1

/

of

12

PayPal, credit cards. Download editable-PDF & invoice in 1 second!

QC/T 1131-2020 English PDF (QCT1131-2020)

QC/T 1131-2020 English PDF (QCT1131-2020)

Regular price

$380.00 USD

Regular price

Sale price

$380.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click QC/T 1131-2020

Historical versions: QC/T 1131-2020

Preview True-PDF (Reload/Scroll if blank)

QC/T 1131-2020: Methods of Detecting Polycyclic Aromatic Hydrocarbons in Automotive Materials

QC/T 1131-2020

QC

AUTOMOBILE INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 43.040

T 40

Methods of Detecting Polycyclic Aromatic

Hydrocarbons in Automotive Materials

ISSUED ON: AUGUST 31, 2020

IMPLEMENTED ON: JANUARY 01, 2021

Issued by: Ministry of Industry and Information Technology of PRC

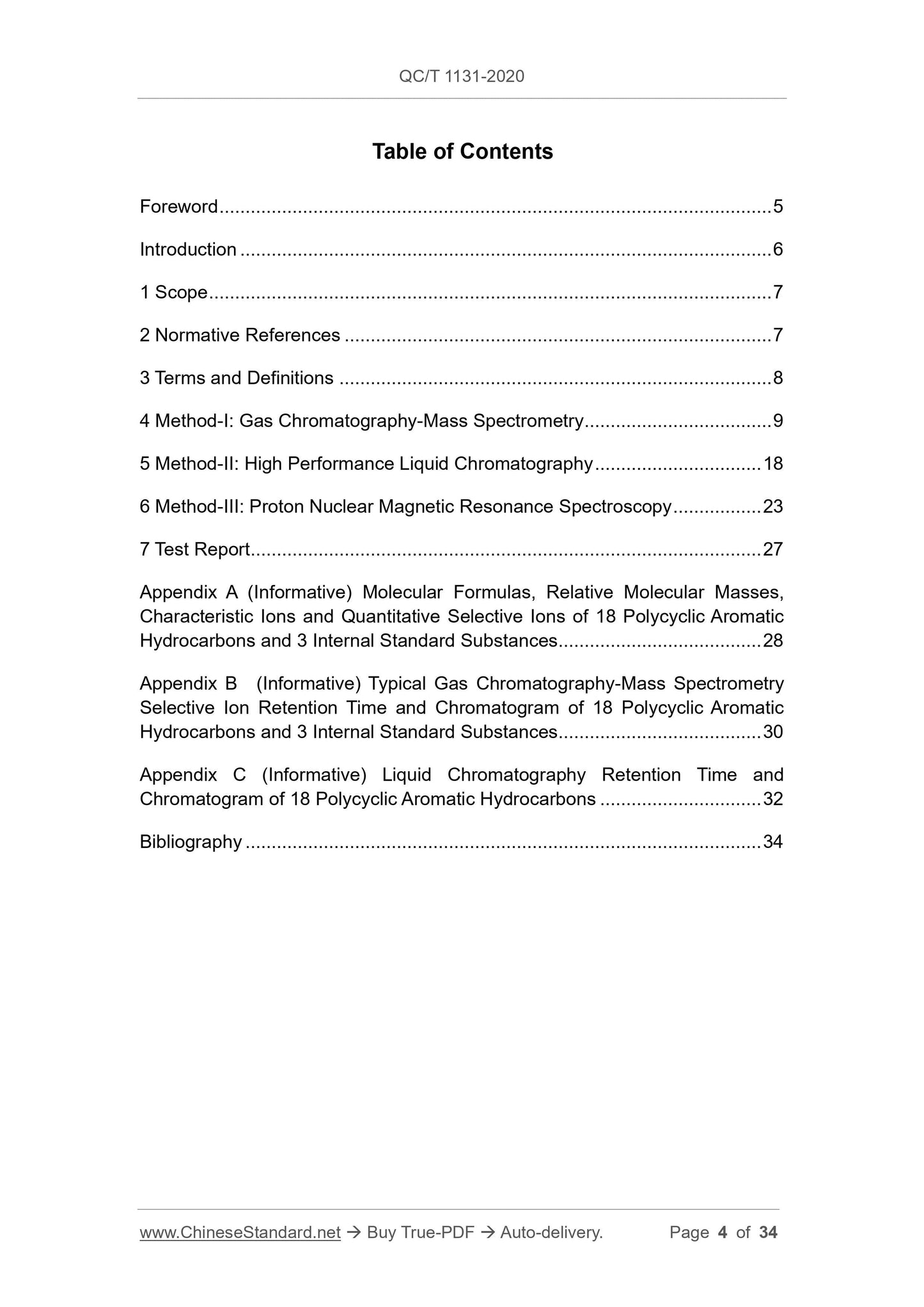

Table of Contents

Foreword ... 5

Introduction ... 6

1 Scope ... 7

2 Normative References ... 7

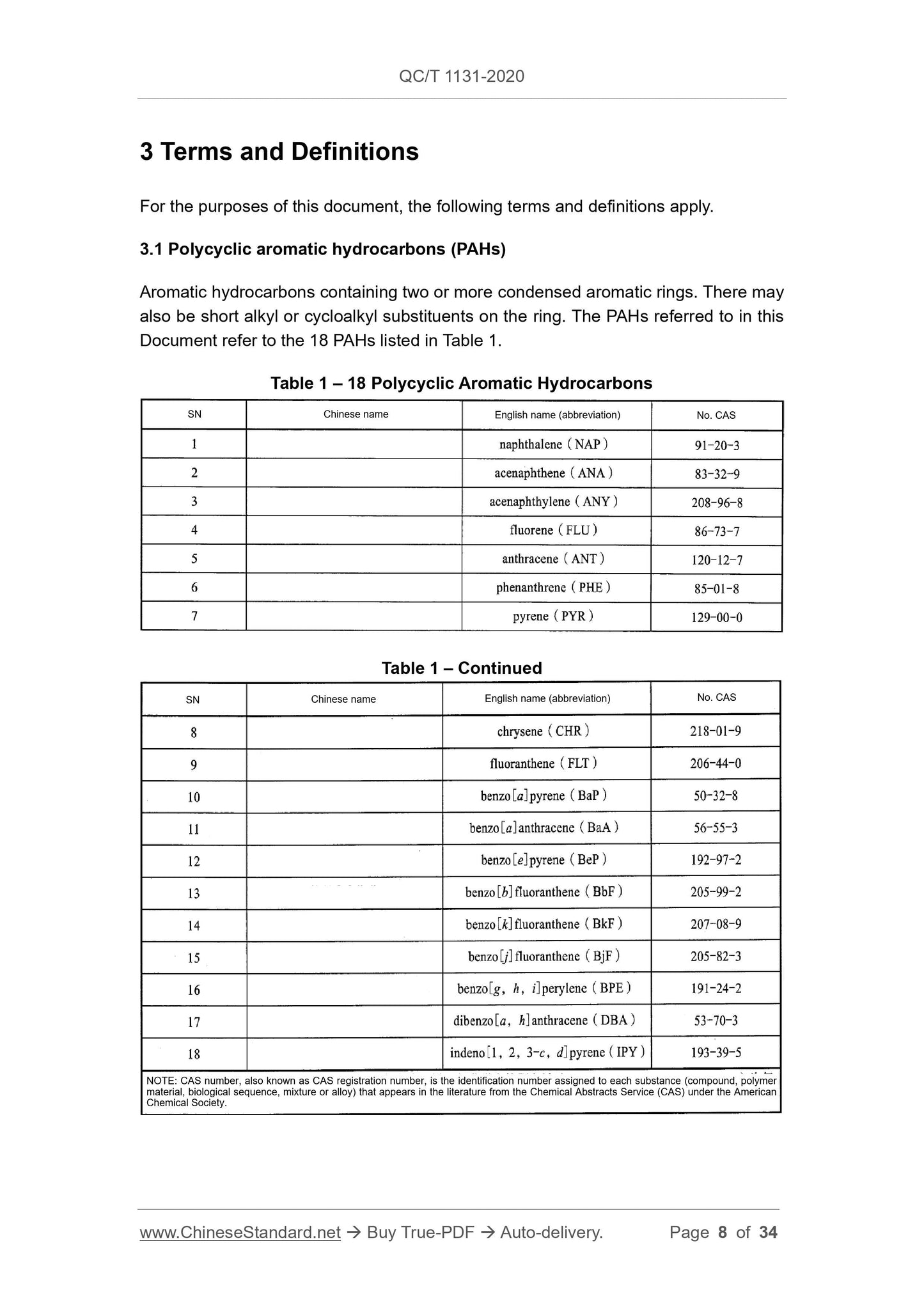

3 Terms and Definitions ... 8

4 Method-I: Gas Chromatography-Mass Spectrometry ... 9

5 Method-II: High Performance Liquid Chromatography ... 18

6 Method-III: Proton Nuclear Magnetic Resonance Spectroscopy ... 23

7 Test Report ... 27

Appendix A (Informative) Molecular Formulas, Relative Molecular Masses,

Characteristic Ions and Quantitative Selective Ions of 18 Polycyclic Aromatic

Hydrocarbons and 3 Internal Standard Substances... 28

Appendix B (Informative) Typical Gas Chromatography-Mass Spectrometry

Selective Ion Retention Time and Chromatogram of 18 Polycyclic Aromatic

Hydrocarbons and 3 Internal Standard Substances... 30

Appendix C (Informative) Liquid Chromatography Retention Time and

Chromatogram of 18 Polycyclic Aromatic Hydrocarbons ... 32

Bibliography ... 34

Methods of Detecting Polycyclic Aromatic

Hydrocarbons in Automotive Materials

Warning: The personnel using this Document shall have practical experience in

formal laboratory work. This Document does not point out all possible security

issues. The user is responsible for taking appropriate safety and health

measures and ensuring compliance with the conditions stipulated by relevant

national laws and regulations.

1 Scope

This Document specifies the terms and definitions of the methods of detecting

polycyclic aromatic hydrocarbons in automotive materials, as well as the detection

methods of gas chromatography-mass spectrometry, high performance liquid

chromatography, proton nuclear magnetic resonance spectroscopy, and the like

contents.

This Document is applicable to the qualitative and quantitative testing of 18 polycyclic

aromatic hydrocarbons in automotive materials. Among them, gas chromatography-

mass spectrometry is suitable for testing polycyclic aromatic hydrocarbons in textiles,

plastics, thermoplastic elastomers, rubber and leather materials; high performance

liquid chromatography is suitable for testing polycyclic aromatic hydrocarbons in

plastics and rubber materials; proton nuclear magnetic resonance spectroscopy is

suitable for testing polycyclic aromatic hydrocarbons in rubber materials.

2 Normative References

The following documents are essential to the application of this document. For the

dated documents, only the versions with the dates indicated are applicable to this

document; for the undated documents, only the latest version (including all the

amendments) is applicable to this document.

GB/T 3516 Rubber - Determination of Solvent Extract

GB/T 6682 Water for Analytical Laboratory Use - Specification and Test Methods

GB/T 29614-2013 Determination the Content of Polycyclic Aromatic

Hydrocarbons in Vulcanized Rubber Compounds

4 Method-I: Gas Chromatography-Mass Spectrometry

4.1 Method summary

After crushing, the specimen is added with organic solvent; extracted by ultrasonic or

microwave; if necessary, the extract is purified, concentrated, made constant volume,

and determined by gas chromatography-mass spectrometer (GC-MS), and qualitative

analysis is performed by retention time; use internal standard method or external

standard method to quantify.

4.2 Applicable material types

This method is suitable for the detection of polycyclic aromatic hydrocarbons in

materials such as textiles, plastics, thermoplastic elastomers, rubber and leather, etc.

4.3 Reagents and materials

4.3.1 n-hexane: chromatographically pure.

4.3.2 Toluene: chromatographically pure.

4.3.3 Acetone: chromatographically pure.

4.3.4 Dichloromethane: chromatographically pure.

4.3.5 Cyclohexane: chromatographically pure.

4.3.6 Sodium chloride: analytically pure.

4.3.7 Class-I water: comply with the provisions of GB/T 6682.

4.3.8 Helium gas: purity≥99.999%.

4.3.9 n-hexane + acetone (volume ratio 1: 1).

4.3.10 n-hexane + dichloromethane (volume ratio 3: 2).

4.3.11 Dimethyl sulfoxide: analytically pure, saturated by cyclohexane (see 4.3.5).

4.3.12 4% sodium chloride solution: 4g of sodium chloride (see 4.3.6) is dissolved in

100mL of Class-I water (see 4.3.7).

4.3.13 Silica gel solid phase extraction column: 500mg/3mL or equivalent; activate with

n-hexane (see 4.3.1) before use to keep it moist.

4.3.14 Standard solutions of 18 polycyclic aromatic hydrocarbons: purity≥95%.

4.4.7 Airtight microwave extractor.

4.4.8 Test tube with stopper.

4.4.9 Solid phase extraction device.

4.4.10 Rotary evaporator.

4.4.11 Thermometer: an accuracy of at least 1°C.

4.4.12 250mL separatory funnel.

4.4.13 Heating device: used to heat sodium chloride solution (see 4.3.12).

4.4.14 5mL volumetric flask.

4.4.15 Filter membrane: made of polytetrafluoroethylene, used to filter organic solvents,

with a pore size of 0.45µm or equivalent.

4.5 Preparation of specimen

Use scissors (or similar tools) to crush representative specimens into particles with a

particle size of less than 1mm and mix them. If necessary, use a liquid nitrogen crusher

(see 4.4.2) for crushing.

For the preparation of tire samples, refer to Appendix B in GB/T 29614-2013.

NOTE: In case of hard specimens, it is recommended to use a liquid nitrogen crusher for

crushing to prevent the loss of polycyclic aromatic hydrocarbons due to temperature rise during

the crushing process.

4.6 Extraction and purification

4.6.1 Extraction

4.6.1.1 Ultrasonic extraction

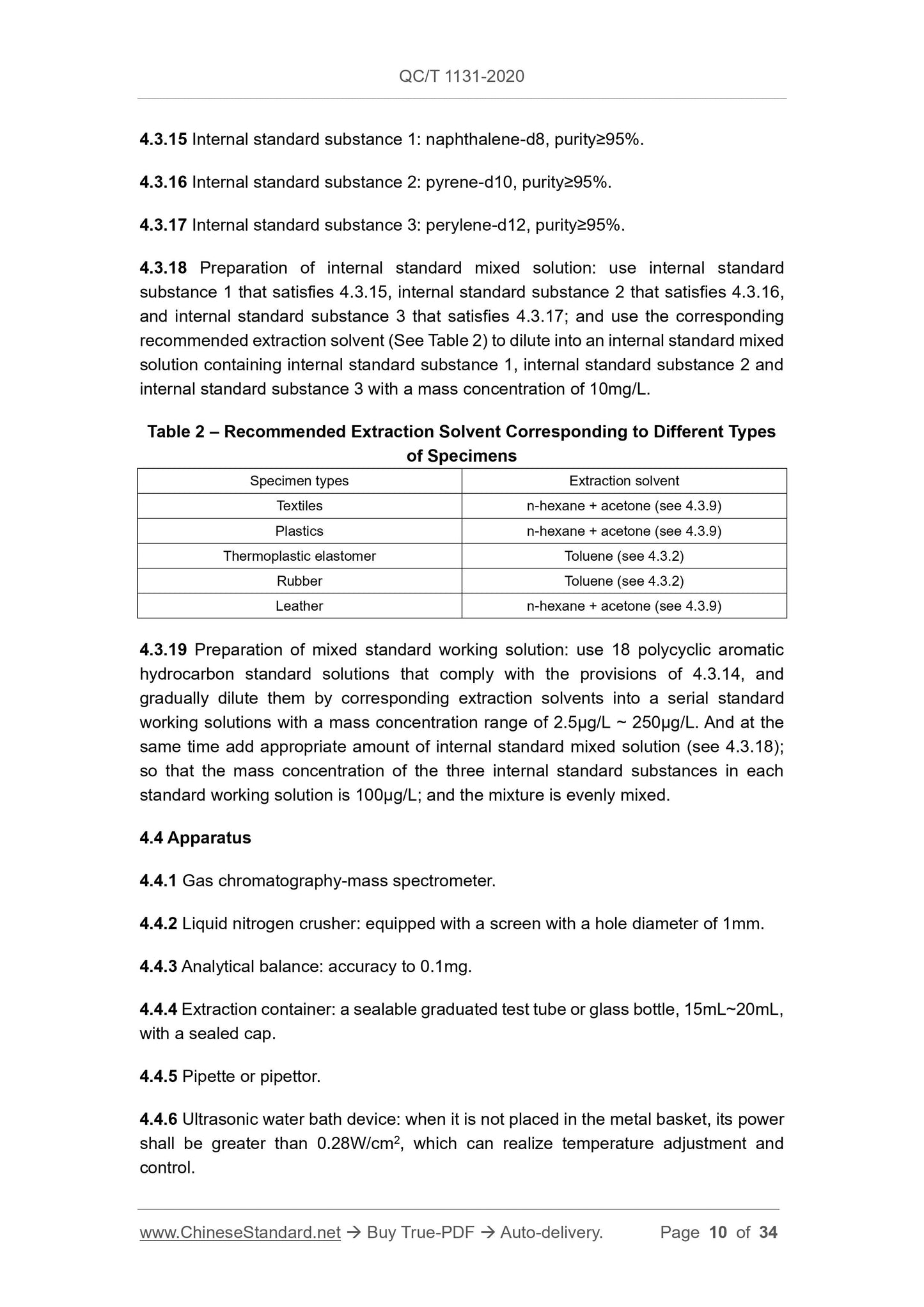

Weigh 0.2g of the specimen after cutting, accurate to 0.1mg; put it into a sealable

extraction container (see 4.4.4). Add 10mL (see Table 2) of extraction solvent with

mass concentration of internal standard substance 1 (see 4.3.15), internal standard

substance 2 (see 4.3.16) and internal standard substance 3 (see 4.3.17) of 50μg/L.

Fully soak the specimen; then seal the extraction container; and place it in an ultrasonic

water bath device (see 4.4.6); perform ultrasonic extraction at 60°C±2°C water

temperature for 60min±2min. After the extraction is completed, take out the extraction

container and cool to room temperature and mix well. If the extraction solution needs

to be purified, follow procedures in 4.6.2 for purification; if no purification is required,

place the extraction solution in a 35°C±2°C water bath and a vacuum of no less than

extraction column (see 4.3.13); and control the flow rate to 1 drop/2s. Then add 5mL

of n-hexane to rinse; discard the washing liquid. Elute the specimen by 5 mL of n-

hexane + dichloromethane (see 4.3.10) solution; and collect the eluate. Use a rotary

evaporator to evaporate the eluate to near dryness in a water bath of 35°C±2°C and a

vacuum of no less than 30kPa. Dissolve it by n-hexane + acetone and make constant

volume to 5mL. After being filtered by a filter membrane, the filtrate is analysed by a

gas chromatography-mass spectrometer. If necessary, analysis can be performed after

dilution.

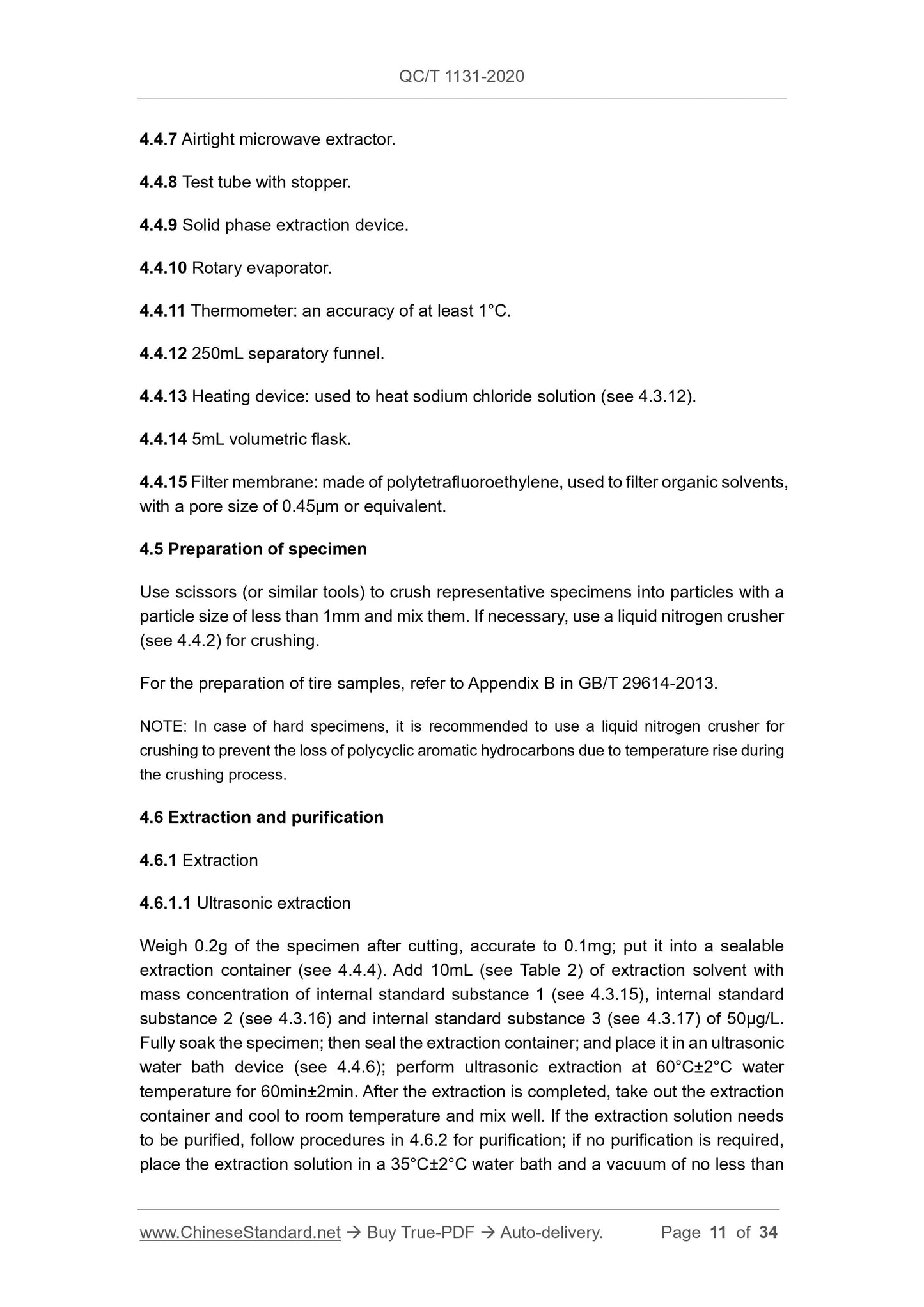

4.6.2.2 Purification of thermoplastic elastomer specimens

Use a rotary evaporator (heating temperature no higher than 40°C) to concentrate the

extract prepared as per the procedures in 4.6.1 to about 1mL; add 10mL of

cyclohexane (see 4.3.5) to dissolve the specimen; transfer th...

Get QUOTATION in 1-minute: Click QC/T 1131-2020

Historical versions: QC/T 1131-2020

Preview True-PDF (Reload/Scroll if blank)

QC/T 1131-2020: Methods of Detecting Polycyclic Aromatic Hydrocarbons in Automotive Materials

QC/T 1131-2020

QC

AUTOMOBILE INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 43.040

T 40

Methods of Detecting Polycyclic Aromatic

Hydrocarbons in Automotive Materials

ISSUED ON: AUGUST 31, 2020

IMPLEMENTED ON: JANUARY 01, 2021

Issued by: Ministry of Industry and Information Technology of PRC

Table of Contents

Foreword ... 5

Introduction ... 6

1 Scope ... 7

2 Normative References ... 7

3 Terms and Definitions ... 8

4 Method-I: Gas Chromatography-Mass Spectrometry ... 9

5 Method-II: High Performance Liquid Chromatography ... 18

6 Method-III: Proton Nuclear Magnetic Resonance Spectroscopy ... 23

7 Test Report ... 27

Appendix A (Informative) Molecular Formulas, Relative Molecular Masses,

Characteristic Ions and Quantitative Selective Ions of 18 Polycyclic Aromatic

Hydrocarbons and 3 Internal Standard Substances... 28

Appendix B (Informative) Typical Gas Chromatography-Mass Spectrometry

Selective Ion Retention Time and Chromatogram of 18 Polycyclic Aromatic

Hydrocarbons and 3 Internal Standard Substances... 30

Appendix C (Informative) Liquid Chromatography Retention Time and

Chromatogram of 18 Polycyclic Aromatic Hydrocarbons ... 32

Bibliography ... 34

Methods of Detecting Polycyclic Aromatic

Hydrocarbons in Automotive Materials

Warning: The personnel using this Document shall have practical experience in

formal laboratory work. This Document does not point out all possible security

issues. The user is responsible for taking appropriate safety and health

measures and ensuring compliance with the conditions stipulated by relevant

national laws and regulations.

1 Scope

This Document specifies the terms and definitions of the methods of detecting

polycyclic aromatic hydrocarbons in automotive materials, as well as the detection

methods of gas chromatography-mass spectrometry, high performance liquid

chromatography, proton nuclear magnetic resonance spectroscopy, and the like

contents.

This Document is applicable to the qualitative and quantitative testing of 18 polycyclic

aromatic hydrocarbons in automotive materials. Among them, gas chromatography-

mass spectrometry is suitable for testing polycyclic aromatic hydrocarbons in textiles,

plastics, thermoplastic elastomers, rubber and leather materials; high performance

liquid chromatography is suitable for testing polycyclic aromatic hydrocarbons in

plastics and rubber materials; proton nuclear magnetic resonance spectroscopy is

suitable for testing polycyclic aromatic hydrocarbons in rubber materials.

2 Normative References

The following documents are essential to the application of this document. For the

dated documents, only the versions with the dates indicated are applicable to this

document; for the undated documents, only the latest version (including all the

amendments) is applicable to this document.

GB/T 3516 Rubber - Determination of Solvent Extract

GB/T 6682 Water for Analytical Laboratory Use - Specification and Test Methods

GB/T 29614-2013 Determination the Content of Polycyclic Aromatic

Hydrocarbons in Vulcanized Rubber Compounds

4 Method-I: Gas Chromatography-Mass Spectrometry

4.1 Method summary

After crushing, the specimen is added with organic solvent; extracted by ultrasonic or

microwave; if necessary, the extract is purified, concentrated, made constant volume,

and determined by gas chromatography-mass spectrometer (GC-MS), and qualitative

analysis is performed by retention time; use internal standard method or external

standard method to quantify.

4.2 Applicable material types

This method is suitable for the detection of polycyclic aromatic hydrocarbons in

materials such as textiles, plastics, thermoplastic elastomers, rubber and leather, etc.

4.3 Reagents and materials

4.3.1 n-hexane: chromatographically pure.

4.3.2 Toluene: chromatographically pure.

4.3.3 Acetone: chromatographically pure.

4.3.4 Dichloromethane: chromatographically pure.

4.3.5 Cyclohexane: chromatographically pure.

4.3.6 Sodium chloride: analytically pure.

4.3.7 Class-I water: comply with the provisions of GB/T 6682.

4.3.8 Helium gas: purity≥99.999%.

4.3.9 n-hexane + acetone (volume ratio 1: 1).

4.3.10 n-hexane + dichloromethane (volume ratio 3: 2).

4.3.11 Dimethyl sulfoxide: analytically pure, saturated by cyclohexane (see 4.3.5).

4.3.12 4% sodium chloride solution: 4g of sodium chloride (see 4.3.6) is dissolved in

100mL of Class-I water (see 4.3.7).

4.3.13 Silica gel solid phase extraction column: 500mg/3mL or equivalent; activate with

n-hexane (see 4.3.1) before use to keep it moist.

4.3.14 Standard solutions of 18 polycyclic aromatic hydrocarbons: purity≥95%.

4.4.7 Airtight microwave extractor.

4.4.8 Test tube with stopper.

4.4.9 Solid phase extraction device.

4.4.10 Rotary evaporator.

4.4.11 Thermometer: an accuracy of at least 1°C.

4.4.12 250mL separatory funnel.

4.4.13 Heating device: used to heat sodium chloride solution (see 4.3.12).

4.4.14 5mL volumetric flask.

4.4.15 Filter membrane: made of polytetrafluoroethylene, used to filter organic solvents,

with a pore size of 0.45µm or equivalent.

4.5 Preparation of specimen

Use scissors (or similar tools) to crush representative specimens into particles with a

particle size of less than 1mm and mix them. If necessary, use a liquid nitrogen crusher

(see 4.4.2) for crushing.

For the preparation of tire samples, refer to Appendix B in GB/T 29614-2013.

NOTE: In case of hard specimens, it is recommended to use a liquid nitrogen crusher for

crushing to prevent the loss of polycyclic aromatic hydrocarbons due to temperature rise during

the crushing process.

4.6 Extraction and purification

4.6.1 Extraction

4.6.1.1 Ultrasonic extraction

Weigh 0.2g of the specimen after cutting, accurate to 0.1mg; put it into a sealable

extraction container (see 4.4.4). Add 10mL (see Table 2) of extraction solvent with

mass concentration of internal standard substance 1 (see 4.3.15), internal standard

substance 2 (see 4.3.16) and internal standard substance 3 (see 4.3.17) of 50μg/L.

Fully soak the specimen; then seal the extraction container; and place it in an ultrasonic

water bath device (see 4.4.6); perform ultrasonic extraction at 60°C±2°C water

temperature for 60min±2min. After the extraction is completed, take out the extraction

container and cool to room temperature and mix well. If the extraction solution needs

to be purified, follow procedures in 4.6.2 for purification; if no purification is required,

place the extraction solution in a 35°C±2°C water bath and a vacuum of no less than

extraction column (see 4.3.13); and control the flow rate to 1 drop/2s. Then add 5mL

of n-hexane to rinse; discard the washing liquid. Elute the specimen by 5 mL of n-

hexane + dichloromethane (see 4.3.10) solution; and collect the eluate. Use a rotary

evaporator to evaporate the eluate to near dryness in a water bath of 35°C±2°C and a

vacuum of no less than 30kPa. Dissolve it by n-hexane + acetone and make constant

volume to 5mL. After being filtered by a filter membrane, the filtrate is analysed by a

gas chromatography-mass spectrometer. If necessary, analysis can be performed after

dilution.

4.6.2.2 Purification of thermoplastic elastomer specimens

Use a rotary evaporator (heating temperature no higher than 40°C) to concentrate the

extract prepared as per the procedures in 4.6.1 to about 1mL; add 10mL of

cyclohexane (see 4.3.5) to dissolve the specimen; transfer th...

Share