1

/

of

11

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

QC/T 62-2021 English PDF (QC/T62-2021)

QC/T 62-2021 English PDF (QC/T62-2021)

Regular price

$350.00

Regular price

Sale price

$350.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

QC/T 62-2021: Shock absorber for motorcycles and mopeds

Delivery: 9 seconds. Download (& Email) true-PDF + Invoice.

Get Quotation: Click QC/T 62-2021 (Self-service in 1-minute)

Historical versions (Master-website): QC/T 62-2021

Preview True-PDF (Reload/Scroll-down if blank)

QC/T 62-2021

QC

AUTOMOTIVE INDUSTRY STANDARD

ICS 43.140

CCS T 83

Replacing QC/T 62-2007

Shock absorber for motorcycles and mopeds

ISSUED ON. AUGUST 21, 2021

IMPLEMENTED ON. FEBRUARY 01, 2022

Issued by. Ministry of Industry and Information Technology of PRC

Table of Contents

Foreword... 5

1 Scope... 7

2 Normative references... 7

3 Terms and definitions... 7

4 Requirements... 9

5 Test methods... 14

6 Inspection rules... 31

7 Product marking, packaging, transportation, storage... 32

Shock absorber for motorcycles and mopeds

1 Scope

This document specifies the requirements, test methods, inspection rules, product

marking, packaging, transportation, storage of shock absorber for motorcycle and

moped.

This document applies to shock absorbers for motorcycle and moped, which are

composed of springs, dampers, connectors (hereinafter referred to as shock absorbers).

Shock absorbers without hydraulic damping can also be implemented by referring to

the relevant provisions.

2 Normative references

The contents of the following documents constitute essential provisions of this

document through normative references in the text. Among them, for dated referenced

documents, only the version corresponding to the date applies to this document; for

undated referenced documents, the latest version (including all amendments) applies to

this document.

GB/T 6461 Methods for corrosion testing of metallic and other inorganic coatings

on metallic substrates - Rating of test specimens and manufactured articles subjected

to corrosion tests

GB/T 10125 Corrosion tests in artificial atmospheres - Salt spray tests

GB/T 11379 Metallic coatings - Electroplated coatings of chromium for engineering

purposes

GB/T 1239.2 Cold coiled helical springs technical specifications - Part 2.

Compressions spring

3 Terms and definitions

The following terms and definitions apply to this document.

3.1

Shock absorber

Components composed of springs, dampers, connectors.

4.1.2 The allowable deviation of the free length of the front shock absorber is ±2.5 mm;

the allowable deviation of the free length of the rear shock absorber is ±2.0 mm.

4.1.3 The surface of electroplating layer and coating shall be smooth, flat, uniform in

color.

4.1.4 The weld shall be smooth and uniform; it shall be free of defects such as weld

beading, burn through, slag inclusions, cracks, blisters, spatter.

4.1.5 There shall be no oil leakage from the shock absorber, whether it is placed flat,

upside down or during operation.

4.1.6 During the compression and stretching process, the dampers of front shock

absorber and rear shock absorber shall move flexibly without getting stuck; there shall

be no metal impact sound or abnormal friction.

4.2 Strength

4.2.1 The structural strength of the shock absorber shall meet the requirements of

product drawings and technical documents.

4.2.2 Riveting, folding and sealing, threaded connections, welding and other parts shall

be free of damage or fracture, under the tensile and compressive loads specified in

product drawings and technical documents.

4.3 Spring performance

4.3.1 Accuracy

The spring shall comply with the provisions of GB/T 1239.2.The accuracy level shall

not be lower than level 2.

4.3.2 Static characteristics

The static characteristics of the spring shall meet the following requirements.

a) When assessing the load at a specified height, the deformation shall be selected

within the range of 20% ~ 80% of the assessment stiffness section. The limit

deviation of the spring load is ±8%;

b) When assessing stiffness, the deformation shall be selected within the range of

25% ~ 75% of the stiffness assessment section; the limit deviation of spring

stiffness is ±8%;

c) The static characteristics of the spring are usually assessed based on the load at a

specified height; the stiffness can also be selected. However, the two cannot be

assessed at the same time.

4.3.3 Permanent deformation

After the spring is compressed to the maximum working load for three consecutive

times, its permanent deformation shall not be greater than 0.3% of the free height before

the test.

4.3.4 Fatigue

After the spring is continuously tested for 2 × 105 times at the working stroke, there

shall be no cracks or fractures; its permanent deformation shall not be greater than 2%

of the free height before the test.

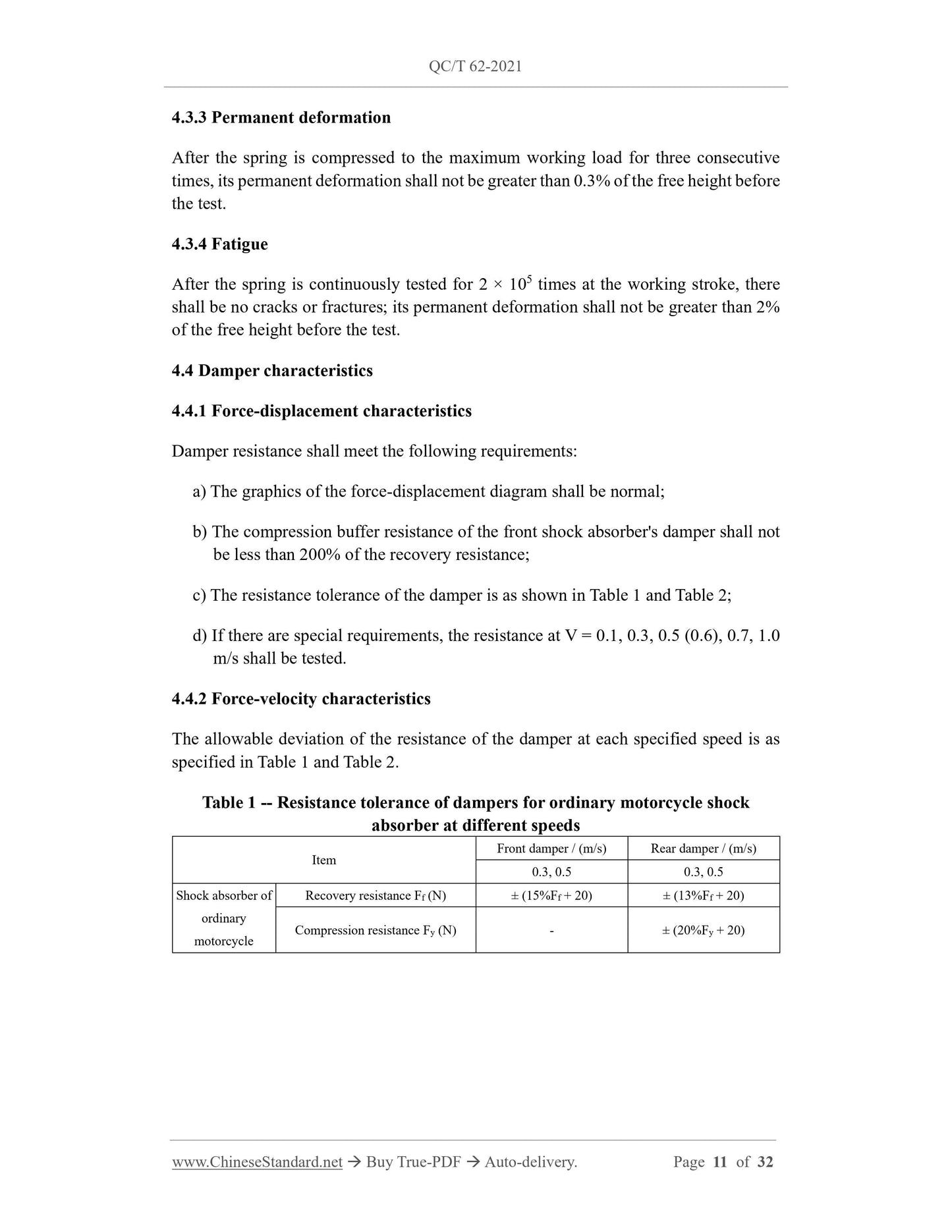

4.4 Damper characteristics

4.4.1 Force-displacement characteristics

Damper resistance shall meet the following requirements.

a) The graphics of the force-displacement diagram shall be normal;

b) The compression buffer resistance of the front shock absorber's damper shall not

be less than 200% of the recovery resistance;

c) The resistance tolerance of the damper is as shown in Table 1 and Table 2;

d) If there are special requirements, the resistance at V = 0.1, 0.3, 0.5 (0.6), 0.7, 1.0

m/s shall be tested.

4.4.2 Force-velocity characteristics

The allowable deviation of the resistance of the damper at each specified speed is as

specified in Table 1 and Table 2.

Table 1 -- Resistance tolerance of dampers for ordinary motorcycle shock

absorber at different speeds

Item Front damper / (m/s) Rear damper / (m/s) 0.3, 0.5 0.3, 0.5

Shock absorber of

ordinary

motorcycle

Recovery resistance Ff (N) ± (15%Ff + 20) ± (13%Ff + 20)

Compression resistance Fy (N) - ± (20%Fy + 20)

absorber shall comply with the product drawings and technical documents.

4.6 Gas recoil force

For gas-filled shock absorbers, the gas recoil force Fa shall comply with the product

drawings and technical documents, OR the technical requirements agreed between the

supplier and the buyer.

4.7 Static load characteristics

The vertical (or axial) static load characteristics of the shock absorber shall comply with

the product drawings and technical documents.

4.8 Anti-foam characteristics

During the test, the damper shall not have obvious abnormal noise; the maximum

fluctuation rate of the three measured force-displacement diagrams shall not exceed

25%.

4.9 Cushion pad durability

After the cushion pad is tested continuously for 2×105 times at the maximum allowable

deformation, there shall be no damage, deformation or wear; its load loss rate shall not

be greater than 30%.

4.10 Shock absorber durability

4.10.1 Vertical vibration

Durability during vertical vibration shall meet the following requirements.

a) During the test, there shall be no abnormal noise. After testing 1 × 106 times, the

parts shall be free of damage, deformation, abnormal wear;

b) If a lateral force test is required, the lateral force is 290 N ~ 490 N. After 200 h of

testing, the parts shall be free of damage, deformation, abnormal wear;

c) There is no oil leakage; there shall be no clearly visible oil layer on the surface of

the working section; if test b) is performed, slight traces of oil less than 12 mm

wide can be seen on the surface of the working section;

d) The resistance attenuation rate shall not be greater than 30%.

4.10.2 Drum vibration

The durability of the drum when vibrating shall meet the following requirements.

a) During the test, there shall be no abnormal noise. After 6 × 105 tests, the parts

shall be free of damage, deformation, abnormal wear;

b) Follow the provisions of 4.10.1c).

4.11 Sand, dust, muddy water resistance of dust cover

4.11.1 During the test, there shall be no abnormal noise. After 1×106 test, there shall be

no sand, dust or muddy water entering the inner lip of the dust seal and the lip of the oil

seal.

4.11.2 Parts shall be free from damage, deformation, abnormal wear.

4.12 Surface treatment

4.12.1 For neutral salt spray test (NSS) for engineering hard chromium coating, the 24

h (or 16 h for copper accelerated acetic salt spray test CASS) surface corrosion

resistance shall not be lower than level 8; for the accelerated acetic salt spray test of

decorative chromium coating copper, the 16 h surface corrosion resistance shall not be

lower than level 8; meanwhile it shall meet the requirements of GB/T 11379 and GB/T

6461, OR comply with product drawings and technical documents.

4.12.2 For the neutral salt spray test for colored zinc coating, the 48 h surface corrosion

resistance shall not be lower than level 5; for the neutral salt spray test for white zinc

coating, the 24 h surface corrosion resistance shall not be lower than level 5; meanwhile

it shall meet the requirements of GB/T 6461, OR comply with the product drawings and

technical documents.

4.12.3 After a 48-hour neutral salt spray test on coatings, anodic electrophoretic

coatings, etc., there shall be no corrosion products, blisters, swelling, peeling, or coating

softening along the 3.0 mm of one side of the notch, 6.0 mm in total, OR comply with

product drawings and technical documents.

4.12.4 For the accelerated acetic acid salt spray test of anodized copper coating, the 16

h surface corrosion resistance shall not be lower than level 7; meanwhile it shall meet

the requirements of GB/T 11379, GB/T 6461, OR comply with product drawings and

technical documents. There shall be no difference in color between the irradiated

surface and the non-irradiated surface during the lighting test; OR it shall comply with

the product drawings and technical documents.

5 Test methods

5.1 General inspection methods

5.1.1 Use measuring tools to check dimensions.

5.1.2 Check the appearance visually.

d) Draw the static characteristic curve when necessary;

e) After compressing the specimen to the maximum working load for 3 consecutive

times, measure the free height before and after the test; calculate the permanent

deformation rate.

5.4 Spring fatigue test

5.4.1 Device

Spring fatigue testing machine or shock absorber durability test bench.

5.4.2 Conditions

The test conditions are as follows.

a) Temperature. The test room is at room temperature; the test piece is at room

temperature;

b) Stroke. Working stroke;

c) Frequency. 1 Hz ~ 4 Hz;

d) Number of times. 2 × 105.

5.4.3 Steps

The test steps are as follows.

a) Install the test piece vertically on the test bench (the test piece shall be in a

preloaded state), with approximately one-half of the working stroke as the

midpoint of the test stroke;

b) Operate the test bench and vibrate, according to the specified stroke and frequency;

c) The test shall be conducted continuously without interruption, until the specified

number of times;

d) Measure the free height of the specimen before and after the test; calculate the

permanent deformation rate.

5.5 Force-displacement characteristic test

5.5.1 Device

The test device is as follows.

a) Simple harmonic displacement vibration mechanical or electro-hydraulic servo

test bench, which has a displacement measurement error of less than 0.5% and a

a) Temperature. According to the provisions of 5.5.2 a);

b) Stroke. According to the provisions of 5.5.2 b);

c) Speed. 1.0 m/s.

5.11.3 Steps

The test steps are as follows.

a) According to the provisions of 5.5.3 a), b), c);

b) Start the air cooling device to dissipate heat; operate the test bench to reciprocate

continuously for 100 times according to the specified stroke and speed; record the

force-displacement diagrams of the 98th, 99th, 100th times.

5.12 Test of cushion pad durability

5.12.1 Device

Special test bench.

5.12.2 Conditions

The test conditions are as follows.

a) Temperature. The test room is at room temperature; the specimen is at room

temperature;

b) Stroke. It is determined based on the maximum allowable deformation of the test

piece;

c) Frequency. 1 Hz ~ 2 Hz;

d) Number of times. 2 × 105.

5.12.3 Steps

The test steps are as follows.

a) Install the specimen vertically on the test bench, using the maximum allowable

deformation as the end of the test stroke;

b) Operate the test bench and vibrate according to the specified stroke and frequency;

c) The test shall be conducted continuously without interruption, until the specified

number of times;

d) According to the provisions of 5.3.3 a), b), d), measure the load value of the

c) According to the provisions of 5.13.3 b), c), d);

d) Check that there shall be no sand and dust, muddy water, oil stains inside the dust

seal lip and the oil seal lip of the test piece after the test; there is no abnormal

wear.

5.16 Corrosion resistance test of electroplating layer and coating layer

5.16.1 Device

Salt spray test chamber.

5.16.2 Conditions

It is carried out according to the provisions of GB/T 10125.

5.16.3 Steps

The test steps are as follows.

a) According to the provisions of GB/T 10125;

b) Before the test of the coating specimen, use the tip of the knife to carve a notch

on the main view surface at an intersection angle of about 30° and a depth to the

metal substrate. After the test, use clean water to rinse the specimen. Let it be

standing indoors for 2 hours. Use a 12 mm wide transparent tape (or similar tape),

one end of which is at right angles to the coating surface. Attach it completely to

the notch. After standing it for 1 ~ 2 minutes, quickly tear it off and check the

other portion than the 3.0 mm width on one side of the notch (totaling 6.0 mm),

to see whether there are corrosion products, blisters, swelling, peeling off, coating

softening.

5.17 Lighting test

5.17.1 Device

UV light test chamber

5.17.2 Conditions

The test conditions are as follows.

a) The distance between the lamp and the test piece is 65 cm ~ 75 cm; the distance

between the lamp and the lamp is 20 cm ~ 25 cm;

b) UV lamp 300 W, 400 h;

c) One cycle lasts for 24 hours, including 23 hours of lighting, 0.5 hours of water

spray, 0.5 hours of condensation.

5.17.3 Steps

The test steps are as follows.

a) Place the test piece in the ultraviolet light chamber. Raise the temperature to 70 °C.

Start timekeeping;

b) According to 5.17.2 c), test to the specified t...

Delivery: 9 seconds. Download (& Email) true-PDF + Invoice.

Get Quotation: Click QC/T 62-2021 (Self-service in 1-minute)

Historical versions (Master-website): QC/T 62-2021

Preview True-PDF (Reload/Scroll-down if blank)

QC/T 62-2021

QC

AUTOMOTIVE INDUSTRY STANDARD

ICS 43.140

CCS T 83

Replacing QC/T 62-2007

Shock absorber for motorcycles and mopeds

ISSUED ON. AUGUST 21, 2021

IMPLEMENTED ON. FEBRUARY 01, 2022

Issued by. Ministry of Industry and Information Technology of PRC

Table of Contents

Foreword... 5

1 Scope... 7

2 Normative references... 7

3 Terms and definitions... 7

4 Requirements... 9

5 Test methods... 14

6 Inspection rules... 31

7 Product marking, packaging, transportation, storage... 32

Shock absorber for motorcycles and mopeds

1 Scope

This document specifies the requirements, test methods, inspection rules, product

marking, packaging, transportation, storage of shock absorber for motorcycle and

moped.

This document applies to shock absorbers for motorcycle and moped, which are

composed of springs, dampers, connectors (hereinafter referred to as shock absorbers).

Shock absorbers without hydraulic damping can also be implemented by referring to

the relevant provisions.

2 Normative references

The contents of the following documents constitute essential provisions of this

document through normative references in the text. Among them, for dated referenced

documents, only the version corresponding to the date applies to this document; for

undated referenced documents, the latest version (including all amendments) applies to

this document.

GB/T 6461 Methods for corrosion testing of metallic and other inorganic coatings

on metallic substrates - Rating of test specimens and manufactured articles subjected

to corrosion tests

GB/T 10125 Corrosion tests in artificial atmospheres - Salt spray tests

GB/T 11379 Metallic coatings - Electroplated coatings of chromium for engineering

purposes

GB/T 1239.2 Cold coiled helical springs technical specifications - Part 2.

Compressions spring

3 Terms and definitions

The following terms and definitions apply to this document.

3.1

Shock absorber

Components composed of springs, dampers, connectors.

4.1.2 The allowable deviation of the free length of the front shock absorber is ±2.5 mm;

the allowable deviation of the free length of the rear shock absorber is ±2.0 mm.

4.1.3 The surface of electroplating layer and coating shall be smooth, flat, uniform in

color.

4.1.4 The weld shall be smooth and uniform; it shall be free of defects such as weld

beading, burn through, slag inclusions, cracks, blisters, spatter.

4.1.5 There shall be no oil leakage from the shock absorber, whether it is placed flat,

upside down or during operation.

4.1.6 During the compression and stretching process, the dampers of front shock

absorber and rear shock absorber shall move flexibly without getting stuck; there shall

be no metal impact sound or abnormal friction.

4.2 Strength

4.2.1 The structural strength of the shock absorber shall meet the requirements of

product drawings and technical documents.

4.2.2 Riveting, folding and sealing, threaded connections, welding and other parts shall

be free of damage or fracture, under the tensile and compressive loads specified in

product drawings and technical documents.

4.3 Spring performance

4.3.1 Accuracy

The spring shall comply with the provisions of GB/T 1239.2.The accuracy level shall

not be lower than level 2.

4.3.2 Static characteristics

The static characteristics of the spring shall meet the following requirements.

a) When assessing the load at a specified height, the deformation shall be selected

within the range of 20% ~ 80% of the assessment stiffness section. The limit

deviation of the spring load is ±8%;

b) When assessing stiffness, the deformation shall be selected within the range of

25% ~ 75% of the stiffness assessment section; the limit deviation of spring

stiffness is ±8%;

c) The static characteristics of the spring are usually assessed based on the load at a

specified height; the stiffness can also be selected. However, the two cannot be

assessed at the same time.

4.3.3 Permanent deformation

After the spring is compressed to the maximum working load for three consecutive

times, its permanent deformation shall not be greater than 0.3% of the free height before

the test.

4.3.4 Fatigue

After the spring is continuously tested for 2 × 105 times at the working stroke, there

shall be no cracks or fractures; its permanent deformation shall not be greater than 2%

of the free height before the test.

4.4 Damper characteristics

4.4.1 Force-displacement characteristics

Damper resistance shall meet the following requirements.

a) The graphics of the force-displacement diagram shall be normal;

b) The compression buffer resistance of the front shock absorber's damper shall not

be less than 200% of the recovery resistance;

c) The resistance tolerance of the damper is as shown in Table 1 and Table 2;

d) If there are special requirements, the resistance at V = 0.1, 0.3, 0.5 (0.6), 0.7, 1.0

m/s shall be tested.

4.4.2 Force-velocity characteristics

The allowable deviation of the resistance of the damper at each specified speed is as

specified in Table 1 and Table 2.

Table 1 -- Resistance tolerance of dampers for ordinary motorcycle shock

absorber at different speeds

Item Front damper / (m/s) Rear damper / (m/s) 0.3, 0.5 0.3, 0.5

Shock absorber of

ordinary

motorcycle

Recovery resistance Ff (N) ± (15%Ff + 20) ± (13%Ff + 20)

Compression resistance Fy (N) - ± (20%Fy + 20)

absorber shall comply with the product drawings and technical documents.

4.6 Gas recoil force

For gas-filled shock absorbers, the gas recoil force Fa shall comply with the product

drawings and technical documents, OR the technical requirements agreed between the

supplier and the buyer.

4.7 Static load characteristics

The vertical (or axial) static load characteristics of the shock absorber shall comply with

the product drawings and technical documents.

4.8 Anti-foam characteristics

During the test, the damper shall not have obvious abnormal noise; the maximum

fluctuation rate of the three measured force-displacement diagrams shall not exceed

25%.

4.9 Cushion pad durability

After the cushion pad is tested continuously for 2×105 times at the maximum allowable

deformation, there shall be no damage, deformation or wear; its load loss rate shall not

be greater than 30%.

4.10 Shock absorber durability

4.10.1 Vertical vibration

Durability during vertical vibration shall meet the following requirements.

a) During the test, there shall be no abnormal noise. After testing 1 × 106 times, the

parts shall be free of damage, deformation, abnormal wear;

b) If a lateral force test is required, the lateral force is 290 N ~ 490 N. After 200 h of

testing, the parts shall be free of damage, deformation, abnormal wear;

c) There is no oil leakage; there shall be no clearly visible oil layer on the surface of

the working section; if test b) is performed, slight traces of oil less than 12 mm

wide can be seen on the surface of the working section;

d) The resistance attenuation rate shall not be greater than 30%.

4.10.2 Drum vibration

The durability of the drum when vibrating shall meet the following requirements.

a) During the test, there shall be no abnormal noise. After 6 × 105 tests, the parts

shall be free of damage, deformation, abnormal wear;

b) Follow the provisions of 4.10.1c).

4.11 Sand, dust, muddy water resistance of dust cover

4.11.1 During the test, there shall be no abnormal noise. After 1×106 test, there shall be

no sand, dust or muddy water entering the inner lip of the dust seal and the lip of the oil

seal.

4.11.2 Parts shall be free from damage, deformation, abnormal wear.

4.12 Surface treatment

4.12.1 For neutral salt spray test (NSS) for engineering hard chromium coating, the 24

h (or 16 h for copper accelerated acetic salt spray test CASS) surface corrosion

resistance shall not be lower than level 8; for the accelerated acetic salt spray test of

decorative chromium coating copper, the 16 h surface corrosion resistance shall not be

lower than level 8; meanwhile it shall meet the requirements of GB/T 11379 and GB/T

6461, OR comply with product drawings and technical documents.

4.12.2 For the neutral salt spray test for colored zinc coating, the 48 h surface corrosion

resistance shall not be lower than level 5; for the neutral salt spray test for white zinc

coating, the 24 h surface corrosion resistance shall not be lower than level 5; meanwhile

it shall meet the requirements of GB/T 6461, OR comply with the product drawings and

technical documents.

4.12.3 After a 48-hour neutral salt spray test on coatings, anodic electrophoretic

coatings, etc., there shall be no corrosion products, blisters, swelling, peeling, or coating

softening along the 3.0 mm of one side of the notch, 6.0 mm in total, OR comply with

product drawings and technical documents.

4.12.4 For the accelerated acetic acid salt spray test of anodized copper coating, the 16

h surface corrosion resistance shall not be lower than level 7; meanwhile it shall meet

the requirements of GB/T 11379, GB/T 6461, OR comply with product drawings and

technical documents. There shall be no difference in color between the irradiated

surface and the non-irradiated surface during the lighting test; OR it shall comply with

the product drawings and technical documents.

5 Test methods

5.1 General inspection methods

5.1.1 Use measuring tools to check dimensions.

5.1.2 Check the appearance visually.

d) Draw the static characteristic curve when necessary;

e) After compressing the specimen to the maximum working load for 3 consecutive

times, measure the free height before and after the test; calculate the permanent

deformation rate.

5.4 Spring fatigue test

5.4.1 Device

Spring fatigue testing machine or shock absorber durability test bench.

5.4.2 Conditions

The test conditions are as follows.

a) Temperature. The test room is at room temperature; the test piece is at room

temperature;

b) Stroke. Working stroke;

c) Frequency. 1 Hz ~ 4 Hz;

d) Number of times. 2 × 105.

5.4.3 Steps

The test steps are as follows.

a) Install the test piece vertically on the test bench (the test piece shall be in a

preloaded state), with approximately one-half of the working stroke as the

midpoint of the test stroke;

b) Operate the test bench and vibrate, according to the specified stroke and frequency;

c) The test shall be conducted continuously without interruption, until the specified

number of times;

d) Measure the free height of the specimen before and after the test; calculate the

permanent deformation rate.

5.5 Force-displacement characteristic test

5.5.1 Device

The test device is as follows.

a) Simple harmonic displacement vibration mechanical or electro-hydraulic servo

test bench, which has a displacement measurement error of less than 0.5% and a

a) Temperature. According to the provisions of 5.5.2 a);

b) Stroke. According to the provisions of 5.5.2 b);

c) Speed. 1.0 m/s.

5.11.3 Steps

The test steps are as follows.

a) According to the provisions of 5.5.3 a), b), c);

b) Start the air cooling device to dissipate heat; operate the test bench to reciprocate

continuously for 100 times according to the specified stroke and speed; record the

force-displacement diagrams of the 98th, 99th, 100th times.

5.12 Test of cushion pad durability

5.12.1 Device

Special test bench.

5.12.2 Conditions

The test conditions are as follows.

a) Temperature. The test room is at room temperature; the specimen is at room

temperature;

b) Stroke. It is determined based on the maximum allowable deformation of the test

piece;

c) Frequency. 1 Hz ~ 2 Hz;

d) Number of times. 2 × 105.

5.12.3 Steps

The test steps are as follows.

a) Install the specimen vertically on the test bench, using the maximum allowable

deformation as the end of the test stroke;

b) Operate the test bench and vibrate according to the specified stroke and frequency;

c) The test shall be conducted continuously without interruption, until the specified

number of times;

d) According to the provisions of 5.3.3 a), b), d), measure the load value of the

c) According to the provisions of 5.13.3 b), c), d);

d) Check that there shall be no sand and dust, muddy water, oil stains inside the dust

seal lip and the oil seal lip of the test piece after the test; there is no abnormal

wear.

5.16 Corrosion resistance test of electroplating layer and coating layer

5.16.1 Device

Salt spray test chamber.

5.16.2 Conditions

It is carried out according to the provisions of GB/T 10125.

5.16.3 Steps

The test steps are as follows.

a) According to the provisions of GB/T 10125;

b) Before the test of the coating specimen, use the tip of the knife to carve a notch

on the main view surface at an intersection angle of about 30° and a depth to the

metal substrate. After the test, use clean water to rinse the specimen. Let it be

standing indoors for 2 hours. Use a 12 mm wide transparent tape (or similar tape),

one end of which is at right angles to the coating surface. Attach it completely to

the notch. After standing it for 1 ~ 2 minutes, quickly tear it off and check the

other portion than the 3.0 mm width on one side of the notch (totaling 6.0 mm),

to see whether there are corrosion products, blisters, swelling, peeling off, coating

softening.

5.17 Lighting test

5.17.1 Device

UV light test chamber

5.17.2 Conditions

The test conditions are as follows.

a) The distance between the lamp and the test piece is 65 cm ~ 75 cm; the distance

between the lamp and the lamp is 20 cm ~ 25 cm;

b) UV lamp 300 W, 400 h;

c) One cycle lasts for 24 hours, including 23 hours of lighting, 0.5 hours of water

spray, 0.5 hours of condensation.

5.17.3 Steps

The test steps are as follows.

a) Place the test piece in the ultraviolet light chamber. Raise the temperature to 70 °C.

Start timekeeping;

b) According to 5.17.2 c), test to the specified t...

Share