1

/

of

12

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

QC/T 792-2022 English PDF (QC/T792-2022)

QC/T 792-2022 English PDF (QC/T792-2022)

Regular price

$305.00 USD

Regular price

Sale price

$305.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click QC/T 792-2022

Historical versions: QC/T 792-2022

Preview True-PDF (Reload/Scroll if blank)

QC/T 792-2022: Motors and controllers for electric motorcycles and electric mopeds

QC/T 792-2022

QC

AUTOMOBILE INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 43.140

CCS T 85

Replacing QC/T 792-2007

Motors and controllers for electric motorcycles and electric mopeds

ISSUED ON: APRIL 08, 2022

IMPLEMENTED ON: OCTOBER 01, 2022

Issued by: Ministry of Industry and Information Technology of PRC

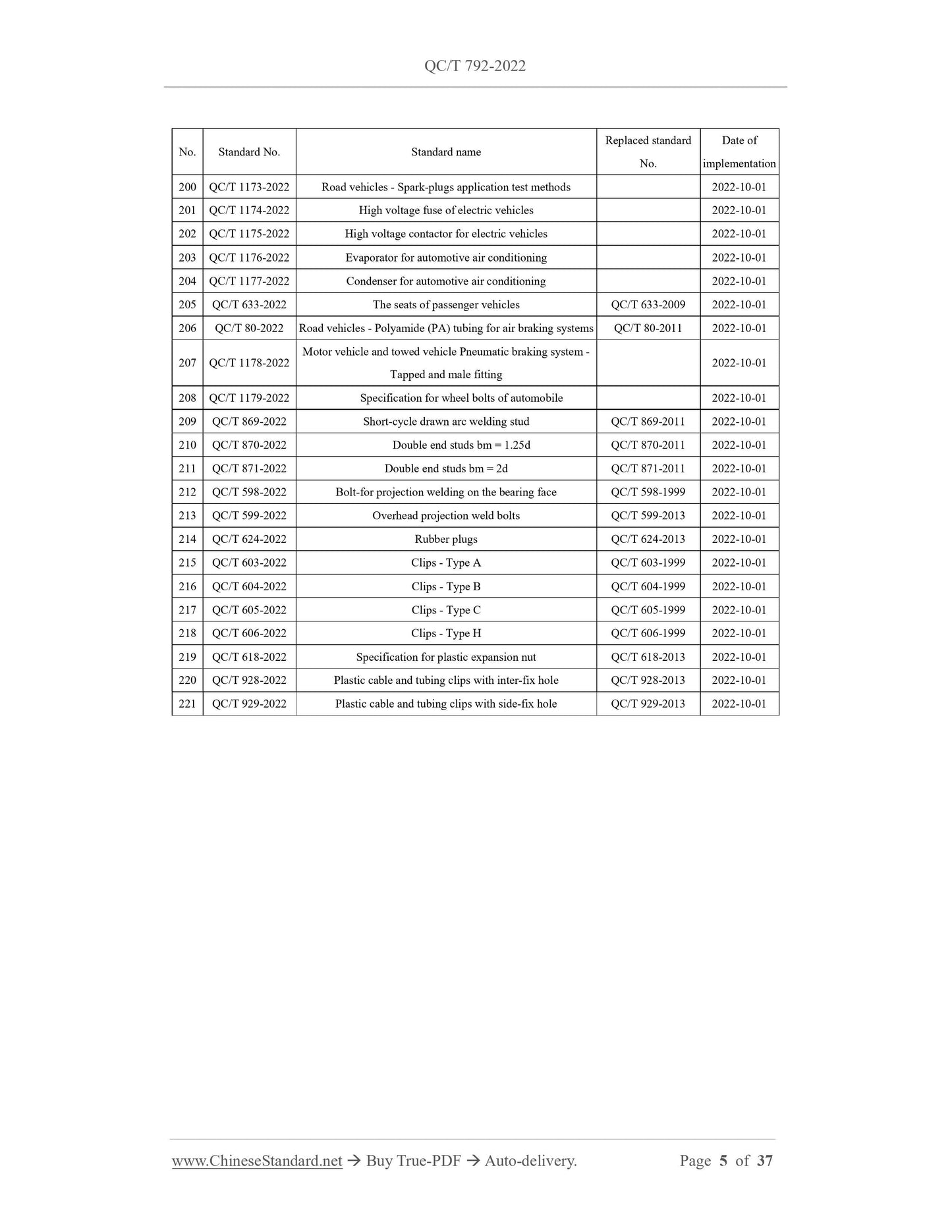

Table of Contents

Foreword ... 6

1 Scope ... 9

2 Normative references ... 9

3 Terms and definitions ... 10

4 Product model compilation ... 12

5 Requirements ... 14

6 Test method ... 23

7 Inspection rules ... 34

Motors and controllers for electric motorcycles and electric mopeds

1 Scope

This document specifies the product model compilation, requirements, test methods,

inspection rules for motors (including motors including reducers) and controllers for

electric motorcycles and electric mopeds.

This document applies to the motors for electric motorcycles and electric mopeds

(hereinafter referred to as motors) and controllers.

2 Normative references

The contents of the following documents constitute the essential provisions of this

document through normative references in the text. Among them, for dated reference

documents, only the version corresponding to the H issue is applicable to this document;

for undated reference documents, the latest version (including all amendments) is

applicable to this document.

GB/T 755 Rotating electrical machines - Rating and performance

GB/T 1184-1996 Geometrical tolerancing - Geometrical tolerance for features

without individual tolerance indications

GB/T 2423.5-2019 Environmental testing - Part 2: Test methods - Test Ea and

guidance: Shock (IEC 60068-2-27:2008; IDT)

GB/T 2423.17-2008 Environmental testing for electric and electronic products - Part

2: Test method - Test Ka: Salt mist (IEC 60068-2-11:1981, IDT)

GB/T 4208-2017 Degrees of protection provided by enclosure (IP code)

GB/T 4942-2021 Degrees of protection provided by the integral design of rotating

electrical machines (IP code) - Classification

GB/T 5171.21-2016 Small power motors - Part 21: General test methods

GB/T 10069.1-2006 Measurement of airborne noise emitted by rotating electrical

machines and the noise limits - Part 1: Method for the measurement of airborne

noise emitted by rotating electrical machines (ISO 1680:1999, MOD)

GB/T 10069.3-2008 Measurement of airborne noise emitted by rotating electrical

machines and the noise limits - Part 3: Noise limits

GB/T 13202-2015 Series of motorcycle rims (ISO 4249-3:2010, ISO 5995-2:1988,

ISO 6054-2:1990, MOD)

GB/T 18387 Limits and test method of magnetic and electric field strength from

electric vehicles

GB/T 18488.1-2015 Drive motor system for electric vehicles - Part 1: Specification

GB/T 18488.2-2015 Drive motor system for electric vehicles - Part 2: Test methods

GB 34660 Road vehicles - Requirements and test methods of electromagnetic

compatibility

ISO 11898.1 Road vehicle - Controller Area Network (CAN) - Part 1: Data link layer

and physical signaling

ISO 11898.2 Road vehicle - Controller Area Network (CAN) - Part 2: High-speed

medium access unit

ISO 14229.2 Road vehicles - Unified Diagnostic Services (UDS) - Part2 : Session

layer services

ISO 15765.2 Road vehicles - Diagnostics on Controller Area Networks (CAN) - Part

2: Network layer services

ISO 16845.1 Road vehicles - Controller Area Network (CAN) conformance test plan

- Part 1: Data link layer and physical signaling

3 Terms and definitions

The following terms and definitions apply to this document.

3.1

Wheel with the outer shell of motor integrated

The motorcycle driving wheel, whose wheel hub and motor casing are made into an

integral part.

3.2

Continuous torque

The specified maximum torque that can work continuously for 30 minutes.

ZK - Brushed DC motor controller;

ZWK- Brushless DC motor controller;

YCK - Permanent magnet synchronous motor controller;

JYK - AC asynchronous motor controller;

KCK - Switched reluctance motor controller.

4.2.2 Voltage level

The controller adopts DC voltage input. The voltage level is indicated by the nominal

voltage value of the DC bus of the controller. If it is less than three digits, add a 0 in

front.

4.2.3 Current level code

The current level of the controller is indicated by the integer value (three Arabic

numerals) of the maximum DC input current of the controller. If there are less than three

digits, add a 0 in front.

4.2.4 Derivative code

The derivative codes are A, B...

Note: The letters I, N, O, Y are not used.

5 Requirements

5.1 General requirements

The motor shall be idling flexibly, without fixed-rotor friction or abnormal noises (such

as periodic abnormal noises, abnormal noises caused by damaged bearings, or abnormal

noises caused by foreign objects stuck in the rotating parts, etc.). The controller shall

have safety management functions, such as communication, fault diagnosis, calibration

and program refresh, which meet the whole vehicle requirements.

5.2 Environmental conditions for use

The motor and controller shall be able to work normally under the following conditions:

- Ambient temperature: -25 °C ~ 60 °C;

- Relative humidity: 0% ~ 100%.

5.3 Rated voltage

The rated voltage shall be the nominal voltage of the DC bus of the controller.

5.4 Appearance

The surface of the motor and controller shall be free of rust, bruises, cracks, peeling of

the coating. The fasteners shall be firmly connected. The lead wires shall be intact. The

contents of nameplate of the motor and controller shall be correct; the words shall be

clear; the background color shall not fade.

5.5 External dimensions and installation dimensions

The external dimensions and installation dimensions of the motor and controller shall

comply with the provisions of the technical documents of the enterprise.

5.6 Assembly requirements

5.6.1 Motor's axial clearance

The axial clearance of the power output end of the direct drive motor, non-direct drive

independent motor, motor and reducer integrated machine shall not be greater than 0.3

mm.

5.6.2 Radial circular runout

The radial circular runout of the output shaft of the inner rotor motors, such as direct

drive motors and non-direct drive independent motors, shall meet the tolerance

requirements of level 6 in GB/T 1184-1996. For the motor and reducer integrated

machine, the radial circular runout of the output shaft of the reducer shall meet the

tolerance requirements of level 6 in GB/T 1184-1996 standard.

5.6.3 End face runout

The end face runout of the outer edge of the integrated wheel-mounted motor wheel

shall not exceed 1 mm.

5.7 Sealing performance of cooling circuit in liquid cooling system

For liquid-cooled motors and controllers, there shall be no leakage, when subjected to

a pressure not lower than 200 kPa.

5.8 Lead wires and connectors

5.8.1 Color of lead wire

Among the three-phase main winding wires of brushless DC motors, permanent magnet

synchronous motors, switched reluctance motors, the U phase wires shall have obvious

blue marks; the V phase wires shall have obvious green marks; the W phase wires shall

have obvious yellow marks.

5.14 Direction of rotation of the motor rotor

The direction of rotation of the motor rotor shall comply with the provisions of the

product technical documentation.

5.15 No-load current

The motor runs at the rated voltage and at the speed specified in th...

Get QUOTATION in 1-minute: Click QC/T 792-2022

Historical versions: QC/T 792-2022

Preview True-PDF (Reload/Scroll if blank)

QC/T 792-2022: Motors and controllers for electric motorcycles and electric mopeds

QC/T 792-2022

QC

AUTOMOBILE INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 43.140

CCS T 85

Replacing QC/T 792-2007

Motors and controllers for electric motorcycles and electric mopeds

ISSUED ON: APRIL 08, 2022

IMPLEMENTED ON: OCTOBER 01, 2022

Issued by: Ministry of Industry and Information Technology of PRC

Table of Contents

Foreword ... 6

1 Scope ... 9

2 Normative references ... 9

3 Terms and definitions ... 10

4 Product model compilation ... 12

5 Requirements ... 14

6 Test method ... 23

7 Inspection rules ... 34

Motors and controllers for electric motorcycles and electric mopeds

1 Scope

This document specifies the product model compilation, requirements, test methods,

inspection rules for motors (including motors including reducers) and controllers for

electric motorcycles and electric mopeds.

This document applies to the motors for electric motorcycles and electric mopeds

(hereinafter referred to as motors) and controllers.

2 Normative references

The contents of the following documents constitute the essential provisions of this

document through normative references in the text. Among them, for dated reference

documents, only the version corresponding to the H issue is applicable to this document;

for undated reference documents, the latest version (including all amendments) is

applicable to this document.

GB/T 755 Rotating electrical machines - Rating and performance

GB/T 1184-1996 Geometrical tolerancing - Geometrical tolerance for features

without individual tolerance indications

GB/T 2423.5-2019 Environmental testing - Part 2: Test methods - Test Ea and

guidance: Shock (IEC 60068-2-27:2008; IDT)

GB/T 2423.17-2008 Environmental testing for electric and electronic products - Part

2: Test method - Test Ka: Salt mist (IEC 60068-2-11:1981, IDT)

GB/T 4208-2017 Degrees of protection provided by enclosure (IP code)

GB/T 4942-2021 Degrees of protection provided by the integral design of rotating

electrical machines (IP code) - Classification

GB/T 5171.21-2016 Small power motors - Part 21: General test methods

GB/T 10069.1-2006 Measurement of airborne noise emitted by rotating electrical

machines and the noise limits - Part 1: Method for the measurement of airborne

noise emitted by rotating electrical machines (ISO 1680:1999, MOD)

GB/T 10069.3-2008 Measurement of airborne noise emitted by rotating electrical

machines and the noise limits - Part 3: Noise limits

GB/T 13202-2015 Series of motorcycle rims (ISO 4249-3:2010, ISO 5995-2:1988,

ISO 6054-2:1990, MOD)

GB/T 18387 Limits and test method of magnetic and electric field strength from

electric vehicles

GB/T 18488.1-2015 Drive motor system for electric vehicles - Part 1: Specification

GB/T 18488.2-2015 Drive motor system for electric vehicles - Part 2: Test methods

GB 34660 Road vehicles - Requirements and test methods of electromagnetic

compatibility

ISO 11898.1 Road vehicle - Controller Area Network (CAN) - Part 1: Data link layer

and physical signaling

ISO 11898.2 Road vehicle - Controller Area Network (CAN) - Part 2: High-speed

medium access unit

ISO 14229.2 Road vehicles - Unified Diagnostic Services (UDS) - Part2 : Session

layer services

ISO 15765.2 Road vehicles - Diagnostics on Controller Area Networks (CAN) - Part

2: Network layer services

ISO 16845.1 Road vehicles - Controller Area Network (CAN) conformance test plan

- Part 1: Data link layer and physical signaling

3 Terms and definitions

The following terms and definitions apply to this document.

3.1

Wheel with the outer shell of motor integrated

The motorcycle driving wheel, whose wheel hub and motor casing are made into an

integral part.

3.2

Continuous torque

The specified maximum torque that can work continuously for 30 minutes.

ZK - Brushed DC motor controller;

ZWK- Brushless DC motor controller;

YCK - Permanent magnet synchronous motor controller;

JYK - AC asynchronous motor controller;

KCK - Switched reluctance motor controller.

4.2.2 Voltage level

The controller adopts DC voltage input. The voltage level is indicated by the nominal

voltage value of the DC bus of the controller. If it is less than three digits, add a 0 in

front.

4.2.3 Current level code

The current level of the controller is indicated by the integer value (three Arabic

numerals) of the maximum DC input current of the controller. If there are less than three

digits, add a 0 in front.

4.2.4 Derivative code

The derivative codes are A, B...

Note: The letters I, N, O, Y are not used.

5 Requirements

5.1 General requirements

The motor shall be idling flexibly, without fixed-rotor friction or abnormal noises (such

as periodic abnormal noises, abnormal noises caused by damaged bearings, or abnormal

noises caused by foreign objects stuck in the rotating parts, etc.). The controller shall

have safety management functions, such as communication, fault diagnosis, calibration

and program refresh, which meet the whole vehicle requirements.

5.2 Environmental conditions for use

The motor and controller shall be able to work normally under the following conditions:

- Ambient temperature: -25 °C ~ 60 °C;

- Relative humidity: 0% ~ 100%.

5.3 Rated voltage

The rated voltage shall be the nominal voltage of the DC bus of the controller.

5.4 Appearance

The surface of the motor and controller shall be free of rust, bruises, cracks, peeling of

the coating. The fasteners shall be firmly connected. The lead wires shall be intact. The

contents of nameplate of the motor and controller shall be correct; the words shall be

clear; the background color shall not fade.

5.5 External dimensions and installation dimensions

The external dimensions and installation dimensions of the motor and controller shall

comply with the provisions of the technical documents of the enterprise.

5.6 Assembly requirements

5.6.1 Motor's axial clearance

The axial clearance of the power output end of the direct drive motor, non-direct drive

independent motor, motor and reducer integrated machine shall not be greater than 0.3

mm.

5.6.2 Radial circular runout

The radial circular runout of the output shaft of the inner rotor motors, such as direct

drive motors and non-direct drive independent motors, shall meet the tolerance

requirements of level 6 in GB/T 1184-1996. For the motor and reducer integrated

machine, the radial circular runout of the output shaft of the reducer shall meet the

tolerance requirements of level 6 in GB/T 1184-1996 standard.

5.6.3 End face runout

The end face runout of the outer edge of the integrated wheel-mounted motor wheel

shall not exceed 1 mm.

5.7 Sealing performance of cooling circuit in liquid cooling system

For liquid-cooled motors and controllers, there shall be no leakage, when subjected to

a pressure not lower than 200 kPa.

5.8 Lead wires and connectors

5.8.1 Color of lead wire

Among the three-phase main winding wires of brushless DC motors, permanent magnet

synchronous motors, switched reluctance motors, the U phase wires shall have obvious

blue marks; the V phase wires shall have obvious green marks; the W phase wires shall

have obvious yellow marks.

5.14 Direction of rotation of the motor rotor

The direction of rotation of the motor rotor shall comply with the provisions of the

product technical documentation.

5.15 No-load current

The motor runs at the rated voltage and at the speed specified in th...

Share