1

/

of

12

PayPal, credit cards. Download editable-PDF & invoice in 1 second!

QC/T 1029-2016 English PDF (QCT1029-2016)

QC/T 1029-2016 English PDF (QCT1029-2016)

Regular price

$110.00 USD

Regular price

Sale price

$110.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click QC/T 1029-2016

Historical versions: QC/T 1029-2016

Preview True-PDF (Reload/Scroll if blank)

QC/T 1029-2016: Polypropylene(PP)cellular board production for vehicles

QC/T 1029-2016

QC

AUTOMOBILE INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 43.020

T 40

Polypropylene(PP) cellular

board production for vehicles

ISSUED ON. JANUARY 15, 2016

IMPLEMENTED ON. JULY 1, 2016

Issued by. Ministry of Industry and Information Technology of the

People's Republic of China

Annex.

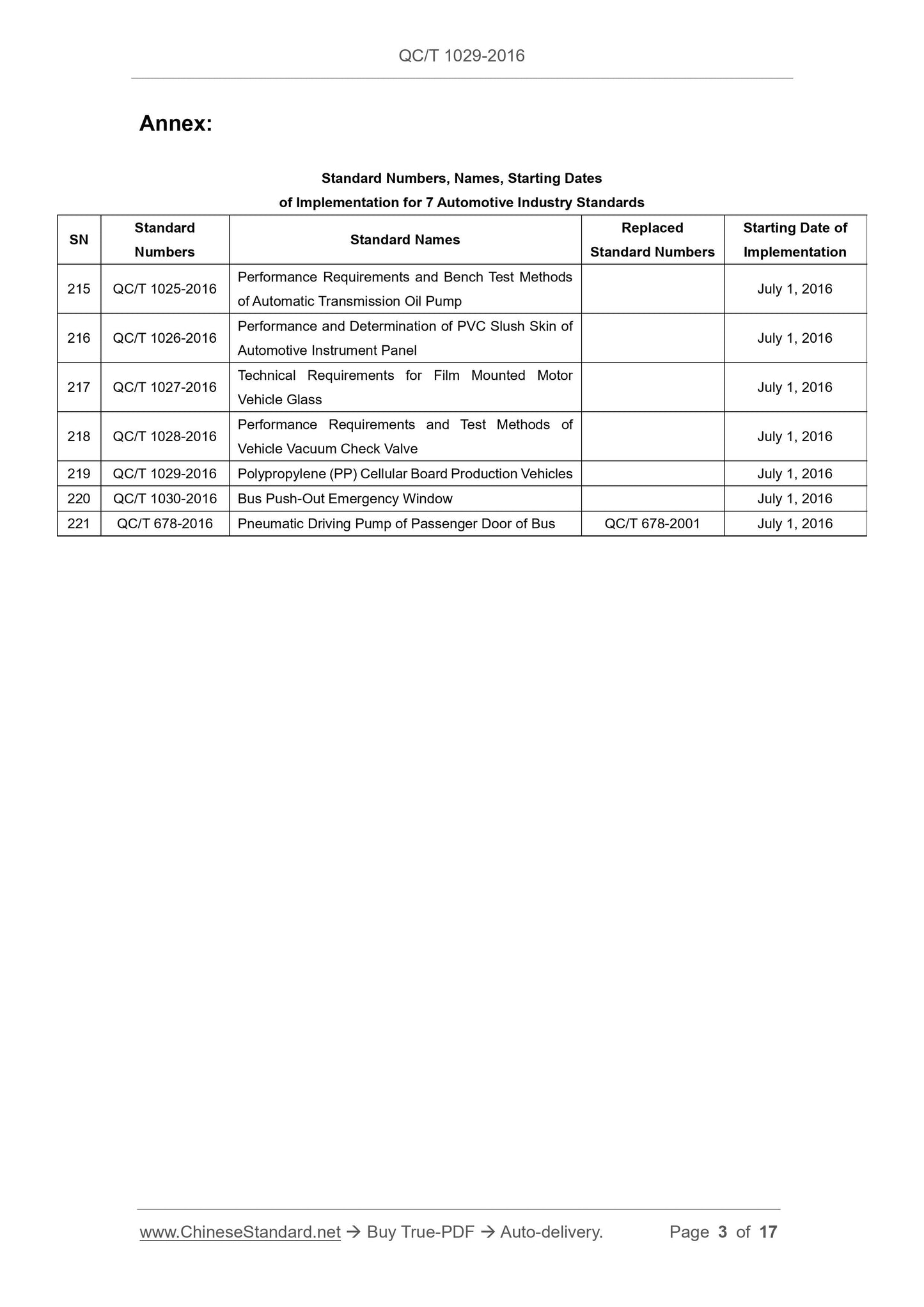

Standard Numbers, Names, Starting Dates

of Implementation for 7 Automotive Industry Standards

SN Standard Numbers Standard Names

Replaced

Standard Numbers

Starting Date of

Implementation

215 QC/T 1025-2016 Performance Requirements and Bench Test Methods of Automatic Transmission Oil Pump July 1, 2016

216 QC/T 1026-2016 Performance and Determination of PVC Slush Skin of Automotive Instrument Panel July 1, 2016

217 QC/T 1027-2016 Technical Requirements for Film Mounted Motor Vehicle Glass July 1, 2016

218 QC/T 1028-2016 Performance Requirements and Test Methods of Vehicle Vacuum Check Valve July 1, 2016

219 QC/T 1029-2016 Polypropylene (PP) Cellular Board Production Vehicles July 1, 2016

220 QC/T 1030-2016 Bus Push-Out Emergency Window July 1, 2016

221 QC/T 678-2016 Pneumatic Driving Pump of Passenger Door of Bus QC/T 678-2001 July 1, 2016

Table of Contents

Foreword ... 5

1 Scope ... 6

2 Normative references ... 6

3 Terms and definitions ... 6

4 General requirements ... 7

5 Performance requirements ... 8

6 Test methods ... 10

7 Inspection rules ... 14

8 Storage ... 15

Annex A (normative) Odor test specification ... 16

Polypropylene(PP) cellular

board production for vehicles

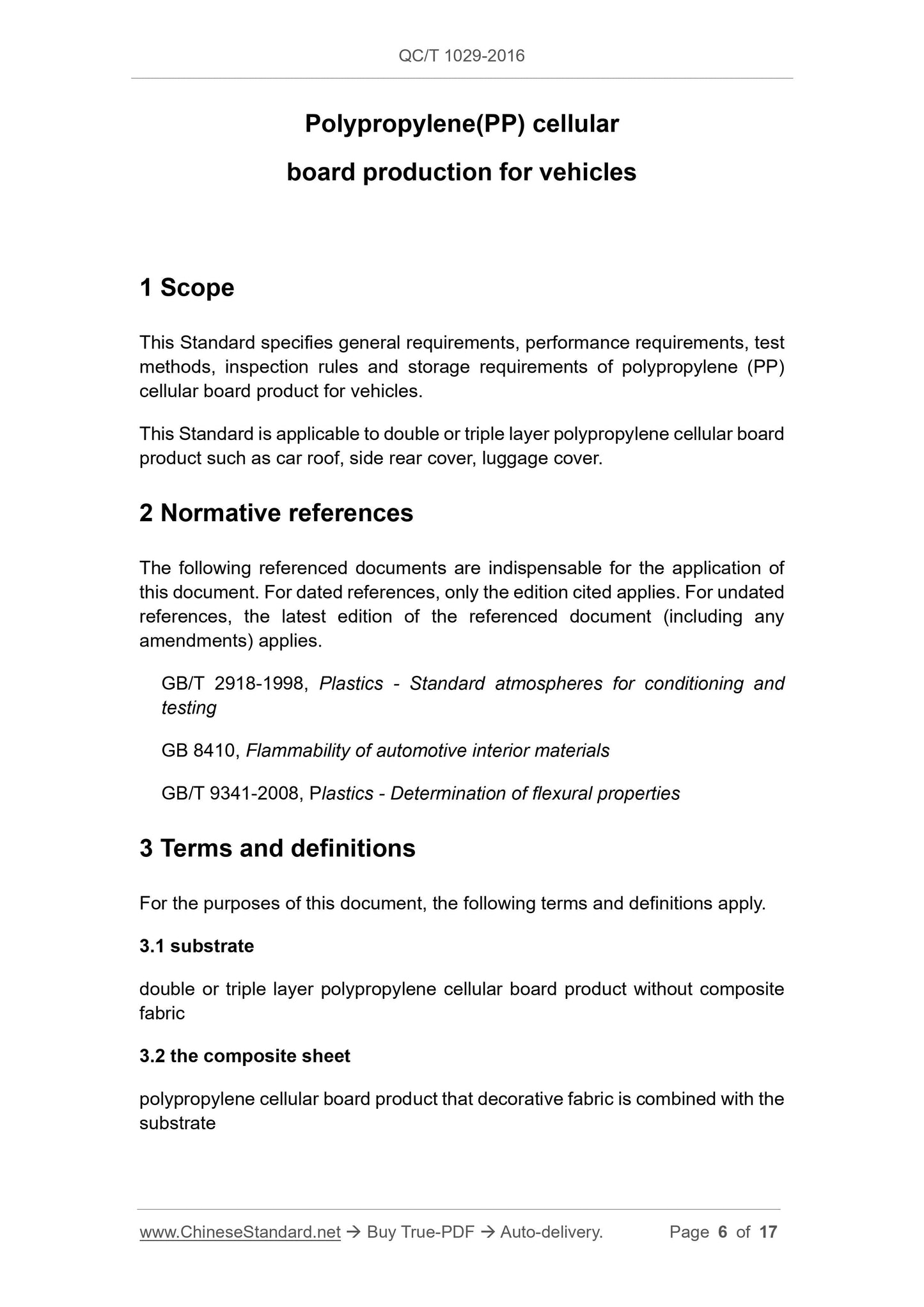

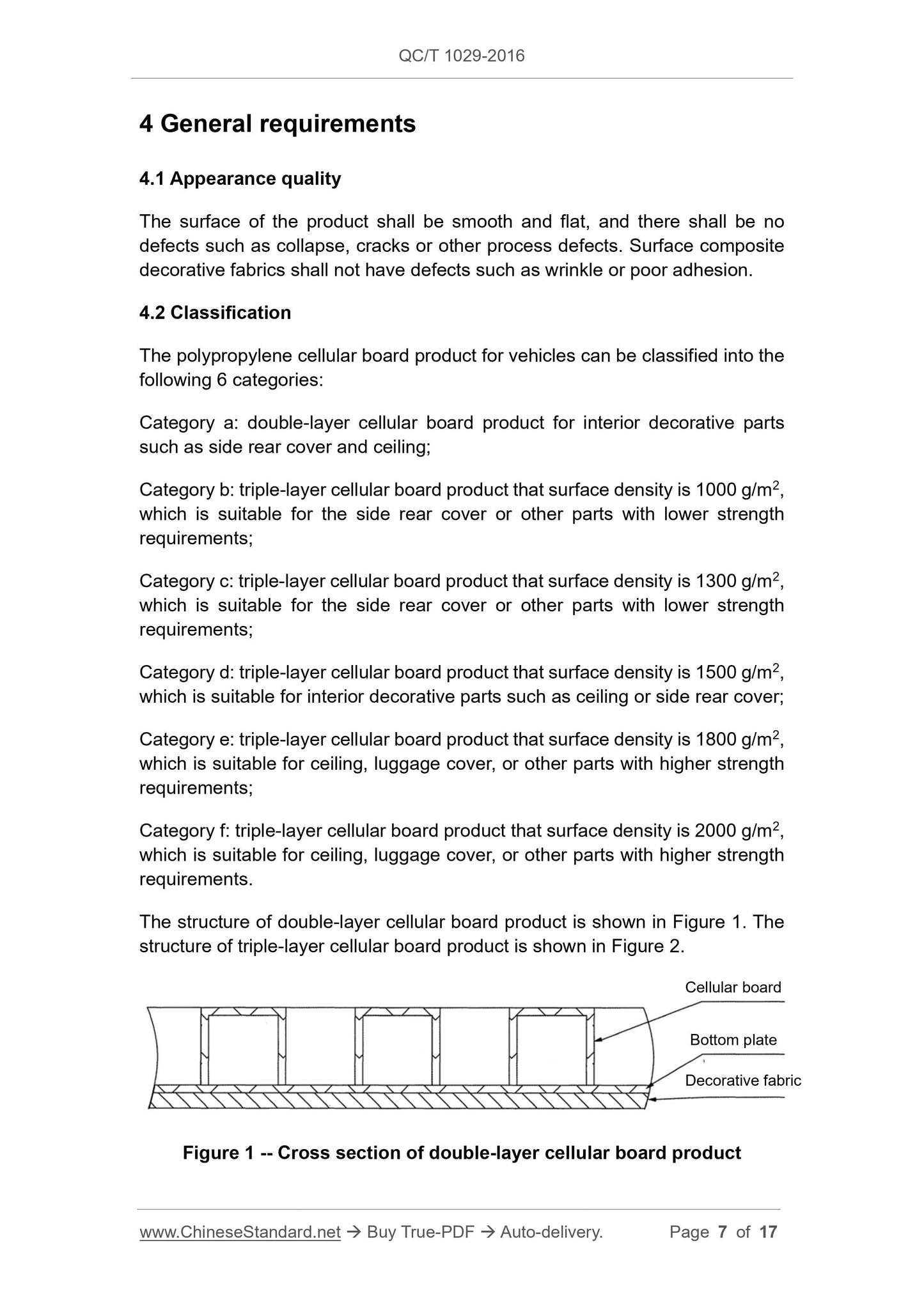

1 Scope

This Standard specifies general requirements, performance requirements, test

methods, inspection rules and storage requirements of polypropylene (PP)

cellular board product for vehicles.

This Standard is applicable to double or triple layer polypropylene cellular board

product such as car roof, side rear cover, luggage cover.

2 Normative references

The following referenced documents are indispensable for the application of

this document. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any

amendments) applies.

GB/T 2918-1998, Plastics - Standard atmospheres for conditioning and

testing

GB 8410, Flammability of automotive interior materials

GB/T 9341-2008, Plastics - Determination of flexural properties

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1 substrate

double or triple layer polypropylene cellular board product without composite

fabric

3.2 the composite sheet

polypropylene cellular board product that decorative fabric is combined with the

substrate

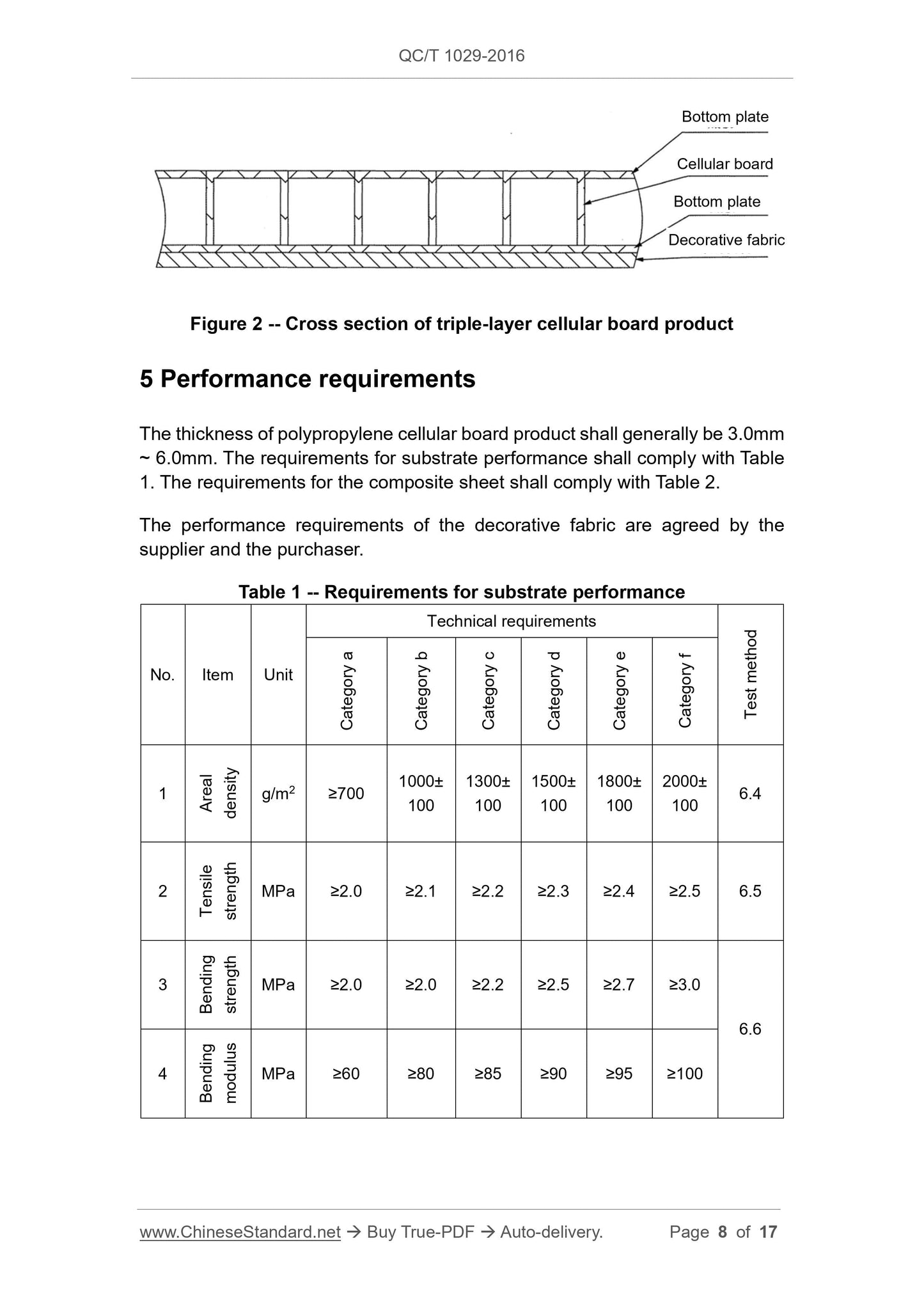

6.6.1 Sample

Take 5 pieces of 120mm × 10mm samples on the product. The sample

thickness is the part thickness.

6.6.2 Test equipment

Tensile machine with a precision of level one.

6.6.3 Test steps

Accurately measure the width and thickness of the specimen with a caliper with

an accuracy of 0.02 mm or more. Test according to the provisions of GB/T 9341-

2008. The indenter radius is 5 mm, the span is 16 times the thickness of the

sample, and the test speed is (2.0 ± 0.4) mm/min. Double-layer polypropylene

cellular board head presses on the flat side.

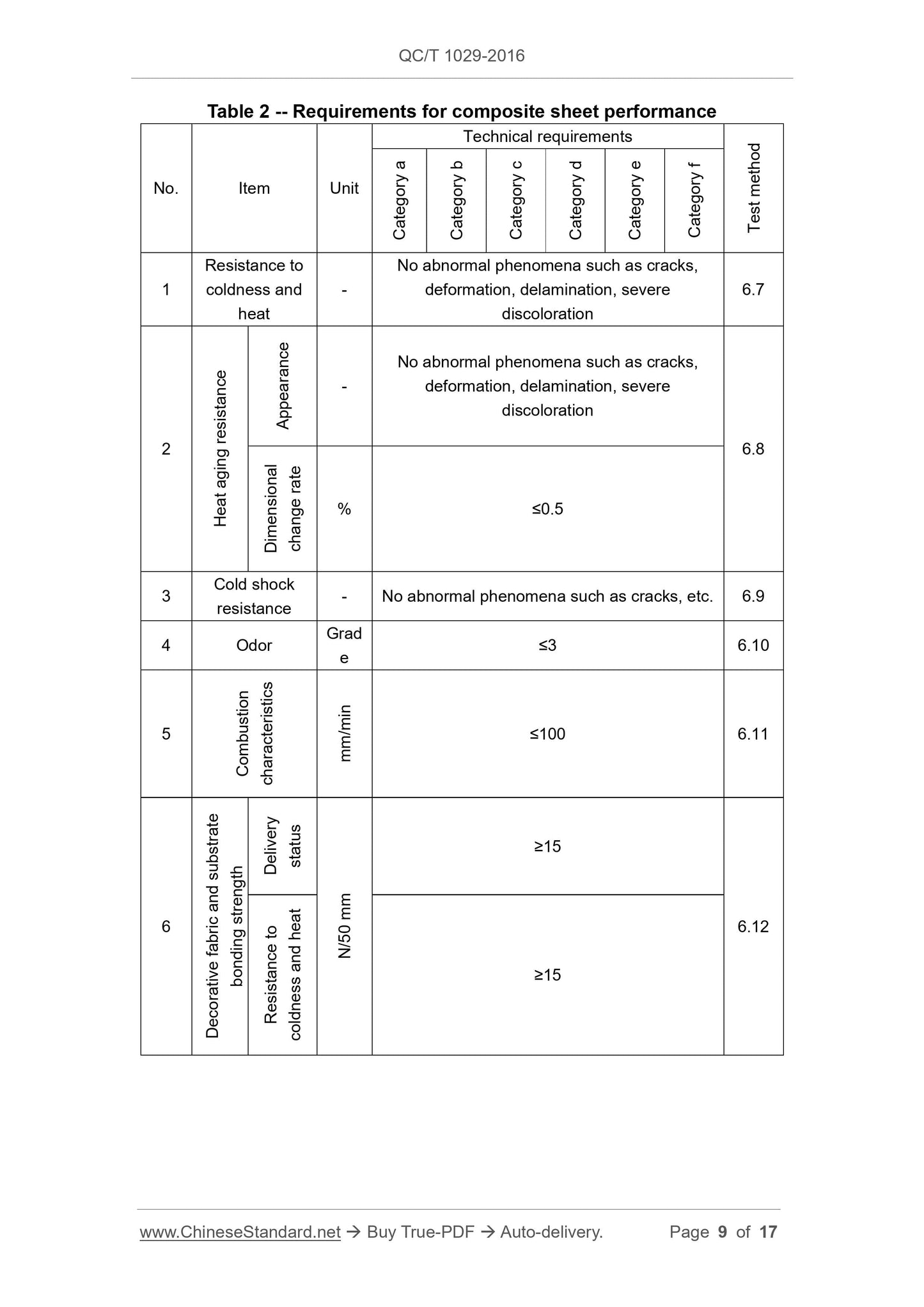

6.7 Resistance to coldness and heat

6.7.1 Sample

3 pieces of products.

6.7.2 Test equipment

Thermostatic oven, low temperature box, humidity box or high and low

temperature humid heat box; temperature accuracy is controlled at ±2°C,

humidity accuracy is controlled at ±5%.

6.7.3 Test steps

Perform 4 cycles of tests when product in under assembly state, of which (80 ±

2 )°C/3 h → RT/1 h → (-40 ± 2)°C/3 h → RT/1 h → ( 55 ± 2 )°C, 95%RH/15 h

→ RT/1 h is one cycle (RT refers to room temperature). Observe the

appearance change after the test.

6.8 Heat aging resistance

6.8.1 Sample

3 pieces of products.

6.8.2 Test equipment

Thermostatic oven, temperature accuracy is controlled at ±2°C.

6.8.3 Test steps

Take 3 pieces of products. Accurately measure the main assembly size or outer

Take 5 pieces of 250mm × 50mm samples on the product. Strip 100 mm at one

end.

6.12.1 Test equipment

Tensile machine, the accuracy is one level; thermostatic oven, low temperature

chamber, humidity chamber, temperature accuracy is controlled at ±2°C, and

the temperature accuracy is controlled at ±5%.

6.12.3 Test conditions

a) Delivery state.

b) Resistance to coldness and heat. perform 4 cycles of tests, of which (80

± 2 )°C/3 h → RT/1 h → (-40 ± 2)°C/3 h → RT/1 h → ( 55 ± 2 )°C,

95%RH/15 h → RT/1 h is one cycle;

c) Heat resistance. (80 ± 2)°C/168h;

d) Coldness resistance. (-40 ± 2)°C/24h.

6.12.4 Test steps

Place the sample treated according to the above test conditions at room

temperature for 2 h. After the decorative fabric is peeled off from the substrate,

one end of the substrate is clamped on the clamp on the tensile machine, and

one end of the decorative fabric is clamped on the clamp under the tension

machine. Perform the 180° peel test with professional fixture at (100 ± 10)

mm/min. Measure the maximum load at the time of peeling and record the 50-

mm wide sample peel force. Take the average value of the results of the five

samples as the test result, in one after the decimal point.

7 Inspection rules

7.1 Testing frequency and project

The testing of cellular board product shall determine the inspection frequency

and project according to quality control requirements.

7.2 Re-inspection

When one of the following conditions occurs, it shall be fully tested in

accordance with this Standard.

a) continuous production for more than half a year;

b) technique conditions change;

Annex A

(normative)

Odor test specification

A.1 Test devices, test conditions

A.1.1 Sample

The sample shall be prepared as much as possible in a considerable area or

volume. A 50 cm2 sample shall be cut from the part.

A.1.2 Test devices

Electric blast drying oven, temperature accuracy is controlled at ±2°C. Use

glass closed container with a volume of 1 L. The container must be cleaned and

dried before each test to ensure that the container is clean and tasteless. It is

recommended to use a glass container with a screw cap.

A.1.3 Test conditions

Method A. (40 ± 2)°C, add 50 mL of distilled water to the container, store (24 ±

1) h, support the sample with a metal bracket to ensure that the sample does

not touch the water.

Method B. (80 ± 2)°C, store (2 ± 0.1) h.

NOTE. Method B is a rapid test method. Under normal circumstances, the odor

at 80°C is greater than the odor at 40°C. If the part is considered to be in a

warm condition, no toxic or odor shall occur, then the test of Method A may not

be performed.

A.2 Test steps

Place the cut sample into a closed container and test it according to Method A

and Method B specified in A.1.3. After taking out, the smell shall be evaluated

as follows. The evaluation environment shall meet the requirements of GB/T

2918-1998.

For Method A. after the test container is taken out of the dry box, the first full-

time inspector opens the lid 30° ~ 45° on one side and sniffs the lid quickly to

ensure that the container is closed, then passes the container to the second

full-time inspector; the second full-time inspector shall pass the container to the

third full-time inspector for assessment. Each full...

Get QUOTATION in 1-minute: Click QC/T 1029-2016

Historical versions: QC/T 1029-2016

Preview True-PDF (Reload/Scroll if blank)

QC/T 1029-2016: Polypropylene(PP)cellular board production for vehicles

QC/T 1029-2016

QC

AUTOMOBILE INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 43.020

T 40

Polypropylene(PP) cellular

board production for vehicles

ISSUED ON. JANUARY 15, 2016

IMPLEMENTED ON. JULY 1, 2016

Issued by. Ministry of Industry and Information Technology of the

People's Republic of China

Annex.

Standard Numbers, Names, Starting Dates

of Implementation for 7 Automotive Industry Standards

SN Standard Numbers Standard Names

Replaced

Standard Numbers

Starting Date of

Implementation

215 QC/T 1025-2016 Performance Requirements and Bench Test Methods of Automatic Transmission Oil Pump July 1, 2016

216 QC/T 1026-2016 Performance and Determination of PVC Slush Skin of Automotive Instrument Panel July 1, 2016

217 QC/T 1027-2016 Technical Requirements for Film Mounted Motor Vehicle Glass July 1, 2016

218 QC/T 1028-2016 Performance Requirements and Test Methods of Vehicle Vacuum Check Valve July 1, 2016

219 QC/T 1029-2016 Polypropylene (PP) Cellular Board Production Vehicles July 1, 2016

220 QC/T 1030-2016 Bus Push-Out Emergency Window July 1, 2016

221 QC/T 678-2016 Pneumatic Driving Pump of Passenger Door of Bus QC/T 678-2001 July 1, 2016

Table of Contents

Foreword ... 5

1 Scope ... 6

2 Normative references ... 6

3 Terms and definitions ... 6

4 General requirements ... 7

5 Performance requirements ... 8

6 Test methods ... 10

7 Inspection rules ... 14

8 Storage ... 15

Annex A (normative) Odor test specification ... 16

Polypropylene(PP) cellular

board production for vehicles

1 Scope

This Standard specifies general requirements, performance requirements, test

methods, inspection rules and storage requirements of polypropylene (PP)

cellular board product for vehicles.

This Standard is applicable to double or triple layer polypropylene cellular board

product such as car roof, side rear cover, luggage cover.

2 Normative references

The following referenced documents are indispensable for the application of

this document. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any

amendments) applies.

GB/T 2918-1998, Plastics - Standard atmospheres for conditioning and

testing

GB 8410, Flammability of automotive interior materials

GB/T 9341-2008, Plastics - Determination of flexural properties

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1 substrate

double or triple layer polypropylene cellular board product without composite

fabric

3.2 the composite sheet

polypropylene cellular board product that decorative fabric is combined with the

substrate

6.6.1 Sample

Take 5 pieces of 120mm × 10mm samples on the product. The sample

thickness is the part thickness.

6.6.2 Test equipment

Tensile machine with a precision of level one.

6.6.3 Test steps

Accurately measure the width and thickness of the specimen with a caliper with

an accuracy of 0.02 mm or more. Test according to the provisions of GB/T 9341-

2008. The indenter radius is 5 mm, the span is 16 times the thickness of the

sample, and the test speed is (2.0 ± 0.4) mm/min. Double-layer polypropylene

cellular board head presses on the flat side.

6.7 Resistance to coldness and heat

6.7.1 Sample

3 pieces of products.

6.7.2 Test equipment

Thermostatic oven, low temperature box, humidity box or high and low

temperature humid heat box; temperature accuracy is controlled at ±2°C,

humidity accuracy is controlled at ±5%.

6.7.3 Test steps

Perform 4 cycles of tests when product in under assembly state, of which (80 ±

2 )°C/3 h → RT/1 h → (-40 ± 2)°C/3 h → RT/1 h → ( 55 ± 2 )°C, 95%RH/15 h

→ RT/1 h is one cycle (RT refers to room temperature). Observe the

appearance change after the test.

6.8 Heat aging resistance

6.8.1 Sample

3 pieces of products.

6.8.2 Test equipment

Thermostatic oven, temperature accuracy is controlled at ±2°C.

6.8.3 Test steps

Take 3 pieces of products. Accurately measure the main assembly size or outer

Take 5 pieces of 250mm × 50mm samples on the product. Strip 100 mm at one

end.

6.12.1 Test equipment

Tensile machine, the accuracy is one level; thermostatic oven, low temperature

chamber, humidity chamber, temperature accuracy is controlled at ±2°C, and

the temperature accuracy is controlled at ±5%.

6.12.3 Test conditions

a) Delivery state.

b) Resistance to coldness and heat. perform 4 cycles of tests, of which (80

± 2 )°C/3 h → RT/1 h → (-40 ± 2)°C/3 h → RT/1 h → ( 55 ± 2 )°C,

95%RH/15 h → RT/1 h is one cycle;

c) Heat resistance. (80 ± 2)°C/168h;

d) Coldness resistance. (-40 ± 2)°C/24h.

6.12.4 Test steps

Place the sample treated according to the above test conditions at room

temperature for 2 h. After the decorative fabric is peeled off from the substrate,

one end of the substrate is clamped on the clamp on the tensile machine, and

one end of the decorative fabric is clamped on the clamp under the tension

machine. Perform the 180° peel test with professional fixture at (100 ± 10)

mm/min. Measure the maximum load at the time of peeling and record the 50-

mm wide sample peel force. Take the average value of the results of the five

samples as the test result, in one after the decimal point.

7 Inspection rules

7.1 Testing frequency and project

The testing of cellular board product shall determine the inspection frequency

and project according to quality control requirements.

7.2 Re-inspection

When one of the following conditions occurs, it shall be fully tested in

accordance with this Standard.

a) continuous production for more than half a year;

b) technique conditions change;

Annex A

(normative)

Odor test specification

A.1 Test devices, test conditions

A.1.1 Sample

The sample shall be prepared as much as possible in a considerable area or

volume. A 50 cm2 sample shall be cut from the part.

A.1.2 Test devices

Electric blast drying oven, temperature accuracy is controlled at ±2°C. Use

glass closed container with a volume of 1 L. The container must be cleaned and

dried before each test to ensure that the container is clean and tasteless. It is

recommended to use a glass container with a screw cap.

A.1.3 Test conditions

Method A. (40 ± 2)°C, add 50 mL of distilled water to the container, store (24 ±

1) h, support the sample with a metal bracket to ensure that the sample does

not touch the water.

Method B. (80 ± 2)°C, store (2 ± 0.1) h.

NOTE. Method B is a rapid test method. Under normal circumstances, the odor

at 80°C is greater than the odor at 40°C. If the part is considered to be in a

warm condition, no toxic or odor shall occur, then the test of Method A may not

be performed.

A.2 Test steps

Place the cut sample into a closed container and test it according to Method A

and Method B specified in A.1.3. After taking out, the smell shall be evaluated

as follows. The evaluation environment shall meet the requirements of GB/T

2918-1998.

For Method A. after the test container is taken out of the dry box, the first full-

time inspector opens the lid 30° ~ 45° on one side and sniffs the lid quickly to

ensure that the container is closed, then passes the container to the second

full-time inspector; the second full-time inspector shall pass the container to the

third full-time inspector for assessment. Each full...

Share