5 mm relative to the weld edge.

5.3 Penetration method

5.3.1 The appropriate penetration method shall be selected according to the structural

characteristics and technical requirements of the workpiece to be tested. Except for the

special case where double-wall penetration is allowed for small-diameter tubes or the

parties to the contract agree to select double-wall penetration method, single-wall

penetration method shall be selected when single-wall penetration conditions are

available. For typical penetration methods of welded joints, see Appendix B.

5.3.2 When using the stepping imaging method to collect images, the movement speed

of the tested workpiece shall be matched with the image acquisition frame rate; the

main X-ray beam shall be vertically penetrated (or aligned after the γ source is

collimated) the tested workpiece and reach the effective imaging area of the detector.

5.3.3 The length of the overlapping area of image acquisition shall be no less than 10

mm.

5.3.4 The double-wall double-image penetration method is used for the girth welded

joints of small-diameter tubes. When the following conditions are met at the same time,

inclined penetration elliptical imaging shall be used:

a) T (wall thickness) ≤ 8 mm;

b) g (weld width) ≤ Do/4.

Where Do - Outer diameter of the tube.

The opening width of the image (maximum spacing between the upper and lower weld

projections) shall be controlled to be about 1 times the weld width. When the above

conditions are not met or elliptical imaging is difficult, vertical penetration overlapping

imaging can be used.

5.4 Selection of penetration geometric parameters

5.4.1 See Appendix B for penetration geometric parameters.

5.4.2 The distance f -- between the selected radiation source and the surface of the

workpiece to be inspected -- shall meet the following requirements:

a) Class A digital imaging detection technology: f ≥ 7.5d • bT -1/3;

b) Class AB digital imaging detection technology: f ≥ 10d • bT -1/3;

c) Class B digital imaging detection technology: f ≥ 15d • bT -1/3.

Where: d - Focus (or source) size.

Note 1: When b ≤ 1.2 T, substitute b = T for calculation. For small diameter tubes,

substitute Do = T for calculation.

Note 2: For asymmetric focus, take the larger value of d for calculation.

5.4.3 The maximum distance b value -- between the surface of the workpiece to be

tested (radiation source side) and the detector -- is calculated in Appendix C.

5.4.4 When using the central penetration method where the radiation source is inside,

if the image quality meets the requirements of 6.2.5 and 6.2.6, the f value can be reduced,

but the reduction value shall not exceed 50% of the specified value.

5.4.5 When using the eccentric penetration method where the radiation source is inside,

the image quality meets the requirements of 6.2.5 and 6.2.6, the f value can be reduced,

but the reduction value shall not exceed 20% of the specified value.

5.4.6 Optimal magnification

Theoretically, for a given detection system, the optimal magnification M0 can be

calculated by formula (1).

Where:

d - Focus (or source) size;

uc - Inherent unsharpness of the system (approximately equal to 2 times the pixel

size of the detector).

5.5 Direction of penetration

During penetration, the center of the ray beam is usually perpendicular to the center of

the penetration area. When necessary, the direction that is conducive to the detection of

defects can be selected for penetration.

5.6 Determination of the minimum number of exposures for non-planar objects

5.6.1 Number of exposures for 100% static imaging of girth welded joints of small-

diameter tubes

5.6.1.1 When using tilted exposure elliptical imaging:

number, part number, penetration date. The penetration after repair shall also have a

repair mark. The penetration with an expanded detection ratio shall have an expanded

detection mark. The identification mark can be written by a computer.

5.8.3 The positioning mark generally includes the center mark " " and the overlap mark

" ". The center mark indicates the center position of the penetration part segment and

the direction of the segment number. The overlap mark is a penetration segment mark,

which is generally composed of appropriate size lead or other suitable heavy metal

numbers, pinyin letters, symbols. When the lead overlap mark is represented by

numbers or letters, the center mark can be omitted.

5.8.4 For the continuous testing of a weld joint, make a positioning mark " " at the

starting position of the testing, where "➔" points to the testing direction. Numbers or

letters can be used to indicate segment marks. Girth weld joint testing can be marked

with a marker in a clockwise direction; longitudinal weld joint testing can be marked

from left to right, meanwhile it shall match the image mark.

5.8.5 The mark shall comply with the relevant provisions of NB/T 47013.2 and shall be

placed outside the testing area. The images of all marks shall not overlap and shall not

be imaged within the effective evaluation range.

5.9 Standard sample

5.9.1 The standard sample is used as a dimension calibration sample when measuring

features in the image. The detailed steps of dimension calibration are as shown in 7.2.1.

5.9.2 The standard sample shall be placed on the workpiece surface on the detector side,

imaged within the effective evaluation range, not interfere with the image within the

effective evaluation range.

5.9.3 The length of the standard sample shall not be less than 15 mm.

5.10 Shielding of useless rays and scattered rays

Appropriate measures such as filter plates, collimators (aperture), lead foils, lead plates,

etc. shall be adopted, to reduce scattered rays and useless rays.

6 Image quality and evaluation

6.1 Image quality

6.1.1 General requirements

6.1.1.1 The requirements of grayscale, image sensitivity, image resolution, normalized

signal-to-noise ratio shall be guaranteed at the same time.

6.1.1.2 Image quality meters for measuring image quality are divided into linear image

6.1.2.2.4 In principle, there shall be an image of the linear image quality meter on each

image. When the penetration parame...

Share