1

/

of

5

PayPal, credit cards. Download editable-PDF & invoice in 1 second!

NB/T 47018.5-2017 English PDF (NBT47018.5-2017)

NB/T 47018.5-2017 English PDF (NBT47018.5-2017)

Regular price

$215.00 USD

Regular price

Sale price

$215.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click NB/T 47018.5-2017

Historical versions: NB/T 47018.5-2017

Preview True-PDF (Reload/Scroll if blank)

NB/T 47018.5-2017: Technical permission of welding materials for pressure equipment. Section 5: Stainless steel strip electrodes and fluxes for overlay welding

NB/T 47018.5-2017

NB

ENERGY INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 25.160.10

J 33

Replacing NB/T 47018.5-2011

Technical Permission of Welding Materials for

Pressure Equipment Section 5: Stainless Steel Strip

Electrodes and Fluxes for Overlay Welding

ISSUED ON: MARCH 28, 2017

IMPLEMENTED ON: AUGUST 01, 2017

Issued by: National Energy Administration

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative References ... 5

3 Model ... 6

4 Technical Requirements ... 7

5 Test Methods ... 10

6 Inspection Rules ... 13

7 Quality Certificate ... 14

8 Packaging ... 15

9 Marking and Product Identification ... 15

Technical Permission of Welding for Pressure

Equipment Section 5: Stainless Steel Strip Electrodes

and Fluxes for Overlay Welding

1 Scope

This Part of NB/T 47018-2017 specifies the model, technical requirements, test

methods, inspection rules, packaging and marking, and product marking of stainless-

steel deposited metal for overlay welding.

This Part is applicable to submerged arc or electroslag corrosion-resistant overlay

welding for pressure equipment.

2 Normative References

The following documents are essential to the application of this document. For the

dated documents, only the versions with the dates indicated are applicable to this

document; for the undated documents, only the latest version (including all the

amendments) is applicable to this document.

GB/T 223 (all parts) Methods for Chemical Analysis for Iron, Steel and Alloy

GB/T 1954 Methods of Measurement for Ferrite Content in Austenitic Cr-Ni

Stainless Steel Weld Metals

GB/T 2653 Bend Test Methods on Welded Joints

GB/T 4334 Corrosion of Metals and Alloys - Test Methods for Intergranular

Corrosion of Stainless Steels

GB/T 17854-1999 Stainless Steel Electrodes and Fluxes for Submerged Arc

Welding

NB/T 47013.3 Non-Destructive Testing of Pressure Equipment - Part 3: Ultrasonic

Testing

NB/T 47013.5 Non-Destructive Testing of Pressure Equipment - Part 5: Penetrant

Testing

NB/T 47018.1 Technical Permission of Welding Materials for Pressure Equipment

- Part 1: General Rule

3 Model

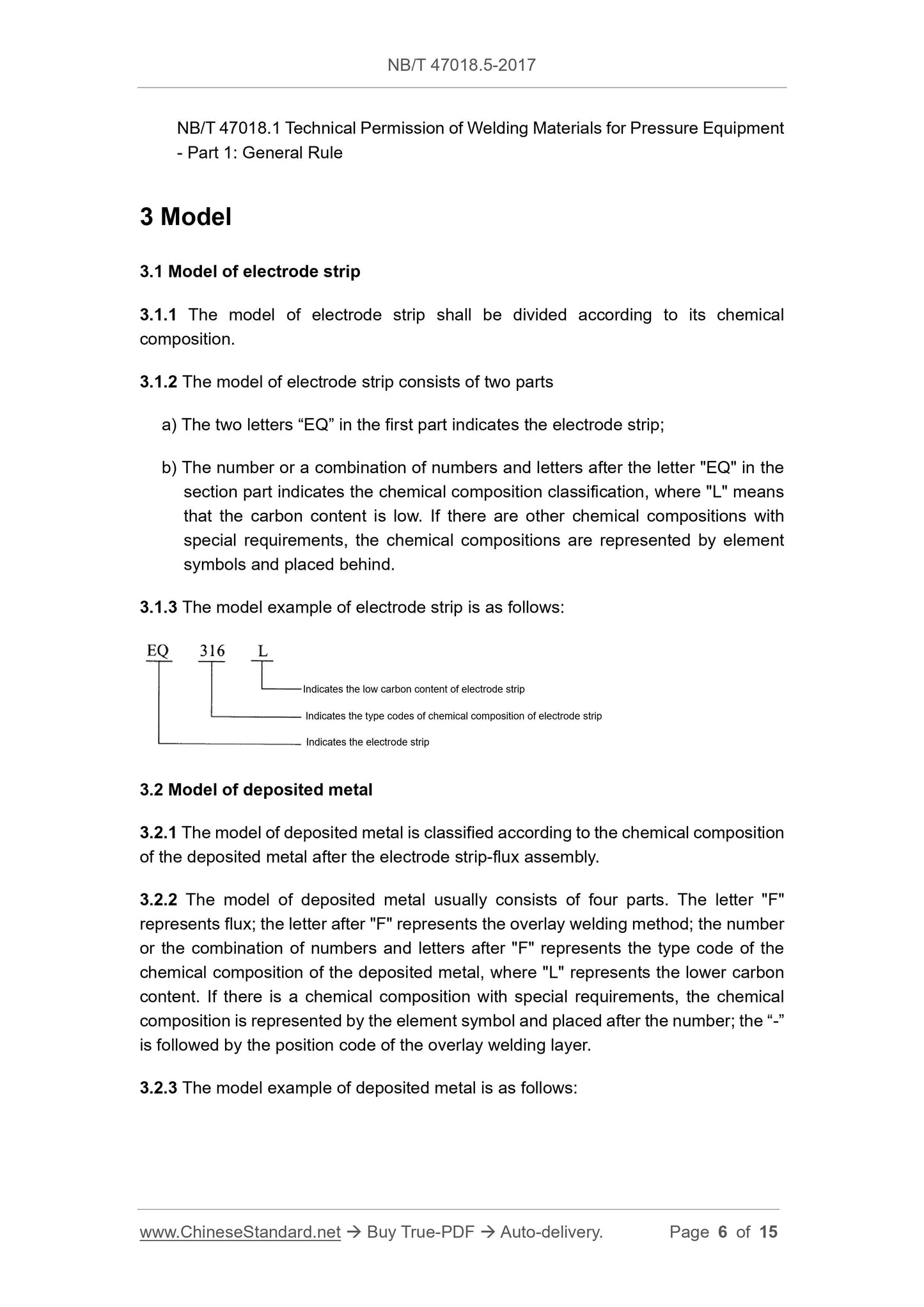

3.1 Model of electrode strip

3.1.1 The model of electrode strip shall be divided according to its chemical

composition.

3.1.2 The model of electrode strip consists of two parts

a) The two letters “EQ” in the first part indicates the electrode strip;

b) The number or a combination of numbers and letters after the letter "EQ" in the

section part indicates the chemical composition classification, where "L" means

that the carbon content is low. If there are other chemical compositions with

special requirements, the chemical compositions are represented by element

symbols and placed behind.

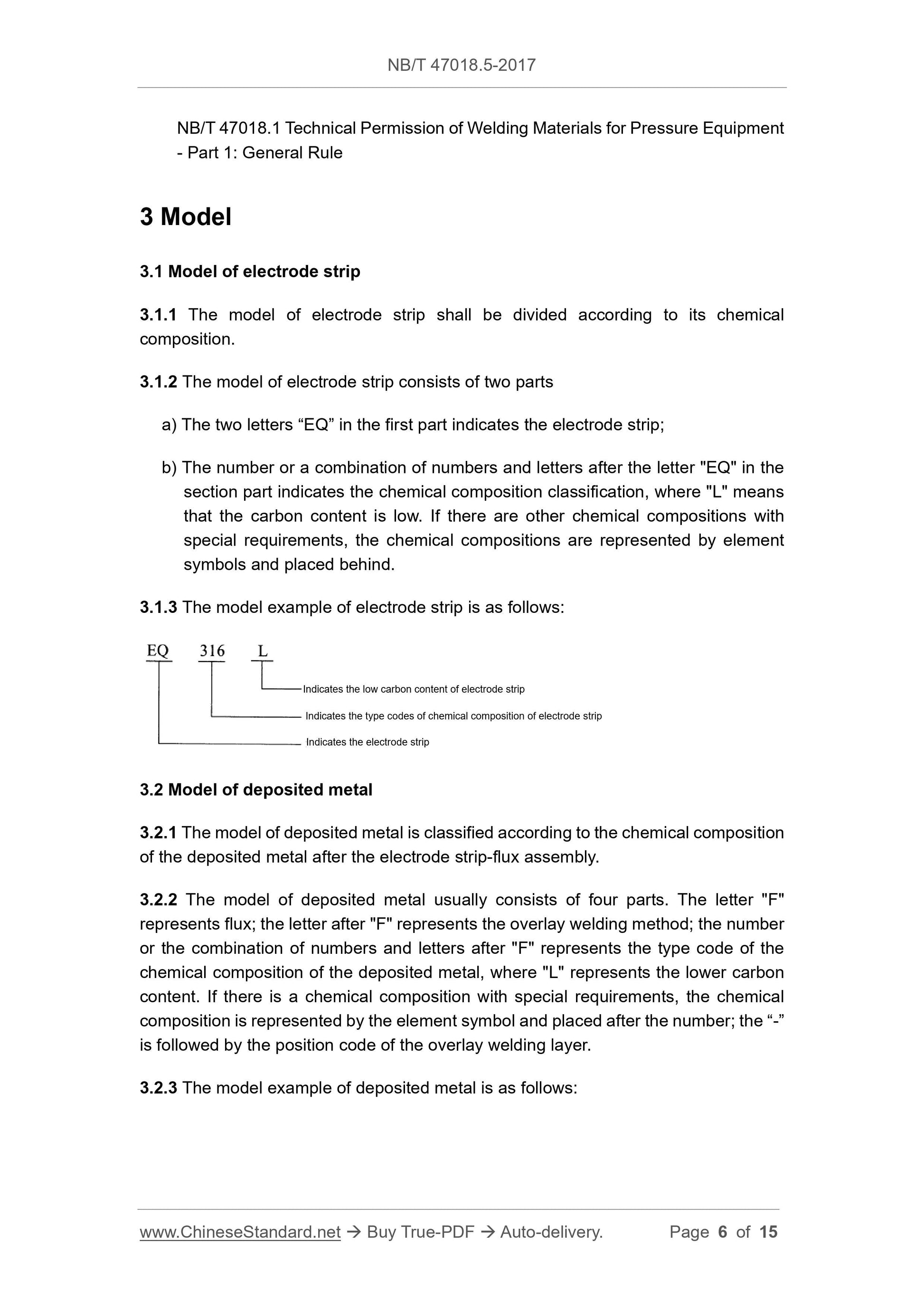

3.1.3 The model example of electrode strip is as follows:

3.2 Model of deposited metal

3.2.1 The model of deposited metal is classified according to the chemical composition

of the deposited metal after the electrode strip-flux assembly.

3.2.2 The model of deposited metal usually consists of four parts. The letter "F"

represents flux; the letter after "F" represents the overlay welding method; the number

or the combination of numbers and letters after "F" represents the type code of the

chemical composition of the deposited metal, where "L" represents the lower carbon

content. If there is a chemical composition with special requirements, the chemical

composition is represented by the element symbol and placed after the number; the “-”

is followed by the position code of the overlay welding layer.

3.2.3 The model example of deposited metal is as follows:

Indicates the low carbon content of electrode strip

Indicates the type codes of chemical composition of electrode strip

Indicates the electrode strip

from each batch of flux; if sampling from the packaged flux, at least 6 bags shall be

sampled from each batch of flux, and a certain amount of flux shall be taken from each

bag, with a total amount of no less than 10kg. Mix the extracted flux uniformly; and

take out 5kg by quarter method for welding test pieces; and the remaining 5kg for

inspection of other items.

6.2 Acceptance

6.2.1 The surface quality inspection results of each batch of electrode strips shall

comply with the provisions of 4.2.1.

6.2.2 The size inspection results of each batch of electrode strips shall comply with the

provisions of Tables 1 and 2.

6.2.3 The chemical composition inspection results of each batch of electrode strips

shall comply with the provisions of Table 3.

6.2.4 The quality inspection results of each batch of flux shall comply with the

provisions of 4.3.

6.2.5 The chemical composition of the deposited metal after each batch of electrode

strip-flux combination shall comply with the provisions of Table 5.

6.2.6 The bending performance results of the deposited metal after each batch of

electrode strip-flux combination shall comply with the provisions of 4.5.

6.2.7 The ferrite content of the deposited metal and the corrosion resistance of the

deposited metal after each batch of electrode strip-flux combination shall comply with

the provisions of 4.6 and 4.7.

7 Quality Certificate

7.1 Inspection content

The quality certificate of overlay welding materials for pressure equipment shall contain

the batch numbers of flux, transition layer electrode strip and corrosion-resistant layer

electrode strip, and their respective inspection results, as well as the results of

inspection after flux, electrode strip and assembly overlay welding.

7.2 Batch number

The batch numbers of flux, transition layer electrode strip and corrosion-resistant layer

electrode strip used for pressure equipment shall meet the requirements of the quality

certificate in 7.1; when only one of the above three batch numbers is different from that

in the quality assurance certificate, it shall be inspected according to the quality

assurance system of this organization, and the technical requirements shall be no

Get QUOTATION in 1-minute: Click NB/T 47018.5-2017

Historical versions: NB/T 47018.5-2017

Preview True-PDF (Reload/Scroll if blank)

NB/T 47018.5-2017: Technical permission of welding materials for pressure equipment. Section 5: Stainless steel strip electrodes and fluxes for overlay welding

NB/T 47018.5-2017

NB

ENERGY INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 25.160.10

J 33

Replacing NB/T 47018.5-2011

Technical Permission of Welding Materials for

Pressure Equipment Section 5: Stainless Steel Strip

Electrodes and Fluxes for Overlay Welding

ISSUED ON: MARCH 28, 2017

IMPLEMENTED ON: AUGUST 01, 2017

Issued by: National Energy Administration

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative References ... 5

3 Model ... 6

4 Technical Requirements ... 7

5 Test Methods ... 10

6 Inspection Rules ... 13

7 Quality Certificate ... 14

8 Packaging ... 15

9 Marking and Product Identification ... 15

Technical Permission of Welding for Pressure

Equipment Section 5: Stainless Steel Strip Electrodes

and Fluxes for Overlay Welding

1 Scope

This Part of NB/T 47018-2017 specifies the model, technical requirements, test

methods, inspection rules, packaging and marking, and product marking of stainless-

steel deposited metal for overlay welding.

This Part is applicable to submerged arc or electroslag corrosion-resistant overlay

welding for pressure equipment.

2 Normative References

The following documents are essential to the application of this document. For the

dated documents, only the versions with the dates indicated are applicable to this

document; for the undated documents, only the latest version (including all the

amendments) is applicable to this document.

GB/T 223 (all parts) Methods for Chemical Analysis for Iron, Steel and Alloy

GB/T 1954 Methods of Measurement for Ferrite Content in Austenitic Cr-Ni

Stainless Steel Weld Metals

GB/T 2653 Bend Test Methods on Welded Joints

GB/T 4334 Corrosion of Metals and Alloys - Test Methods for Intergranular

Corrosion of Stainless Steels

GB/T 17854-1999 Stainless Steel Electrodes and Fluxes for Submerged Arc

Welding

NB/T 47013.3 Non-Destructive Testing of Pressure Equipment - Part 3: Ultrasonic

Testing

NB/T 47013.5 Non-Destructive Testing of Pressure Equipment - Part 5: Penetrant

Testing

NB/T 47018.1 Technical Permission of Welding Materials for Pressure Equipment

- Part 1: General Rule

3 Model

3.1 Model of electrode strip

3.1.1 The model of electrode strip shall be divided according to its chemical

composition.

3.1.2 The model of electrode strip consists of two parts

a) The two letters “EQ” in the first part indicates the electrode strip;

b) The number or a combination of numbers and letters after the letter "EQ" in the

section part indicates the chemical composition classification, where "L" means

that the carbon content is low. If there are other chemical compositions with

special requirements, the chemical compositions are represented by element

symbols and placed behind.

3.1.3 The model example of electrode strip is as follows:

3.2 Model of deposited metal

3.2.1 The model of deposited metal is classified according to the chemical composition

of the deposited metal after the electrode strip-flux assembly.

3.2.2 The model of deposited metal usually consists of four parts. The letter "F"

represents flux; the letter after "F" represents the overlay welding method; the number

or the combination of numbers and letters after "F" represents the type code of the

chemical composition of the deposited metal, where "L" represents the lower carbon

content. If there is a chemical composition with special requirements, the chemical

composition is represented by the element symbol and placed after the number; the “-”

is followed by the position code of the overlay welding layer.

3.2.3 The model example of deposited metal is as follows:

Indicates the low carbon content of electrode strip

Indicates the type codes of chemical composition of electrode strip

Indicates the electrode strip

from each batch of flux; if sampling from the packaged flux, at least 6 bags shall be

sampled from each batch of flux, and a certain amount of flux shall be taken from each

bag, with a total amount of no less than 10kg. Mix the extracted flux uniformly; and

take out 5kg by quarter method for welding test pieces; and the remaining 5kg for

inspection of other items.

6.2 Acceptance

6.2.1 The surface quality inspection results of each batch of electrode strips shall

comply with the provisions of 4.2.1.

6.2.2 The size inspection results of each batch of electrode strips shall comply with the

provisions of Tables 1 and 2.

6.2.3 The chemical composition inspection results of each batch of electrode strips

shall comply with the provisions of Table 3.

6.2.4 The quality inspection results of each batch of flux shall comply with the

provisions of 4.3.

6.2.5 The chemical composition of the deposited metal after each batch of electrode

strip-flux combination shall comply with the provisions of Table 5.

6.2.6 The bending performance results of the deposited metal after each batch of

electrode strip-flux combination shall comply with the provisions of 4.5.

6.2.7 The ferrite content of the deposited metal and the corrosion resistance of the

deposited metal after each batch of electrode strip-flux combination shall comply with

the provisions of 4.6 and 4.7.

7 Quality Certificate

7.1 Inspection content

The quality certificate of overlay welding materials for pressure equipment shall contain

the batch numbers of flux, transition layer electrode strip and corrosion-resistant layer

electrode strip, and their respective inspection results, as well as the results of

inspection after flux, electrode strip and assembly overlay welding.

7.2 Batch number

The batch numbers of flux, transition layer electrode strip and corrosion-resistant layer

electrode strip used for pressure equipment shall meet the requirements of the quality

certificate in 7.1; when only one of the above three batch numbers is different from that

in the quality assurance certificate, it shall be inspected according to the quality

assurance system of this organization, and the technical requirements shall be no

Share