1

/

of

6

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

Q/BQB 401-2014 English PDF (QBQB401-2014)

Q/BQB 401-2014 English PDF (QBQB401-2014)

Regular price

$225.00 USD

Regular price

Sale price

$225.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.Newer version: (Replacing this standard) QBQB401-2019

Get QUOTATION in 1-minute: Click Q/BQB 401-2014

Historical versions: Q/BQB 401-2014

Preview True-PDF (Reload/Scroll if blank)

Q/BQB 401-2014: Cold rolled steel sheet and strip - Size, shape, weight and permissible deviations

Q/BQB 401-2014

TECHNICAL SUPPLY CONDITION OF

BAOSTEEL GROUP CORPORATION

Replacing Q/BQB 401-2009

Dimension, shape, weight and tolerance for

cold-rolled steel plates and strips

ISSUED ON. OCTOBER 18, 2014

IMPLEMENTED ON. MARCH 31, 2015

Issued by. Baosteel Group Corporation

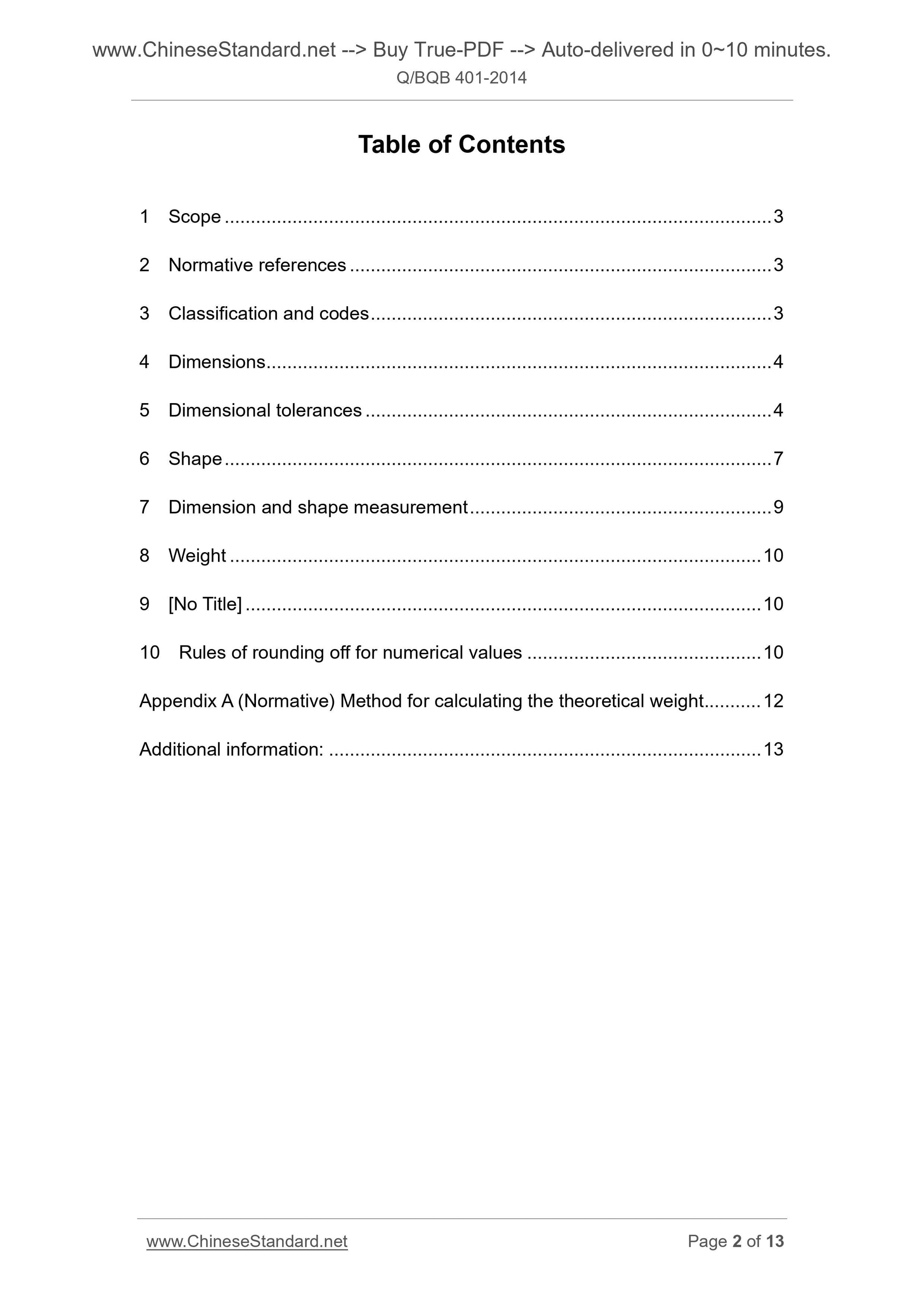

Table of Contents

1 Scope ... 3

2 Normative references ... 3

3 Classification and codes ... 3

4 Dimensions ... 4

5 Dimensional tolerances ... 4

6 Shape ... 7

7 Dimension and shape measurement ... 9

8 Weight ... 10

9 [No Title] ... 10

10 Rules of rounding off for numerical values ... 10

Appendix A (Normative) Method for calculating the theoretical weight ... 12

Additional information... 13

Dimension, shape, weight and tolerance for

cold-rolled steel plates and strips

1 Scope

This Standard specifies the requirements for the classification and code,

dimension, shape, weight and tolerance of cold-rolled steel plates and strips.

This Standard is applicable to the cold-rolled steel strips with the thickness of

0.17mm to 3.50mm and the width of 400mm to 1,850mm, and the steel plates

cut from the above-mentioned steel strips (hereinafter referred to as “steel

plates and strips”), which are produced by Baosteel Group Corporation.

2 Normative references

The following documents are essential to the application of this document. For

dated references, only the editions with the dates indicated are applicable to

this document. For undated references, only the latest editions (including all the

amendments) are applicable to this document.

GB/T 8170-2008 Rules of rounding off for numerical values and expression and

judgement of limiting values

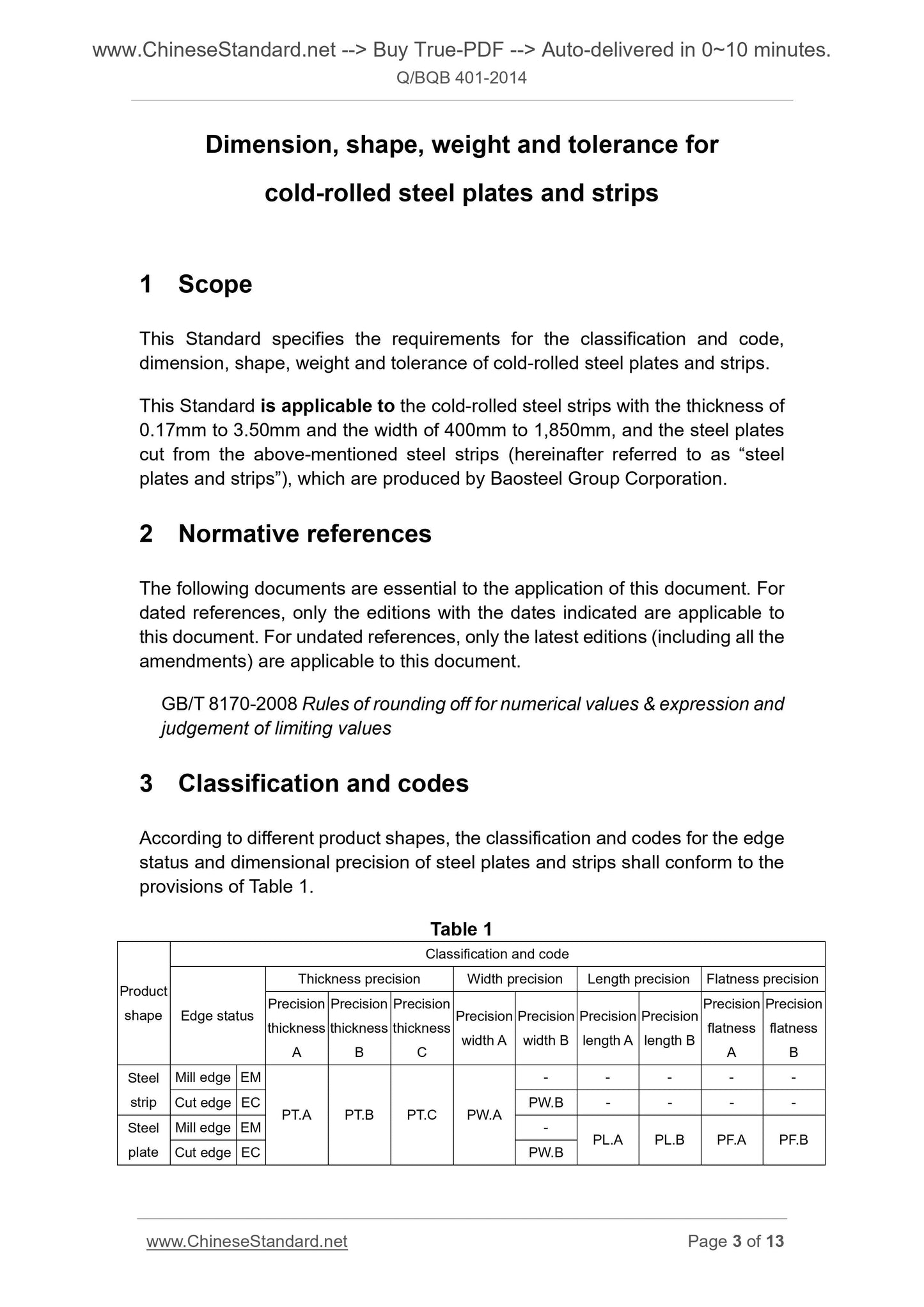

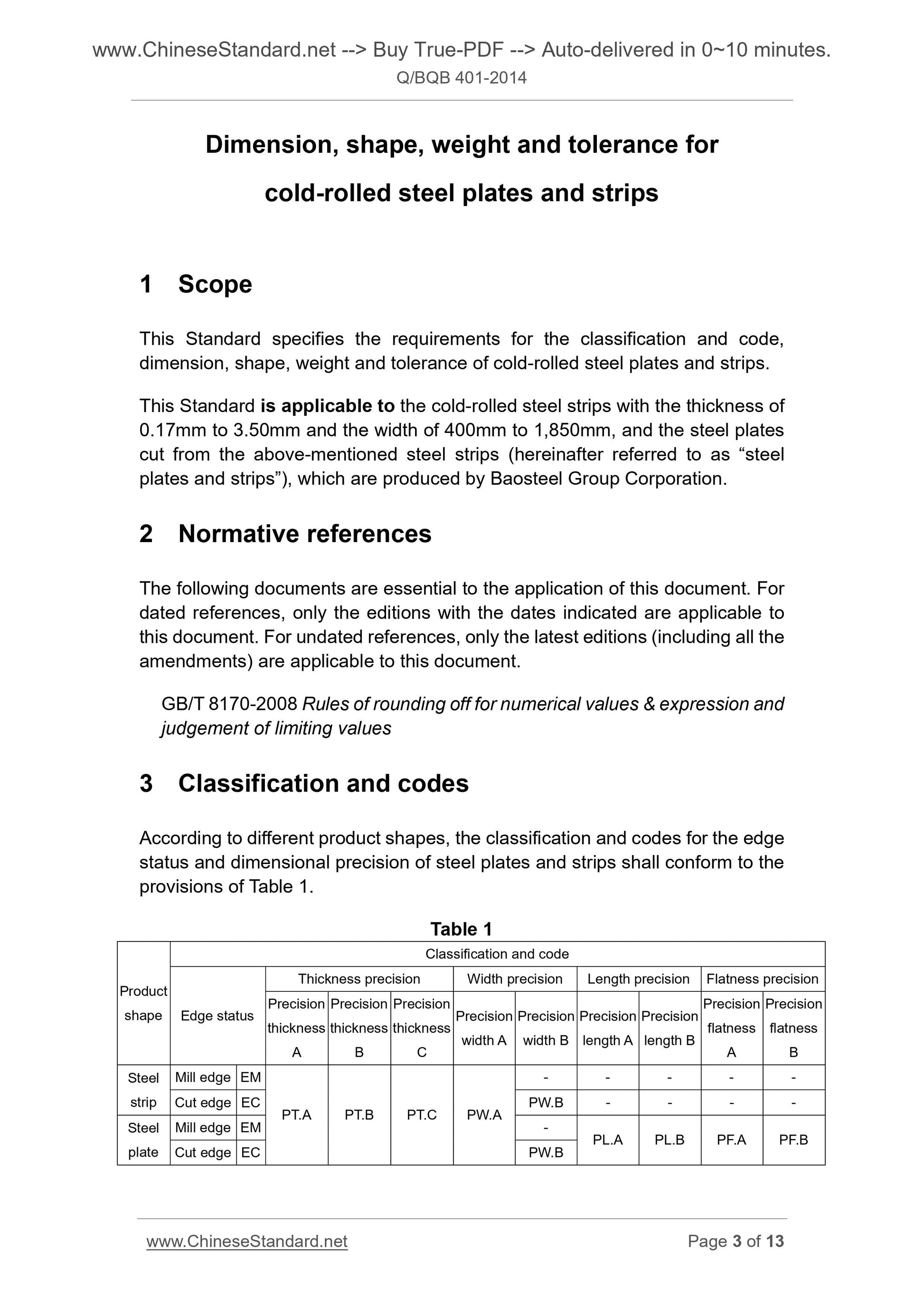

3 Classification and codes

According to different product shapes, the classification and codes for the edge

status and dimensional precision of steel plates and strips shall conform to the

provisions of Table 1.

Table 1

Product

shape

Classification and code

Edge status

Thickness precision Width precision Length precision Flatness precision

Precision

thickness

Precision

thickness

Precision

thickness

Precision

width A

Precision

width B

Precision

length A

Precision

length B

Precision

flatness

Precision

flatness

Steel

strip

Mill edge EM

PT.A PT.B PT.C PW.A

- - - - -

Cut edge EC PW.B - - - -

Steel

plate

Mill edge EM - PL.A PL.B PF.A PF.B Cut edge EC PW.B

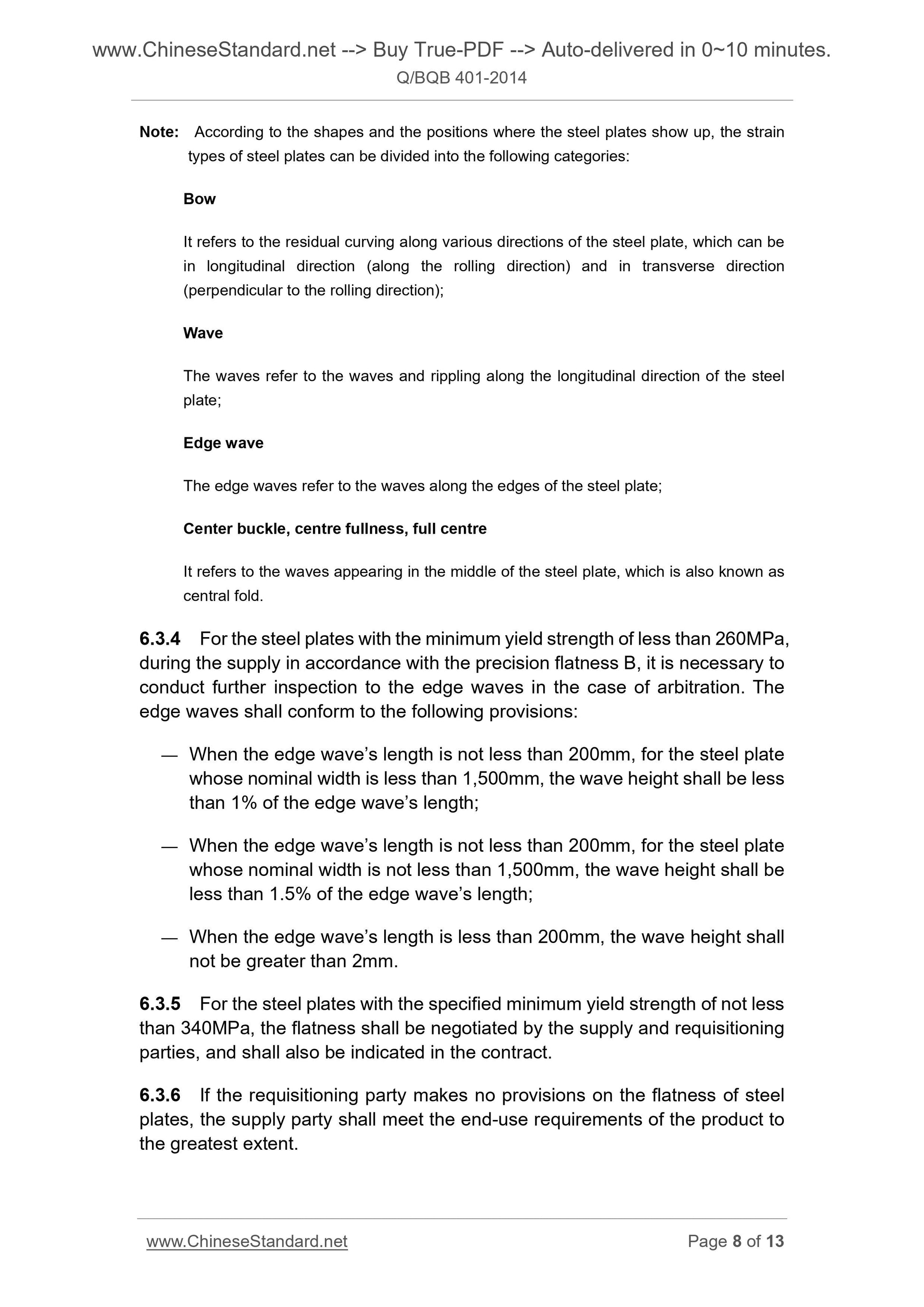

Note. According to the shapes and the positions where the steel plates show up, the strain

types of steel plates can be divided into the following categories.

Bow

It refers to the residual curving along various directions of the steel plate, which can be

in longitudinal direction (along the rolling direction) and in transverse direction

(perpendicular to the rolling direction);

Wave

The waves refer to the waves and rippling along the longitudinal direction of the steel

plate;

Edge wave

The edge waves refer to the waves along the edges of the steel plate;

Center buckle, centre fullness, full centre

It refers to the waves appearing in the middle of the steel plate, which is also known as

central fold.

6.3.4 For the steel plates with the minimum yield strength of less than 260MPa,

during the supply in accordance with the precision flatness B, it is necessary to

conduct further inspection to the edge waves in the case of arbitration. The

edge waves shall conform to the following provisions.

— When the edge wave’s length is not less than 200mm, for the steel plate

whose nominal width is less than 1,500mm, the wave height shall be less

than 1% of the edge wave’s length;

— When the edge wave’s length is not less than 200mm, for the steel plate

whose nominal width is not less than 1,500mm, the wave height shall be

less than 1.5% of the edge wave’s length;

— When the edge wave’s length is less than 200mm, the wave height shall

not be greater than 2mm.

6.3.5 For the steel plates with the specified minimum yield strength of not less

than 340MPa, the flatness shall be negotiated by the supply and requisitioning

parties, and shall also be indicated in the contract.

6.3.6 If the requisitioning party makes no provisions on the flatness of steel

plates, the supply party shall meet the end-use requirements of the product to

the greatest extent.

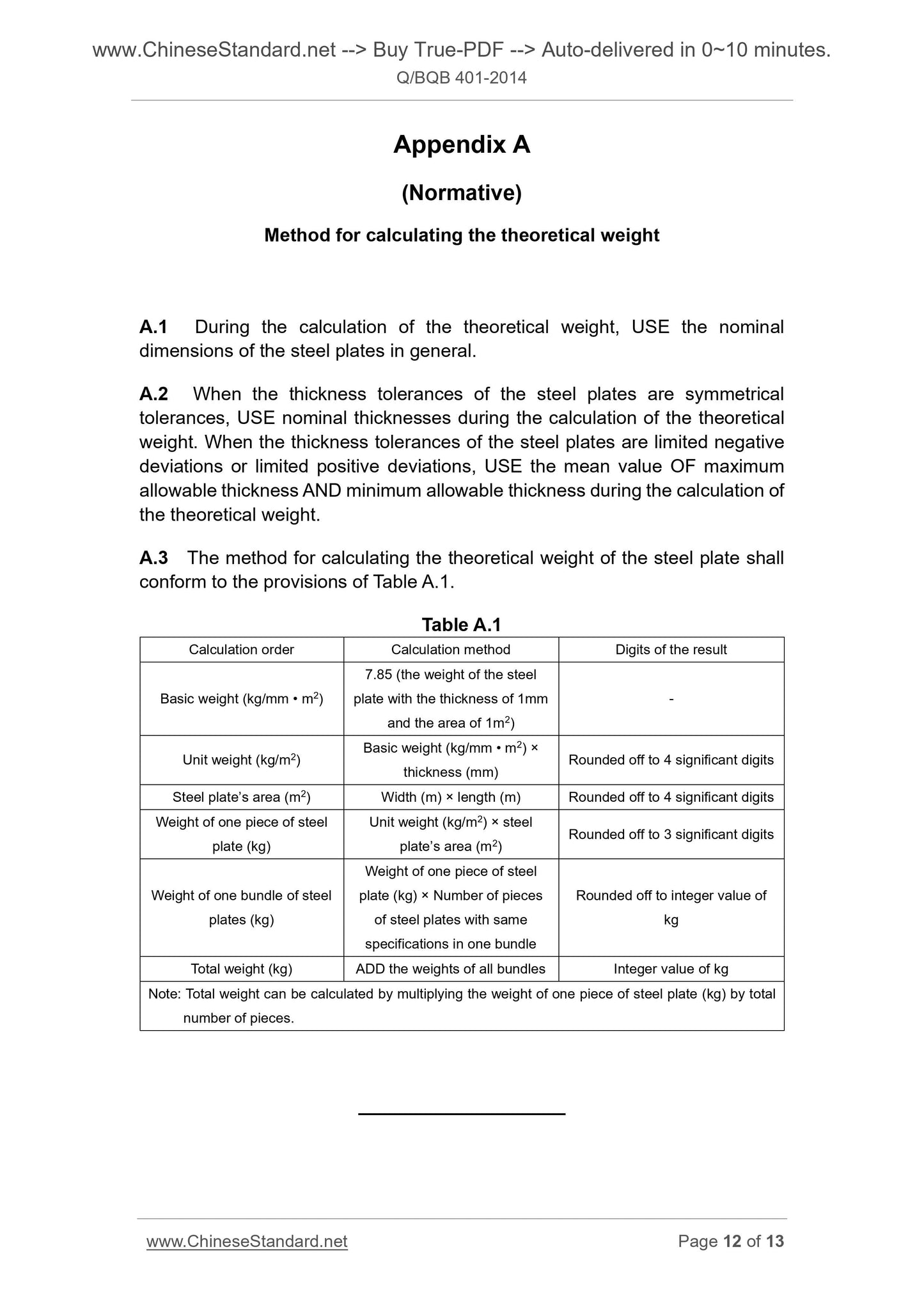

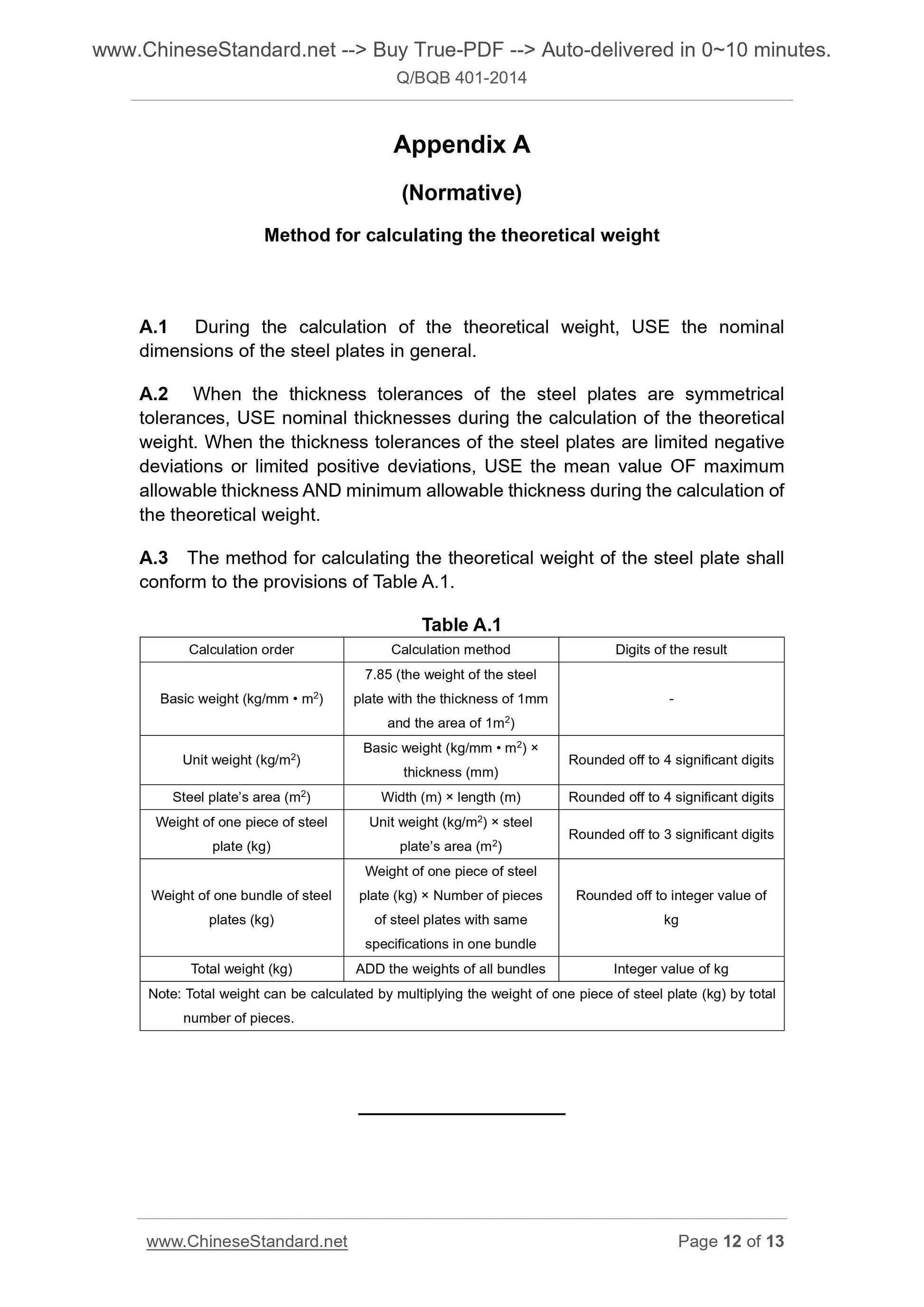

Appendix A

(Normative)

Method for calculating the theoretical weight

A.1 During the calculation of the theoretical weight, USE the nominal

dimensions of the steel plates in general.

A.2 When the thickness tolerances of the steel plates are symmetrical

tolerances, USE nominal thicknesses during the calculation of the theoretical

weight. When the thickness tolerances of the steel plates are limited negative

deviations or limited positive deviations, USE the mean value OF maximum

allowable thickness AND minimum allowable thickness during the calculation of

the theoretical weight.

A.3 The method for calculating the theoretical weight of the steel plate shall

conform to the provisions of Table A.1.

Table A.1

Calculation order Calculation method Digits of the result

Basic weight (kg/mm • m2)

7.85 (the weight of the steel

plate with the thickness of 1mm

and the area of 1m2)

Unit weight (kg/m2) Basic weight (kg/mm • m

2) ×

thickness (mm) Rounded off to 4 significant digits

Steel plate’s area (m2) Width (m) × length (m) Rounded off to 4 significant digits

Weight of one piece of steel

plate (kg)

Unit weight (kg/m2) × steel

plate’s area (m2) Rounded off to 3 significant digits

Weight of one bundle of steel

plates (kg)

Weight of one piece of steel

plate (kg) × Number of pieces

of steel plates with same

specifications in one bundle

Rounded off to integer value of

kg

Total weight (kg) ADD the weights of all bundles Integer value of kg

Note. Total weight can be calculated by multiplying the weight of one piece of steel plate (kg) by total

number of pieces.

Additional information.

This Technical Condition was drafted by reference to EN 10131.2006, JIS

G3141.2011 and GMW 3224-2012.

This Technical Condition replaces Q/BQB 401-2009.

Compared with Q/BQB 401-2009, the major modifications in this Technical

Condition are as follows.

— DELETE the provisions on the original slitting steel strips;

— ADD the provisions on the precision thickness C;

— ADD the provisions on using the diagonal method for measuring the out

of squareness.

The Appendix A of this Technical Condition is normative appendix.

This Technical Condition was proposed by the Manufacturing Management

Department of Baosteel Group Corporation.

This Technical Condition was drafted by the Manufacturing Management

Department of Baosteel Group Corporation.

Drafter of this Technical Condition. Sun Zhongming.

This Technical Condition was first released in 1988. The first revision was

released in 1994. The second revision was released in 1999. The third revision

was released in 2003. The fourth revision was released in 2009. This is the fifth

revision.

Get QUOTATION in 1-minute: Click Q/BQB 401-2014

Historical versions: Q/BQB 401-2014

Preview True-PDF (Reload/Scroll if blank)

Q/BQB 401-2014: Cold rolled steel sheet and strip - Size, shape, weight and permissible deviations

Q/BQB 401-2014

TECHNICAL SUPPLY CONDITION OF

BAOSTEEL GROUP CORPORATION

Replacing Q/BQB 401-2009

Dimension, shape, weight and tolerance for

cold-rolled steel plates and strips

ISSUED ON. OCTOBER 18, 2014

IMPLEMENTED ON. MARCH 31, 2015

Issued by. Baosteel Group Corporation

Table of Contents

1 Scope ... 3

2 Normative references ... 3

3 Classification and codes ... 3

4 Dimensions ... 4

5 Dimensional tolerances ... 4

6 Shape ... 7

7 Dimension and shape measurement ... 9

8 Weight ... 10

9 [No Title] ... 10

10 Rules of rounding off for numerical values ... 10

Appendix A (Normative) Method for calculating the theoretical weight ... 12

Additional information... 13

Dimension, shape, weight and tolerance for

cold-rolled steel plates and strips

1 Scope

This Standard specifies the requirements for the classification and code,

dimension, shape, weight and tolerance of cold-rolled steel plates and strips.

This Standard is applicable to the cold-rolled steel strips with the thickness of

0.17mm to 3.50mm and the width of 400mm to 1,850mm, and the steel plates

cut from the above-mentioned steel strips (hereinafter referred to as “steel

plates and strips”), which are produced by Baosteel Group Corporation.

2 Normative references

The following documents are essential to the application of this document. For

dated references, only the editions with the dates indicated are applicable to

this document. For undated references, only the latest editions (including all the

amendments) are applicable to this document.

GB/T 8170-2008 Rules of rounding off for numerical values and expression and

judgement of limiting values

3 Classification and codes

According to different product shapes, the classification and codes for the edge

status and dimensional precision of steel plates and strips shall conform to the

provisions of Table 1.

Table 1

Product

shape

Classification and code

Edge status

Thickness precision Width precision Length precision Flatness precision

Precision

thickness

Precision

thickness

Precision

thickness

Precision

width A

Precision

width B

Precision

length A

Precision

length B

Precision

flatness

Precision

flatness

Steel

strip

Mill edge EM

PT.A PT.B PT.C PW.A

- - - - -

Cut edge EC PW.B - - - -

Steel

plate

Mill edge EM - PL.A PL.B PF.A PF.B Cut edge EC PW.B

Note. According to the shapes and the positions where the steel plates show up, the strain

types of steel plates can be divided into the following categories.

Bow

It refers to the residual curving along various directions of the steel plate, which can be

in longitudinal direction (along the rolling direction) and in transverse direction

(perpendicular to the rolling direction);

Wave

The waves refer to the waves and rippling along the longitudinal direction of the steel

plate;

Edge wave

The edge waves refer to the waves along the edges of the steel plate;

Center buckle, centre fullness, full centre

It refers to the waves appearing in the middle of the steel plate, which is also known as

central fold.

6.3.4 For the steel plates with the minimum yield strength of less than 260MPa,

during the supply in accordance with the precision flatness B, it is necessary to

conduct further inspection to the edge waves in the case of arbitration. The

edge waves shall conform to the following provisions.

— When the edge wave’s length is not less than 200mm, for the steel plate

whose nominal width is less than 1,500mm, the wave height shall be less

than 1% of the edge wave’s length;

— When the edge wave’s length is not less than 200mm, for the steel plate

whose nominal width is not less than 1,500mm, the wave height shall be

less than 1.5% of the edge wave’s length;

— When the edge wave’s length is less than 200mm, the wave height shall

not be greater than 2mm.

6.3.5 For the steel plates with the specified minimum yield strength of not less

than 340MPa, the flatness shall be negotiated by the supply and requisitioning

parties, and shall also be indicated in the contract.

6.3.6 If the requisitioning party makes no provisions on the flatness of steel

plates, the supply party shall meet the end-use requirements of the product to

the greatest extent.

Appendix A

(Normative)

Method for calculating the theoretical weight

A.1 During the calculation of the theoretical weight, USE the nominal

dimensions of the steel plates in general.

A.2 When the thickness tolerances of the steel plates are symmetrical

tolerances, USE nominal thicknesses during the calculation of the theoretical

weight. When the thickness tolerances of the steel plates are limited negative

deviations or limited positive deviations, USE the mean value OF maximum

allowable thickness AND minimum allowable thickness during the calculation of

the theoretical weight.

A.3 The method for calculating the theoretical weight of the steel plate shall

conform to the provisions of Table A.1.

Table A.1

Calculation order Calculation method Digits of the result

Basic weight (kg/mm • m2)

7.85 (the weight of the steel

plate with the thickness of 1mm

and the area of 1m2)

Unit weight (kg/m2) Basic weight (kg/mm • m

2) ×

thickness (mm) Rounded off to 4 significant digits

Steel plate’s area (m2) Width (m) × length (m) Rounded off to 4 significant digits

Weight of one piece of steel

plate (kg)

Unit weight (kg/m2) × steel

plate’s area (m2) Rounded off to 3 significant digits

Weight of one bundle of steel

plates (kg)

Weight of one piece of steel

plate (kg) × Number of pieces

of steel plates with same

specifications in one bundle

Rounded off to integer value of

kg

Total weight (kg) ADD the weights of all bundles Integer value of kg

Note. Total weight can be calculated by multiplying the weight of one piece of steel plate (kg) by total

number of pieces.

Additional information.

This Technical Condition was drafted by reference to EN 10131.2006, JIS

G3141.2011 and GMW 3224-2012.

This Technical Condition replaces Q/BQB 401-2009.

Compared with Q/BQB 401-2009, the major modifications in this Technical

Condition are as follows.

— DELETE the provisions on the original slitting steel strips;

— ADD the provisions on the precision thickness C;

— ADD the provisions on using the diagonal method for measuring the out

of squareness.

The Appendix A of this Technical Condition is normative appendix.

This Technical Condition was proposed by the Manufacturing Management

Department of Baosteel Group Corporation.

This Technical Condition was drafted by the Manufacturing Management

Department of Baosteel Group Corporation.

Drafter of this Technical Condition. Sun Zhongming.

This Technical Condition was first released in 1988. The first revision was

released in 1994. The second revision was released in 1999. The third revision

was released in 2003. The fourth revision was released in 2009. This is the fifth

revision.

Share