1

/

of

5

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

SB/T 10381-2012 English PDF (SB/T10381-2012)

SB/T 10381-2012 English PDF (SB/T10381-2012)

Regular price

$150.00 USD

Regular price

Sale price

$150.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click SB/T 10381-2012

Historical versions: SB/T 10381-2012

Preview True-PDF (Reload/Scroll if blank)

SB/T 10381-2012: Vacuumized soft package for pot-roast meat products

SB/T 10381-2012

SB

DOMESTIC TRADE INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 67.120.10

X 22

Record No.. 37216-2012

Replacing SB/T 10381-2005

Vacuumized soft package for pot-roast meat products

真空软包装卤肉制品

ISSUED ON. AUGUST 1, 2012

IMPLEMENTED ON. NOVEMBER 1, 2012

Issued by. People's Republic of China Ministry of Commerce

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Terms and definitions ... 5

4 Raw materials, excipients and food additives ... 6

5 Technical requirements ... 6

6 Hygiene requirements for production processes ... 7

7 Inspection methods ... 7

8 Inspection rules ... 8

9 Labels, marks, packaging, storage, transport and sales ... 10

10 Recall ... 10

Vacuumized soft package for pot-roast meat products

1 Scope

This Standard specifies the terms and definitions, raw materials, excipients and

food additives, technical requirements, hygiene requirements for production

processes, inspection methods, inspection rules, labels, marks, packaging,

transport, storage, sales and recall requirements of vacuumized soft package

for pot-roast meat products.

This Standard is applicable to the production, inspection and sales for the

product defined in 3.1.

2 Normative references

The following referenced documents are indispensable for the application of

this document. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any

amendments) applies.

GB/T 191, Packaging and storage marks

GB 2726, Hygienic standard for cooked meat

GB 2760, National Food Safety Standard - Standards for Uses of Food

Additives

GB/T 4789.17, Microbiological examination of food hygiene - Examination of

meat and meat products

GB/T 4789.26, Microbiological examination of food hygiene - Examination of

commercial sterilization of canned food

GB 5009.5, National Food Safety Standard - Determination of Protein in

Foods

GB/T 5009.11, Determination of total arsenic and abio-arsenic in food

GB 5009.12, Method for determination of lead in food

GB/T 5009.15, Determination of cadmium in foods

GB/T 5009.17, Method for determination of total mercury in foods

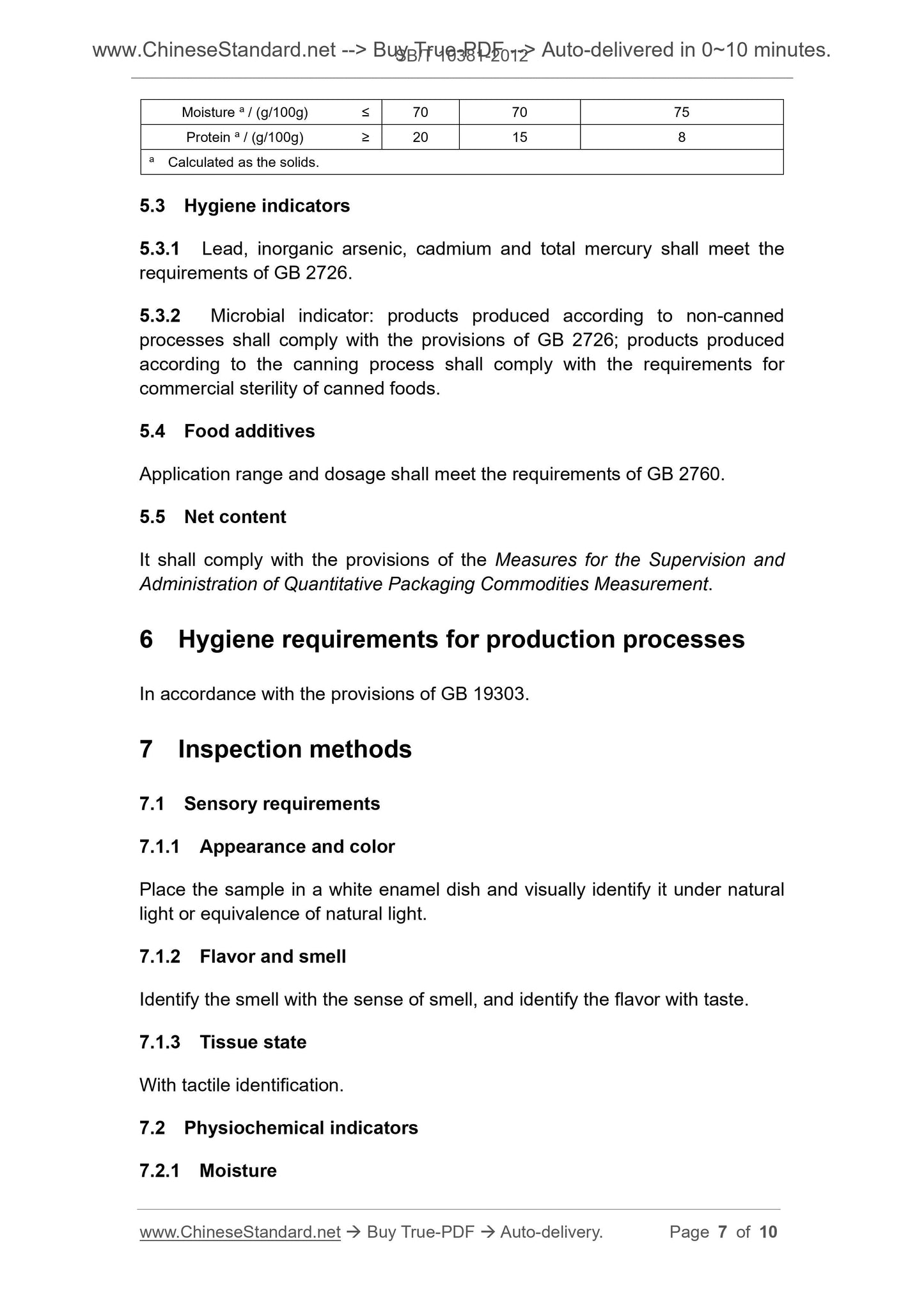

Moisture a/(g/100g) ≤ 70 70 75

Protein a/(g/100g) ≥ 20 15 8

a Calculated as the solids.

5.3 Hygiene indicators

5.3.1 Lead, inorganic arsenic, cadmium and total mercury shall meet the

requirements of GB 2726.

5.3.2 Microbial indicator. products produced according to non-canned

processes shall comply with the provisions of GB 2726; products produced

according to the canning process shall comply with the requirements for

commercial sterility of canned foods.

5.4 Food additives

Application range and dosage shall meet the requirements of GB 2760.

5.5 Net content

It shall comply with the provisions of the Measures for the Supervision and

Administration of Quantitative Packaging Commodities Measurement.

6 Hygiene requirements for production processes

In accordance with the provisions of GB 19303.

7 Inspection methods

7.1 Sensory requirements

7.1.1 Appearance and color

Place the sample in a white enamel dish and visually identify it under natural

light or equivalence of natural light.

7.1.2 Flavor and smell

Identify the smell with the sense of smell, and identify the flavor with taste.

7.1.3 Tissue state

With tactile identification.

7.2 Physiochemical indicators

7.2.1 Moisture

Each batch of products shall be inspected before leaving the factory. The exit-

factory inspection items for the products produced by non-canned processes

include sensory requirements, net content, total number of colonies, and

coliforms. The exit-factory inspection items for the products produced by

canned processes include sensory requirements, net content, commercial

sterility.

8.4 Type inspection

8.4.1 Type inspection shall be carried out at least once a year. Type inspection

shall be performed in one of the following situations.

a) trial model identification for new product;

b) great changes in raw materials, production technique after official

production which may affect product quality;

c) production resumed after discontinued production of more than half a year;

d) great difference between exit-factory inspection results and previous type

inspection results;

e) required by national quality supervision organization.

8.4.2 Type inspection items include all items and labels in Clause 5.

8.5 Determination rules

8.5.1 Determination and reinspection of exit-factory inspection

8.5.1.1 When all exit-factory inspection items meet the requirements of this

Standard, it shall be accepted.

8.5.1.2 Should one of exit-factory inspection items (except for the total

number of colonies, coliforms or commercial sterility) fail to meet this Standard,

it shall double sampling for the reinspection. Should it still fail to meet this

Standard, it shall be rejected.

8.5.1.3 If the total number of colonies, coliforms or commercial sterility does

not meet this Standard, the batch of products shall be rejected and shall not be

re-inspected.

8.5.2 Determination and reinspection of type inspection

8.5.2.1 When all type inspection items meet the requirements of this Standard,

it shall be accepted.

8.5.2.2 When type inspection items (not exceeding three items including three,

excluding the total number of colonies, coliforms or commercial sterility) do not

Get QUOTATION in 1-minute: Click SB/T 10381-2012

Historical versions: SB/T 10381-2012

Preview True-PDF (Reload/Scroll if blank)

SB/T 10381-2012: Vacuumized soft package for pot-roast meat products

SB/T 10381-2012

SB

DOMESTIC TRADE INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 67.120.10

X 22

Record No.. 37216-2012

Replacing SB/T 10381-2005

Vacuumized soft package for pot-roast meat products

真空软包装卤肉制品

ISSUED ON. AUGUST 1, 2012

IMPLEMENTED ON. NOVEMBER 1, 2012

Issued by. People's Republic of China Ministry of Commerce

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Terms and definitions ... 5

4 Raw materials, excipients and food additives ... 6

5 Technical requirements ... 6

6 Hygiene requirements for production processes ... 7

7 Inspection methods ... 7

8 Inspection rules ... 8

9 Labels, marks, packaging, storage, transport and sales ... 10

10 Recall ... 10

Vacuumized soft package for pot-roast meat products

1 Scope

This Standard specifies the terms and definitions, raw materials, excipients and

food additives, technical requirements, hygiene requirements for production

processes, inspection methods, inspection rules, labels, marks, packaging,

transport, storage, sales and recall requirements of vacuumized soft package

for pot-roast meat products.

This Standard is applicable to the production, inspection and sales for the

product defined in 3.1.

2 Normative references

The following referenced documents are indispensable for the application of

this document. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any

amendments) applies.

GB/T 191, Packaging and storage marks

GB 2726, Hygienic standard for cooked meat

GB 2760, National Food Safety Standard - Standards for Uses of Food

Additives

GB/T 4789.17, Microbiological examination of food hygiene - Examination of

meat and meat products

GB/T 4789.26, Microbiological examination of food hygiene - Examination of

commercial sterilization of canned food

GB 5009.5, National Food Safety Standard - Determination of Protein in

Foods

GB/T 5009.11, Determination of total arsenic and abio-arsenic in food

GB 5009.12, Method for determination of lead in food

GB/T 5009.15, Determination of cadmium in foods

GB/T 5009.17, Method for determination of total mercury in foods

Moisture a/(g/100g) ≤ 70 70 75

Protein a/(g/100g) ≥ 20 15 8

a Calculated as the solids.

5.3 Hygiene indicators

5.3.1 Lead, inorganic arsenic, cadmium and total mercury shall meet the

requirements of GB 2726.

5.3.2 Microbial indicator. products produced according to non-canned

processes shall comply with the provisions of GB 2726; products produced

according to the canning process shall comply with the requirements for

commercial sterility of canned foods.

5.4 Food additives

Application range and dosage shall meet the requirements of GB 2760.

5.5 Net content

It shall comply with the provisions of the Measures for the Supervision and

Administration of Quantitative Packaging Commodities Measurement.

6 Hygiene requirements for production processes

In accordance with the provisions of GB 19303.

7 Inspection methods

7.1 Sensory requirements

7.1.1 Appearance and color

Place the sample in a white enamel dish and visually identify it under natural

light or equivalence of natural light.

7.1.2 Flavor and smell

Identify the smell with the sense of smell, and identify the flavor with taste.

7.1.3 Tissue state

With tactile identification.

7.2 Physiochemical indicators

7.2.1 Moisture

Each batch of products shall be inspected before leaving the factory. The exit-

factory inspection items for the products produced by non-canned processes

include sensory requirements, net content, total number of colonies, and

coliforms. The exit-factory inspection items for the products produced by

canned processes include sensory requirements, net content, commercial

sterility.

8.4 Type inspection

8.4.1 Type inspection shall be carried out at least once a year. Type inspection

shall be performed in one of the following situations.

a) trial model identification for new product;

b) great changes in raw materials, production technique after official

production which may affect product quality;

c) production resumed after discontinued production of more than half a year;

d) great difference between exit-factory inspection results and previous type

inspection results;

e) required by national quality supervision organization.

8.4.2 Type inspection items include all items and labels in Clause 5.

8.5 Determination rules

8.5.1 Determination and reinspection of exit-factory inspection

8.5.1.1 When all exit-factory inspection items meet the requirements of this

Standard, it shall be accepted.

8.5.1.2 Should one of exit-factory inspection items (except for the total

number of colonies, coliforms or commercial sterility) fail to meet this Standard,

it shall double sampling for the reinspection. Should it still fail to meet this

Standard, it shall be rejected.

8.5.1.3 If the total number of colonies, coliforms or commercial sterility does

not meet this Standard, the batch of products shall be rejected and shall not be

re-inspected.

8.5.2 Determination and reinspection of type inspection

8.5.2.1 When all type inspection items meet the requirements of this Standard,

it shall be accepted.

8.5.2.2 When type inspection items (not exceeding three items including three,

excluding the total number of colonies, coliforms or commercial sterility) do not

Share